2

CONTENTS

1. SPECIFICATIONS .........................................................................................................................

2. FEATURES & TECHNICAL EXPLANATION ................................................................................ 4

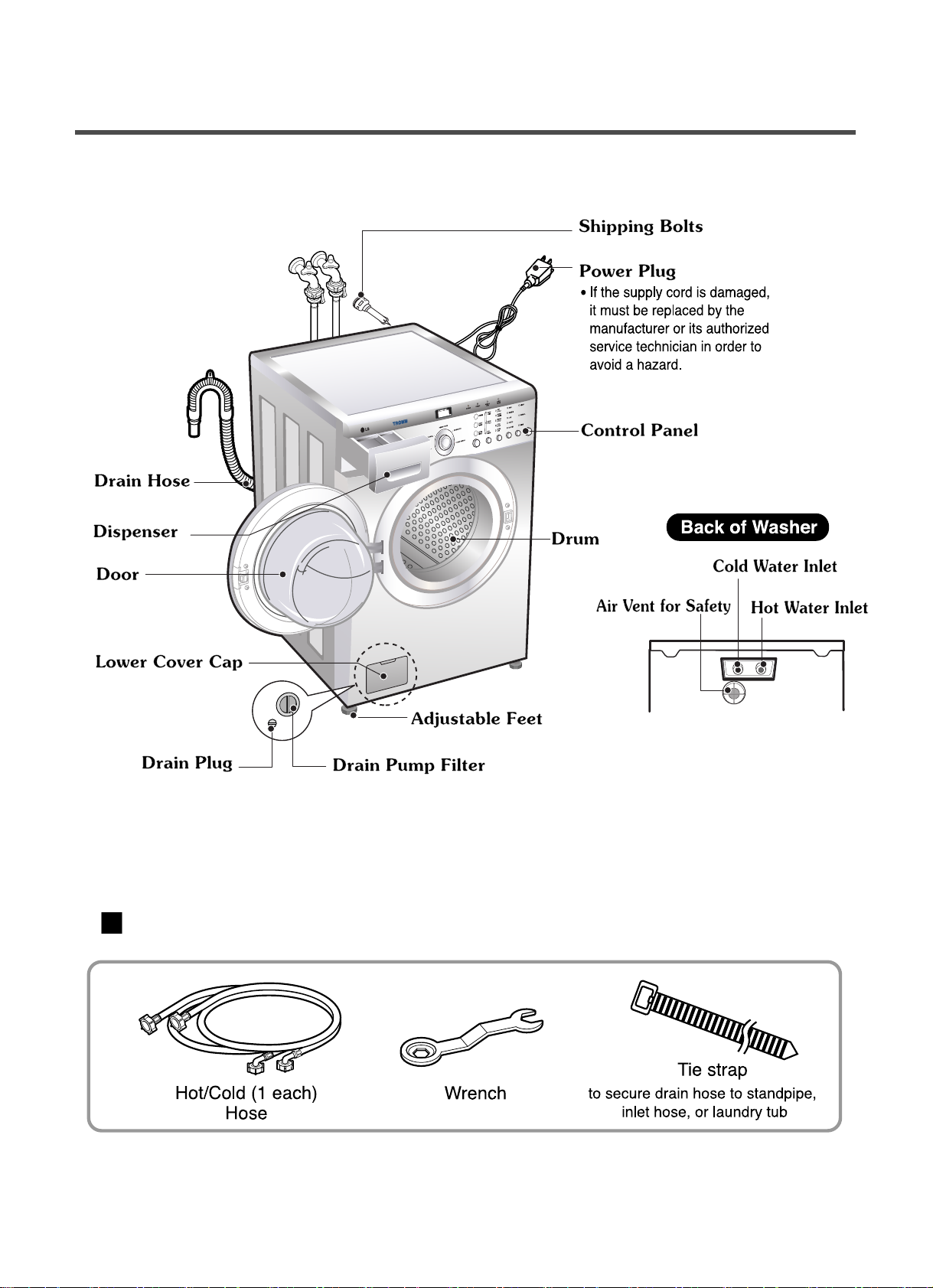

. PARTS IDENTIFICATION ............................................................................................................ 7

