Deca i-TIG 320 LAB User manual

Instore "130"youcanfind and buy almostall necessary goodsforyourauto in

Kyiv and other cities,delivery by ground andpostal services.Ourexperienced

consultantswill provide youwithexhaustive informationand helpyoutochose

the very particular thing. We are waiting foryou atthe address

https://130.com.ua

PHONES

0 (800) 800 130

(050) 462 0 130

(063) 462 0 130

(067) 462 0 130

Internet storeof

autogoods

CARRECEIVERS —Receivers •Mediareceiversandstations•Nativereceivers •CD/DVD changers •FM-modulators/USBadapters•Flashmemory•Faciaplates and adapters •Antennas •Accessories |

CARAUDIO —Car audiospeakers •Amplifiers•Subwoofers •Processors•Crossovers •Headphones•Accessories|TRIPCOMPUTERS —Universalcomputers •Modelcomputers •Accessories|

GPSNAVIGATORS —PortableGPS•Built-in GPS•GPSmodules •GPStrackers •Antennas forGPSnavigators•Accessories|VIDEO —DVR •TVsetsand monitors•Car TVtuners•Cameras •Videomodules

•Transcoders •Car TVantennas•Accessories|SECURITYSYSTEMS —Car alarms •Bikealarms •Mechanicalblockers •Immobilizers •Sensors •Accessories |OPTICANDLIGHT —Xenon•Bixenon •Lamps

•LED •Stroboscopes •OpticandHeadlights •Washers •Light,rainsensors •Accessories |PARKTRONICS ANDMIRRORS —Rear parktronics•Frontparktronics •Combined parktronics •Rear-viewmirrors

•Accessories |HEATINGANDCOOLING —Seat heaters •Mirrorsheaters •Screen-wipers heaters •Engineheaters •Auto-refrigerators •Airconditioningunits •Accessories |TUNING —Vibro-isolation

•Noise-isolation •Tintfilms •Accessories |ACCESSORIES —Radar-detectors•Handsfree,Bluetooth•Windowlifters•Compressors •Beeps,loudspeakers •Measuring instruments •Cleaners •Carsits

•Miscellaneous|MOUNTING —Installationkits •Upholstery•Grilles•Tubes•Cableand wire •Tools•Miscellaneous|POWER —Batteries •Converters •Start-chargingequipment•Capacitors

•Accessories |MARINE AUDIOANDELECTRONICS —Marinereceivers•Marineaudiospeakers •Marinesubwoofers •Marineamplifiers•Accessories |CARCARE PRODUCTS —Additives •Washer fluid •

Care accessories •Car polish •Flavors •Adhesives andsealants |LIQUIDANDOIL —Motoroil•Transmissionoil •Brakefluid •Antifreeze•Technicallubricant

SKYPE

km-130

1

950677-00 07/07/18

TIG

IT 5 Manuale istruzione

EN 7 Instruction Manual

FR 9 Manuel d’instruction

ES 11 Manual de instrucciones

PT 13 Manual de instruções

DE 15 Bedienungsanleitung

DA 17 Brugermanual

NL 19 Handleiding

SV 21 Brukanvisning

NO 23 Instruksjonsmanual

FI 25 Käyttöohjekirja

ET 27 Kasutusõpetus

CS 35 Návod k obsluze

HU 37 Használati kézikönyv

SK 39 Návod k obsluhe

HR

AR 57

Autogoods “130”

