Linear Technology LTC3558 User manual

LTC3558

1

3558f

, LT, LTC, LTM and Burst Mode are registered trademarks of Linear Technology

Corporation. All other trademarks are the property of their respective owners.

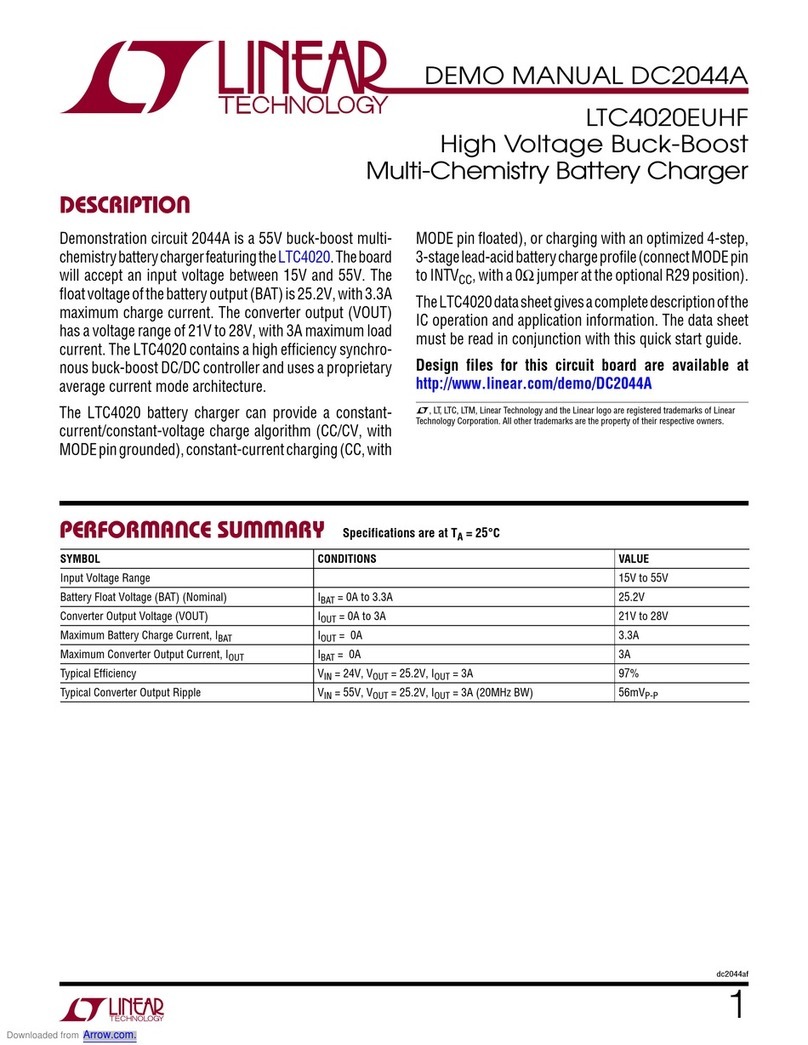

TYPICAL APPLICATION

FEATURES

APPLICATIONS

DESCRIPTION

Linear USB Battery Charger

with Buck and

Buck-Boost Regulators

The LTC

®

3558 is a USB battery charger with dual high ef-

ficiency switching regulators. The device is ideally suited

to power single-cell Li-Ion/Polymer based handheld ap-

plications needing multiple supply rails.

Battery charge current is programmed via the PROG pin

and the HPWR pin with capability up to 950mA of current

at the BAT pin. The CHRG pin allows battery status to be

monitored continuously during the charging process. An

internal timer controls charger termination.

The part includes monolithic synchronous buck and buck-

boost regulators that can provide up to 400mA of output

current each and operate at efficiencies greater than 90%

over the entire Li-Ion/Polymer battery range. The buck-

boostregulatorcanregulateits programmedoutputvoltage

at its rated deliverable current over the entire Li-Ion range

without drop out, increasing battery runtime.

TheLTC3558is offered in alowprofile(0.75mm), thermally

enhanced, 20-lead (3mm ×3mm) QFN package.

USB Charger Plus Buck Regulator and Buck-Boost Regulator

Battery Charger

nStandalone USB Charger

nUp to 950mA Charge Current Programmable via

Single Resistor

nHPWR Input Selects 20% or 100% of Programmed

Charge Current

nNTC Input for Temperature Qualified Charging

nInternal Timer Termination

nBad Battery Detection

Switching Regulators (Buck and Buck-Boost)

nUp to 400mA Output Current per Regulator

n2.25MHz Constant-Frequency Operation

nPower Saving Burst Mode

®

Operation

nLow Profile, 20-Lead, 3mm ×3mm QFN Package

nSD/Flash-Based MP3 Players

nLow Power Handheld Applications

VCC

NTC

PROG

SUSP

HPWR

EN1

4.7µH 10µF

649k

324k

10pF

22µF

10pF

LTC3558

GND

EXPOSED

PAD

1µF

2.2µH

1.74k

EN2

MODE

BAT

USB (4.3V TO 5.5V)

DIGITAL

CONTROL

PVIN1

PVIN2

SW1

FB1

SWAB2

SWCD2

VOUT2

FB2

VC2

1.2V AT 400mA

SINGLE

Li-lon CELL

(2.7V TO 4.2V)

105k

324k

15k

121k

3.3V AT 400mA

330pF

33pF

3558 TA01

+

CHRG

10µF

Demo Board

LTC3558

2

3558f

ABSOLUTE MAXIMUM RATINGS

VCC (Transient);

t < 1ms and Duty Cycle < 1%....................... –0.3V to 7V

VCC (Static) .................................................. –0.3V to 6V

BAT, CHRG ................................................... –0.3V to 6V

PROG, SUSP.................................–0.3V to (VCC + 0.3V)

HPWR, NTC................... –0.3V to Max (VCC, BAT) + 0.3V

PROG Pin Current ...............................................1.25mA

BAT Pin Current ..........................................................1A

PVIN1, PVIN2 ..................................–0.3V to (BAT + 0.3V)

EN1, EN2, MODE, VOUT2 .............................. –0.3V to 6V

FB1, SW1......................... –0.3V to (PVIN1 + 0.3V) or 6V

FB2, VC2, SWAB2............. –0.3V to (PVIN2 + 0.3V) or 6V

SWCD2 ............................–0.3V to (VOUT2 + 0.3V) or 6V

ISW1 ...............................................................600mA DC

ISWAB2, ISWCD2, IVOUT2 ...................................750mA DC

Junction Temperature (Note 2) ............................. 125°C

Operating Temperature Range (Note 3).... –40°C to 85°C

Storage Temperature.............................. –65°C to 125°C

(Note 1)

PIN CONFIGURATION

20 19 18 17 16

7 8

TOP VIEW

21

UD PACKAGE

20-LEAD (3mm ×3mm) PLASTIC QFN

910

GND

BAT

MODE

FB1

EN1

EN2

VC2

FB2

SUSP

VOUT2

SW1

PVIN1

PVIN2

SWAB2

SWCD2

12

11

13

14

15

4

5

3

2

1

6

VCC

CHRG

PROG

NTC

HPWR

TJMAX = 125°C, θJA = 68°C/W

EXPOSED PAD (PIN 21) IS GND, MUST BE SOLDERED TO PCB

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC3558EUD#PBF LTC3558EUD#TRPBF LDCD 20-Lead (3mm ×3mm) Plastic QFN –40°C to 85°C

Consult LTC Marketing for parts specified with wider operating temperature ranges.

