4

Circuit Diagnosis

LIFAN 630

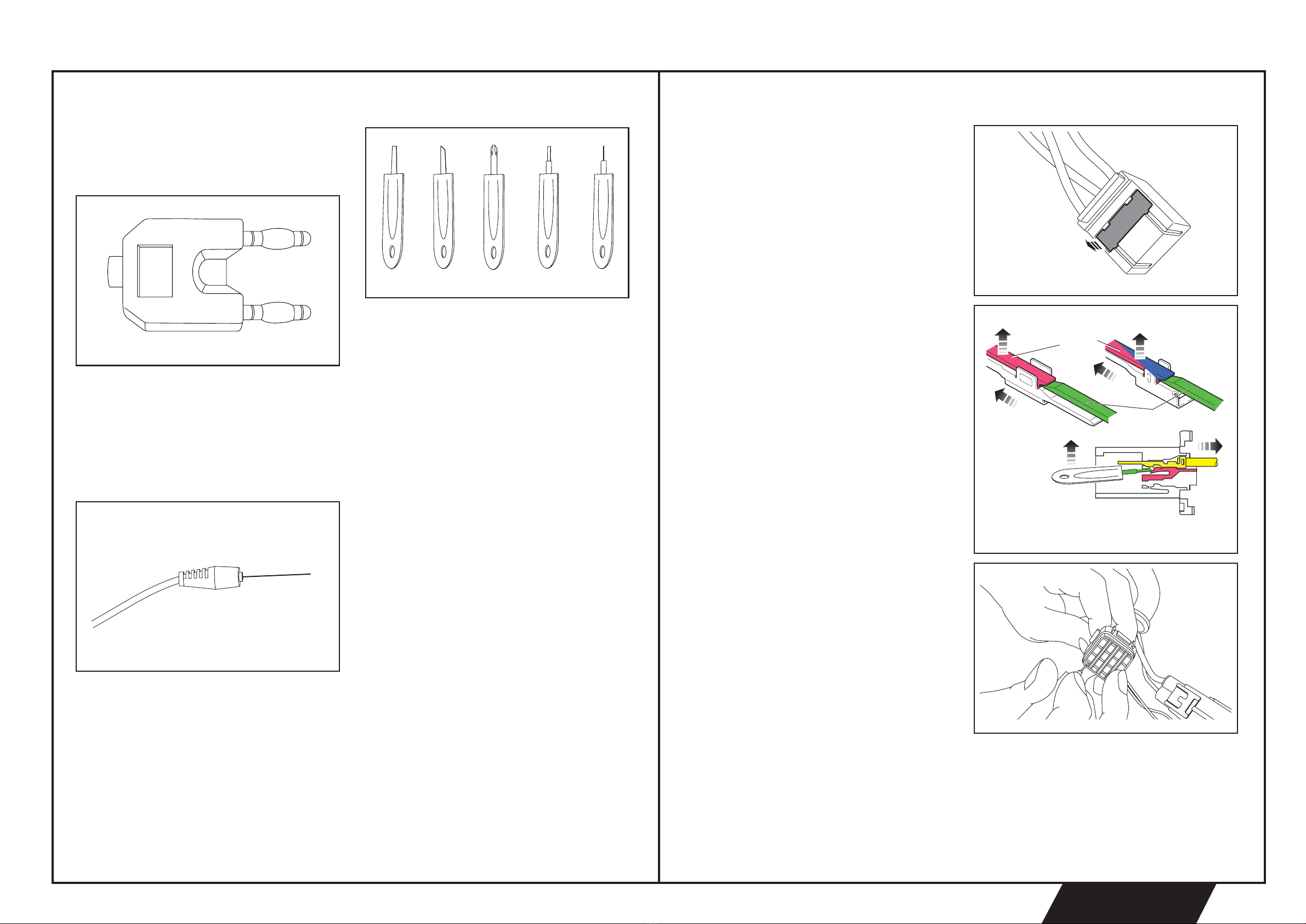

2. Test Light with Self-supply and Ohmmeter

Use test light with own 12V power supply or

ohmmeter to test the circuit continuity. Test

light comprises a bulb, battery and a pair of

wires. The bulb will be lit when the two wires

contacted. Before test, disconnect the battery

negative and pull out the fuse of the circuit to

be tested. To test the circuit continuity,

contact two wires to the two measurement

points. If the bulb is lit, it means the circuit is

continuous.