130.com.ua

1

950677-00 07/07/18

P

O

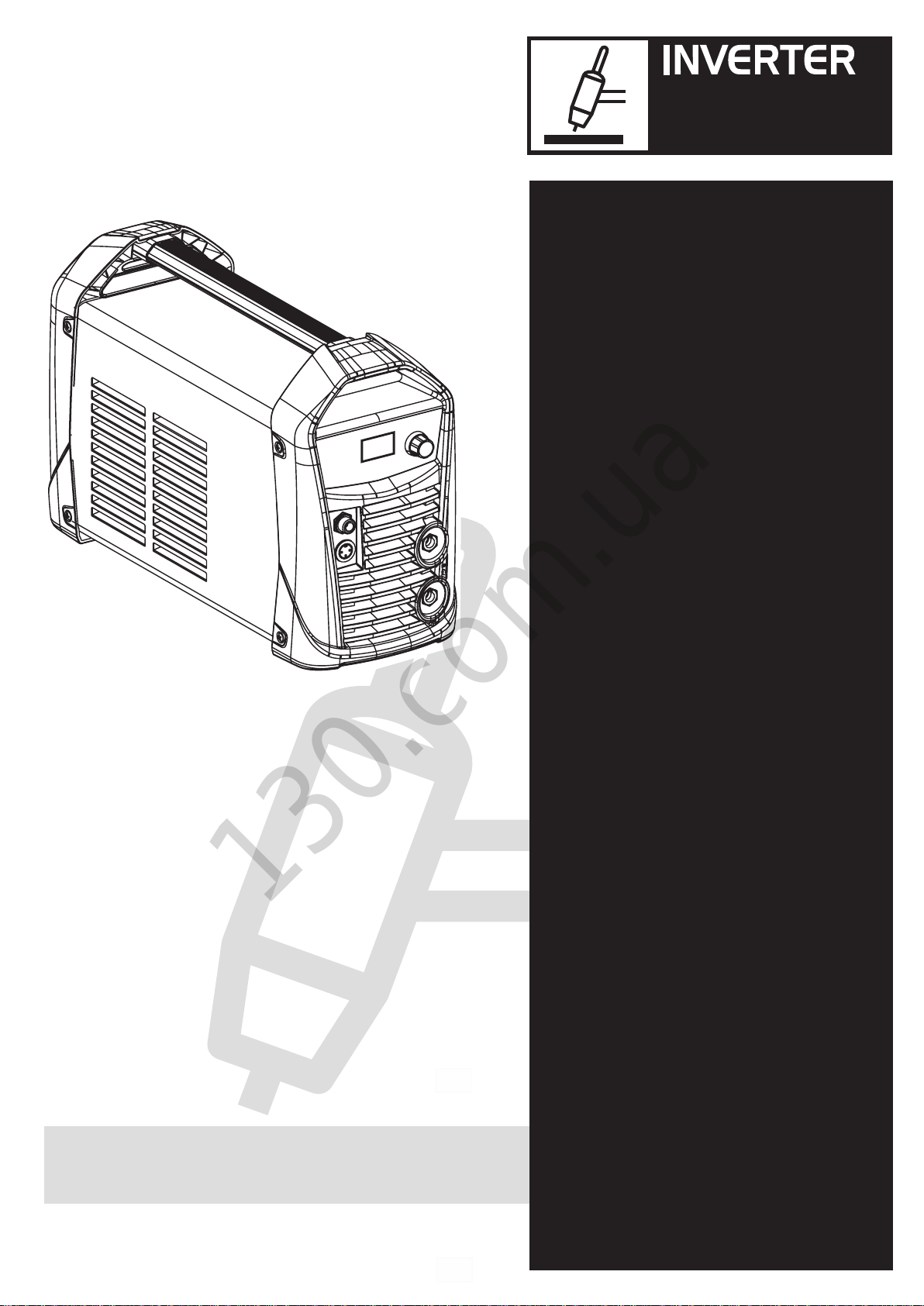

Fig.1

A

B

Mod.1 TIG DC PULSE Mod.2 TIG DC

F1F2

F3 F4

F5F6

L

G

IMF

N

E1

E2

F1F2

F3

F5F6

L

G

IMF

N

E1

E2

Fig.2

Kg

L

M

XXXXXXXXXXX

UV1=XXX

1~XX/XXHz

XXA/XXXV-XXXA/XXV

XA/XXV-XXXA/XXV

X 40 % 60 %

UV

o= XX

100 %

I2XXX A XXX A XXX A

U2XXX V XXX V XXX V

X60 %

UV

o= XX

100 %

I2XX A XX A

XX V XX V

U2

40 %

XX A

XX V

IA

1eff

XX

EN XXXXX/X

XXXXXXXXXXXXXX

Serial N.