Consult LTC Marketing for information on non-standard lead based finish parts.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifications, go to: http://www.linear.com/tapeandreel/

LTC3558

3

3558f

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Battery Charger

VCC Input Supply Voltage l4.3 5.5 V

IVCC Battery Charger Quiescent Current

(Note 4)

Standby Mode, Charge Terminated

Suspend Mode, VSUSP = 5V

285

8.5

400

17

µA

µA

VFLOAT BAT Regulated Output Voltage

0°C ≤ TA≤ 85°C

4.179

4.165

4.200

4.200

4.221

4.235

V

V

ICHG Constant-Current Mode Charge

Current

HPWR = 1

HPWR = 0

l440

84

460

92

500

100

mA

mA

IBAT Battery Drain Current Standby Mode, Charger Terminated, EN1 = EN2 = 0

Shutdown, VCC < VUVLO, BAT = 4.2V, EN1 = EN2 = 0

Suspend Mode, SUSP = 5V, BAT = 4.2V, EN1 = EN2 = 0

VCC = 0V, EN1 = EN2 = 1, MODE = 1,

FB1 = FB2 = 0.85V, VOUT2 = 3.6V

–3.5

–2.5

–1.5

–50

–7

–4

–3

–100

µA

µA

µA

µA

VUVLO Undervoltage Lockout Threshold BAT = 3.5V, VCC Rising 3.85 4 4.125 V

ΔVUVLO Undervoltage Lockout Hysteresis BAT = 3.5V 200 mV

VDUVLO Differential Undervoltage Lockout

Threshold

BAT = 4.05V, (VCC – BAT) Falling 30 50 70 mV

ΔVDUVLO Differential Undervoltage Lockout

Hysteresis

BAT = 4.05V 130 mV

VPROG PROG Pin Servo Voltage HPWR = 1

HPWR = 0

BAT < VTRKL

1.000

0.200

0.100

V

V

V

hPROG Ratio of IBAT to PROG Pin Current 800 mA/mA

ITRKL Trickle Charge Current BAT < VTRKL 36 46 56 mA

VTRKL Trickle Charge Threshold Voltage BAT Rising 2.8 2.9 3 V

ΔVTRKL Trickle Charge Hysteresis Voltage 100 mV

ΔVRECHRG Recharge Battery Threshold Voltage Threshold Voltage Relative to VFLOAT –75 –95 –115 mV

tRECHRG Recharge Comparator Filter Time BAT Falling 1.7 ms

tTERM Safety Timer Termination Period BAT = VFLOAT 3.5 4 4.5 Hour

tBADBAT Bad Battery Termination Time BAT < VTRKL 0.4 0.5 0.6 Hour

hC/10 End-of-Charge Indication Current Ratio (Note 5) 0.085 0.1 0.11 mA/mA

tC/10 End-of-Charge Comparator Filter Time IBAT Falling 2.2 ms

RON(CHG) Battery Charger Power FET On-

Resistance (Between VCC and BAT)

IBAT = 190mA 500 mΩ

TLIM Junction Temperature in Constant

Temperature Mode

105 °C

NTC

VCOLD Cold Temperature Fault Threshold

Voltage

Rising NTC Voltage

Hysteresis

75 76.5

1.6

78 %VCC

%VCC

VHOT Hot Temperature Fault Threshold

Voltage

Falling NTC Voltage

Hysteresis

33.4 34.9

1.6

36.4 %VCC

%VCC

VDIS NTC Disable Threshold Voltage Falling NTC Voltage

Hysteresis

l0.7 1.7

50

2.7 %VCC

mV

INTC NTC Leakage Current VNTC = VCC = 5V –1 1 µA

ELECTRICAL CHARACTERISTICS

The ldenotes specifications that apply over the full operating temperature

range, otherwise specifications are at TA = 25°C. VCC = 5V, BAT = PVIN1 = PVIN2 = 3.6V, RPROG = 1.74k, unless otherwise noted.

LTC3558

4

3558f

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Logic (HPWR, SUSP, CHRG, EN1, EN2, MODE)

VIL Input Low Voltage HPWR, SUSP, MODE, EN1, EN2 Pins 0.4 V

VIH Input High Voltage HPWR, SUSP, MODE, EN1, EN2 Pins 1.2 V

RDN Logic Pin Pull-Down Resistance HPWR, SUSP Pins l1.9 4 6.3 MΩ

VCHRG CHRG Pin Output Low Voltage ICHRG = 5mA 100 250 mV

ICHRG CHRG Pin Input Current BAT = 4.5V, VCHRG = 5V 0 1 µA

Buck Switching Regulator

PVIN1 Input Supply Voltage l2.7 4.2 V

IPVIN1 Pulse Skip Input Current

Burst Mode Current

Shutdown Current

Supply Current in UVLO

FB1 = 0.85V, MODE = 0 (Note 6)

FB1 = 0.85V, MODE = 1 (Note 6)

EN1 = 0

PVIN1 = PVIN2 = 2V

l

220

35

0

4

400

50

2

8

µA

µA

µA

µA

PVIN1 UVLO PVIN1 Falling

PVIN1 Rising

l

l

2.30 2.45

2.55 2.70

V

V

fOSC Switching Frequency MODE = 0 1.91 2.25 2.59 MHz

ILIMSW1 Peak PMOS Current Limit 550 800 1050 mA

VFB1 Feedback Voltage MODE = 0 l780 800 820 mV

IFB1 FB Input Current FB1 = 0.85V –50 50 nA

DMAX1 Maximum Duty Cycle FB1 = 0V l100 %

RPMOS1 RDS(ON) of PMOS ISW1 = 100mA 0.65 Ω

RNMOS1 RDS(ON) of NMOS ISW1 = –100mA 0.75 Ω

RSW1(PD) SW Pull-Down in Shutdown 13 kΩ

Buck-Boost Switching Regulator

PVIN2 Input Supply Voltage l2.7 4.2 V

IPVIN2 PWM Input Current

Burst Mode Input Current

Shutdown Current

Supply Current in UVLO

MODE = 0, IOUT = 0A, FB2 = 0.85V (Note 6)

MODE = 1, IOUT = 0A, FB2 = 0.85V (Note 6)

EN2 = 0, IOUT = 0A

PVIN1 = PVIN2 = 2V

220

20

0

4

400

30

1

8

µA

µA

µA

µA

PVIN2 UVLO PVIN2 Falling

PVIN2 Rising

l

l

2.30 2.45

2.55 2.70

V

V

VOUT2(LOW) Minimum Regulated Buck-Boost VOUT 2.65 2.75 V

VOUT2(HIGH) Maximum Regulated Buck-Boost VOUT 5.45 5.60 V

ILIMF2 Forward Current Limit (Switch A) MODE = 0 l580 700 820 mA

IPEAK2(BURST) Forward Current Limit (Switch A) MODE = 1 l180 250 320 mA

ILIMR2 Reverse Current Limit (Switch D) MODE = 0 l325 450 575 mA

IZERO2(BURST) Reverse Current Limit (Switch D) MODE = 1 l–35 0 35 mA

IMAX2(BURST) Maximum Deliverable Output Current

in Burst Mode Operation

2.7V < PVIN2 < 4.2V

2.75V < VOUT2 < 5.5V

50 mA

VFB2 Feedback Servo Voltage l780 800 820 mV

IFB2 FB2 Input Current FB2 = 0.85V –50 50 nA

fOSC Switching Frequency MODE = 0 1.91 2.25 2.59 MHz

ELECTRICAL CHARACTERISTICS

The ldenotes specifications that apply over the full operating temperature

range, otherwise specifications are at TA = 25°C. VCC = 5V, BAT = PVIN1 = PVIN2 = 3.6V, RPROG = 1.74k, unless otherwise noted.

