21

Replacing the 4x00 X-Axis Motor Belt

DOC #:7301-0-US70-111318-AM-01-02

support@torchmate.com

Replacing the 4x00 X-Axis Motor Belt

Intro: Over me, the ming belts on the 4400 and 4800 machines that join the

motor and pinion gear pulleys will wear out and require replacements. The

instrucons below explain the procedure for replacing the belts.

Tools: 1/8 Allen Wrench

3/16 Allen Wrench

9/64 Allen Wrench

5/64 Allen Wrench

1/4 Allen Wrench

(1) Zip Tie

Warning: BEFORE BEGINNING, PLEASE POWER OFF ALL EQUIPMENT INCLUDING THE

ACCUMOVE CONTROLLER!*

*Irreparable damage will occur to the controller and will not be covered

under warranty if the equipment is not turned o.

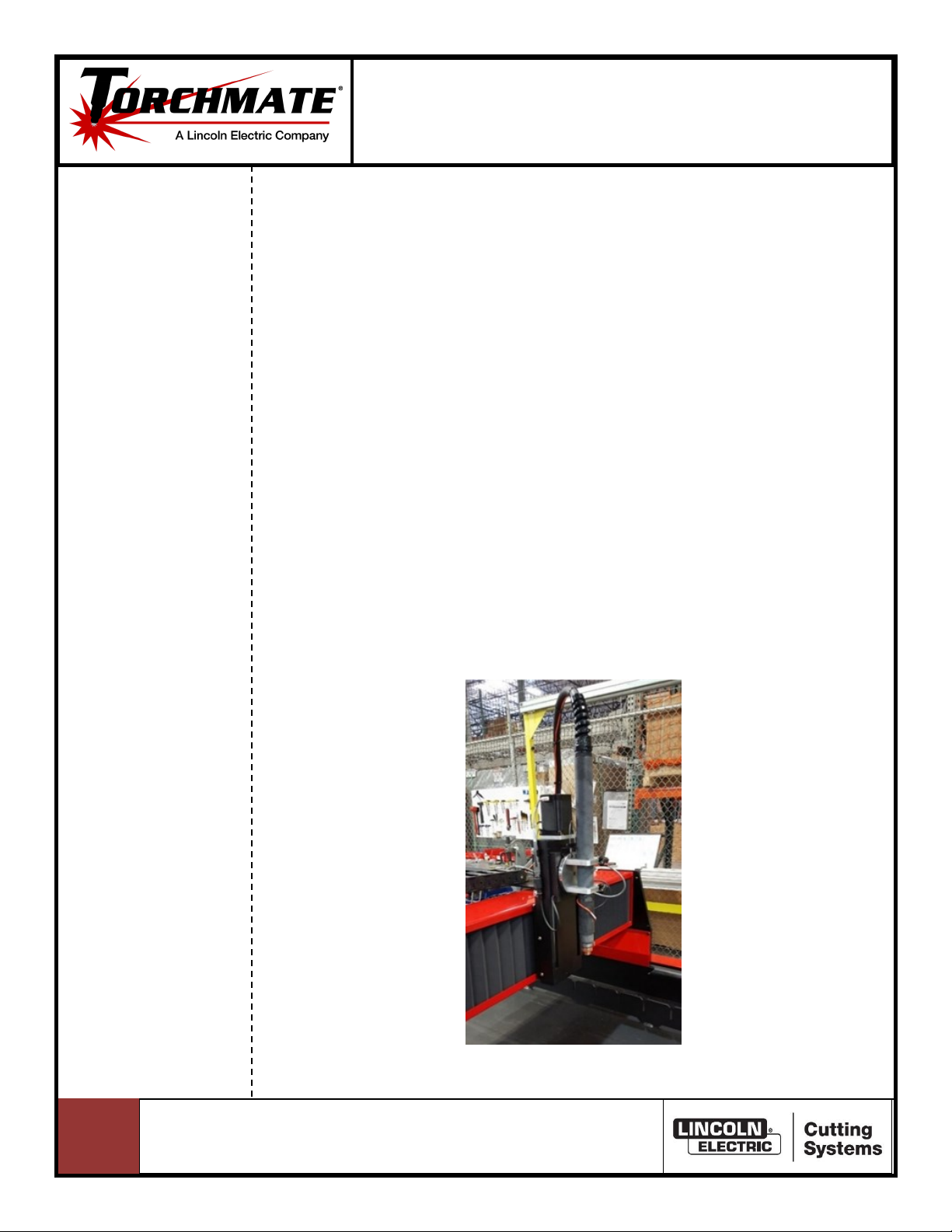

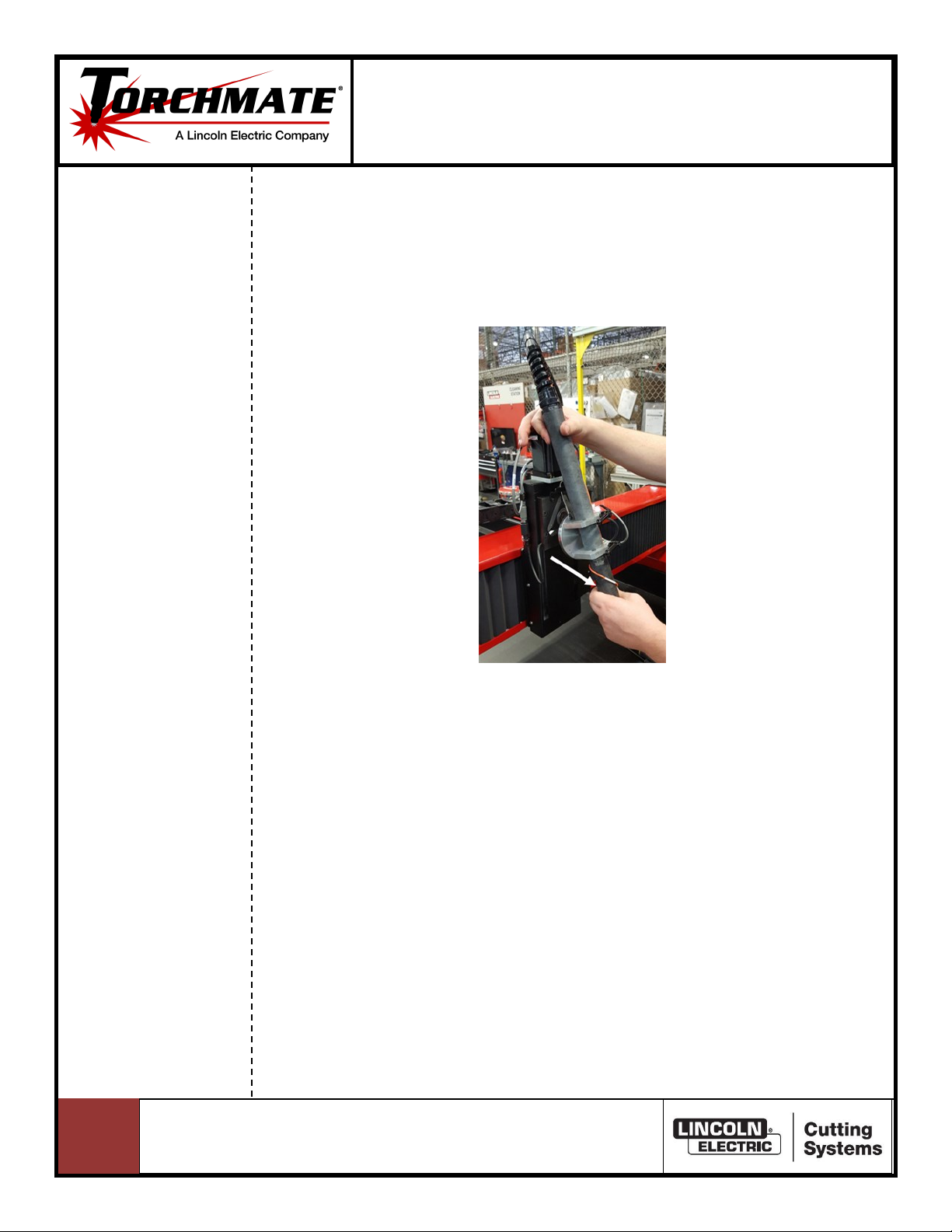

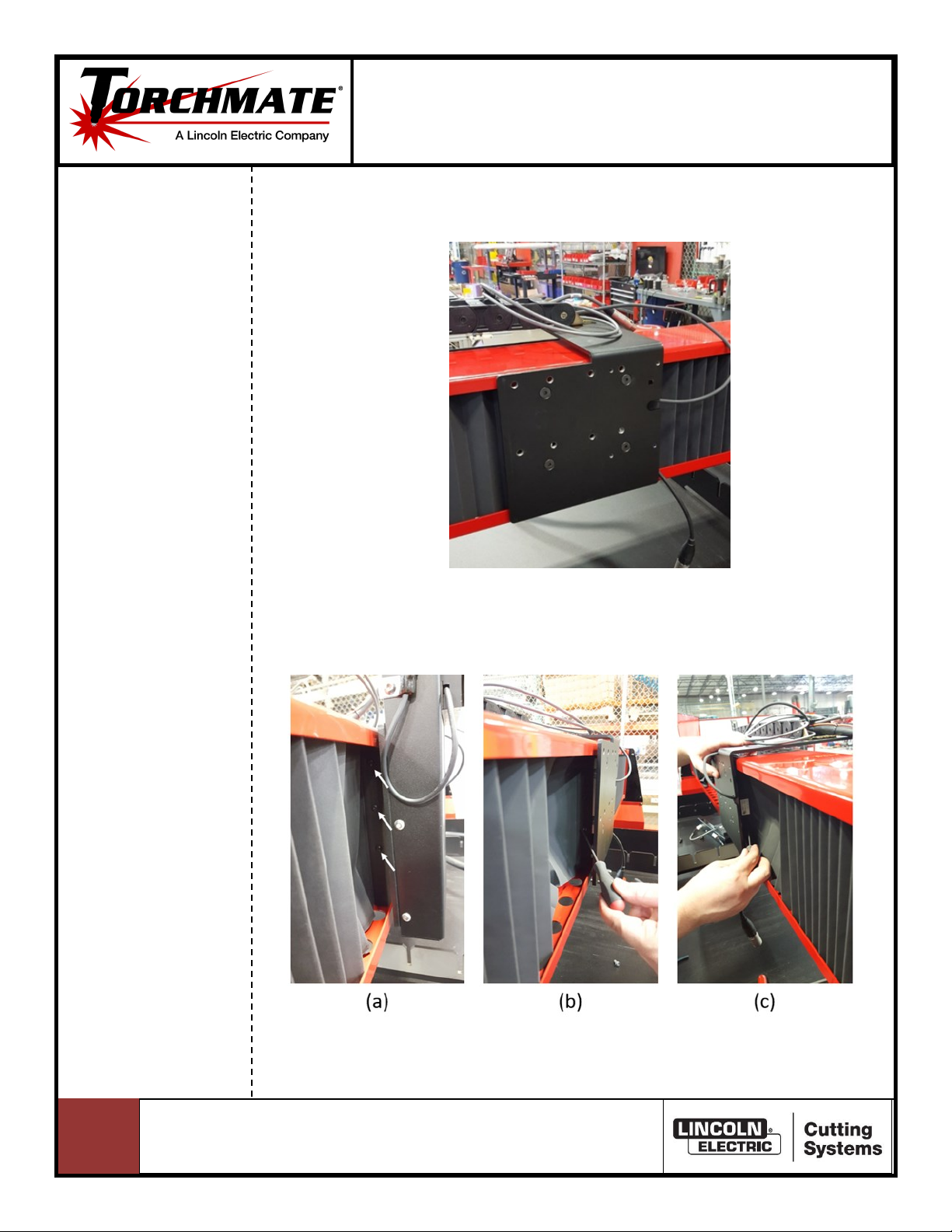

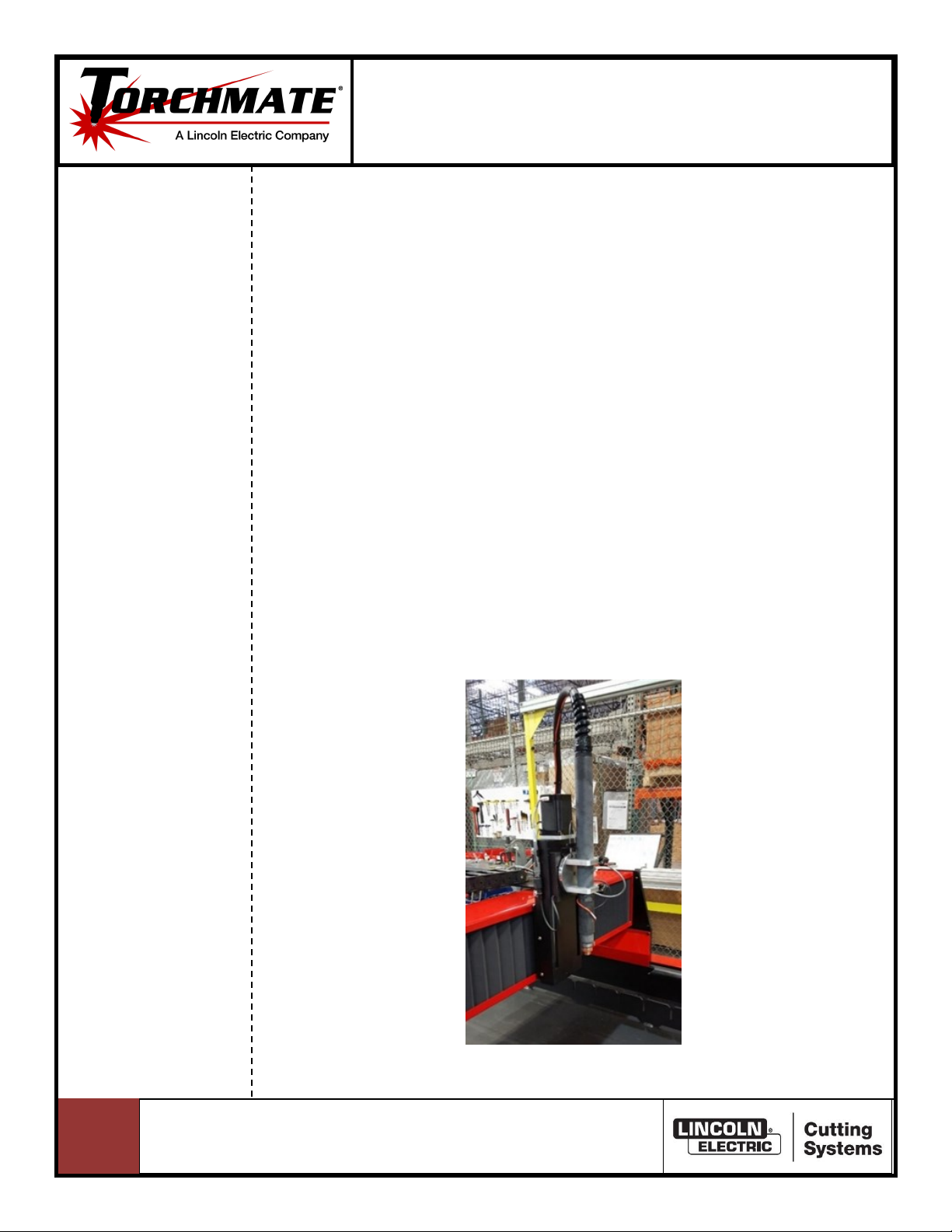

Part 1: Removing the plasma torch shown in Fig. 1.

Fig. 1: Plasma torch.