CONTENT

1. PREFACE……………………………………………………………………………………………………………………………………………………………………..2

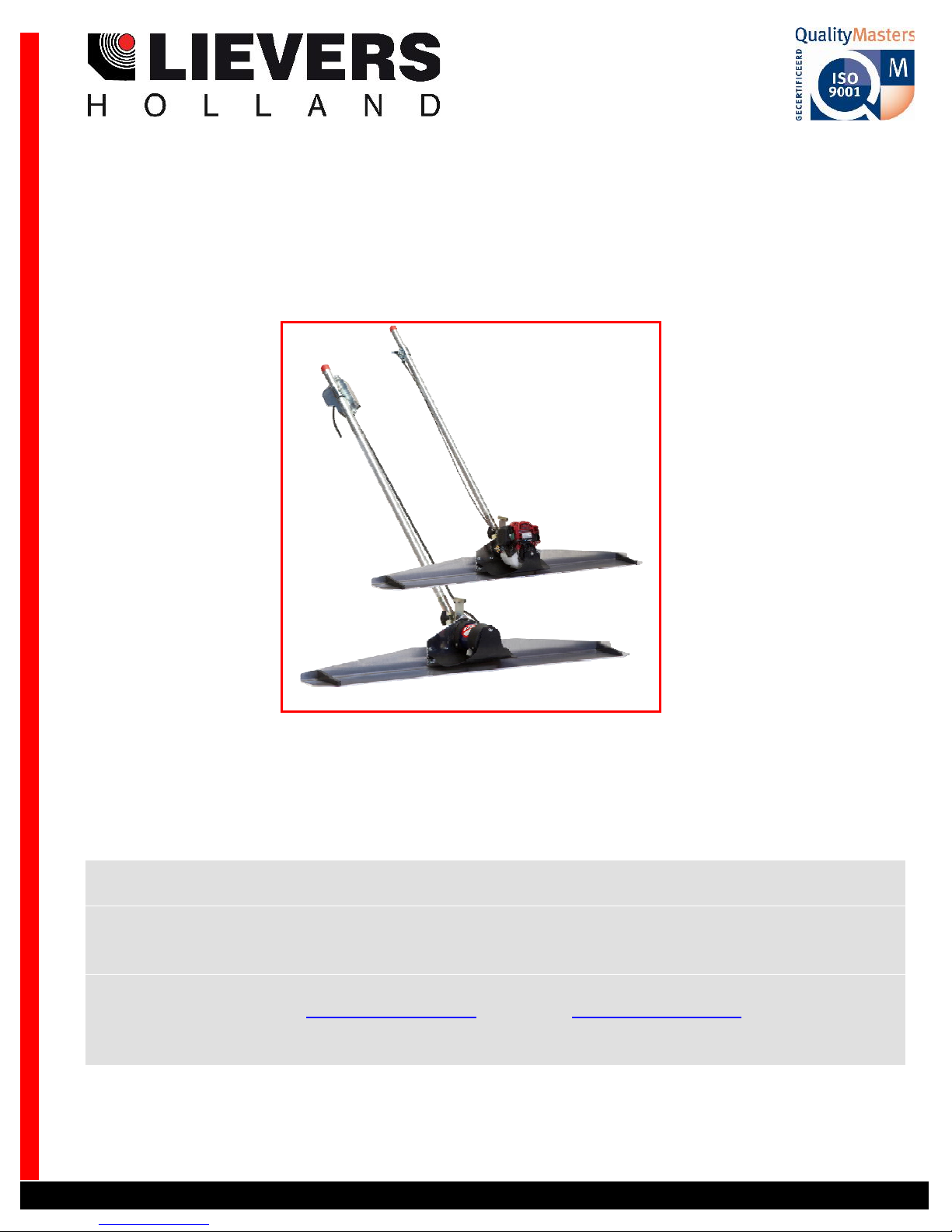

2. INTRODUCTION..…………………………………………………………………………………………………………………………………………………………4

3. TECHNICAL SPECIFICATIONS .........................................................................................................................................5