LTC3558

5

3558f

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: TJis calculated from the ambient temperature TAand power

dissipation PDaccording to the following formula:

T

J = TA + (PD • θJA)

Note 3: The LTC3558E is guaranteed to meet specifications from 0°C to

85°C. Specifications over the –40°C to 85°C operating temperature range

are assured by design, characterization and correlation with statistical

process controls.

Note 4: VCC supply current does not include current through the PROG pin

or any current delivered to the BAT pin. Total input current is equal to this

specification plus 1.00125 • IBAT where IBAT is the charge current.

Note 5: IC/10 is expressed as a fraction of measured full charge current

with indicated PROG resistor.

Note 6: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

RDSP(ON) PMOS RDS(ON) VOUT = 3.6V 0.6 Ω

RDSN(ON) NMOS RDS(ON) 0.6 Ω

ILEAK(P) PMOS Switch Leakage Switches A, D –1 1 µA

ILEAK(N) NMOS Switch Leakage Switches B, C –1 1 µA

DCBUCK(MAX) Maximum Buck Duty Cycle MODE = 0 l100 %

DCBOOST(MAX) Maximum Boost Duty Cycle MODE = 0 75 %

tSS2 Soft-Start Time 0.5 ms

ROUT(PD) VOUT Pull-Down in Shutdown 10 kΩ

ELECTRICAL CHARACTERISTICS

The ldenotes specifications that apply over the full operating temperature

range, otherwise specifications are at TA = 25°C. VCC = 5V, BAT = PVIN1 = PVIN2 = 3.6V, RPROG = 1.74k, unless otherwise noted.

LTC3558

6

3558f

PROG Voltage

vs Battery Charge Current

TEMPERATURE (°C)

–55

3.9

4.0

4.2

545

3558 G07

3.8

3.7

–35 –15 25 65 85

3.6

3.5

4.1

VCC (V)

BAT = 3.5V

RISING

FALLING

Battery Drain Current in Undervoltage

Lockout vs Temperature

TEMPERATURE (°C)

–55

IBAT (µA)

2.0

2.5

3.0

545

3558 G08

1.5

1.0

–35 –15 25 65 85

0.5

0

BAT = 4.2V

EN1 = EN2 = 0V

BAT = 3.6V

IBAT (mA)

0

VPROG (V)

0.4

0.8

1.2

0.2

0.6

1.0

100 200 300 400

3558 G09

500500 150 250 350 450

VCC = 5V

HPWR = 5V

RPROG = 1.74k

EN1 = EN2 = 0V

Battery Charger Undervoltage

Lockout Threshold vs Temperature

TEMPERATURE (°C)

–55

0

CURRENT (µA)

1

3

4

5

10

7

–15 25 45

3558 G01

2

8

9IVCC

6

–35 565 85

VCC = 5V

BAT = 4.2V

SUSP = 5V

EN1 = EN2 = 0V

IBAT

TYPICAL PERFORMANCE CHARACTERISTICS

TEMPERATURE (°C)

–55

VFLOAT (V)

4.23

5

3558 G02

4.20

4.18

–35 –15 25

4.17

4.16

4.24

4.22

4.21

4.19

45 65 85

VCC = 5V

IBAT (mA)

100

VBAT (V)

4.180

4.190

4.205

4.200

900

3558 G03

4.170

4.160

4.175

4.185

4.195

4.165

4.155

4.150 300 500 700

2000 400 600 800 1000

VCC = 5V

HPWR = 5V

RPROG = 845

EN1 = EN2 = 0V

VCC (V)

4.3

440

IBAT (mA)

450

460

470

480

500

4.5 4.6 4.9 5.1

3558 G04

5.34.4 4.7 4.8 5.0 5.2 5.4 5.5

490

445

455

465

475

495

485

VCC = 5V

HPWR = 5V

RPROG = 1.74k

EN1 = EN2 = 0V

VBAT (V)

2

IBAT (mA)

300

400

500

4

3558 G05

200

100

250

350

450

150

50

02.5 33.5 4.5

VCC = 5V

RPROG = 1.74k

HPWR = 5V

HPWR = 0V

TEMPERATURE (°C)

–55

0

IBAT (mA)

50

150

200

250

500

350

–15 25 45 125

3558 G06

100

400

450

300

–35 5 65 85 105

VCC = 5V

HPWR = 5V

RPROG = 1.74k

EN1 = EN2 = 0

Suspend State Supply and BAT

Currents vs Temperature

Battery Regulation (Float)

Voltage vs Temperature

Battery Regulation (Float) Voltage

vs Battery Charge Current,

Constant-Voltage Charging

Battery Charge Current

vs Supply Voltage

Battery Charge Current

vs Battery Voltage

Battery Charge Current vs Ambient

Temperature in Thermal Regulation

TA = 25°C, unless otherwise noted.

LTC3558

7

3558f

Timer Accuracy vs Temperature

Buck and Buck-Boost Regulator

Switching Frequency vs Temperature

TEMPERATURE (°C)

–55

–2

PERCENT ERROR (%)

–1

1

2

3

25

7

3558 G16

0

–15

–35 45 65

585

4

5

6

VCC = 5V

TIME (HOUR)

0

IBAT (mA)BAT (V)CHRG (V)

5.0

200

0

400

800

600

1000

35

3558 G17

3.5

3.0

5.0

4.5

4.0

3.0

4.0

1.0

2.0

0

12 4 6

VCC = 5V

RPROG = 0.845k

HPWR = 5V

Recharge Threshold

vs Temperature

Battery Charger FET

On-Resistance vs Temperature

SUSP/HPWR Pin Rising

Thresholds vs Temperature

CHRG Pin Output Low Voltage

vs Temperature Timer Accuracy vs Supply Voltage

TEMPERATURE (°C)

–55

75

VRECHARGE (mV)

79

87

91

95

115

103

–15 25 45

3558 G10

83

107

111

99

–35 565 85

VCC = 5V

TEMPERATURE (°C)

–55

RDS(ON) (m)

500

550

600

85

3558 G11

450

400

300 –35 –15 5 25 45 65

350

700

650

VCC = 4V

IBAT = 200mA

EN1 = EN2 = 0V

TEMPERATURE (°C)

–55

THRESHOLD (V)

1.1

5

3558 G12

0.8

0.6

–35 –15 25

0.5

0.4

1.2

1.0

0.9

0.7

45 65 85

VCC = 5V

TEMPERATURE (°C)

–55

80

100

140

545

3558 G13

60

40

–35 –15 25 65 85

20

0

120

VOLTAGE (mV)

VCC = 5V

ICHRG = 5mA

CHRG Pin I-V Curve

CHRG (V)

0

70

60

50

40

30

20

10

035

3558 G14

12 46

ICHRG (mA)

VCC = 5V

BAT = 3.8V

VCC (V)

4.3

–1.0

PERCENT ERROR (%)

–0.5

0

0.5

1.0

2.0

4.5 4.7 4.9 5.1

3558 G15

5.3 5.5

1.5

TYPICAL PERFORMANCE CHARACTERISTICS

Complete Charge Cycle

2400mAh Battery

TEMPERATURE (°C)

–55

1.725

FREQUENCY (MHz)

1.825

2.025

2.125

2.225

2.425

–15 25 45 125

3558 G18

1.925

2.325

–35 5 65 85 105

BAT = 4.2V

BAT = 2.7V BAT = 3.6V

VCC = 0V, MODE = 0

BAT = PVIN1 = PVIN2

TA = 25°C, unless otherwise noted.