IP XX

S

X~ f1 f2

S

IA1max

XX

A

B

C

E

K

H

G

I

J

D1

D2

Fig.2.1

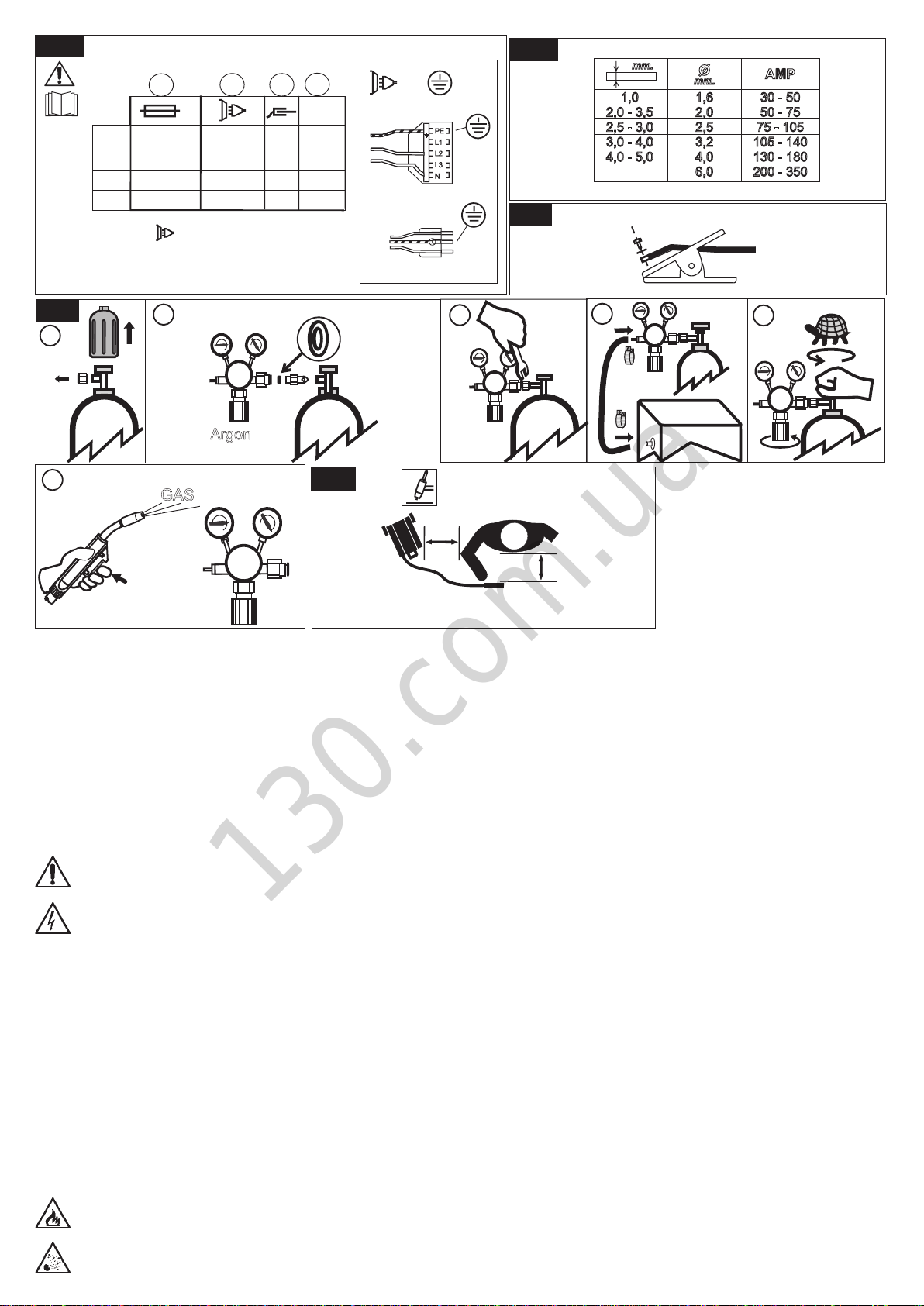

I max (A) X (%)

Argon

mm

Ø

Voltage class=113 Volt

0,5 - 2,4

0,5 - 2,4

35

35

140 DC

125 AC

Cooling

Air

F

Mod.1

Mod.2

C

D

Process Parameter

I

Arcforce

Hot start

I

Pre gas

Slope up

Slope down

Post gas

Spot time

Pulse freq.

U.M.

