Linear Technology DC1978A User manual

Looking for a discount?

Check out our current promotions!

This coversheet was created by Verical, a division of Arrow Electronics, Inc. (“Verical”). The attached document was created by the part supplier,

not Verical, and is provided strictly 'as is.' Verical, its subsidiaries, affiliates, employees, and agents make no representations or warranties

regarding the attached document and disclaim any liability for the consequences of relying on the information therein. All referenced brands,

product names, service names, and trademarks are the property of their respective owners.

00000005981LF-000

EOS Power

Buy Now

We have 45,000 LP502030-PCM-NTC-LD-A02554 - EEMB - Lithium Battery Rectangular 3.7V 250mAh Rechargeable in

stock now. Starting at $0.034. This EEMB part is fully warrantied and traceable.

1-855-837-4225

Give us a call

International: 1-555-555-5555 1-415-281-3866

1-415-281-3866

Arrow Electronics,

Verical Division

P.O. Box 740970

Los Angeles, CA 90074-0970

Arrow Electronics, Inc

9201 East Dry Creek Road

Centennial, CO 80112

DC1978A

ANALOG DEVICES

Buy Now

1

dc1978af

DEMO MANUAL DC1978A

DESCRIPTION

LTC2974 Quad

Digital Power Supply

Manager with EEPROM

The DC1978A is a demonstration system for the LTC

®

2974

quad I2C/SMBus/PMBus power supply monitor and con-

troller with EEPROM. The DC1978A demonstrates the

ability of the LTC2974 to monitor, supervise, sequence,

trim, margin and log faults for four power supplies. Each

power supply channel of the LTC2974 monitors current,

voltage and temperature. This demonstration system is

supported by the LTpowerPlay™ graphical user interface

(GUI)thatenablescompletecontrolofallLTC2974features.

The DC1978A consists of two circuit boards designed to

work as a pair, DC1809A and DC1810A. The DC1809A

contains all the circuitry needed to insert the LTC2974

into a power system and control four power supplies.

The DC1810A contains four power supplies, two LTC3860

DrMOS supplies and two LTM

®

4620 supplies, which are

configuredtobecontrolled by the LTC2974. Together,these

two boards form a sophisticated four-channel digitally

programmable power supply.

Together,theLTpowerPlay software andDC1978Ahardware

system create a powerful development environment for

designing and testing LTC2974 configuration settings.

These settings can be stored in the LTC2974 internal

EEPROM or in a file. This file can later be used to order

preprogrammed devices or to program devices in a pro-

duction environment. The LTpowerPlay software displays

all of the configuration settings and real time measure-

ments from the LTC2974. Telemetry allows easy access

and decoding of the fault log created by the LTC2974. The

LTC2974 on the DC1809A board comes preprogrammed

with the EEPROM values appropriate for the four power

supplies used on the DC1810A. Just plug and play!

Multiple DC1978A board sets can be cascaded together to

form a high channel count power supply (see Multiboard

Arrays). This cascaded configuration demonstrates

features of the LTC2974 which enable timing and fault

information to be shared across multiple LTC2974s allow-

ing for the formation of a single, coherent power supply

control system. This cascaded configuration is supported

L, LT, LTC, LTM, μModule, PolyPhase, Linear Technology and the Linear logo are registered

trademarks and LTpowerPlay is a trademark of Linear Technology Corporation. All other

trademarks are the property of their respective owners. Protected by U.S. Patents Including

7382303 and 7420359.

by the LTpowerPlay GUI and allows the user to configure

up to nine LTC2974s, thereby controlling up to 36 sepa-

rate power supplies. Larger arrays (>9) of LTC2974s are

supported through programmable I2C base address or

bus segmentation.

TheDC1809A/DC1810Aboardsare powered by an external

12V power supply. Communication with the LTpowerPlay

software is via the DC1613 USB to I2C/SMBus/PMBus

controller. The following is a checklist of items which can

be obtained from the LTC website or LTC Field Sales.

• USB to I2C/PMBus Controller (DC1613)

