Linde AGA Series User manual

Other Linde Welding System manuals

Linde

Linde BOC Raptor CUT 30C User manual

Linde

Linde Ryval 400 aXe User manual

Linde

Linde BOC Smootharc TIG 200 ACDC User manual

Linde

Linde BOC Smootharc MIG 250 User manual

Linde

Linde Ryval 250 MIG MAN User manual

Linde

Linde BOC Smootharc Advance MIG 425R User manual

Linde

Linde BOC Smoothcut 100A User manual

Linde

Linde RYVAL 60 PLASMA User manual

Linde

Linde BOC RAPTOR 140 MMA User manual

Linde

Linde BOC Smootharc Advance MIG 255R User manual

Linde

Linde BOC RAPTOR 200 MIG User manual

Linde

Linde BOC RAPTOR 135 User manual

Linde

Linde RYVAL 200 AC/DC dave User manual

Linde

Linde BOC Smootharc Advance II MIG 400R User manual

Linde

Linde BOC RAPTOR User manual

Linde

Linde BOC Raptor 200C MIG User manual

Linde

Linde BOC RAPTOR 160 MIG User manual

Linde

Linde TPL 300 puls DC User manual

Linde

Linde FSM-1 User manual

Linde

Linde BOC RAPTOR 250R MIG User manual

Popular Welding System manuals by other brands

Everlast

Everlast PowerARC 210ST Operator's manual

Air Liquide

Air Liquide OERLIKON MINICITO 1700 Safety instruction for use and maintenance

Deca

Deca i-TIG 320 LAB instruction manual

WARPP

WARPP AIRCUT 100I operating manual

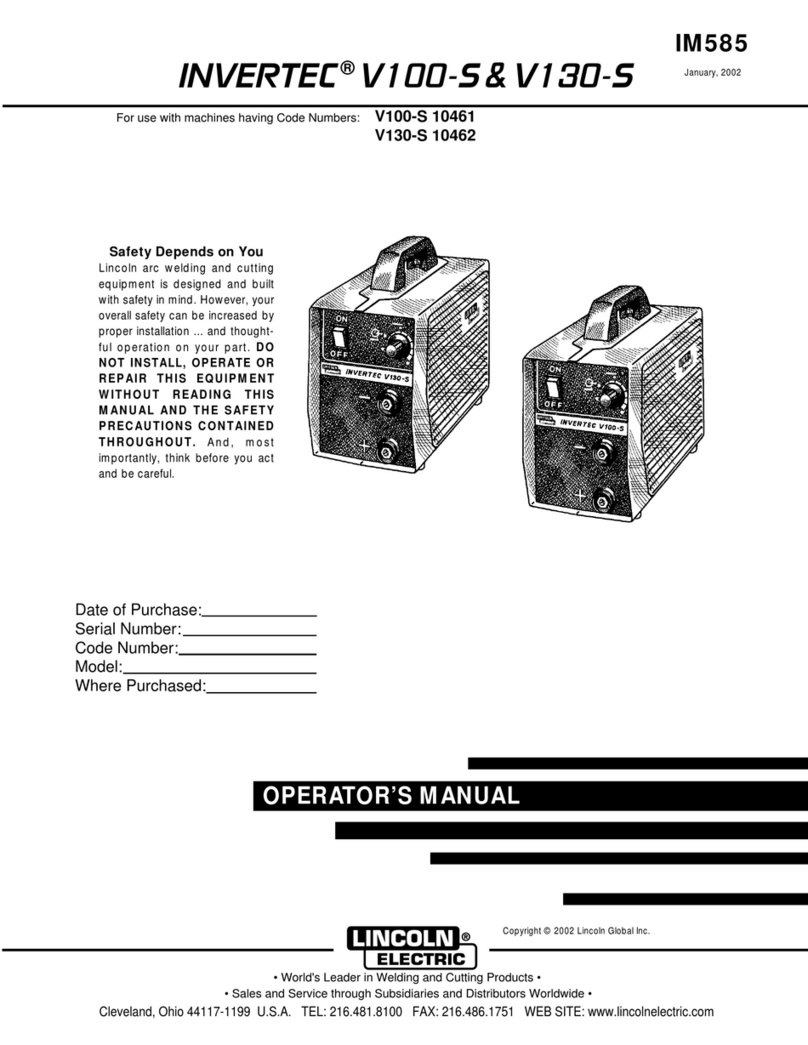

Lincoln Global

Lincoln Global INVERTEC V100-S Operator's manual

Miller Electric

Miller Electric 145 Specifications

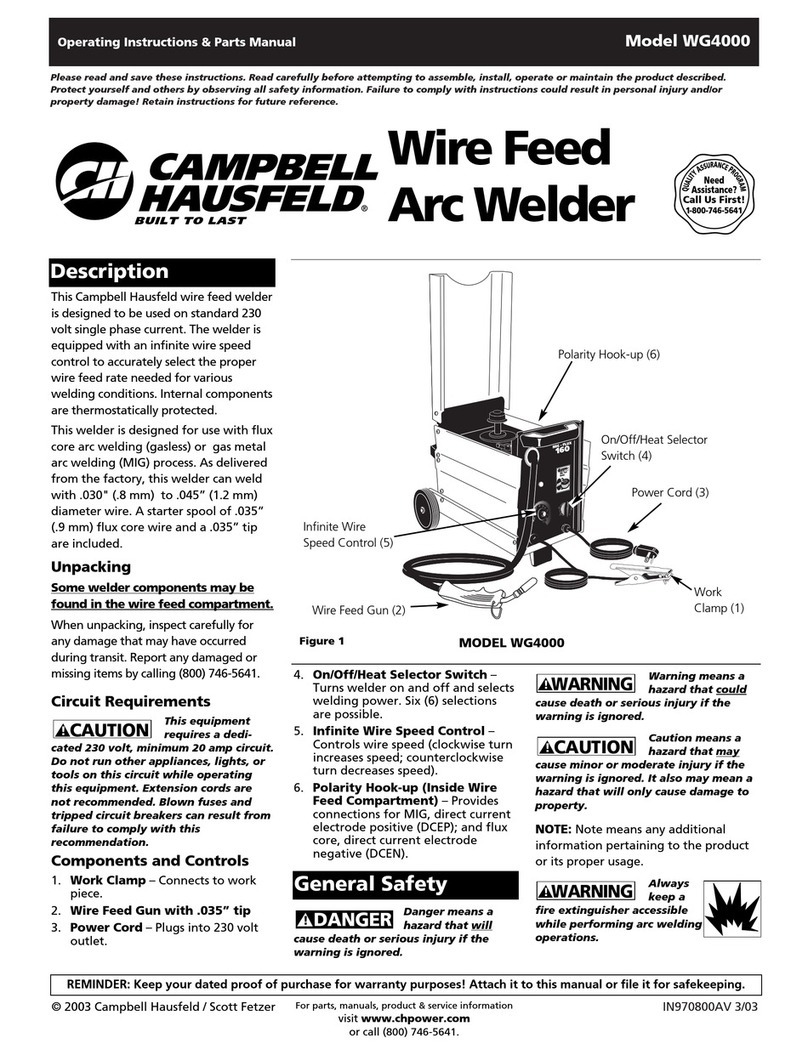

Campbell Hausfeld

Campbell Hausfeld WG4000 Operating instructions and parts manual

Raider

Raider RD-IW27 user manual

Lincoln Electric

Lincoln Electric INVERTEC 400TP Operator's manual

Arcoweld

Arcoweld ArcoTiG HF 315 AC/DC Operator's manual

Red-D-Arc Welderentals

Red-D-Arc Welderentals D300K 3+3 SE Operator's manual

Northern Industrial

Northern Industrial ARC 200 Operator's manual