Amp

%

%

Amp

sec

sec

sec

sec

sec

Hz

Range

10-180

0-100

0-100

5-200

0-5

0-10

0-20

0,1-25

0-10

0-250

TIG DC

Default

100

30

30

120

0

0

0

5

Off

Off

Step

1

10

10

1

0,1

0,1

0,1

0,1

0,01

Var

Tab.1

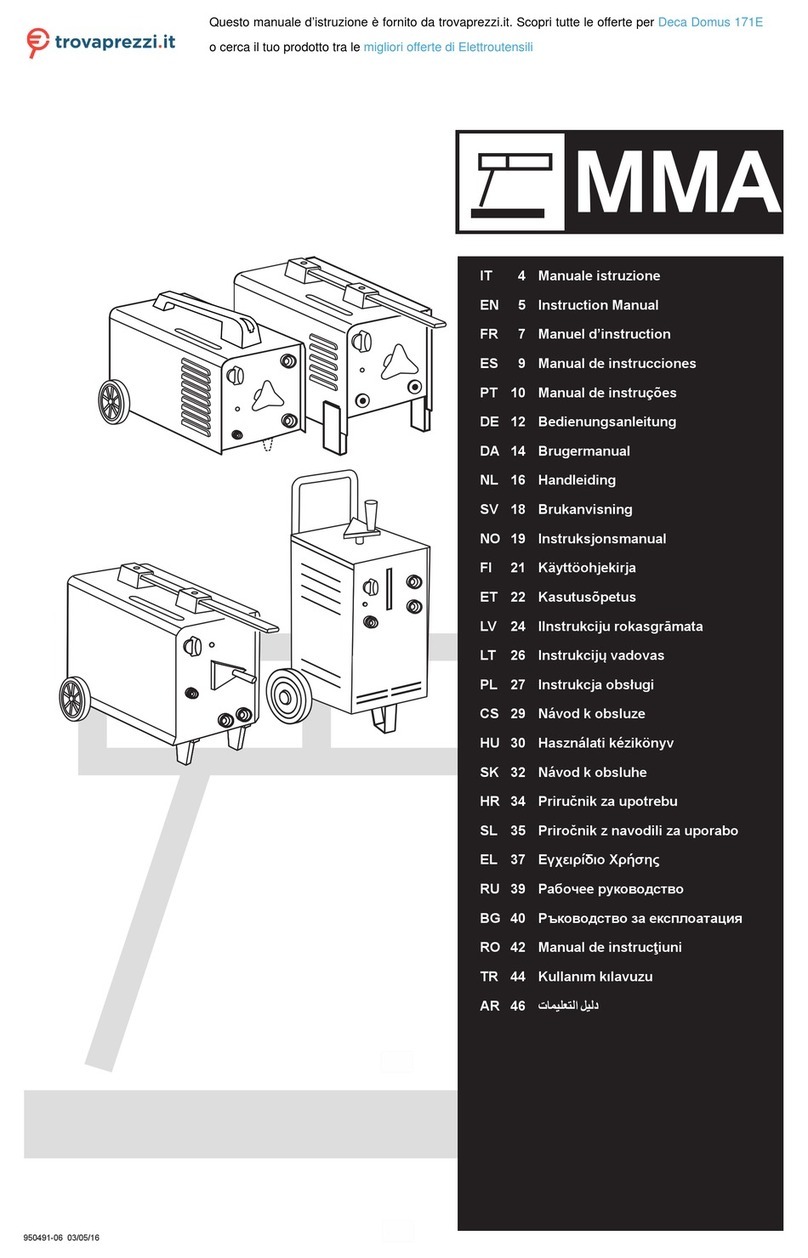

MMA

Mod.1 Mod.2

Range

10-160

0-100

0-100

5-180

0-5

0-10

0-20

0,1-25

Default

100

30

30

120

0

0

0

5

Step

1

10

10

1

0,1

0,1

0,1

0,1

Autogoods “130”

130.com.ua

2

950677-00 07/07/18

•

(IT)(EN)(FR)(ES) SEÑALES

(PT)(EL)(DE)

(DA) (NL) (SV)

(FI)(ET)(LV)

(LT) (PL)

(CS) (SK)

(HU) (RU) (BG)

(HR)(NO)(SL)

IN PREPOVEDI (RO)(TR))

db

da

Fig.7

14

Fig.6

Argon

25

6

GAS

3

6-8Lt/min

Fig.5

Fig.4

1,0

2,0-3,5

2,5-3,0

3,0-4,0

4,0-5,0

1,6

2,0

2,5

3,2

4,0

6,0

30-50

50-75

75-105

105-140

130-180

200-350

AMP

mm. mm.

Ø

1Ph

230 V

230 V

Fig.3

Zmax**

ohm

3,4

1Ph

I

max

(A)

2

220V

230V

240V mm

2

220V

230V

240V

3,1 3,2 3,3

180

200 T25A 16

16

T25A 32A

32A 0,254

0,192

** Zmax1Ph 230 V

Autogoods “130”

130.com.ua

3

950677-00 07/07/18

•

Autogoods “130”

130.com.ua

4

950677-00 07/07/18

(IT)

(EN)

(FR)

(ES)

(PT)

(DE)

(DA)

(NL)

(SV)

(NO)

(FI)

(ET)

(LV)

(LT)

(PL)

(CS)

(HU)

(SK)

(HR)

(SL)

(EL)

(RU)

(BG)

(RO)

(TR)

Autogoods “130”

130.com.ua

5

950677-00 07/07/18

IT

Manuale istruzione

IEC o CLC/TS 62081

Avvertenze di sicurezza

Fig 7 DaDb

Apparecchiatura di Classe A

Saldatura in condizioni a rischio

Avvertenze supplementari

Descrizione della saldatrice

Fig.1.

Organi principali Fig.1

Dati tecnici

Fig.2

D1D2

1˜

U0V

I2, U2

X

A / V

U1

I1 eff

I1 max

Fig 2.1

** (Questo componente può non essere incluso su alcuni modelli).

Autogoods “130”

130.com.ua

950677-00 07/07/18

L

E2) Selettore TIG 2T / TIG 4T

¾“2T”

¾“4T”

F) Saldatura MMA: parametri regolabili

¾“I (Amp)” “F3”

¾“ARC FORCE“F5”

¾“HOT START”“F2”

F) Saldatura TIG: parametri regolabili

¾“PREGAS” “F1”

¾“SLOPE-UP” “F2”

“I (Amp)”.