• LTpowerPlay Software

• Configuration File (.proj file) for the DC1978A

Design files for this circuit board are available at

http://www.linear.com/demo

LTC2974 Features

• I2C/SMBus Serial Interface

• PMBus Compliant Command Set

• Configuration EEPROM with CRC

• Black Box Fault Logging to Internal EEPROM

• Differential Input, 16-Bit ΔΣADC with Less Than

±0.25% of Total Unadjusted Error

• Four Voltage Servos Precisely Adjust Supply

Voltages Using 10-Bit DACs with Soft Connect

• MonitorsFour Output Voltages,Four Output Currents

and One Input Voltage

• Monitors Four External Temperature Sensors and

Internal Die Temperature

• 4-Channel Sequencer, Time Based or Tracking

• Programmable Watchdog Timer

2

dc1978af

DEMO MANUAL DC1978A

DESCRIPTION

• Four OV/UV VOUT and One VIN Supervisor

• Four Overcurrent/Undercurrent Supervisors

• Supports Multichannel Fault Management

• OperatesAutonomously without Additional Software

• Powered from 3.3V or 4.5V to 15V

• Available in 64-Lead 9mm × 9mm QFN

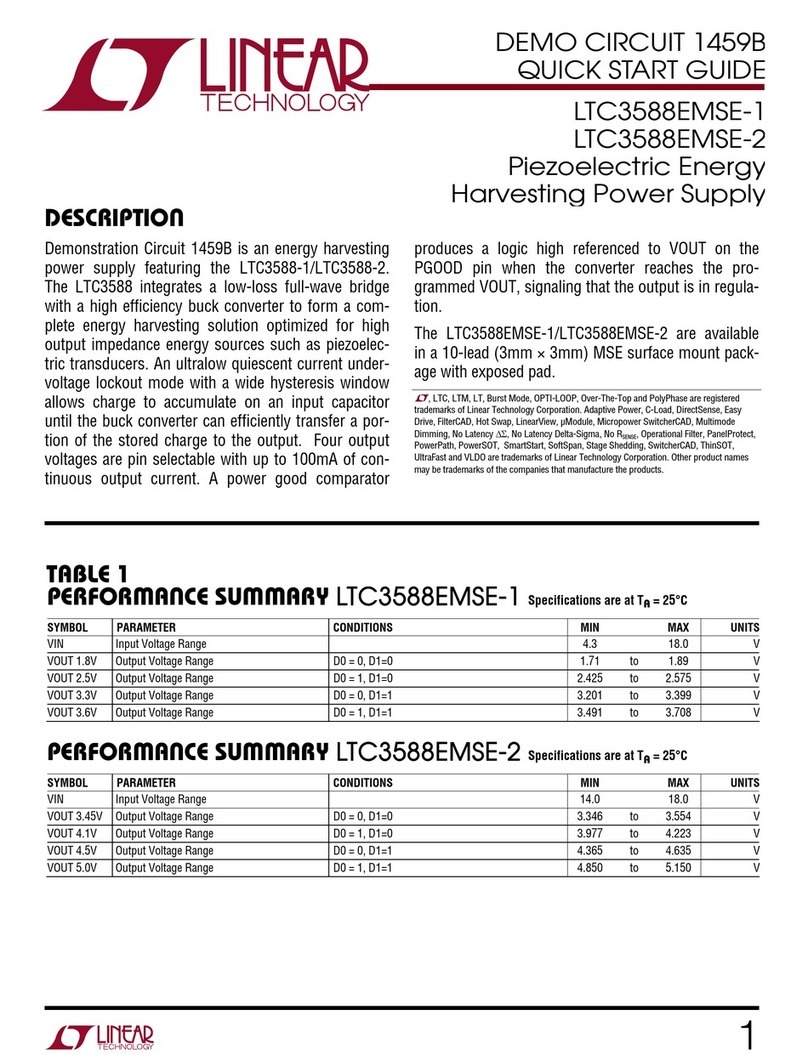

PERFORMANCE SUMMARY

PARAMETER CONDITIONS MIN TYP MAX UNITS

VPWR Supply Input Voltage Range 4.5 15 V

VDD33 Supply Input Voltage Range 3.13 3.47 V

ADC Total Unadjusted Error VIN_ADC ≥ 1V ±0.25 %

ADC Voltage Sensing Input Range Differential Voltage: VIN_ADC = (VSENSEP[n] – VSENSEM[n])

VSENSEM[n]

0

–0.1

6

0.1

V

V

ADC Voltage Sensing Resolution 122 μV/LSB

ADC Current Sense Input Range ISENSEP[n], ISENSEM[n]

Differential Voltage: VIN_ADC = (ISENSEP[n] – ISENSEM[n])

–0.1

–170

6

170

V

mV

ADC Current Sense Resolution RSENSE(IOUT_CAL_GAIN) = 1Ω

0mV ≤ |VIN_ADC| < 16mV

16mV ≤ |VIN_ADC| < 32mV

32mV ≤ |VIN_ADC| < 63.9mV

63.9mV ≤ |VIN_ADC| < 127.9mV

127.9mV ≤ |VIN_ADC|

15.265

31.25

62.5

125

250

μA/LSB

μA/LSB

μA/LSB

μA/LSB

μA/LSB

Trim DAC Resolution 10 Bits

Trim DAC Full Scale Output Voltage Buffer Gain Setting 0 (MFR_CONFIG(dac_gain) = 0)

Buffer Gain Setting 1 (MFR_CONFIG(dac_gain) = 1)

1.38

2.65

V

V

Temperature Sensor Resolution 0.136 °C/LSB

Voltage Supervisor Input Voltage Range Low Resolution, VIN_VS = (VSENSEP[n] – VSENSEM[n])

High Resolution, VIN_VS = (VSENSEP[n] – VSENSEM[n])