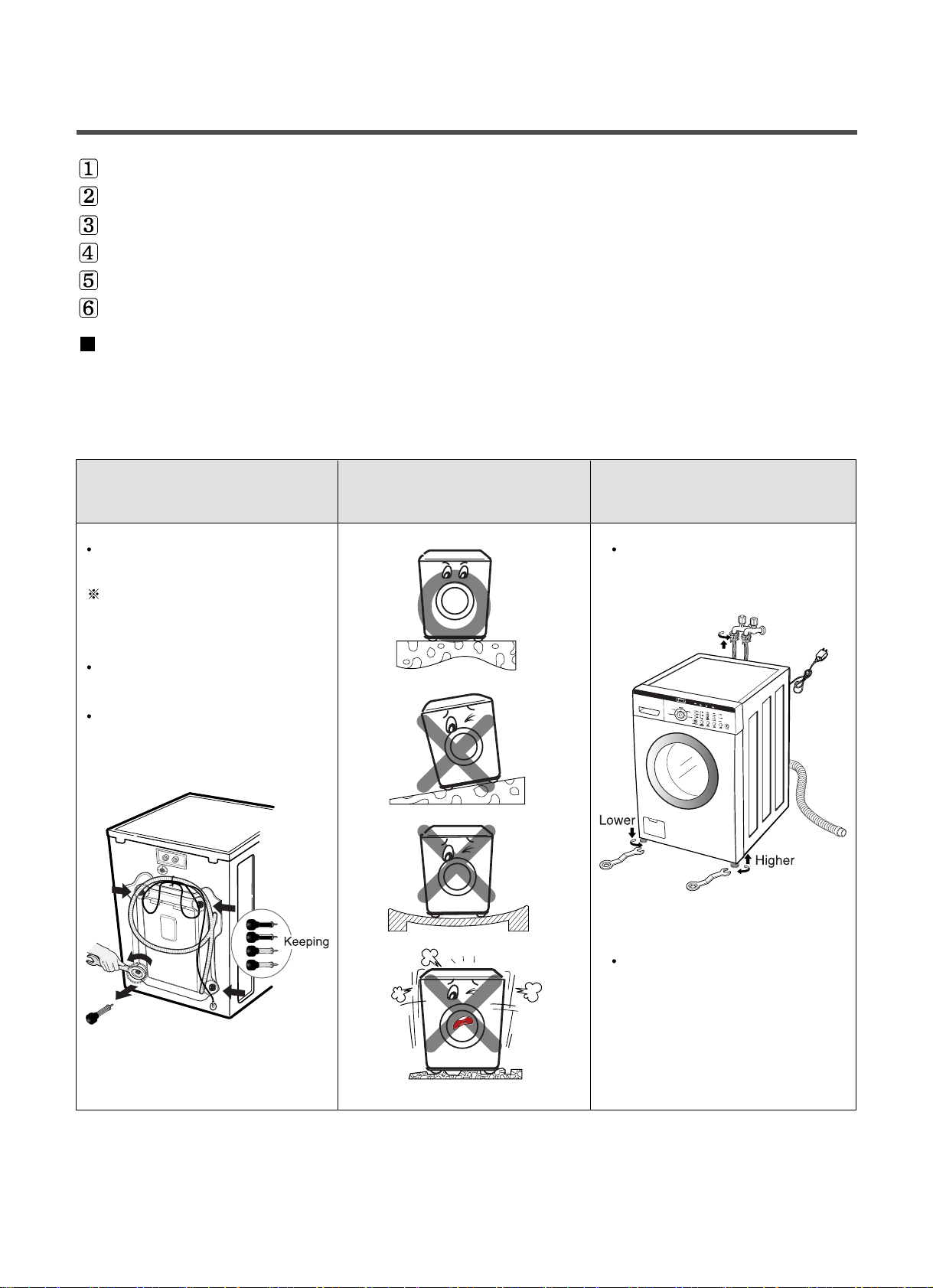

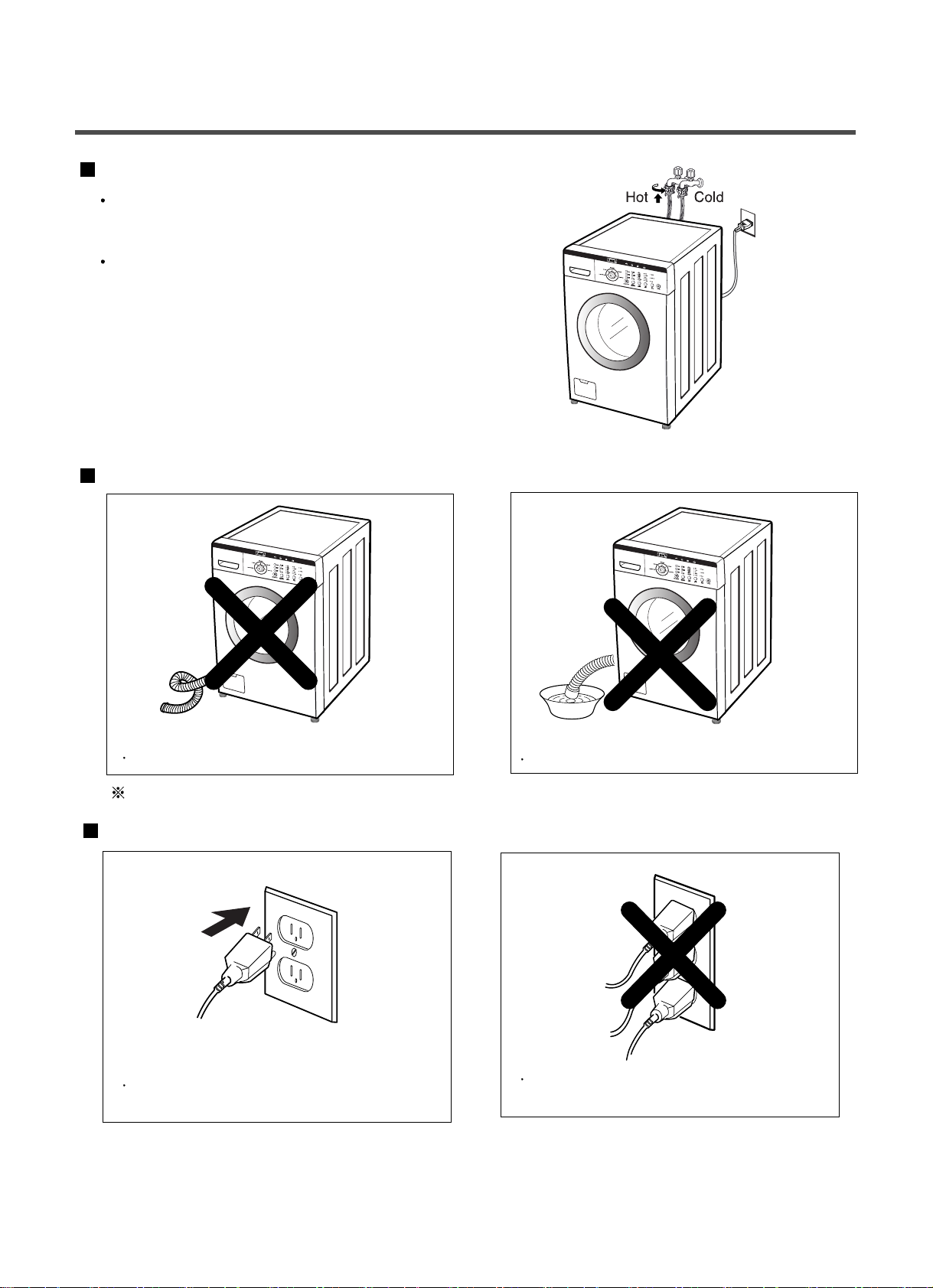

4. INSTALLATION & TEST ............................................................................................................... 8

5. OPERATION ................................................................................................................................11

6. WIRING DIAGRAM/PROGRAM CHART.....................................................................................14

7. TROUBLESHOOTING.................................................................................................................16

7-1. BEFORE PERFORMING SERVICE ...................................................................................16

7-2. QC TEST MODE.................................................................................................................16

7- . HOW TO CHECK THE WATER LEVEL FREQUENCY ......................................................16

7-4. ERROR DISPLAY ...............................................................................................................17

8. ERROR DIAGNOSIS AND CHECK LIST ....................................................................................19

8-1. DIAGNOSIS AND SOLUTION FOR ABNORMAL OPERATION ........................................19

8-2. FAULT DIAGNOSIS AND TROUBLESHOOTING ..............................................................22

9. DISASSEMBLY INSTRUCTIONS ............................................................................................... 1