Warning

DO NOT use test light with self-

supply to test the control module. To do

so, it could damage the circuit inside the

control module. Please use a ohmmeter

with 10M Ωor higher internal impedance.

Ohmmeter has the same usage method as

voltmeter, but ohmmeter can show the

impedance value. The lower impedance, the

better continuity.

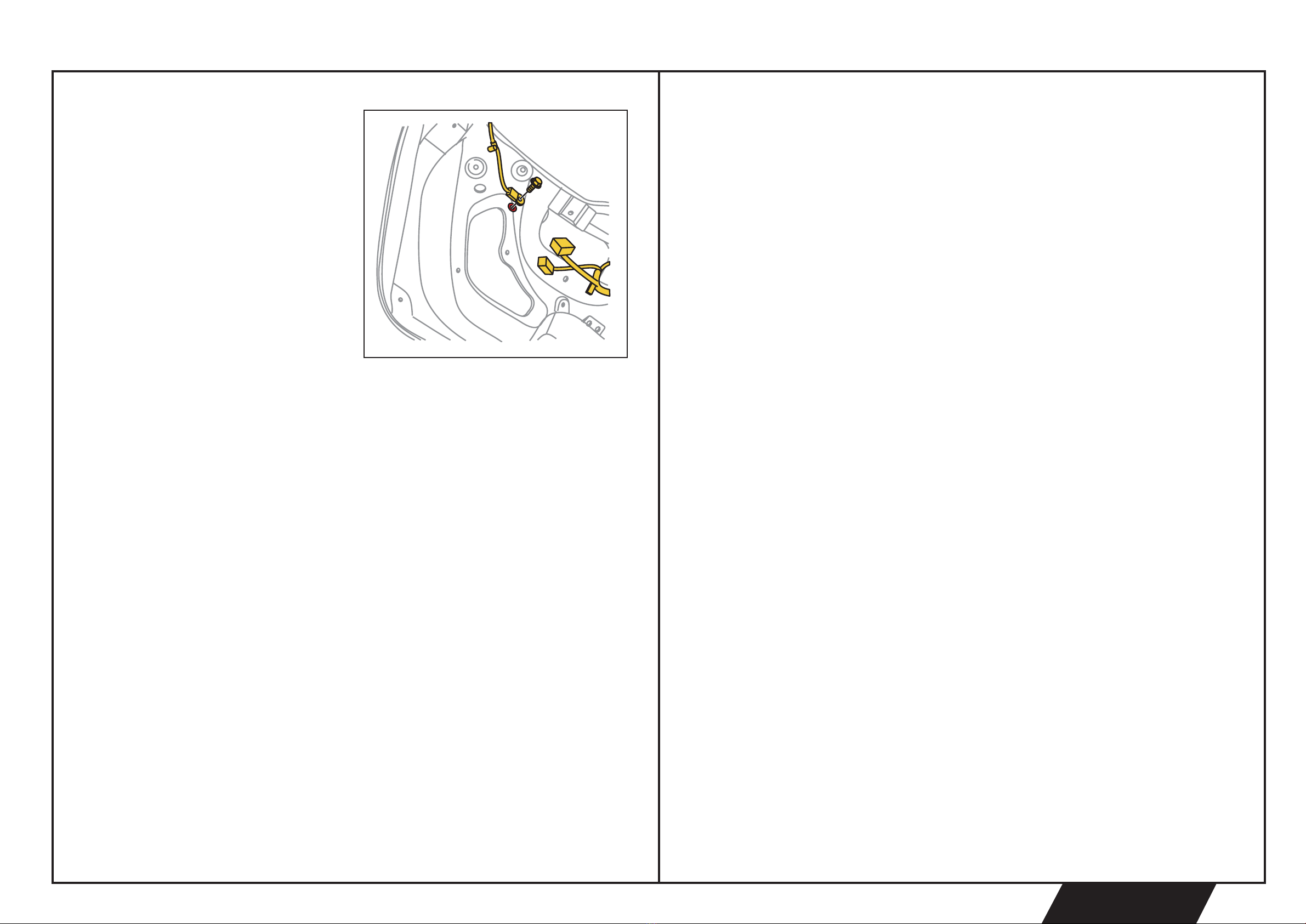

3. Jumper with Fuse

Use jumper to test a broken point for open

loop circuit (circuit broken). The jumper

should be in tandem with the circuit to be

tested.

Warning

To protect the circuit, DO NOT

use the fuse with higher rated capacity

than the circuit to be tested. DO NOT use

the jumper as the input or output signal

when a control module like ECM, TCM is in

the circuit. To do so, it could damage the

circuit inside the control module.