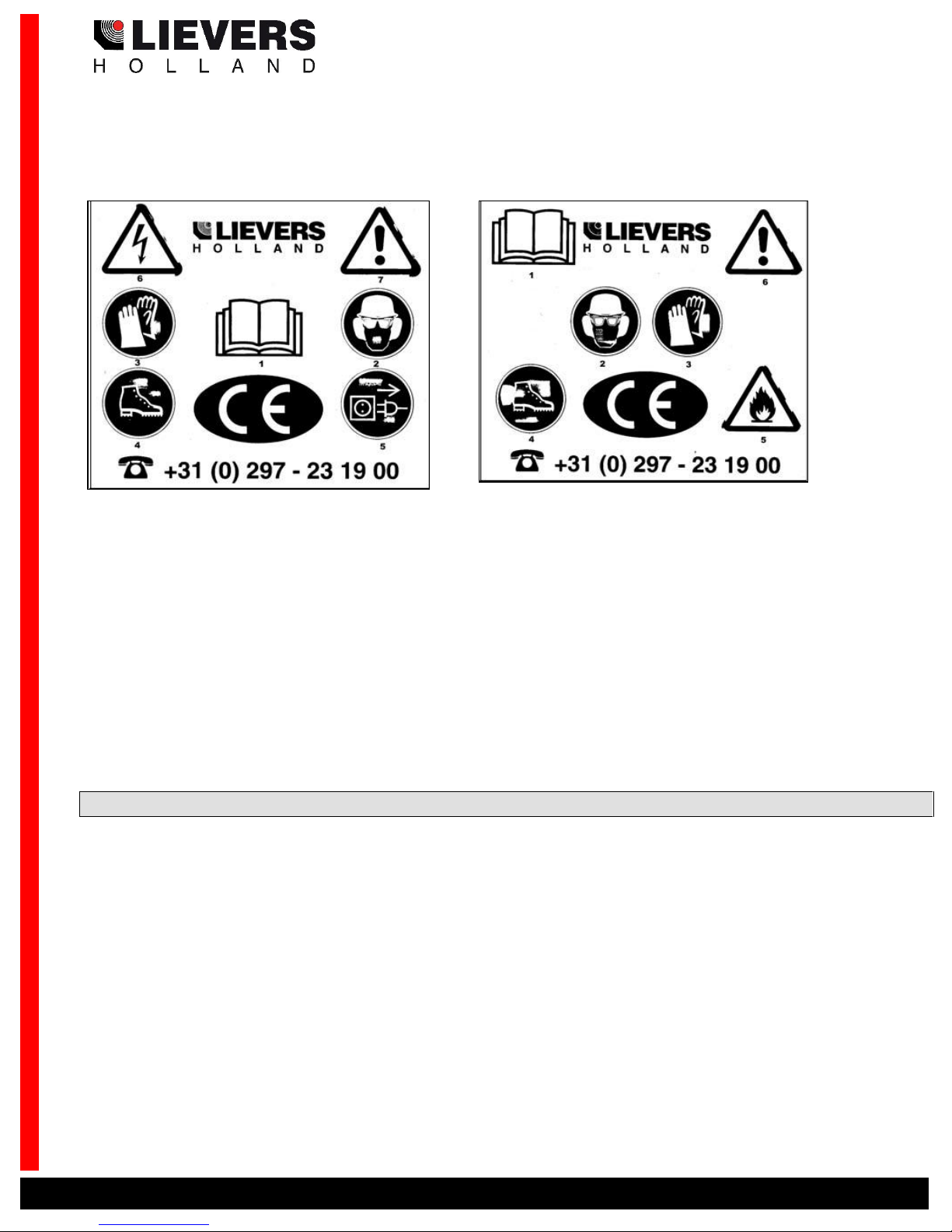

4. SAFETY.......................................................................................................................................................................... 6

4.1. SAFETY ASPECTS ................................................................................................................................................................. 6

4.2 SAFETY PRECAUTIONS. ......................................................................................................................................................... 6

5. USE ............................................................................................................................................................................... 9

5.1. ASSEMBLING THE BULLFLOAT ................................................................................................................................................ 9

