Linear Technology DC086 Quick setup guide

1

DEMO MANUAL DC086

BATTERY CHARGER

LT1510 Constant-Voltage/

Constant-Current Lithium-Ion

Battery Charger

DESCRIPTIO

U

Demonstration board DC086 is a complete lithium-ion

battery charger designed for 1-, 2- or 3-cell applications

(otherrechargeablebatterytypescanalsobecharged,see

page three). The LT

®

1510 is used in a high efficiency

current mode step-down switching topology, capable of

providingup to 1.5A of charging current.This demo board

uses all surface mount components, resulting in a circuit

occupying approximately 1 square inch of board area with

less than 0.3 in. (7.6mm) height.

Jumpers J1 and J2, located on the demo board, are used

to select the correct charging voltage for the number of

cells being charged (4.2V, 8.4V or 12.6V). Charging cur-

rent is programmed for 1.3A by resistor R1.

The DC input voltage must be at least 3V greater than the

output voltage. When the input voltage is removed, an

external low current MOSFET (Q1) provides a disconnect

for the output voltage divider resistors and the chip goes

into a sleep mode, draining approximately 3µA from the

battery.

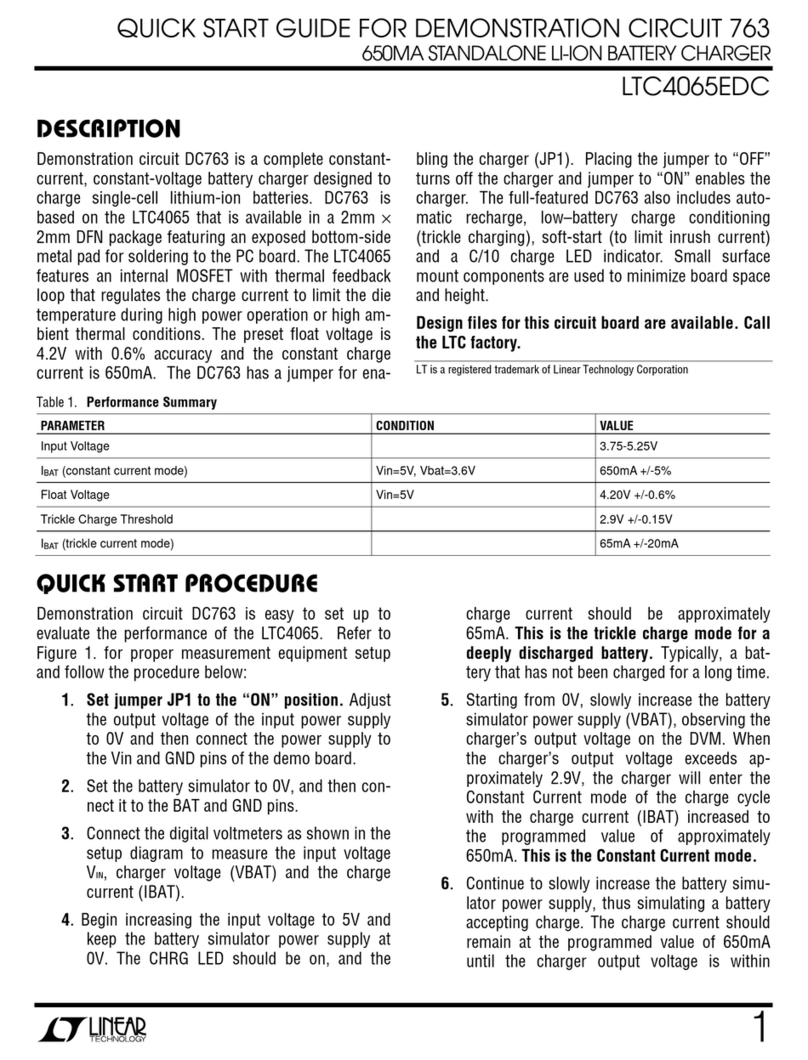

PARAMETER CONDITIONS LIMITS

V

IN

V

OUT

+ 3V ≤V

IN

≤28V*

Battery Voltage (V

BAT

)V

IN

= 10V 4.2 ±0.7%

When Charging Terminates V

IN

= 15V 8.4V ±0.7%

V

IN

= 20V 12.6V ±0.7%

Maximum Battery Charging Current 1.3A ±5%

PERFOR A CE SU ARY

UWWW

Charging Efficiency

BATTERY CHARGING CURRENT (A)