L

¾“I (Amp)” “F3”

¾“SLOPE-DOWN” “F5”

L

¾“POST-GAS” “F6”POST-GAS

¾“T (SPOT)” “F3 + F4”“SPOT”

¾“PULSE (Hz)” “F4”“TIG PULSE”

L) Spia di segnalazione comando remoto (pedale)

collegato

M) Spia di segnalazione intervento termico

X protettore

termico

“Reset” della macchina

“F”

L

Consigli per l’uso

LAl primo

Manutenzione

Manutenzione straordinaria

elettromeccanico periodicamente

Messa in funzione

Assemblaggio ed allacciamento elettrico

¾ (Fig.5).

¾

Fig.3,1.

LSe

L

Fig.3,4

¾Spinad’alimentazione.

potenza Fig.3,2

Fig.3,2

Preparazione del circuito di saldatura MMA

¾

¾

L

Preparazione del circuito di saldatura TIG

¾

¾

¾“B”

¾“P”

L

Fig.3,3

Fig.6

L

** (Questo componente può non essere incluso su alcuni modelli).

Procedimento di saldatura: descrizione comandi e

segnalazioni

¾“E”.

¾ “F”

la manopola “G”

L

nella Tab.1

E1) Selettore MMA / TIG LIFT / TIG HF

¾MMA

¾TIG HF

¾TIG LIFT

L

L

Autogoods “130”

130.com.ua

950677-00 07/07/18

Class A equipment

Welding in conditions of risk

Additional warnings

Description of the welding machine

Fig. 1.

Main parts Fig. 1

Technical data

Fig. 2

D1D2

1˜

U0V

I2, U2

X

A/V

U1

I1 eff

I1 max

Fig.2,1

** (This component may not be included with some models).

EN

Instruction Manual

: IEC or CLC/TS 62081.

Safety warnings

Fig 7 DaDb

Autogoods “130”

130.com.ua

950677-00 07/07/18

E2) TIG 2T / TIG 4T selector

¾2T

¾4T

F) MMA welding: adjustable parameters

¾“I (Amp)“F3”

¾“ARC FORCE(led slope down) “F5”

¾“HOT START” (led slope up) “F2”

F) TIG welding: adjustable parameters

¾“PREGAS” “F1”

¾“SLOPE-UP” “F2”

I (Amp)

¾“I (Amp)“F3”

¾“SLOPE-DOWN“F5”

¾“POST-GAS“F6” POST-GAS

¾“T (SPOT)” “F3 + F4” In the “SPOT

¾“PULSE (Hz)” “F4” In the “TIG PULSE

L) Remote (Foot pedal) control connection pilot lamp

M) Thermal cutout signal

Xthermal cutout

Machine reset

F

LDo not connect

Recommendations for use

L

Maintenance

Extraordinary maintenance

Starting up

Assembly and electrical connections

¾ (Fig.5)

¾

Fig. 3,1.

L

L

Fig.3,4.

¾Power plug.

Fig 3,2

Fig 3,2.

Preparing the welding circuit MMA

¾

¾

L

Preparing the welding circuit TIG

¾

¾

¾Connect the torch control connector into the connector “B”

¾“P”

L

Fig. 3,3.

Fig. 6

L

** (This component may not be included with some models).

Welding process: description of controls and signals

¾“E”

¾“F”

G

LTable 1

E1) MMA, TIG LIFT, TIG HF selector

¾MMA

¾TIG LIFT

¾TIG HF:

L

L

L

Autogoods “130”

130.com.ua

950677-00 07/07/18

FR

Manuel d’instruction

,

Avertissements de sécurité

Fig 7 DaDb

Appareillage de Classe A

Soudage en situations de risque

Avertissements supplémentaires

Description de la soudeuse

Fig.1.

Principaux organes Fig.1

Caractéristiques techniques

Fig.2

D1D2

1˜

U0V

I2, U2

X

Autogoods “130”

130.com.ua

950677-00 07/07/18

A / V

U1

I1 eff

I1 max

Fig.2,1

** (Ce composant peut ne pas être inclus pour certains modèles).

Mise en service

Montage et raccordement électrique

¾(Fig. 5)

¾

Fig.3,1

L

L

Fig.3,4

¾Fiche d’alimentation.

Fig.3.2

Fig.3.2.