LTC3558

8

3558f

Buck Regulator Input Current vs

Temperature, Pulse Skip Mode

Buck and Buck-Boost Regulator

Enable Thresholds

vs Temperature

Buck Regulator PMOS RDS(0N)

vs Temperature

TEMPERATURE (°C)

–55

100

INPUT CURRENT (µA)

150

250

300

350

–15 25 45 125

3558 G22

200

–35 5 65 85 105

400 FB1 = 0.85V

PVIN1 = 4.2V

PVIN1 = 2.7V

TEMPERATURE (°C)

–55

400

RDS(ON) (m)

500

700

800

900

65

1300

3558 G23

600

5

–35 85

25

–15 105

45 12

5

1000

1100

1200

PVIN1 = 2.7V

PVIN1 = 4.2V

Buck Regulator NMOS RDS(0N)

vs Temperature

TEMPERATURE (°C)

–55

400

RDS(ON) (m)

500

700

800

900

65

1300

3558 G24

600

5

–35 85

25

–15 105

45 12

5

1000

1100

1200

PVIN1 = 2.7V

PVIN1 = 4.2V

TYPICAL PERFORMANCE CHARACTERISTICS

Buck Regulator Input Current vs

Temperature, Burst Mode Operation

TEMPERATURE (°C)

–55

20

INPUT CURRENT (µA)

25

35

40

45

–15 25 45 125

3558 G21

30

–35 5 65 85 105

50 FB1 = 0.85V

PVIN1 = 4.2V

PVIN1 = 2.7V

Buck and Buck-Boost Regulator

Undervoltage Thresholds

vs Temperature

ILOAD (mA)

30

EFFICIENCY (%)

90

100

20

10

80

50

70

60

40

0.1 10 100 1000

3558 G25

0

1

VOUT = 1.2V

PVIN1 = 2.7V

PVIN1 = 4.2V

Burst Mode

OPERATION

PULSE SKIP

MODE

Buck Regulator Efficiency vs ILOAD Buck Regulator Load Regulation

ILOAD (mA)

1

1.19

VOUT (V)

1.20

1.21

1.22

1.23

10 100 100

0

3558 G26

1.18

1.17

1.16

1.15

1.24

1.25 PVIN1 = 3.6V

VOUT = 1.2V

Burst Mode

OPERATION

PULSE SKIP

MODE

Buck Regulator Line Regulation

TEMPERATURE (°C)

–55

2.250

INPUT VOLTAGE (V)

2.300

2.400

2.450

2.500

2.750

2.600

–15 25 45 125

3558 G19

2.350

2.650

2.700

2.550

–35 5 65 85 105

RISING

BAT = PVIN1 = PVIN2

FALLING

TEMPERATURE (°C)

–55

400

VEN (V)

500

700

800

900

1200

1100

–15 25 45 125

3558 G20

600

1000

–35 5 65 85 105

RISING

BAT = PVIN1 = PVIN2 = 3.6V

FALLING

2.700 3.300 3.900 4.200

3.000 3.600

PVIN1 (V)

VOUT (V)

1.170

1.220

1.230

1.240

1.250

1.200

1.160

1.210

1.150

1.190

1.180

3558 G27

ILOAD = 200mA

TA = 25°C, unless otherwise noted.

LTC3558

9

3558f

Buck Regulator Start-Up Transient

Buck Regulator

Pulse Skip Mode Operation

VOUT

500mV/DIV

EN

2V/DIV

PVIN1 = 3.8V

PULSE SKIP MODE

LOAD = 6

50µs/DIV 3558 G28

INDUCTOR

CURRENT

IL= 200mA/

DIV

Buck Regulator

Burst Mode Operation

VOUT

20mV/

DIV (AC)

SW

2V/DIV

PVIN1 = 3.8V

LOAD = 10mA

200ns/DIV 3558 G29

INDUCTOR

CURRENT

IL= 50mA/

DIV

VOUT

20mV/

DIV (AC)

SW

2V/DIV

PVIN1 = 3.8V

LOAD = 60mA

2µs/DIV 3558 G30

INDUCTOR

CURRENT

IL= 60mA/

DIV

TYPICAL PERFORMANCE CHARACTERISTICS

Buck Regulator Transient

Response, Pulse Skip Mode

VOUT

50mV/

DIV (AC)

LOAD STEP

5mA TO

290mA

PVIN1 = 3.8V 50µs/DIV 3558 G31

INDUCTOR

CURRENT

IL = 200mA/

DIV

Buck Regulator Transient

Response, Burst Mode Operation

VOUT

50mV/

DIV (AC)

LOAD STEP

5mA TO

290mA

PVIN1 = 3.8V 50µs/DIV 3558 G32

INDUCTOR

CURRENT

IL= 200mA/

DIV

Buck-Boost Regulator Input

Current vs Temperature

Buck-Boost Regulator Input

Current vs Temperature

Buck-Boost Regulator PMOS

RDS(ON) vs Temperature

Buck-Boost Regulator NMOS

RDS(ON) vs Temperature

TEMPERATURE (°C)

–55

5

INPUT CURRENT (µA)

10

20

25

30

–15 25 45 125

3558 G33

15

–35 5 65 85 105

Burst Mode OPERATION

FB2 = 0.85V

PVIN2 = 2.7V

PVIN2 = 4.2V

TEMPERATURE (°C)

–55

100

INPUT CURRENT (µA)

150

250

300

350

500

450

–15 25 45 125

3558 G34

200

400

–35 5 65 85 105

PVIN2 = 2.7V

PVIN2 = 4.2V

PWM MODE

FB2 = 0.85V

–55 –15 25 45 125

–35 5 65 85 105

TEMPERATURE (°C)

RDS(ON) (m)

400

650

700

750

800

300

550

350

600

250

200

500

450

3558 G35

PVIN2 = 2.7V

PVIN2 = 4.2V

TEMPERATURE (°C)

–55

200

RDS(ON) (m)

300

500

600

700

1200

900

–15 25 45 125

3558 G36

400

1000

1100

800

–35 5 65 85 105

PVIN2 = 2.7V

PVIN2 = 4.2V

TA = 25°C, unless otherwise noted.

LTC3558

10

3558f

TYPICAL PERFORMANCE CHARACTERISTICS

Buck-Boost Regulator Start-Up

Transient, PWM Mode

Buck-Boost Regulator Start-Up

Transient, Burst Mode Operation

Buck-Boost Regulator

Line Regulation

Buck-Boost Regulator

Efficiency vs Input Voltage

Buck-Boost Efficiency

vs Load Current

Buck-Boost Regulator

Load Regulation

2.700 3.300 3.900 4.200

3.000 3.600

PVIN2 (V)

EFFICIENCY (%)

60

85

90

95

100

75

55

80

50

70

65

3558 G37

ILOAD = 100mA

ILOAD = 400mA

ILOAD = 10mA ILOAD = 1mA

VOUT = 3.3V

Burst Mode

OPERATION

PWM MODE

ILOAD (mA)

3.27

VOUT (V)

3.29

3.31

3.33

3.35

0.10 10 100 1000

3.24

3.25

1

3.36

3.28

3.30

3.32

3.34

3.26

3558 G39

PWM MODE

Burst Mode OPERATION

PVIN2 = 3.6V

2.700 3.300 3.900 4.200

3.000 3.600

PVIN2 (V)

VOUT (V)

3.28

3.33

3.34

3.35

3.36

3.26

3.31

3.27

3.32

3.25

3.24

3.30

3.29

3558 G40

PWM MODE

ILOAD = 100mA

Burst Mode

OPERATION

ILOAD = 10mA

ILOAD (mA)

30

EFFICIENCY (%)

50

70

90

0

10

100

40

60

80

20

3558 G38

3.6V

4.2V

3.6V

4.2V

2.7V

2.7V

VOUT = 3.3V

PVIN2, Burst Mode

OPERATION

PVIN2, PWM MODE

0.10 10 100 10001

VOUT

1V/DIV

EN2

1V/DIV

100µs/DIV 3558 G41

INDUCTOR

CURRENT

IL = 200mA/DIV

PVIN2 = 3.6V

RLOAD = 332

VOUT

1V/DIV

EN2

1V/DIV

100µs/DIV 3558 G42

INDUCTOR

CURRENT

IL = 200mA/DIV

PVIN2 = 3.6V

RLOAD = 16

TA = 25°C, unless otherwise noted.