0.1

EFFICIENCY (%)

0.7

DM086 • TPC01

0.3 0.5 0.9

96

94

92

90

88

86

84

82

80 1.1 1.3 1.5

V

CC

= 15V

V

BAT

= 8.4V

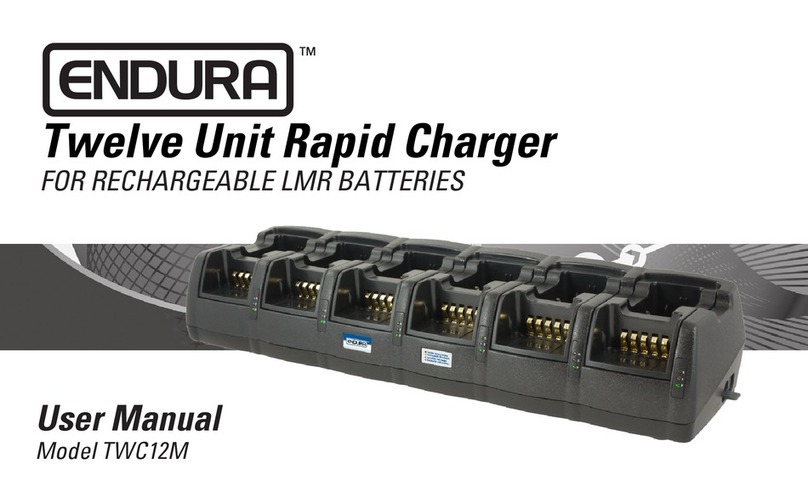

Component Side Demo Board

Note: Good thermal PC board layout techniques are required when operating near maximum power levels to prevent excessive junction temperatures.

Note: For 0.5% battery-voltage accuracy, replace R3 to R8 with 0.1% resistors.

*For V

IN

> 25V, C1 should be replaced with a higher voltage rating capacitor.

TYPICAL PERFOR A CE CHARACTERISTICS A D BOARD PHOTO

UU

W

, LTC and LT are registered trademarks of Linear Technology Corporation.

2

DEMO MANUAL DC086

BATTERY CHARGER

LT1510CS

FOUR CORNER PINS ARE FUSED TO

INTERNAL DIE ATTACH PADDLE FOR

HEAT SINKING TO PC BOARD

USE GENEROUS AMOUNTS OF PC BOARD

COPPER AROUND LEADS (SEE LT1510

DATA SHEET AND DESIGN NOTE 124)

PACKAGE A D SCHE ATIC DIAGRA S

UWW

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GND

SW

BOOST

GND

OVP

SENSE

GND

GND

GND

V

CC

V

CC

PROG

V

C

BAT

GND

GND

LT1510

D2

MBRS140L

D1

MBRS140L

J4

V

IN

J3

GND

C1

10µF

R9

1k

C5

0.1µF

R2

300ΩR1

3.83k

0.25%

C3

1µF

16V

C4

22µF

+

Li-Ion

BATTERY

J6

J5

Q1

2N7002 V

IN

C2

0.22µF

D3

MMBD914

L1

CTX33-2

33µH

1, 4

2, 3

R4

3.52k

0.25%

R3

4.99k

0.25%

R5

4.99k

0.25%

R6

3.52k

0.25%

R7

4.99k

0.25%

R8

3.52k

0.25%

J1 J2

I

BAT

V

BAT

BATTERY

J1 J2 VOLTAGE

CLOSED CLOSED 4.2V

CLOSED OPEN 8.4V

OPEN OPEN 12.6V

PROGRAM OUTPUT VOLTAGE

DM086 • SCHEMATIC

+

TOP VIEW

S PACKAGE

16-LEAD PLASTIC SO

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

GND

SW

BOOST

GND

OVP

SENSE

GND

GND

GND

V

CC2

V

CC1

PROG

V

C

BAT

GND

GND

Figure 1. Demo Board Schematic

PARTS LIST

REFERENCE

DESIGNATOR QUANTITY PART NUMBER DESCRIPTION VENDOR TELEPHONE

1E106ZY5U-C304F-T Tokin (408) 432-8020

C1 1 THCS50EIE106Z 10µF 25V 20% Y5U Ceramic Capacitor United Chemicon/Marcon (708) 696-2000