Raccordement aux moto-générateurs

Préparation du circuit de soudage MMA

¾

¾

L

Préparation du circuit de soudage TIG

¾

¾

¾«R»

¾« P»

L

Fig.3,3.

Fig.6

L

** (Ce composant peut ne pas être inclus pour certains modèles).

Procédé de soudage: description des commandes et

signalisations

¾ “E”

¾“F”

G

L

E1) Sélecteur MMA, TIG LIFT, TIG HF

¾MMA

¾TIG LIFT

¾TIG HF

L

L

L

E2) Sélecteur TIG 2T / TIG 4T

¾2T

¾4T

F) Soudage MMA : paramètres réglables

¾“I (Amp)” “F3”

¾“ARC FORCE” (led slope down) “F5” (led slope up)

¾“HOT START” (led slope up) “F2”

F) Soudage TIG : paramètres réglables

¾“PREGAS“F1”

¾“SLOPE-UP“F5”

I (Amp)

L“F2”

¾“I (Amp)“F3”

¾“SLOPE-DOWN”“F5”

L

¾“POST-GAS“F6”

¾“T (SPOT)” “F3 + F4” En mode “SPOT

¾“PULSE (Hz)” “F4” En mode “TIG PULSE

L) Témoin de signalisation commande à distance

(pédale) connecté

M) Témoin de signalisation de l’intervention thermique

X

protecteur thermique

“Reset” de la machine

F

L

Conseils d’utilisation

L

Autogoods “130”

130.com.ua

11

950677-00 07/07/18

Fig 7 Da = cm

Db

Equipo de Clase A

Soldadura en condiciones de riesgo

Advertencias adicionales

Descripción de la soldadora

Fig. 1.

Piezas principales Fig.1

Datos técnicos

Fig.2

D1D2

Entretien

Entretien extraordinaire ,

ES

Manual de instrucciones

,

IEC o CLC/TS 62081

Advertencias de seguridad

Autogoods “130”

130.com.ua

12

950677-00 07/07/18

U0V

I2, U2

X

A / V

U1

I1 eff

I1 max

Fig.2,1

** (Este componente puede no estar incluido en algunos modelos).

Puesta en funcionamiento

Ensamblaje y conexión eléctrica

¾(Fig. 5)

¾

Fig.3,1.

L

L

Fig.3,4.

¾Enchufe de corriente.

Fig.3,2.

Fig.3,2.

Conexión a motogeneradores

Preparación del circuito de soldadura MMA

¾

¾

L

Preparación del circuito de soldadura TIG

¾

¾

¾“B”

¾“P”

L

Fig.3,3.

Fig.6.

L

** (Este componente puede no estar incluido en algunos modelos).

Procedimiento de soldadura: descripción mandos y

señalaciones

¾“E”

¾“F”

G

L

indican en la Tabla 1

E1) Selector MMA, TIG LIFT, TIG HF

¾MMA

¾TIG LIFT

¾TIG HF

L

L

L

E2) Selector TIG 2T / TIG 4T

¾2T

¾4T

F) Soldadura MMA: parámetros ajustables

¾“I (Amp)” “F3”

¾“ARC FORCE” (led slope down) “F5”

¾“HOT START” (led slope up) “F2”

F) Soldadura TIG: parámetros ajustables

¾“PREGAS“F1”

¾“SLOPE-UP” “F2”

I (Amp)

L

¾“I (Amp)” “F3”

¾“SLOPE-DOWN” “F5”

L

¾“POST-GAS” “F6”

¾“T(SPOT)”“F3 + F4” Enla modalidad “SPOT”

¾“PULSE (Hz)” “F4” En la modalidad “TIG PULSE”

L) Dispositivo luminoso que indica la conexión del

mando a distancia (pedal)

M) Dispositivo luminoso que indica un accionamiento

térmico

X

protector térmico

“Reset” de la máquina

F

Autogoods “130”

130.com.ua

13

950677-00 07/07/18

Recomendaciones para el uso

LLa

Mantenimiento

Mantenimiento extraordinario

, en

PT

Manual de instruções

em

ncia

: IEC ou CLC/TS 62081.

Advertências de segurança

Fig. 7 Da =

Db

Aparelhagem de Classe A

Soldadura em condições a risco

Advertências suplementares

Descrição da soldadora

Fig. 1.

Órgãos principais Fig.1

Autogoods “130”

130.com.ua

14

950677-00 07/07/18

Dados técnicos

Fig.2

D1D2

1˜

U0V

I2, U2

X

A / V

U1

I1 eff

I1 máx

Fig.2,1

** (Este componente pode não estar incluído em alguns modelos).

Pôr a funcionar

Montagem e ligação eléctrica

¾(Fig.5)

¾

Fig.3,1.

L

L

Fig.3,4.

¾Tomada de alimentação.