LTC3558

11

3558f

PIN FUNCTIONS

GND (Pin 1): Ground. Connect to Exposed Pad (Pin 21).

BAT (Pin 2): Charge Current Output. Provides charge cur-

rent to the battery and regulates final float voltage to 4.2V.

MODE (Pin 3): MODE Pin for Switching Regulators. When

held high, both regulators operate in Burst Mode Opera-

tion. When held low, the buck regulator operates in pulse

skip mode and the buck-boost regulator operates in PWM

mode. This pin is a high impedance input; do not float.

FB1 (Pin 4): Buck Regulator Feedback Voltage Pin. Re-

ceives feedback by a resistor divider connected across

the output.

EN1 (Pin 5): Enable Input Pin for the Buck Regulator. This

pin is a high impedance input; do not float. Active high.

SW1 (Pin 6): Buck Regulator Switching Node. External

inductor connects to this node.

PVIN1 (Pin 7): Input Supply Pin for Buck Regulator. Con-

nect to BAT and PVIN2. A single 10µF input decoupling

capacitor to GND is required.

PVIN2 (Pin 8): Input Supply Pin for Buck-Boost Regulator.

Connect to BAT and PVIN1. A single 10µF input decoupling

capacitor to GND is required.

SWAB2 (Pin 9): Switch Node for Buck-Boost Regulator

ConnectedtotheInternal Power Switches A andB.External

inductor connects between this node and SWCD2.

SWCD2 (Pin 10): Switch Node for Buck-Boost Regulator

Connectedtothe Internal Power SwitchesCandD. External

inductor connects between this node and SWAB2.

VOUT2 (Pin 11): Regulated Output Voltage for Buck-Boost

Regulator.

SUSP (Pin 12): Suspend Battery Charging Operation. A

voltage greater than 1.2V on this pin puts the battery char-

ger in suspend mode, disables the charger and resets the

termination timer. A weak pull-down current is internally

applied to this pin to ensure it is low at power-up when

the input is not being driven externally.

FB2 (Pin 13): Buck-Boost Regulator Feedback Voltage

Pin. Receives feedback by a resistor divider connected

across the output.

VC2 (Pin 14): Output of the Error Amplifier and Voltage

Compensation Node for the Buck-Boost Regulator. Ex-

ternal Type I or Type III compensation (to FB2) connects

to this pin.

EN2 (Pin 15): Enable Input Pin for the Buck-Boost Regu-

lator. This pin is a high impedance input; do not float.

Active high.

HPWR (Pin 16): High Current Battery Charging Enabled.

A voltage greater than 1.2V at this pin programs the

BAT pin current at 100% of the maximum programmed

charge current. A voltage less than 0.4V sets the BAT pin

current to 20% of the maximum programmed charge

current. When used with a 1.74k PROG resistor, this pin

can toggle between low power and high power modes per

USB specification. A weak pull-down current is internally

applied to this pin to ensure it is low at power-up when

the input is not being driven externally.

NTC (Pin 17): Input to the NTC Thermistor Monitoring

Circuit. The NTC pin connects to a negative temperature

coefficient thermistor which is typically co-packaged with

the battery pack to determine if the battery is too hot or too

cold to charge. If the battery temperature is out of range,

charging is paused until the battery temperature re-enters

the valid range. A low drift bias resistor is required from

VCC to NTC and a thermistor is required from NTC to

ground. To disable the NTC function, the NTC pin should

be tied to ground.

PROG (Pin 18): Charge Current Program and Charge

Current Monitor Pin. Charge current is programmed by

connecting a resistor from PROG to ground. When charg-

ing in constant-current mode, the PROG pin servos to 1V

if the HPWR pin is pulled high, or 200mV if the HPWR pin

is pulled low. The voltage on this pin always represents

the BAT pin current through the following formula:

IPROG

R

BAT PROG

=•800

CHRG (Pin 19): Open-Drain Charge Status Output. The

CHRG pin indicates the status of the battery charger. Four

possible states are represented by CHRG charging, not

charging (i.e., the charge current is less than one-tenth

LTC3558

12

3558f

BLOCK DIAGRAM

of the full-scale charge current), unresponsive battery

(i.e., the battery voltage remains below 2.9V after one half

hour of charging) and battery temperature out of range.

CHRG requires a pull-up resistor and/or LED to provide

indication.

VCC (Pin 20): Battery Charger Input. A 1µF decoupling

capacitor to GND is recommended.

Exposed Pad (Pin 21): Ground. The Exposed Pad must

be soldered to PCB ground to provide electrical contact

and rated thermal performance.

PIN FUNCTIONS

19

–

+

TA

800x

BAT

1x

TDIE

TDIE

PVIN1

OT

CA

NTCA

NTC REF

LOGIC

CHRG

20

2

PROG

BATTERY CHARGER

BUCK REGULATOR

CONTROL

LOGIC

MODEEN

CLK

0.8V

18

PVIN1 7

SW1 6

PVIN2 8

VOUT2

SWAB2

D

C

A

B

9

1 21

VCC

16 HPWR

12 SUSP

NTC

MODE

MP

MN

EN1

EN2

FB1

MAXER

VCC BAT

BODY

–

+

Gm

BUCK-BOOST REGULATOR

3558 BD

CONTROL

LOGIC

MODEEN

VC2

GND EXPOSED PAD

CLK

0.8V

–

+

UNDERVOLTAGE

LOCKOUT

DIE

TEMPERATURE

ERROR

AMP

BANDGAP

OSCILLATOR

2.25MHz

VREF

= 0.8V

CLK

17

3

5

15

4

FB2

13

VC2

14

11

SWCD2 10

PVIN2

LTC3558

13

3558f

OPERATION

The LTC3558 is a linear battery charger with a monolithic

synchronous buck regulator and a monolithic synchro-

nous buck-boost regulator. The buck regulator is inter-

nally compensated and needs no external compensation

components.

Thebattery charger employs a constant-current, constant-

voltage charging algorithm and is capable of charging a

singleLi-Ionbattery at charging currentsupto950mA.The

usercanprogramthemaximumcharging current available

at the BAT pin via a single PROG resistor. The actual BAT

pin current is set by the status of the HPWR pin.

For proper operation, the BAT, PVIN1 and PVIN2 pins

must be tied together, as shown in Figure 1. Cur-

rent being delivered at the BAT pin is 500mA. Both

switching regulators are enabled. The sum of the

averageinputcurrentsdrawnbybothswitchingregulators

is 200mA. This makes the effective battery charging cur-

rent only 300mA. If the HPWR pin were tied LO, the BAT

pin current would be 100mA. With the switching regulator

conditions unchanged, this would cause the battery to

discharge at 100mA.

Figure 1. For Proper Operation, the BAT, PVIN1 and PVIN2 Pins Must Be Tied Together

APPLICATIONS INFORMATION

Battery Charger Introduction

The LTC3558 has a linear battery charger designed to

charge single-cell lithium-ion batteries. The charger uses

a constant-current/constant-voltage charge algorithm

with a charge current programmable up to 950mA. Ad-

ditional features include automatic recharge, an internal

terminationtimer, low-battery trickle chargeconditioning,

bad-battery detection, and a thermistor sensor input for

out of temperature charge pausing.

