5

DEMO MANUAL DC102

50V N-CHANNEL HALF BRIDGE

OPERATION

U

floating capacitor. Thus, at a point between 90% and

100% duty cycles, the floating capacitor will be depleted,

causing a discontinuity and potential overdissipation of

the top MOSFETs.

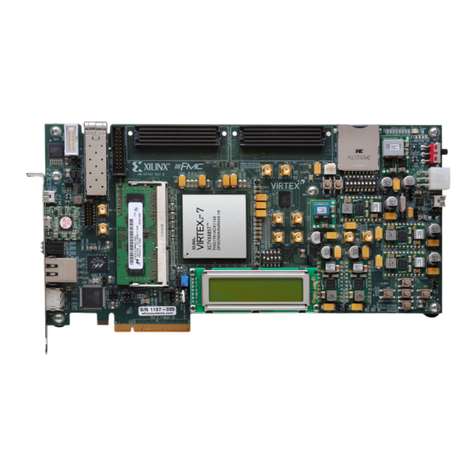

In this demo board the built-in switching regulator of the

LT1336 comes configured as a flyback regulator, as

shown in Figure 1. To configure a flyback regulator, a

resistor,adiode,asmall1:1turnsratiotransformeranda

capacitor are needed. The maximum voltage across the

switch, assuming an ideal transformer, will be about

V

IN

+11.3V.Leakageinductanceinnonidealtransformers

will induce an overvoltage spike at the switch the instant

that it opens. These spikes are clamped using the snub-

bing network D3, C9 and R7. Using the components as

showninFigure1,theflybackregulatorwillrunataround

800kHz.Tolowerthefrequency,increasethevalueofC11;

to raise the frequency, decrease the value of C11.

Theflybackregulatorworksasfollows:whentheswitchis

on, the primary current ramps up as the magnetic field

buildsup.Themagneticfieldinthecoreinducesavoltage

onthesecondarywindingequaltoV

IN

.However,nopower

is transferred to V

BOOST

because the rectifier diode D1 is

reverse biased. The energy is stored in the transformer’s

magneticfield.Whentheprimaryinductorpeakcurrentis

reached, the switch is turned off. Energy is no longer

transferredtothetransformer,causingthemagneticfield

tocollapse.Thecollapsingmagneticfieldinducesachange

involtage across the transformer’s windings.During this

transition the Switch pin’s voltage flies to 10.6V plus a

diodeaboveV

IN

,thesecondaryforwardbiasestherectifier

diode D1 and the transformer’s energy is transferred to

V

BOOST

. Meanwhile, the primary inductor current goes to

zeroandthevoltageatI

SENSE

decaystothelowerinductor

currentthresholdwithatime constant of(R2)(C11), thus

completing the cycle.

Using the flyback regulator allows the maximum voltage

(50V)tobeappliedatthehighvoltagerail,HV.Inapplica-

tionswherethehighvoltageraildoesnotexceed40V,the

boost topology can be used. The advantage, as shown in

Figure2, is simplicity.Only aresistor,asmall inductor,a

diode and a capacitor are needed; there is no need for a

snubbercircuit.ThecurrentdrawnfromV

IN

willbehigher,

however, by a factor of V

BOOST

/V

IN

.

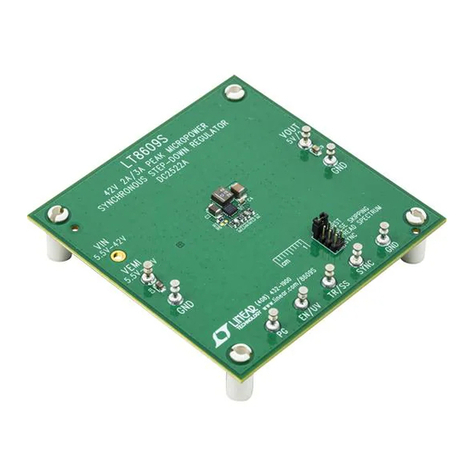

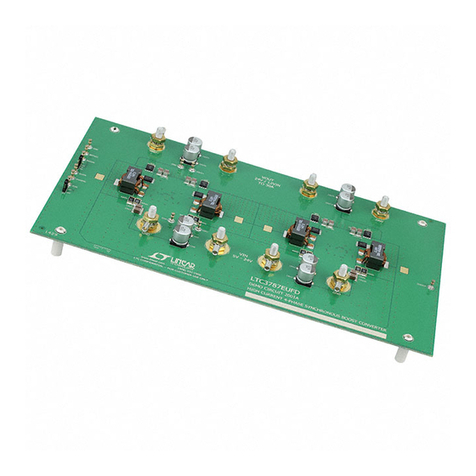

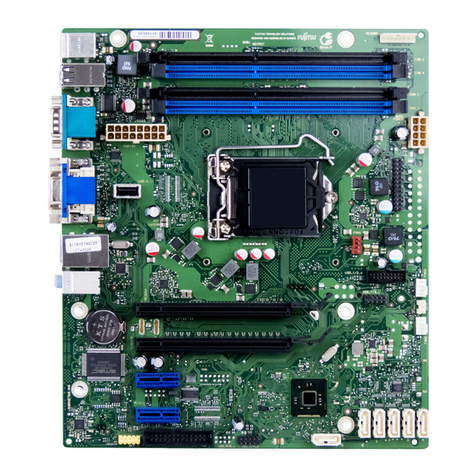

To reconfigure the demo board’s flyback regulator into a

boost regulator, remove the snubber circuit’s compo-

nents, C9, R7, D3 and the transformer T1. Reconnect

diodeD1 andinsertthe optionalinductor as shownin the

Board Photos. Using the components provided with the

demo board (2Ωsense resistor, 200µH inductor and 1µF

capacitor) the boost regulator will run at around 700kHz.

To lower the frequency increase the inductor value; to

increase the frequency decrease the inductor value.

The boost regulator works as follows: when the switch is

on, the inductor current ramps up as the magnetic field

buildsup.Duringthisintervalenergyisbeingstoredinthe

inductorandnopoweristransferredtoV

BOOST

.Whenthe

2Ωresistorsensesthatthepeakinductorcurrenthasbeen

reached, the switch is turned off. Energy is no longer

transferred to the inductor, causing the magnetic field to

collapse. The collapsing magnetic field induces a change

in voltage across the inductor. The Switch pin’s voltage

rises until diode D1 starts conducting. As the inductor

currentrampsdown,thelowerinductorcurrentthreshold

is reached and the switch is turned on, starting the next

cycle.

Current drawn from V

IN

is delivered to V

BOOST

. Some of

this current (~1.5mA) flows through the topside driver to

E2. This current is typically returned to ground via the

bottomMOSFETsortheoutputload.IfthebottomMOSFETs

areoffandtheoutputloadisreturnedtoHV,E2willreturn

the current to HV through the top MOSFET or the output

load. If the HV supply cannot sink current and no load

drawinggreater than 1.5mAis connected tothesupply, a

resistor from HV to ground may be needed to prevent

voltage buildup on the HV supply.