Fig. 3,2.

Fig. 3,2

Ligação em motogeradores

Preparação do circuito de soldadura MMA

¾

¾

L

Preparação do circuito de soldadura TIG

¾

¾

¾“B”

¾“P”

L

Fig.3,3

Fig.6

L

** (Este componente pode não estar incluído em alguns modelos).

Procedimento de soldadura: descrição comandos e

sinalizações

¾“E”

¾“F”

G

L

Tab.1

E1) Selector MMA, TIG LIFT, TIG HF

¾MMA

¾TIG LIFT

¾TIG HF

L

L

L

E2) Selector TIG 2T / TIG 4T

¾2T

¾4T

F) Soldadura MMA: parâmetros reguláveis

¾“I (Amp)” “F3”

¾“ARCFORCE” (led slope down) “F5”

¾“HOT START” (led slope up) “F2”

F) Soldadura TIG: parâmetros reguláveis

¾“PREGAS” “F1”

¾“SLOPE-UP” “F2”

I (Amp)

L

¾“I (Amp)” “F3”:

¾“SLOPE-DOWN” “F5”

L

¾“POST-GAS” “F6”

¾“T (SPOT)” “F3 + F4” No modo “SPOT

¾“PULSE (Hz)” “F4” Nomodo “TIG PULSE”

L) Indicador luminoso de sinalização comando remoto

(pedal) ligado

M) Luz piloto de sinalização da intervenção térmica

Xprotector térmico

Autogoods “130”

130.com.ua

15

950677-00 07/07/18

“Reset” da máquina

F

Conselhos para o uso

LNa primeira

utilizaçã

Manutenção

Manutenção extraordinária

DE

Bedienungsanleitung

: IEC oder CLC/TS 62081 .

Sicherheitshinweise

Fig 7 DaDb

Gerät der Klasse A

Schweißen unter Risikobedingungen

Zusätzliche Warnhinweise

Beschreibung der Schweißmaschine

Autogoods “130”

130.com.ua

950677-00 07/07/18

Abb.1

Hauptbauteile Abb.1

Technische Daten

Abb.2

D1D2

1˜

U0V

I2,U2

X

A / V

U1

I1 eff

I1 max

Abb. 2,1

** (Dieses Teil kann bei einigen Modellen fehlen).

Inbetriebnahme

Zusammenbau und Stromanschluss

¾ (Abb.5)

¾

Abb.3,1.

L

L

Abb.3,4

¾Netzstecker.

(Abb. 3.2)

(Abb. 3.2)

Anschluss an Motorgeneratoren

Vorbereitung des Schweißkreises MMA

¾

¾

L

Vorbereitung des Schweißkreises TIG

¾

¾

¾ “B

¾“P”

L

Abb.6

L

** (Dieses Teil kann bei einigen Modellen fehlen).

Schweißverfahren: Beschreibung der

Bedienvorrichtungen und Anzeigen

¾“E”

¾“F”

„G“

L

Tab. 1

E1) Wählschalter MMA, TIG LIFT, TIG HF

¾MMA

¾TIG LIFT

¾TIG HF

L

L

L

E2) Wählschalter TIG 2T / TIG 4T

¾2T

¾4T

F) MMA-Schweißen: einstellbare Parameter

¾“I (Amp)” “F3”:

¾ARC FORCE (led slope down) “F5”:

¾HOT START (led slope up) “F2” :

F) WIG-Schweißen: einstellbare Parameter

¾“PREGAS” “F1”

¾“SLOPE-UP” “F2”

I (Amp)

Autogoods “130”

130.com.ua

950677-00 07/07/18

L

¾“I (Amp)” “F3”

¾„SLOPE-DOWN” “F5”

L

¾„POST-GAS“ “F6”

¾“T (SPOT)” “F3 + F4”“SPOT”

¾“PULSE (Hz)” “F4” “TIG PULSE” Die

L) Kontrollleuchte für Fernbedienung angeschlossen

(Pedal)

M) Anzeigeleuchte angesprochener Schutzschalter

X

Thermoschutzschalter

Rückstellen der Maschine

F

L

Ratschläge für den Gebrauch

LDaher

Instandhaltung

AAußerordentliche Wartung:

DA

Brugermanual

Sikkerhedsadvarsler

Autogoods “130”

130.com.ua

950677-00 07/07/18

Fig.2,1

** (Denne komponent er muligvis ikke inkluderet i visse modeller).

Opstart

Montering og elektriske forbindelser

¾(Fig. 5)

¾

Fig. 3,1.

L

L

Fig. 3,4.

¾Strømforsyningsstik.

Fig. 3.2.