Fault Test

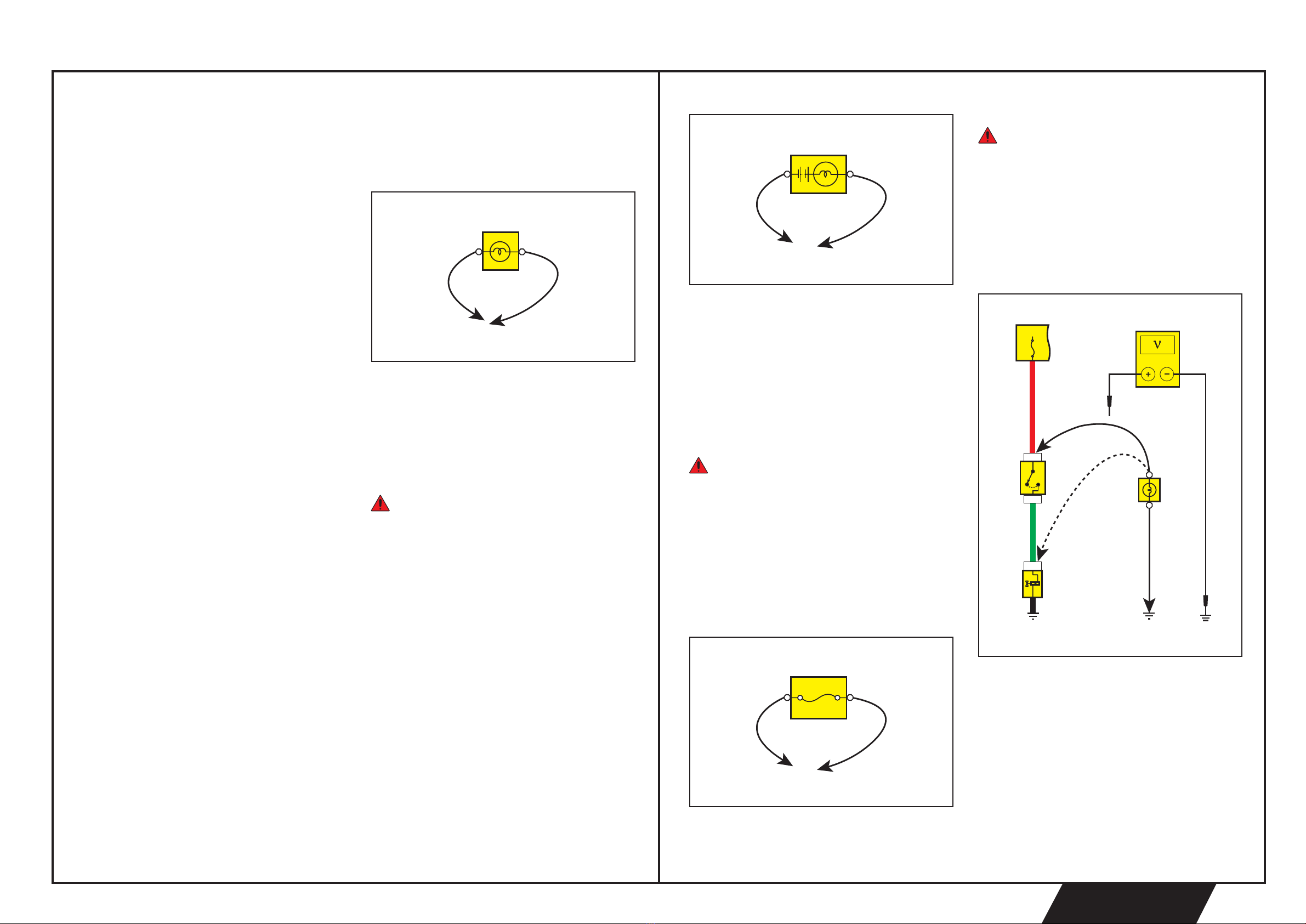

1. Voltage Test

Voltage test process is to test the voltage at a

certain point. When testing the connector

terminals, insert the positive probe into the

wire instead of breaking the harness.

1 When testing the voltage with test light or

voltmeter, connect the negative wire of

the test light or the negative probe of the

voltmeter to the ground.

2 Connect the other wire of the test light or

the positive probe of the voltmeter to the

place to be tested.

a1105002

5A

a1105003

I/P Fuse and Relay Box

Switch

Solenoid

Test Light

Voltmeter

5A

+B

0.5RD0.5G

2 E00

1E00

1C00

a1105022

Circuit Diagnostic Procedure

Refer to the following procedure for the circuit

diagnosis:

1. Confirm the Fault

To do the proper repair, confirm the fault

descibed by the customer firstly. Inspect the

relevant component carefully and make

record. DO NOT disassemble the component

before confirmation of the fault scope and

causes.

2. Read the Wiring Diagram and Analyze the

Causes.

Make a complete analysis on the faulty

components from power supply to ground

according to the sub-system wiring diagram

and determine the repair solution. If can not

determine the repair solution, please read the

system description in the “Description and

Operation” in the workshop manual to clear

the working principle. And inspect other

circuits that has common part with the faulty

circuit, for example, the fuse, ground, switch,

etc. Inspect the circuit not covered in step 1. If

other components on the common circuit

work properly, it means the fault exists in its

own circuit. Otherwise, the fuse or ground

might has faults.

3. Inspect the Circuits and Components.

