2

CONTENTS

1. SPECIFICATIONS ............................................................................................................................. 3

2. FEATURES & TECHNICAL EXPLANATION ..................................................................................... 4

3. PARTS IDENTIFICATION ................................................................................................................. 6

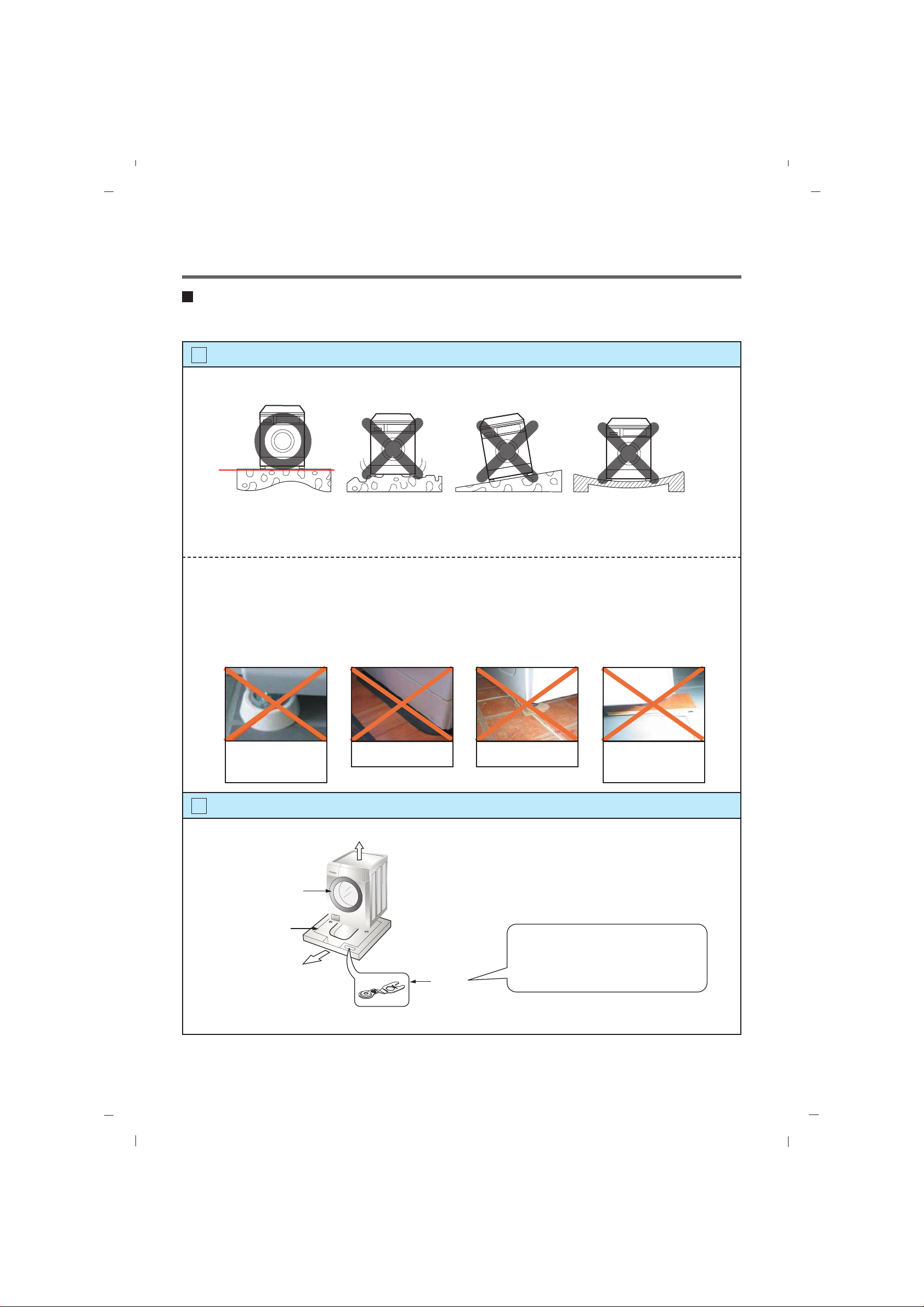

4. INSTALLATION .................................................................................................................................. 7

5. OPERATION ................................................................................................................................... 12

6. WIRING DIAGRAM / PCB LAYOUT / Filter Assembly Filter Layout ................................................ 14

7. TROUBLESHOOTING......................................................................................................................17

7-1.BEFORE PREFORMING SERVICE ......................................................................................... 17

7-2.LOAD TEST MODE .................................................................................................................. 17

7-3.HOW TO KNOW THE WATER LEVEL FREQUENCY ............................................................. 18

7-4.

HOW TO KNOW TO TEMPERATURE OF EACH THERMISTOR AT OPERATING CONDITION

.. 18

7-5.ERROR DISPLAY ..................................................................................................................... 19

7-6.TROUBLESHOOTING WITH ERROR ..................................................................................... 21

• IE (Water Inlet Error) .............................................................................................................. 21

• UE (Unbalanced Error) ........................................................................................................... 22

• OE (Water Outlet Error) .......................................................................................................... 23

• FE (Flow over Error) ............................................................................................................... 25

• PE (Pressure Sensor S/W Error) ............................................................................................ 26

• DE (Door open Error) ............................................................................................................. 27

• tE (Thermistor (Heating) Error) ............................................................................................... 28

• LE (Motor Lock Error) ............................................................................................................. 29

• DHE (Dry Heater Error) .......................................................................................................... 30

• Dry Heater Trouble ................................................................................................................. 31

• Dry Fan Motor Trouble ............................................................................................................ 32

8. TROUBLESHOOTING WITHOUT ERROR CODES ....................................................................... 33

• PF(Power Failure or No Power)................................................................................................33

• Vibation & Noise in spin ......................................................................................................... 34

• Detergent & Softener does not flow in .................................................................................... 35

• Water Leak ............................................................................................................................. 36

9. DISASSEMBLY INSTRUCTIONS ................................................................................................... 38

10. EXPLODED VIEW ......................................................................................................................... 46