C2 1 12063C224MAT2A 0.22µF 25V 20% X7R Ceramic Capacitor AVX (207) 282-5111

C3 1 1206YG105ZAT2A 1µF 16V Y5V Ceramic Capacitor AVX (207) 282-5111

C4 1 TPSD226M025R0200 22µF 25V 20% Tantalum Capacitor AVX (207) 282-5111

C5 1 12065C104MAT2A 0.1µF 50V 20% X7R Ceramic Capacitor AVX (207) 282-5111

D1, D2 2 MBRS140LT3 1A 40V Schottky Diode Motorola (602) 244-3550

D3 1 MMBD914LT1 100V Silicon Diode Motorola (602) 244-3550

J1, J2 2 TSW-102-07-G-S 0.1"cc, 0.025"sq. 2-Pin Jumper Samtech (800) 726-8329

J3 to J6 4 1502-2 0.090" Turret Terminal Keystone (718) 956-8900

L1 1 CTX33-2 33µH 2A SMT Inductor Coiltronics (407) 241-7876

Q1 1 2N7002 N-Channel MOSFET Transistor Siliconix (800) 554-5565

R1 1 CR1206F3K83CT 3.83k 1/4W 0.25% Chip Resistor IRC (512) 992-7900

R2 1 CR32-301J-T 300Ω1/8W 5% Chip Resistor AVX (207) 282-5111

R3, R5, R7 3 CR1206F4K99CT 4.99k 1/4W 0.25% Chip Resistor IRC (512) 992-7900

R4, R6, R8 3 CR1206F3K52CT 3.52k 1/4W 0.25% Chip Resistor IRC (512) 992-7900

R9 1 CR32-102J-T 1k 1/8W 5% Chip Resistor AVX (207) 282-5111

U1 1 LT1510CS SO-16 Battery Charger IC LTC (408) 432-1900

3

DEMO MANUAL DC086

BATTERY CHARGER

OPERATIO

U

lead-acid batteries, reprogram the OVP (overvoltage pro-

tection) feedback resistor divider for the correct battery

charging voltage using the following formula:

RR

V

V

FOUT

REF

=

3

1–

where R

F

= total resistance between OVP pin and BAT pin,

V

REF

= 2.465V, select R3 = 4.99k, 1% or less.

Maximum charging current (up to 1.5A) is programmed

by R1 using the following formula:

RICHARGE

12000 2 465

=

()( )

.

where 2.465V = reference voltage present at PROG pin.

The maximum charging current (or current limit) is 2000

times the current out of the PROG pin. This current has both

AC and DC components present; therefore, to provide high

DCaccuracy,averagingcomponentsR2andC3arerequired.

For nickel-cadmium and nickel-metal-hydride batteries,

the normal charging method is constant current. Fast

charging requires some method to detect full charge and

terminate the high charge current. Some methods often

used to indicate full charge include battery temperature

riseandobservingbatteryvoltageprofileduringcharging.

LT1510 Step-Down Switching Regulator

The LT1510 is designed for constant-voltage and/or con-

stant-current operation with a 0.5% voltage accuracy and

a5%currentaccuracy. Anexternalresistorvoltagedivider

programs the output voltage, while a single resistor (or a

programming current from a DAC) sets the maximum

charging current .

An internal 2A NPN switch operating at 200kHz provides

high efficiency with low inductor values using a minimum

number of external components. The charging current

sense resistor is included on the die and can be wired for

sensing charging current at either the positive or negative

side of the battery.

Refer to the LT1510 data sheet for complete product

specifications and design notes DN111 and DN124 for

additional application information.

The DC086 demonstration board is intended for evaluat-

ing the LT1510 switching regulator battery charger IC.