Furthermore, the battery charger is capable of operating

from a USB power source. In this application, charge

current can be programmed to a maximum of 100mA or

500mA per USB power specifications.

Input Current vs Charge Current

The battery charger regulates the total current delivered

to the BAT pin; this is the charge current. To calculate the

total input current (i.e., the total current drawn from the

VCC pin), it is necessary to sum the battery charge current,

charger quiescent current and PROG pin current.

Undervoltage Lockout (UVLO)

The undervoltage lockout circuit monitors the input volt-

age (VCC) and disables the battery charger until VCC rises

above V

UVLO

(typically 4V). 200mV of hysteresis prevents

oscillations around the trip point. In addition, a differential

undervoltage lockout circuit disables the battery charger

VCC

PROG

RPROG

SUSP

HPWR

EN1

500mA

LTC3558

EN2

MODE

HIGH

HIGH

HIGH

LOW

BAT

USB (5V)

PVIN1

PVIN2

SW1 VOUT1

SINGLE Li-lon

CELL 3.6V

200mA

300mA

3558 F01

10µF

+

2.2µH

SWAB2

SWCD2

VOUT2

+

LTC3558

14

3558f

APPLICATIONS INFORMATION

when VCC falls to within V

DUVLO

(typically 50mV) of the

BAT voltage.

Suspend Mode

The battery charger can also be disabled by pulling the

SUSP pin above 1.2V. In suspend mode, the battery

drain current is reduced to 1.5µA and the input current is

reduced to 8.5µA.

Charge Cycle Overview

When a battery charge cycle begins, the battery charger

first determines if the battery is deeply discharged. If the

battery voltage is below V

TRKL

,typically2.9V,an automatic

trickle charge feature sets the battery charge current to

10% of the full-scale value.

Once the battery voltage is above 2.9V, the battery charger

begins charging in constant-current mode. When the

battery voltage approaches the 4.2V required to maintain

a full charge, otherwise known as the float voltage, the

charge current begins to decrease as the battery charger

switches into constant-voltage mode.

Trickle Charge and Defective Battery Detection

Any time the battery voltage is below VTRKL, the charger

goes into trickle charge mode and reduces the charge

current to 10% of the full-scale current. If the battery

voltage remains below VTRKL for more than 1/2 hour, the

charger latches the bad-battery state, automatically termi-

nates, and indicates via the CHRG pin that the battery was

unresponsive. If for any reason the battery voltage rises

above VTRKL, the charger will resume charging. Since the

charger has latched the bad-battery state, if the battery

voltage then falls below VTRKL again but without rising past

VRECHRG first, the charger will immediately assume that

the battery is defective. To reset the charger (i.e., when

the dead battery is replaced with a new battery), simply

remove the input voltage and reapply it or put the part in

and out of suspend mode.

Charge Termination

The battery charger has a built-in safety timer that sets

the total charge time for 4 hours. Once the battery voltage

rises above V

RECHRG

(typically 4.105V) and the charger

enters constant-voltage mode, the 4-hour timer is started.

After the safety timer expires, charging of the battery will

discontinue and no more current will be delivered.

Automatic Recharge

After the battery charger terminates, it will remain off,

drawing only microamperes of current from the battery.

If the portable product remains in this state long enough,

thebattery will eventually self discharge. To ensure that the

battery is always topped off, a charge cycle will automati-

cally begin when the battery voltage falls below VRECHRG

(typically 4.105V). In the event that the safety timer is

running when the battery voltage falls below VRECHRG, it

will reset back to zero. To prevent brief excursions below

VRECHRG fromresettingthesafetytimer, the batteryvoltage

must be below VRECHRG for more than 1.7ms. The charge

cycle and safety timer will also restart if the VCC UVLO or

DUVLO cycles low and then high (e.g., VCC is removed

and then replaced) or the charger enters and then exits

suspend mode.

Programming Charge Current

The PROG pin serves both as a charge current program

pin, and as a charge current monitor pin. By design, the

PROG pin current is 1/800th of the battery charge current.

Therefore, connecting a resistor from PROG to ground

programsthe chargecurrentwhile measuring thePROGpin

voltage allows the user to calculate the charge current.

Full-scale charge current is defined as 100% of the con-

stant-current mode charge current programmed by the

PROG resistor. In constant-current mode, the PROG pin

servos to 1V if HPWR is high, which corresponds to charg-

ing at the full-scale charge current, or 200mV if HPWR

is low, which corresponds to charging at 20% of the full-

scale charge current. Thus, the full-scale charge current

and desired program resistor for a given full-scale charge

current are calculated using the following equations:

IV

R

RV

I

CHG PROG

PROG CHG

=

=

800

800

LTC3558

15

3558f

APPLICATIONS INFORMATION

In any mode, the actual battery current can be determined

by monitoring the PROG pin voltage and using the follow-

ing equation:

IPROG

R

BAT PROG

=•800

Thermal Regulation

To prevent thermal damage to the IC or surrounding

components, an internal thermal feedback loop will auto-

matically decrease the programmed charge current if the

die temperature rises to approximately 115°C. Thermal

regulation protects the battery charger from excessive

temperature due to high power operation or high ambient

thermal conditions and allows the user to push the limits

of the power handling capability with a given circuit board

design without risk of damaging the LTC3558 or external

components. The benefit of the LTC3558 battery charger

thermal regulation loop is that charge current can be set

according to actual conditions rather than worst-case

conditions with the assurance that the battery charger

will automatically reduce the current in worst-case con-

ditions.

Charge Status Indication

The CHRG pin indicates the status of the battery charger.

Four possible states are represented by CHRG charging,

notcharging, unresponsivebattery andbattery temperature

out of range.

The signal at the CHRG pin can be easily recognized as one

of the above four states by either a human or a micropro-

cessor. The CHRG pin, which is an open-drain output, can

drive an indicator LED through a current limiting resistor

for human interfacing, or simply a pull-up resistor for

microprocessor interfacing.

To make the CHRG pin easily recognized by both humans

and microprocessors, the pin is either a low for charging,

a high for not charging, or it is switched at high frequency

(35kHz) to indicate the two possible faults: unresponsive

battery and battery temperature out of range.

When charging begins, CHRG is pulled low and remains

low for the duration of a normal charge cycle. When the

charge current has dropped to below 10% of the full-scale

current, the CHRG pin is released (high impedance). If

a fault occurs after the CHRG pin is released, the pin re-

mains high impedance. However, if a fault occurs before

the CHRG pin is released, the pin is switched at 35kHz.

Whileswitching,itsduty cycle is modulated betweenahigh

and low value at a very low frequency. The low and high

duty cycles are disparate enough to make an LED appear

to be on or off thus giving the appearance of “blinking”.

Each of the two faults has its own unique “blink” rate for

human recognition as well as two unique duty cycles for

microprocessor recognition.

Table 1 illustrates the four possible states of the CHRG

pin when the battery charger is active.

Table 1. CHRG Output Pin

STATUS FREQUENCY

MODULATION

(BLINK)

FREQUENCY DUTY CYCLE

Charging 0Hz 0 Hz (Lo-Z) 100%

I

BAT

< C/10 0Hz 0 Hz (Hi-Z) 0%

NTC Fault

35kHz

1.5Hz at 50% 6.25%, 93.75%

Bad Battery

35kHz

6.1Hz at 50% 12.5%, 87.5%

An NTC fault is represented by a 35kHz pulse train whose

duty cycle alternates between 6.25% and 93.75% at a

1.5Hz rate. A human will easily recognize the 1.5Hz rate as

a “slow” blinking which indicates the out of range battery

temperature while a microprocessor will be able to decode

either the 6.25% or 93.75% duty cycles as an NTC fault.