Fig. 3.2

Tilslutning til motorgeneratorer

Forberedelse af svejsekredsløbet MMA

¾

¾

L

Forberedelse af svejsekredsløbet TIG

¾

¾

¾”B”

¾“P”

L

Fig. 3.3

Fig. 6

L

** (Denne komponent er muligvis ikke inkluderet i visse modeller).

Svejseproces: beskrivelse af kontrolfunktioner og

signaler

¾“E”

¾“F”

G

LTab. 1

E1) MMA, TIG LIFT, TIG HF vælger

¾MMA

¾TIG LIFT

¾TIG HF

Fig 7 DaDb

Klasse A-apparat

Svejsning under risikable forhold

Yderlige advarsler

Beskrivelse af svejsemaskinen

Fig. 1.

Vigtigste dele Fig. 1

Tekniske data

Fig. 2

D1D2

U0V

I2, U2

X

A / V

U1

I1 eff

I1 max

Autogoods “130”

130.com.ua

This manual suits for next models

3

Table of contents

Languages:

Other Deca Welding System manuals

Deca

Deca SW 28 User manual

Deca

Deca I-PAC 370 User manual

Deca

Deca Domus 171E User manual

Deca

Deca MIG JOB 635 LAB User manual

Deca

Deca MMA T-ARC 529 User manual

Deca

Deca JOB 220 LAB User manual

Deca

Deca D-MIG500 User manual

Deca

Deca MIGA 320 User manual

Deca

Deca SIL series User manual

Deca

Deca EASYJOB 220 User manual

Popular Welding System manuals by other brands

Magmaweld

Magmaweld Monotig 160i user manual

Lincoln Electric

Lincoln Electric POWER WAVE 655/R Service manual

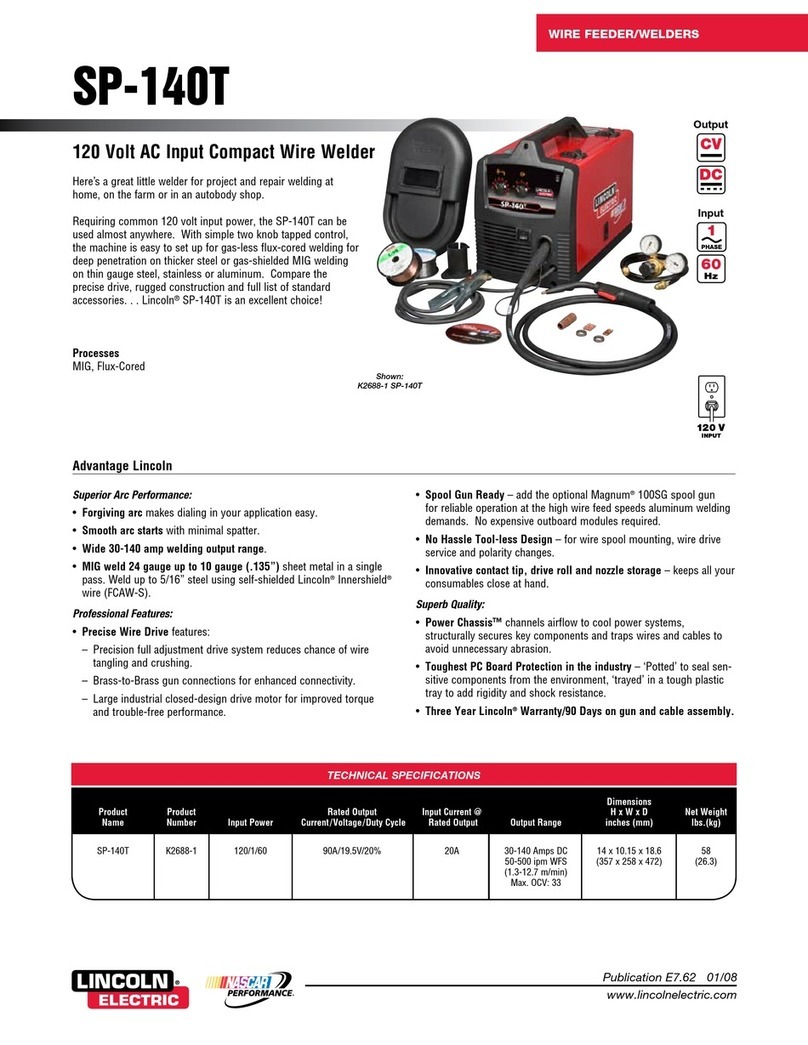

Lincoln Electric

Lincoln Electric SP-140T Technical specifications

Magmate

Magmate MMA 160 operating manual

Rothenberger

Rothenberger ROWELD ROFUSE Sani 160 Instructions for use

Miller Electric

Miller Electric Subarc DC 650 owner's manual