Solder terminals are provided for easy hookup to a power

supply and to a lithium-ion battery to be charged. The

correct charging voltage for either 1, 2 or 3 cells is

selectable by a combination of jumpers (J1 and J2) on the

board.Seetheschematicdiagramforjumperinformation.

Current limit is set for 1.29A by resistor R1.

With a suitable input power supply and a discharged

battery connected to the demo board, the battery will

begin charging at the programmed current limit of 1.29A.

As the battery charges, the voltage rises and approaches

the program voltage of either 4.2V, 8.4V or 12.6V. The

charger will then maintain a constant voltage across the

battery, with the charging current decreasing to zero over

time as the battery reaches a fully charged condition.

The IC goes into a sleep mode when the input voltage is

removed.Inthesleepmode,thedrainfromthebatterydue

to the LT1510 is approximately 3µA. An additional source

of battery drain is due to the leakage current of Schottky

diode D1. Selecting a low leakage Schottky diode such as

a Motorola MBRD340 or a low leakage 3A silicon diode

can minimize this current drain.

Some lithium-ion battery manufacturers recommend ter-

minating the constant-voltage float mode after the charge

currenthas droppedbelowa specificlevel(typically 50mA

to 100mA) and a specific amount of time has elapsed

(typically from 30 to 90 minutes). This may extend the life

of the battery, but check with the manufacturer of the

battery you are using for details. Included on the board is

an area for breadboarding a timing circuit.

Other Battery Types

Although the demo board was designed for charging

Li-Ion batteries, simple modifications will allow other

battery types to be charged.

Sealed lead-acid batteries are charged using a current-

limited constant voltage. Over a 0°C to 40°C temperature

range, a charge voltage of 2.35V/cell can be used with no

chargetermination needed. The maximum chargecurrent

is determined by the battery manufacturer and is typically

0.25Cor less. To use the demo board for charging sealed

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no represen-

tationthatthe interconnectionofits circuitsasdescribed hereinwillnot infringeonexisting patentrights.

Note: Cis the capacity rating of the battery in Ampere-Hours.