If a battery is found to be unresponsive to charging (i.e.,

its voltage remains below VTRKL for over 1/2 hour), the

CHRG pin gives the battery fault indication. For this fault,

a human would easily recognize the frantic 6.1Hz “fast”

blinking of the LED while a microprocessor would be able

to decode either the 12.5% or 87.5% duty cycles as a bad

battery fault.

Although very improbable, it is possible that a duty cycle

reading could be taken at the bright-dim transition (low

duty cycle to high duty cycle). When this happens the

duty cycle reading will be precisely 50%. If the duty cycle

reading is 50%, system software should disqualify it and

take a new duty cycle reading.

LTC3558

16

3558f

NTC Thermistor

The battery temperature is measured by placing a nega-

tive temperature coefficient (NTC) thermistor close to the

battery pack. The NTC circuitry is shown in Figure 3.

To use this feature, connect the NTC thermistor, RNTC,

betweentheNTC pin and ground,anda bias resistor,RNOM,

from VCC to NTC. RNOM should be a 1% resistor with a

value equal to the value of the chosen NTC thermistor at

25°C (R25). A 100k thermistor is recommended since

thermistor current is not measured by the battery charger

and its current will have to be considered for compliance

with USB specifications.

The battery charger will pause charging when the re-

sistance of the NTC thermistor drops to 0.54 times the

APPLICATIONS INFORMATION

value of R25 or approximately 54k (for a Vishay “Curve

1” thermistor, this corresponds to approximately 40°C). If

the battery charger is in constant-voltage mode, the safety

timer will pause until the thermistor indicates a return to

a valid temperature.

As the temperature drops, the resistance of the NTC

thermistor rises. The battery charger is also designed

to pause charging when the value of the NTC thermistor

increases to 3.25 times the value of R25. For a Vishay

“Curve 1” thermistor, this resistance, 325k, corresponds

to approximately 0°C. The hot and cold comparators each

haveapproximately3°Cofhysteresisto prevent oscillation

about the trip point. Grounding the NTC pin disables all

NTC functionality.

IF SUSP < 0.4V AND

VCC > 4V AND

VCC > BAT + 130mV?

DUVLO, UVLO AND SUSPEND DISABLE MODE

1/10 FULL CHARGE CURRENT

CHRG STRONG PULL-DOWN

30 MINUTE TIMER BEGINS

TRICKLE CHARGE MODE

FULL CHARGE CURRENT

CHRG STRONG PULL-DOWN

CONSTANT CURRENT MODE

BATTERY CHARGING SUSPENDED

CHRG PULSES

NTC FAULT

NO CHARGE CURRENT

CHRG PULSES

DEFECTIVE BATTERY

4-HOUR TERMINATION TIMER

BEGINS

CONSTANT VOLTAGE MODE

NO CHARGE CURRENT

CHRG HIGH IMPEDANCE

STANDBY MODE

CHRG HIGH IMPEDANCE

3558 F02

BAT b2.9V

BAT > 2.9V

2.9V < BAT < 4.105V

30 MINUTE

TIMEOUT

BAT DROPS BELOW 4.105V

4-HOUR TERMINATION TIMER RESETS

YES

NO FAULT

FAULT

NO

POWER

ON

4-HOUR

TIMEOUT

Figure 2. State Diagram of Battery Charger Operation

LTC3558

17

3558f

Alternate NTC Thermistors and Biasing

The battery charger provides temperature qualified

charging if a grounded thermistor and a bias resistor are

connected to the NTC pin. By using a bias resistor whose

value is equal to the room temperature resistance of the

thermistor (R25) the upper and lower temperatures are

pre-programmed to approximately 40°C and 0°C, respec-

tively (assuming a Vishay “Curve 1” thermistor).

The upper and lower temperature thresholds can be ad-

justed by either a modification of the bias resistor value

or by adding a second adjustment resistor to the circuit.

If only the bias resistor is adjusted, then either the upper

or the lower threshold can be modified but not both. The

other trip point will be determined by the characteristics

of the thermistor. Using the bias resistor in addition to an

adjustmentresistor,both the upper and the lower tempera-

ture trip points can be independently programmed with

the constraint that the difference between the upper and

lower temperature thresholds cannot decrease. Examples

of each technique are given below.

NTC thermistors have temperature characteristics which

areindicatedon resistance-temperature conversiontables.

TheVishay-Dalethermistor NTHS0603N011-N1003F,used

in the following examples, has a nominal value of 100k

and follows the Vishay “Curve 1” resistance-temperature

characteristic.

In the explanation below, the following notation is used.

R25 = Value of the thermistor at 25°C

R

NTC|COLD

= Value of thermistor at the cold trip point

R

NTC|HOT

= Value of the thermistor at the hot trip point

rCOLD = Ratio of RNTC|COLD to R25

rHOT = Ratio of RNTC|HOT to R25

R

NOM

= Primary thermistor bias resistor (see Figure 3)

R1 = Optional temperature range adjustment resistor (see

Figure 4)

The trip points for the battery charger’s temperature quali-

fication are internally programmed at 0.349 • VCC for the

hot threshold and 0.765 • VCC for the cold threshold.

Therefore, the hot trip point is set when:

R

RR VV

NTCHOT

NOM NTCHOT CC CC

|

|

•.•

+=0 349

and the cold trip point is set when:

R

RR VV

NTC COLD

NOM NTC COLD CC CC

|

|

•.•

+=0 765

Solving these equations for R

NTC|COLD

and R

NTC|HOT

results in the following:

R

NTC|HOT = 0.536 • RNOM

and

R

NTC|COLD = 3.25 • RNOM

By setting RNOM equal to R25, the above equations result

in rHOT = 0.536 and rCOLD = 3.25. Referencing these ratios

to the Vishay Resistance-Temperature Curve 1 chart gives

a hot trip point of about 40°C and a cold trip point of about

0°C. The difference between the hot and cold trip points

is approximately 40°C.

By using a bias resistor, RNOM, different in value from

R25, the hot and cold trip points can be moved in either

direction.Thetemperature span will changesomewhatdue

to the nonlinear behavior of the thermistor. The following

equations can be used to easily calculate a new value for

the bias resistor:

RrR

RrR

NOM HOT

NOM COLD

=

=

0 536 25

325 25

.•

.•

where r

HOT

and r

COLD

are the resistance ratios at the

de-

sired

hot and cold trip points. Note that these equations

are linked. Therefore, only one of the two trip points can

be chosen, the other is determined by the default ratios

designed in the IC. Consider an example where a 60°C

hot trip point is desired.

FromtheVishay Curve 1 R-Tcharacteristics,rHOT is0.2488

at 60°C. Using the above equation, R

NOM

should be set

APPLICATIONS INFORMATION

LTC3558

18

3558f

APPLICATIONS INFORMATION

to 46.4k. With this value of R

NOM

, the cold trip point is

about 16°C. Notice that the span is now 44°C rather than

the previous 40°C.

The upper and lower temperature trip points can be inde-

pendentlyprogrammedbyusing an additional bias resistor

as shown in Figure 4. The following formulas can be used

to compute the values of R

NOM

and R

1

:

Rrr

R

RRr

NOM COLD HOT

NOM HOT

=

=

–

.•

.• – •

2 714 25

1 0 536 RR25

For example, to set the trip points to 0°C and 45°C with

a Vishay Curve 1 thermistor choose:

Rkk

NOM ==

3 266 0 4368

2 714 100 104 2

.–.

.•.

the nearest 1% value is 105k.

R1 = 0.536 • 105k – 0.4368 • 100k = 12.6k

the nearest 1% value is 12.7k. The final solution is shown

in Figure 4 and results in an upper trip point of 45°C and

a lower trip point of 0°C.

