7

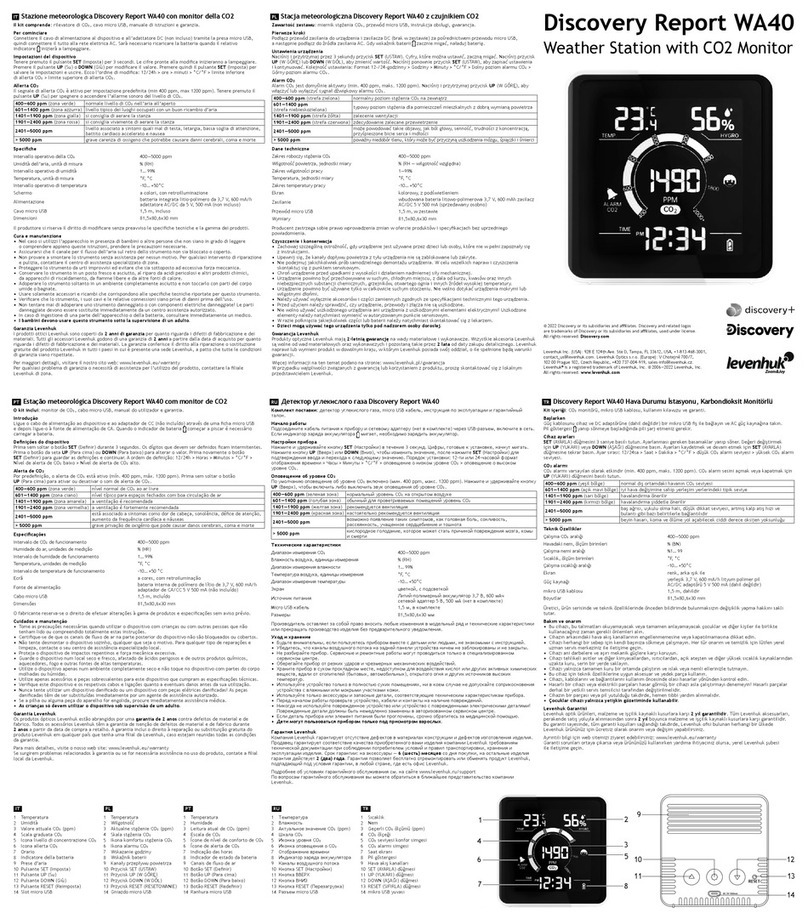

E. Power LED: This indicator will flash on and off

when the machine is first turned on. After

approximately 2 seconds it will stop flashing and

remain on to signal that the machine is ready.

F. Thermal LED: This indicator will turn on when the

machine is overheated and the output has been

disabled. This normally occurs when the duty cycle

of the machine has been exceeded. Leave the

machine on to allow the internal components to

cool. When the indicator turns off, normal operation

is again possible.

G. Remote LED [text removed]: This indicator will turn

on when a remote control is connected to the

machine via the remote control connector. Using a

remote control will change the function of the output

current control, refer to the output current control

section [text removed].

H. Output LED: This indicator turns on when the

output of the machine is on. Both the type of

machine and the position of the mode switch

determine when the output of the machine is turned

on.

V270-S: In the stick welding mode, the output of

the machine is automatically turned ON. However,

in the Lift TIG welding mode, the connection of a

remote control determines if the output is ON or

OFF. If a remote control is not connected (the

Remote LED is OFF) then the output of the machine

is automatically turned ON. If a remote control is

connected (the Remote LED is ON) then the output

of the machine is turned ON and OFF by the remote

connector on the front of the machine.

V270-T: In stick welding mode, the output of the

machine is automatically turned ON. However, in

both of the TIG welding modes, the output of the

machine is turned ON and OFF by the TIG torch

connected to the trigger connector on the front of

the machine.

I. Meter [text removed]: This meter displays the

preset welding current before welding and the actual

welding current during welding. Like the output

current control, the function of the meter is changed

if a remote control is connected. If the Remote LED

is ON, this indicates that a remote control is

connected and the meter will display the following

information before welding (during welding, the

meter always displays the actual welding current):

Stick Welding Mode: The meter displays the

preset welding current but this is adjusted from the

remote control as explained in the Output Current

Control section.

TIG Welding Modes: The meter displays the

maximum output current which is set by the output

current control knob. The preset welding current is

then adjusted by the remote control, but it is not

displayed on the meter.

V270-S: The V270-S has a Voltage / Current switch

to change the displayed value on the meter. If this

switch is set to voltage, the meter will always display

the output voltage of the machine.

J. Output Current Control: This controls the output, or

welding, current of the machine.

The function of this control knob is changed if a

remote control is connected. If the Remote LED is

ON, this indicates that a remote control is connected

and the function of the output current control will be:

Stick Welding Mode: The remote control will

adjust the output current of the machine from 5 to

270A. The output current control knob on the

display panel is not used.