4

DEMO MANUAL DC086

BATTERY CHARGER

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900

●

FAX

: (408) 434-0507

●

TELEX

: 499-3977

LT/GP 0696 500 • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1996

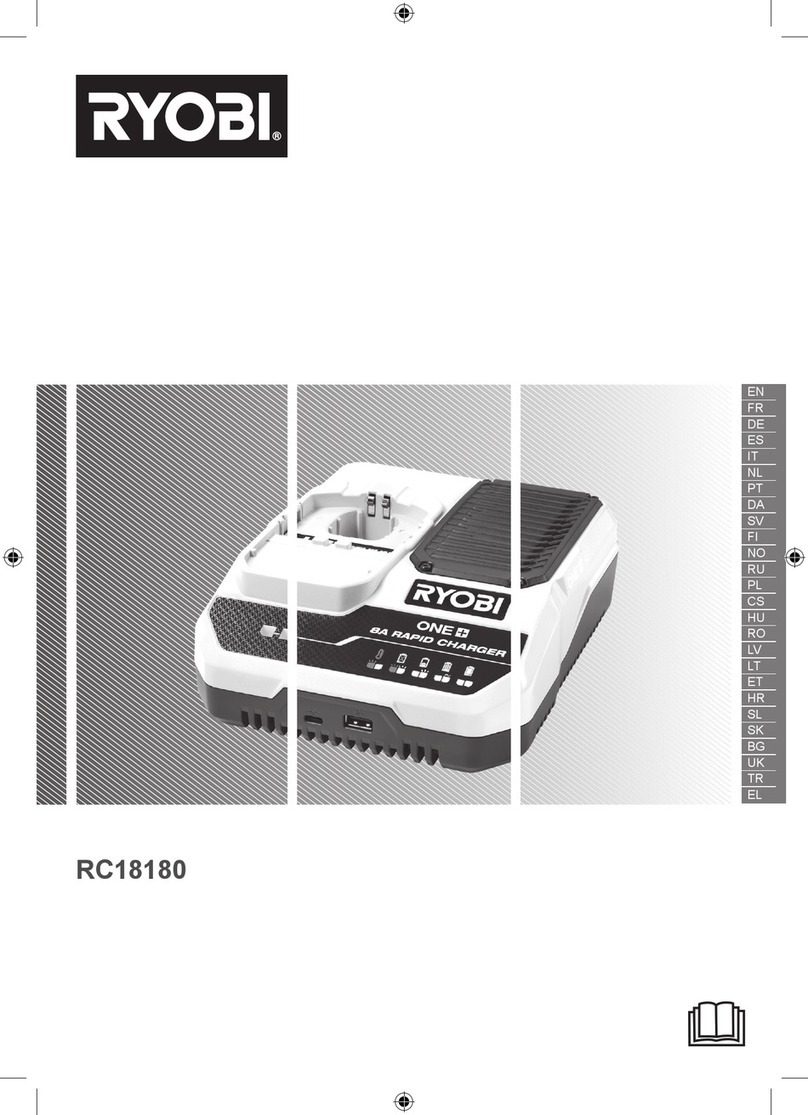

PCB LAYOUT AUD FILW

WU

Component Side Silkscreen Component Side

Component Side Solder Mask Solder Side

PC FAB DRAWI G

U

2.000

3.000

0.150

0.150

F

F

E

E

E

E

B

C

DD DD

DC086 • PC DWG

SYMBOL

NONE

B

C

D

E

F

DIAMETER

0.010

0.015

0.035

0.040

0.095

0.070

NUMBER

OF HOLES

10

17

80

4

4

2

117

TOTAL HOLES

NOTES:

1.BOARD MATERIAL IS FR-4, 0.062" THICK,

2 0Z COPPER

2.PCB WILL BE DOUBLE-SIDED

WITH PLATED THROUGH HOLES

3.SOLDER MASK BOTH SIDES WITH PC4014.

SILKSCREEN COMPONENT SIDE. USE

WHITE NONCONDUCTIVE INK

4.ALL DIMENSIONS IN INCHES ±0.005"