3558 F03

RNOM

100k

RNTC

100k

–

+

–

+

–

+

TOO_COLD

TOO_HOT

NTC_ENABLE

0.765 • VCC

(NTC RISING)

NTC BLOCK

0.349 • VCC

(NTC FALLING)

17 NTC

20 VCC

0.017 • VCC

(NTC FALLING)

3558 F04

RNOM

105k

RNTC

100k

–

+

–

+

–

+

TOO_COLD

TOO_HOT

NTC_ENABLE

R1

12.7k

0.765 • VCC

(NTC RISING)

0.349 • VCC

(NTC FALLING)

17 NTC

0.017 • VCC

(NTC FALLING)

20 VCC

Figure 3. Typical NTC Thermistor Circuit Figure 4. NTC Thermistor Circuit with Additional Bias Resistor

LTC3558

19

3558f

APPLICATIONS INFORMATION

USB and Wall Adapter Power

Although the battery charger is designed to draw power

from a USB port to charge Li-Ion batteries, a wall adapter

can also be used. Figure 5 shows an example of how to

combine wall adapter and USB power inputs. A P-channel

MOSFET, MP1, is used to prevent back conduction into

the USB port when a wall adapter is present and Schottky

diode, D1, is used to prevent USB power loss through the

1k pull-down resistor.

Typically, a wall adapter can supply significantly more

current than the 500mA-limited USB port. Therefore, an

N-channelMOSFET,MN1,and an extraprogramresistor are

used to increase the maximum charge current to 950mA

when the wall adapter is present.

current. It is not necessary to perform any worst-case

power dissipation scenarios because the LTC3558 will

automatically reduce the charge current to maintain the

die temperature at approximately 105°C. However, the

approximate ambient temperature at which the thermal

feedback begins to protect the IC is:

TCP

TCVVI

ADJA

A CC BAT BAT JA

=°

=°

()

105

105

–

–– ••

θ

θ

Example: Consider an LTC3558 operating from a USB port

providing 500mA to a 3.5V Li-Ion battery. The ambient

temperature above which the LTC3558 will begin to reduce

the 500mA charge current is approximately:

TCVVmACW

TC

A

A

=°

()()

°

=°

105 5 3 5 500 68

105 0

––.• • /

–.. • / –75 68 105 51

54

WCW C C

TC

A

°=° °

=°

The LTC3558 can be used above 70°C, but the charge cur-

rentwillbereduced from 500mA. The approximate current

at a given ambient temperature can be calculated:

ICT

VV

BAT A

CC BAT JA

=°

()

105 –

–•θ

Using the previous example with an ambient tem-

perature of 88°C, the charge current will be reduced to

approximately:

ICC

VV CW

C

CA

BAT =°°

()

°=°

°

105 88

535 68

17

102

–

–. • / /

IImA

BAT =167

Furthermore, the voltage at the PROG pin will change

proportionally with the charge current as discussed in

the Programming Charge Current section.

It is important to remember that LTC3558 applications do

not need to be designed for worst-case thermal conditions

since the IC will automatically reduce power dissipation

when the junction temperature reaches approximately

105°C.

VCC

MP1

MN1

1k 1.74k

1.65k

IBAT

Li-Ion

BATTERY

3558 F05

BATTERY

CHARGER

BAT

USB

POWER

500mA ICHG

5V WALL

ADAPTER

950mA ICHG

PROG +

D1

Figure 5. Combining Wall Adapter and USB Power

Power Dissipation

The conditions that cause the LTC3558 to reduce charge

current through thermal feedback can be approximated

by considering the power dissipated in the IC. For high

charge currents, the LTC3558 power dissipation is

approximately:

PVV I

D CC BAT BAT

=

()

–•

where PDis the power dissipated, VCC is the input supply

voltage, VBAT is the battery voltage, and IBAT is the charge

LTC3558

20

3558f

Battery Charger Stability Considerations

TheLTC3558 batterychargercontainstwocontrolloops: the

constant-voltageand constant-currentloops.Theconstant-

voltage loop is stable without any compensation when a

battery is connected with low impedance leads. Excessive

lead length, however, may add enough series inductance

to require a bypass capacitor of at least 1.5µF from BAT

to GND. Furthermore, a 4.7µF capacitor with a 0.2Ωto 1Ω

series resistor from BAT to GND is required to keep ripple

voltage low when the battery is disconnected.

High value capacitors with very low ESR (especially

ceramic) reduce the constant-voltage loop phase margin,

possibly resulting in instability. Ceramic capacitors up to

22µF may be used in parallel with a battery, but larger

ceramics should be decoupled with 0.2Ωto 1Ωof series

resistance.

In constant-current mode, the PROG pin is in the feedback

loop,notthebattery.Becauseofthe additional pole created

by the PROG pin capacitance, capacitance on this pin must

be kept to a minimum. With no additional capacitance on

the PROG pin, the charger is stable with program resistor

values as high as 25K. However, additional capacitance on

this node reduces the maximum allowed program resis-

tor. The pole frequency at the PROG pin should be kept

above 100kHz. Therefore, if the PROG pin is loaded with a

capacitance,CPROG,thefollowingequationshouldbeused

to calculate the maximum resistance value for RPROG:

RC

PROG

PROG

≤1

210

5

π••

APPLICATIONS INFORMATION

Average,ratherthan instantaneous,battery current maybe

of interest to the user. For example, if a switching power

supply operating in low-current mode is connected in

parallel with the battery, the average current being pulled

out of the BAT pin is typically of more interest than the

instantaneous current pulses. In such a case, a simple RC

filter can be used on the PROG pin to measure the average

battery current as shown in Figure 6. A 10k resistor has

been added between the PROG pin and the filter capacitor

to ensure stability.

USB Inrush Limiting

When a USB cable is plugged into a portable product,

the inductance of the cable and the high-Q ceramic input

capacitorformanL-Cresonantcircuit. If there is not much

impedance in the cable, it is possible for the voltage at

the input of the product to reach as high as twice the

USB voltage (~10V) before it settles out. In fact, due to

the high voltage coefficient of many ceramic capacitors

(a nonlinearity), the voltage may even exceed twice the

USB voltage. To prevent excessive voltage from damag-

ing the LTC3558 during a hot insertion, the soft connect

circuit in Figure 7 can be employed.

In the circuit of Figure 7, capacitor C1 holds MP1 off

when the cable is first connected. Eventually C1 begins

to charge up to the USB input voltage applying increasing

gate support to MP1. The long time constant of R1 and

C1 prevents the current from building up in the cable too

fast thus dampening out any resonant overshoot.

3558 F06

CFILTER

CHARGE

CURRENT

MONITOR

CIRCUITRY

RPROG

LTC3558

PROG

GND

10k

Figure 6. Isolated Capacitive Load on PROG Pin and Filtering

R1

40k

5V USB

INPUT

3558 F07

C1

100nF

C2

10µF

MP1

Si2333

USB CABLE

VCC

GND

LTC3558

Figure 7. USB Soft Connect Circuit

Table of contents

Other Linear Technology Batteries Charger manuals

Linear Technology

Linear Technology DC1614A Quick setup guide

Linear Technology

Linear Technology DC763 Series User manual

Linear Technology

Linear Technology DC1229B User manual

Linear Technology

Linear Technology DC1484A-A User manual

Linear Technology

Linear Technology LT3651EUHE-4.1 Quick setup guide

Linear Technology

Linear Technology LT3652EDD User manual

Linear Technology

Linear Technology DC086 Quick setup guide

Linear Technology

Linear Technology LTC1760 User manual

Linear Technology

Linear Technology DC2151A Quick setup guide

Linear Technology

Linear Technology LTC4075XEDD User manual