TIG Welding Modes: The maximum output current

of the machine is set by the output current control

knob. Then the remote control adjusts the output

current from the minimum output (5A) to the value

set by the output current control knob. For example,

if the output current control knob on the machine is

set to 100A then the remote control will adjust the

output current from a minimum of 5A to a maximum

of 100A.

K. Hot Start (V270-S only): In stick welding mode, this

controls the amount of current used during the start

of the arc to help ignite the arc quickly and reliably.

In TIG welding mode, this is not used.

L. Arc Force (V270-S only): In stick welding mode,

this controls the amount of current used during any

intermittent short circuiting of the electrode during

welding. In TIG welding mode, this is not used.

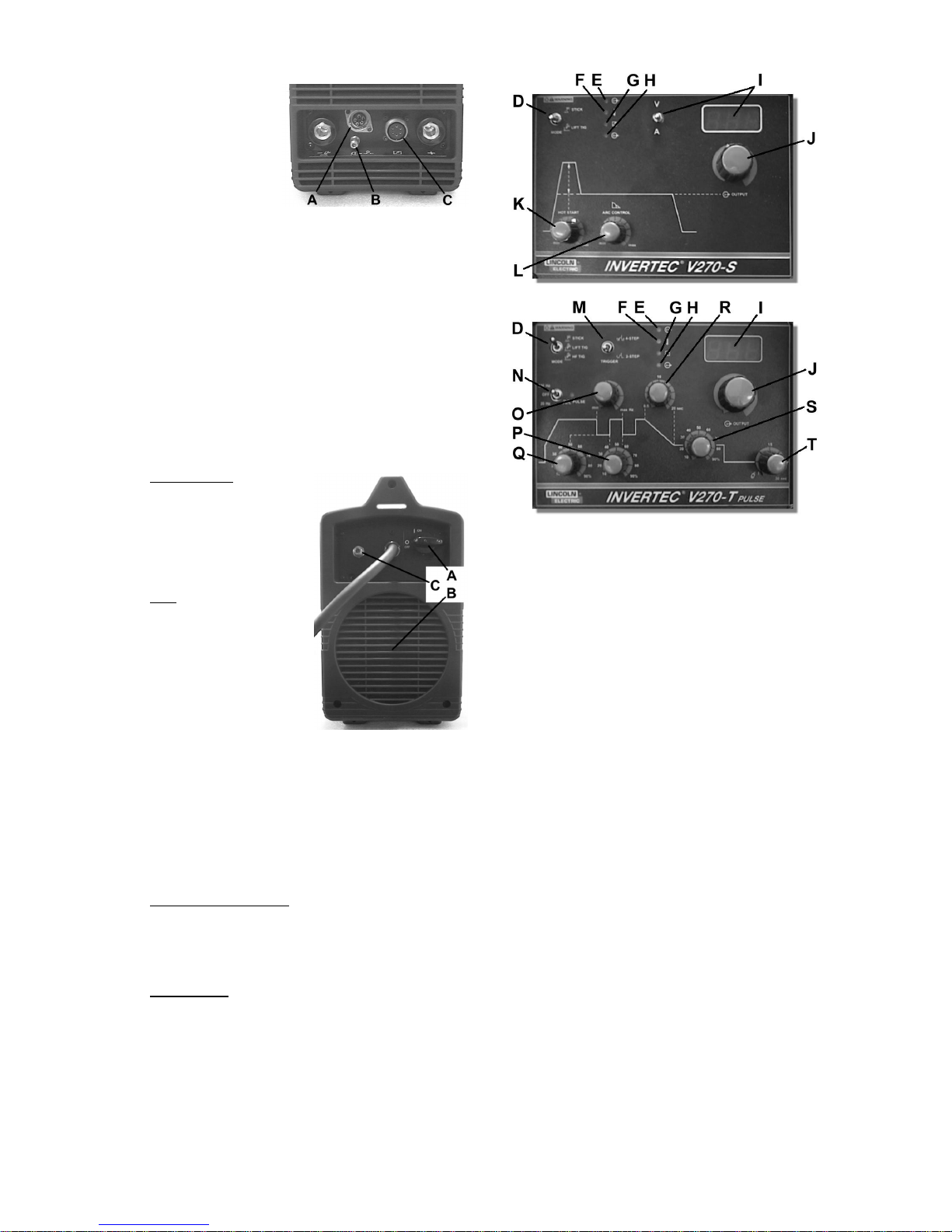

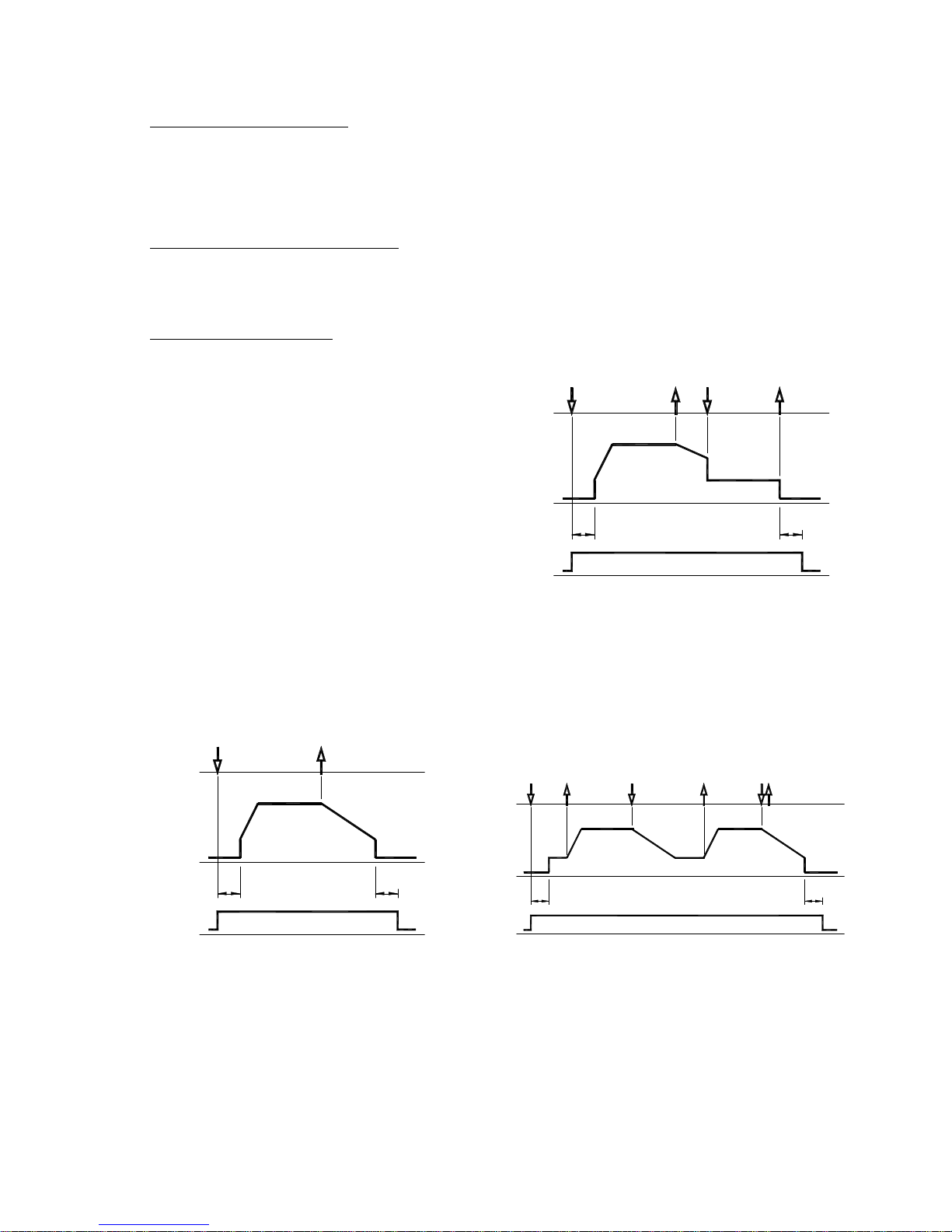

M. Trigger Mode Switch (V270-T only): This switch

changes between 2-step and 4-step trigger

sequences. For an explanation of these trigger

sequences refer to the trigger sequences explained

below.

N. Pulsing Mode Switch (V270-T only): In the TIG

welding modes, this switch turns the pulsing

function ON and controls the pulsing frequency

range (20Hz or 300Hz). In Stick welding mode, this

is not used.

The Pulsing LED next to the Pulsing Mode Switch

shows the pulsing frequency when pulsing is turned

ON. With this indication, the operator can adjust the

frequency to the desired value before welding.

(Note: At higher frequencies the LED flashes very

fast and seems to be continuously ON however it is

pulsing.)

O. Pulsing Frequency Control (V270-T only): When

the pulsing function is ON, this control knob will

adjust the pulsing frequency. The pulsing frequency

adjustment range is 0.2 - 20Hz or 3 - 300Hz

depending on the Pulsing Mode Switch position.

P. Pulsing On-time Control (V270-T only): When the

pulsing function is ON, this control knob will adjust

the pulsing on-time. The on-time can be adjusted

from 10% to 90% of the pulsing period.

Q. Pulsing Background Current Control (V270-T only):

When the pulsing function is ON, this control knob

will adjust the pulsing background current. This is

the current during the low portion of the pulse

waveform; it can be adjusted from 10% to 90% of