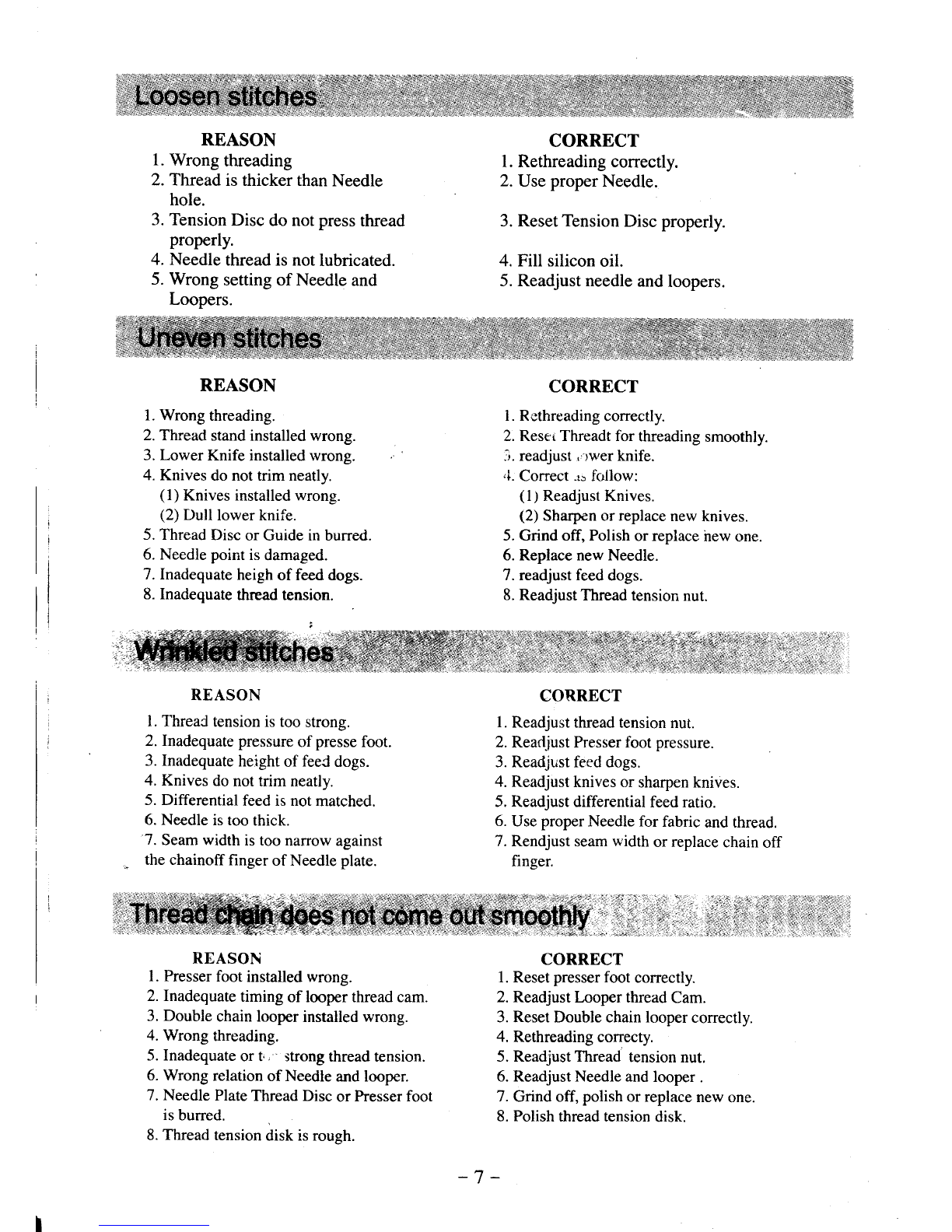

REASON

1. Wrong threading

2. Thread is thicker than Needle

hole.

3. Tension Disc do not press thread

properly.

4. Needle thread is not lubricated.

5. Wrong setting of Needle and

Loopers.

CORRECT

1. Rethreading correctly.

2. Use proper Needle.

3. Reset Tension Disc properly.

4. Fill silicon oil.

5. Readjust needle and loopers.

REASON

l. Wrong threading.

2. Thread stand installed wrong.

3. Lower Knife installed rvrong.

4. Knives do not trim neatly.

(1) Knives installed wrong.

(2) Dull lower knife.

5. Thread Disc or Guide in burred.

6. Needle point is damaged.

7. Inadequate heigh of feed dogs.

8. Inadequate thread tension.

REASON

l. ThreaC tension is too strong.

2. Inadequate pressure ofpresse foot.

3. Inadequate height of feeC dogs.

4. Knives do not trim neatly.

5. Differential feed is not matched.

6. Needle is too thick.

7. Seam width is too narrow against

the chainoff finger of Needle plate.

REASON

l. Presser foot installed wrong.

2. Inadequate timing of looper thread cam.

3. Double chain looper installed wrong.

4. Wrong threading.

5. Inadequate or t,, ' strong thread tension.

6. Wrong relation of Needle and looper.

7. Needle Plate Thread Disc or Presser foot

is burred.

8. Thread tension disk is rough.

CORRECT

l. Rethreading correctly.

2. Resei Threadt for threading smoothly.

ii. readjust ,.rwer knife.

,1. Correct -r" follow:

(l) Readjust Knives.

(2) Sharpen or replace new knives.

5. Grind off, Polish or replace irew one.

6. Replace new Needle.

7. readjust feed dogs.

8. Readjust Thread tension nut.

CORRECT

R.eadjust thread tension nut.

Readjust Presser foot pressure

Readjrist feed dogs.

Readjust knives or sharpen knives.

Readjust differential feed ratio.

Use proper Needle for fabric and thread.

Rendjust seam width or replace chain off

finger.

l.

2.

4.

5.

6.

"7.

+irffi$iffi

CORRECT

l. Reset presser foot correctly.

2. Readjust Looper thread Cam.

3. Reset Double chain looper correctly.

4. Rethreading correcty.

5. Readjust Thread tension nut.

6. Readjust Needle and looper .

7. Grind off, polish or replace new one.

8. Polish thread tension disk.

-7 -