Always use the wiring diagram together with

workshop manual and refer to the diagnostic

procedure for the relevant circuits or

components in the workshop manual. For the

circuit with a control module, fully use

diagnostic tools to do the test. Effective

diagnosis should be a logical and reasonable

operation. Fully use the diagnoistic

procedures in the workshop manual and start

the inspection from the most likely causes

and the compents be easiest to inspect.

4. Repair

Repair the faulty circuit. Refer to the wiring

diagram and workshop manual for fault

treatment. For example, the treatment on bad

connection to ground and the harness

connector.

5. Confirm the Fault Removed.

After repair, confirm the fault removed and all

functions work properly. For the fuse blown

fault, check all the relevant circuits.

Circuit Diagnostic Device

1. Voltmeter and Test Light

Use test light or voltmeter to check the circuit

status.

Test light comprises a pair of wires and a 12V

bulb. When inspecting, connect one wire to

the ground and the other one to the

measurement point. If the bulb is lit, it means

the measurement point has power supply.

Warning

DO NOT use test light to test the

control module voltage. To do so, it could

damage the circuit inside the control

module. Please use a voltmeter with 10M Ω

or higher internal impedance (e.g. to test

the ECM voltage.).

Voltmeter has the same connection method

as the test light, but voltmeter can display the

voltage value of the circuit. Use a voltmeter

with high impedance to test the voltage. If the

circuit has poor connection, the voltmeter

may show the normal value, but the voltage

can not drive the load successfully.

a1105001