Table of contents

Other Linear Technology Batteries Charger manuals

Linear Technology

Linear Technology LTC3558 User manual

Linear Technology

Linear Technology LTC1760 User manual

Linear Technology

Linear Technology LT3652EDD User manual

Linear Technology

Linear Technology LTC4075XEDD User manual

Linear Technology

Linear Technology LT3651EUHE-4.1 Quick setup guide

Linear Technology

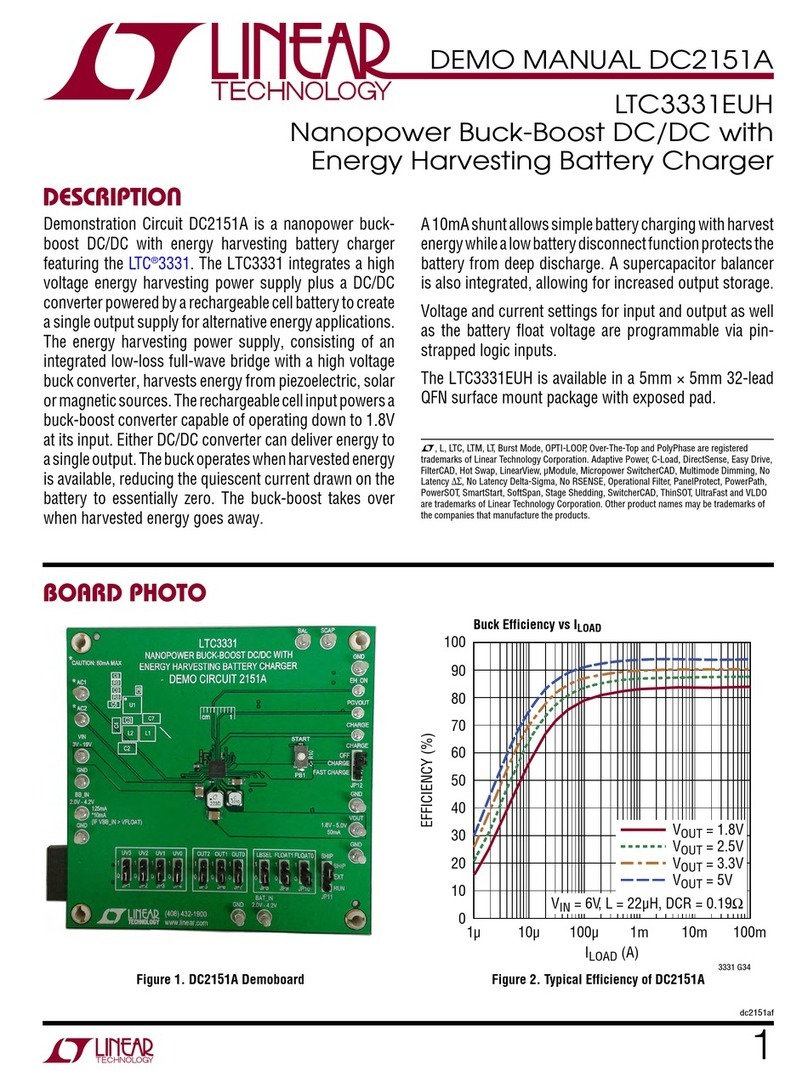

Linear Technology DC2151A Quick setup guide

Linear Technology

Linear Technology DC1614A Quick setup guide

Linear Technology

Linear Technology DC1229B User manual

Linear Technology

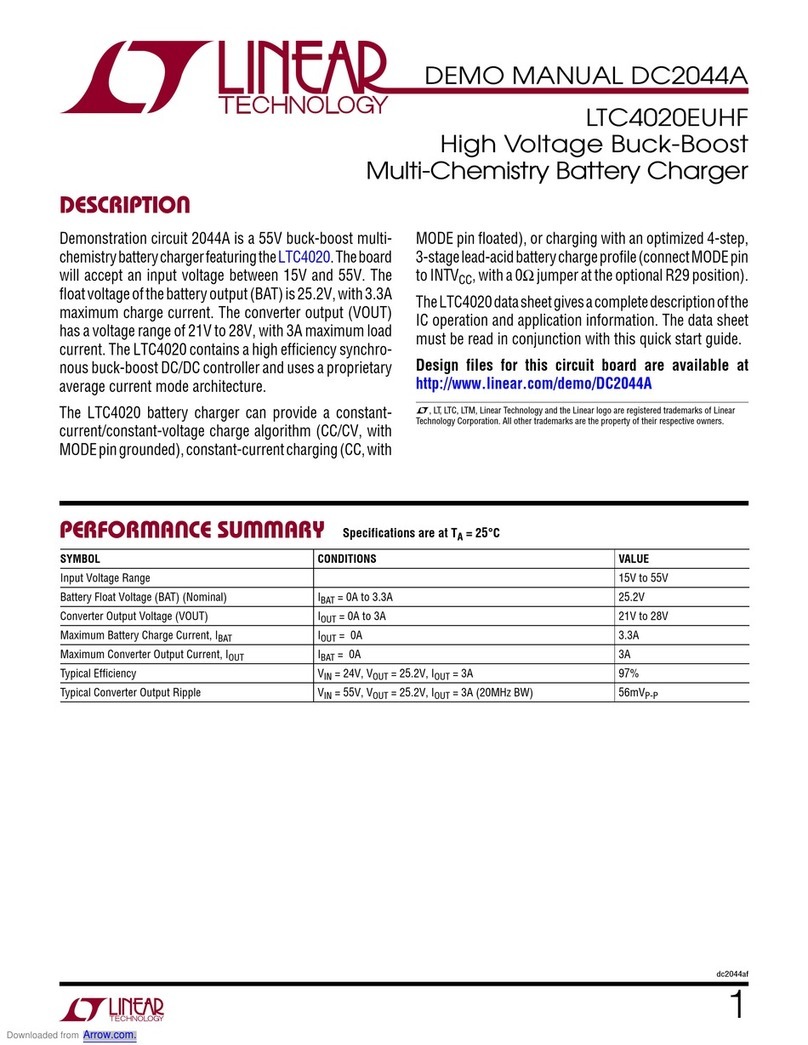

Linear Technology LTC4020EUHF Quick setup guide

Linear Technology

Linear Technology DC1484A-A User manual