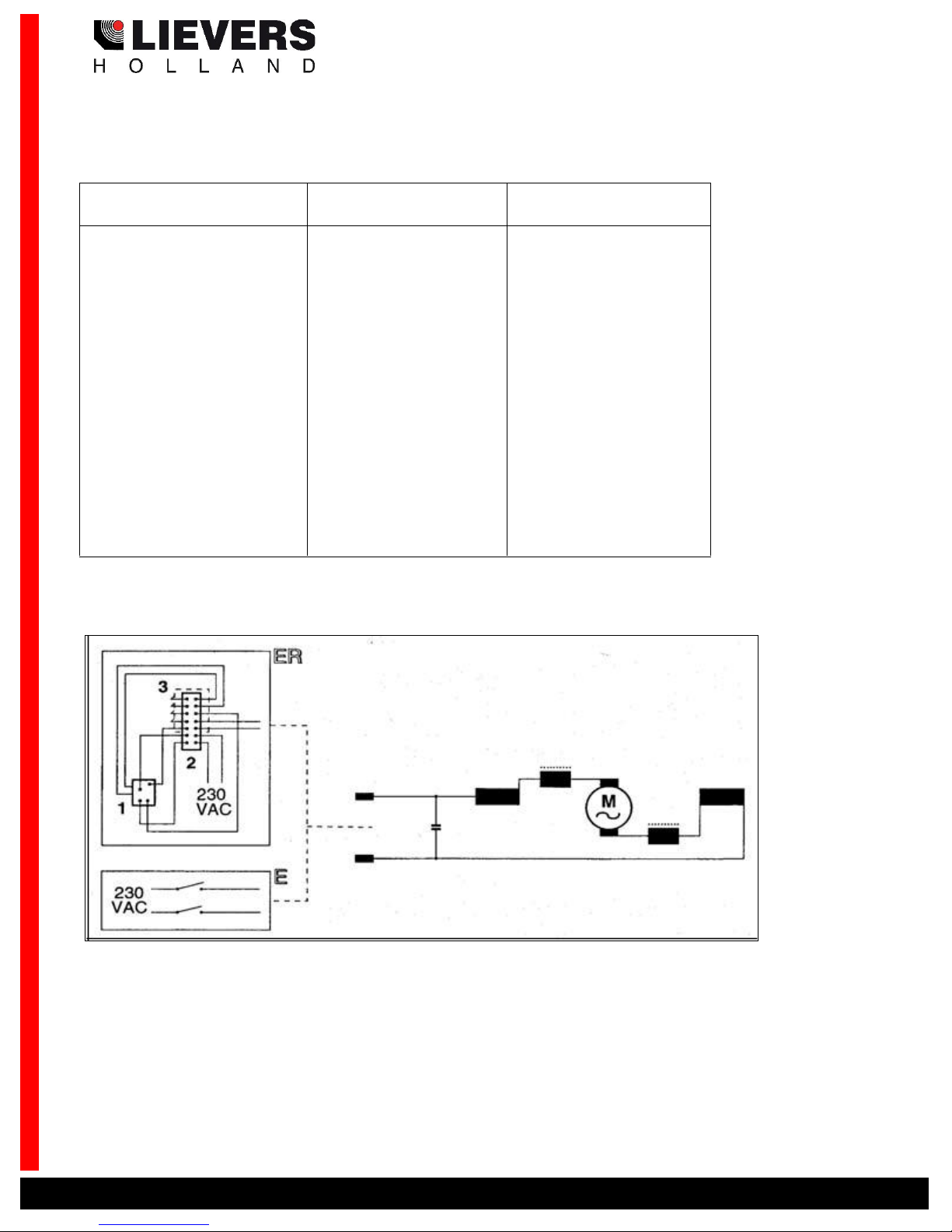

5.2 USE OF K-150 E / ER.......................................................................................................................................................... 9

5.3 USE OF K-150 WITH PETROL ENGINE .................................................................................................................................... 11

6. MAINTENANCE ........................................................................................................................................................... 12

7.TROUBLESHOOTING, REPAIRS ..................................................................................................................................... 12

8.DISMANTLING, DISPOSAL ............................................................................................................................................ 13

9. PART LISTS .................................................................................................................................................................. 14

10. DECLARATION OF CONFORMITY ............................................................................................................................... 23

© Lievers Holland, NL 2005

All rights are reserved. Reprints, copies, adaptations for new editions and publications in any form or through any

media, including abstract forms are not permitted unless written permissions is first obtained from Lievers Holland.

Lievers Holland may not be held responsible for any guarantees or liabilities for the contents of this publication and

points to, in this case, all implied securities for suitability of merchantability or any other purposes. Lievers Holland

further retains the right to revise this publication and to alter the contents over certain per iods of time, without the

obligation to report such alterations and changes first.