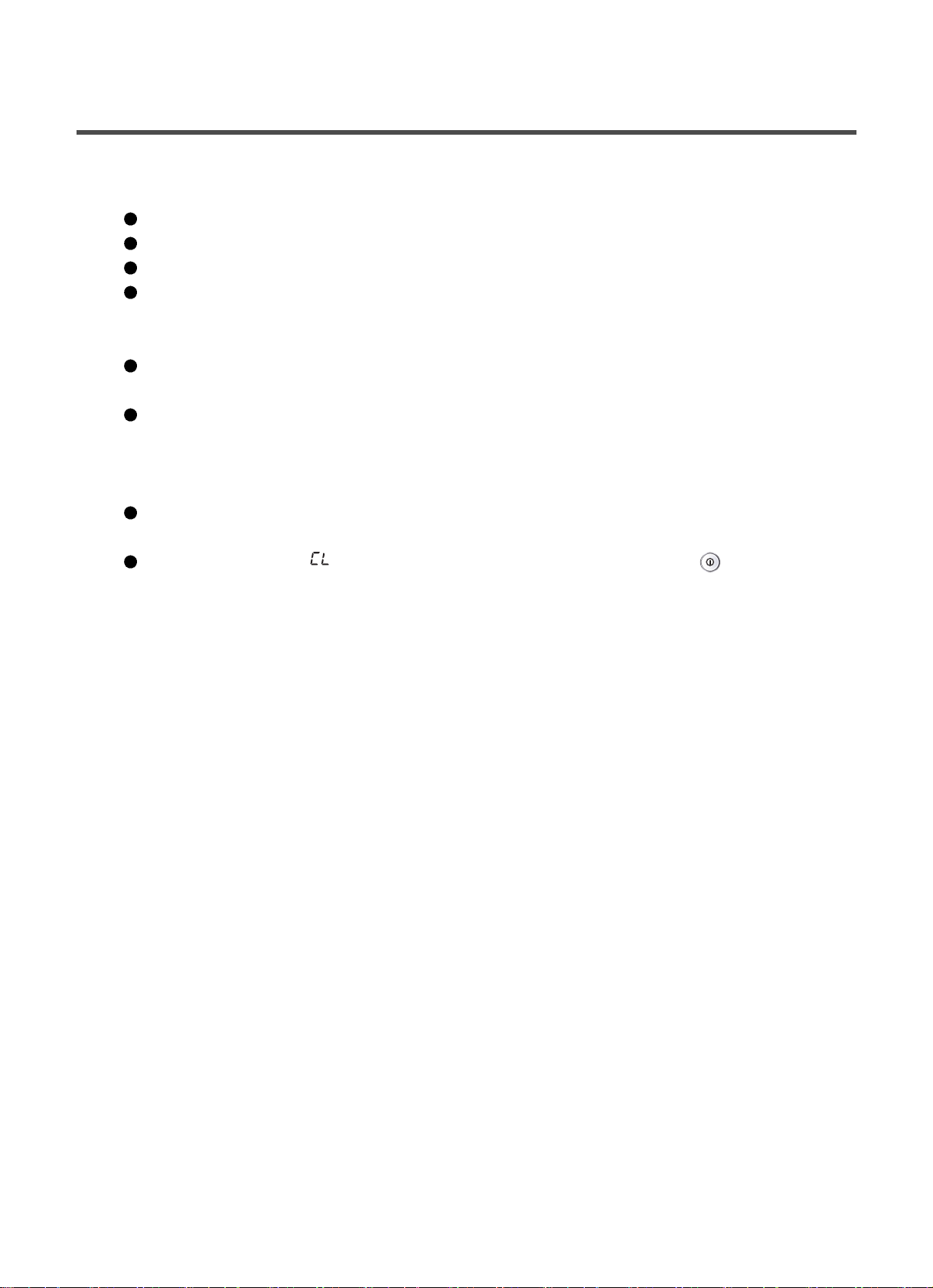

10. EXPLODED VIEW .....................................................................................................................40

10-1. CABINET & CONTROL PANEL ASSEMBLY....................................................................40

10-2. DRUM & TUB ASSEMBLY................................................................................................41

10- . DISPENSER ASSEMBLY .................................................................................................42

4

7

8

11

12

1

1

1

1

14

16

16

19

26

4

4

5

6