VSENSEM[n]

0

0

–0.1

6

3.8

0.1

V

V

V

Voltage Supervisor Sensing Resolution 0V to 3.8V Range

0V to 6V Range

4

8

mV/LSB

mV/LSB

Voltage Supervisor Total Unadjusted

Error

2V < VIN_VS < 6V, Low Resolution Mode

1.5V < VIN_VS < 3.8V, High Resolution Mode

0.8V < VIN_VS < 1.5V, High Resolution Mode

±1.25

±1.0

±1.5

%

%

%

Current Supervisor Input Range ISENSEP[n], ISENSEM[n] –0.1 6 V

Differential Voltage: VIN_CS = (ISENSEP[n] – ISENSEM[n])) –170 170 mV

Current Supervisor Resolution IOUT_xC_FAULT_LIMIT × IOUT_CAL_GAIN 400 μV/LSB

Current Supervisor Total Unadjusted

Error

50mV ≤ VIN_CS ≤ 170mV

VIN_CS < 50mV

±3

±1.5

%

mV

I2C Serial Clock Frequency 10 400 kHz

DC1978A Power Supply Specifications

POWER SUPPLY CHANNEL CH0 CH1 CH2 CH3

Controller LTC3860, VOUT1 LTC3860, VOUT2 LTM4620, VOUT1 LTM4620, VOUT2

Nominal Untrimmed Output Voltage 1.8V ± 2.1 % 1.5V ± 2.1 % 1.2V ± 2.1 % 1.0V ± 2.1 %

Rated Output Current 2A 2A 5A 5A

Output Trim Range (VDAC_FS = 1.38V) 13/–19 % 11 /–15% 16/–21 % 16/–21 %

Specifications valid over full operating temperature range.

DC1978A DEMO SYSTEM SPECIFICATIONS

3

dc1978af

DEMO MANUAL DC1978A

LTpowerPlay GUI SOFTWARE

LTpowerPlay is a powerful Windows based development

environmentthatsupportsLinearTechnologydigitalpower

ICs with EEPROM, including the LTC2974 and LTC2978

quad and octal PMBus power supply managers, and

the LTC3880 dual output PolyPhase

®

step-down DC/DC

controller with digital power system management. The

software supports a variety of different tasks. You can

use LTpowerPlay to evaluate Linear Technology ICs by

connecting to a demo board system. LTpowerPlay can

also be used in an offline mode (with no hardware pres-

ent) in order to build a multichip configuration file that

can be saved and reloaded at a later time. LTpowerPlay

provides unprecedented diagnostic and debug features. It

becomes a valuable diagnostic tool during board bring up

to program or tweak the power management scheme in

a system or to diagnose power issues when bringing up

rails. LTpowerPlay utilizes the DC1613A USB-to-SMBus

controller to communicate with one of many potential

targets, including the LTC2974’s DC1978A demo system

or a customer board. The software also provides an au-

tomatic update feature to keep the software current with

the latest set of device drivers and documentation. The

LTpowerPlay software can be downloaded from:

http://linear.com/ltpowerplay

To access technical support documents for LTC Digital

Power Products visit Help, View Online help on the

LTpowerPlay menu.

Figure 1. Interface of the LTpowerPlay GUI

DC1978a F01

4

dc1978af

DEMO MANUAL DC1978A

QUICK START PROCEDURE

Thefollowingproceduredescribeshowtosetup a DC1978A

demo system.

1. Download and install the LTpowerPlay GUI:

http://linear.com/ltpowerplay

2. Remove both boards from the ESD protective bags

and place them on a level surface. Connect the boards

together using the 50-pin edge connector. Be especially

careful not to misalign the connectors. Connect the

DC1613 I2C/SMBus/PMBus controller to the DC1809A

board.

3. Confirm that all jumpers and switches on DC1809A are

set to their defaults as follows:

a. Set both JP1 and JP2 (Address select ASEL0 and

ASEL1) to LOW to select I2C address 0x5C.

b. Set JP3 (WRITE PROTECT) to OFF to enable writing

to the LTC2974 EEPROM.

c. Set the control jumpers JP4 to JP7 to SW0 to SW3

position to connect the switches to the LTC2974

control pins.

d. Set all control switches SW0, SW1, SW2 and SW3

to HI.

4. Confirm that all jumpers and switches on DC1810A are

set to their defaults as follows.

a. Set JP1, JP2 and JP3 to SOFT-START to enable

independent startup of CH1, CH2 and CH3.

b. Set the preload switches SW1, SW2, SW3 and SW4

to ON.

5. Plug the USB to I2C/SMBus/PMBus Controller into a

USB port on your PC.

6. Connect a 12V power supply with > 0.5A capacity to

the VIN input of the DC1810A. The board should power

up and all power good outputs should be illuminated

green.

7. Launch the LTpowerPlay GUI.

a. The GUI should automatically indentify the LTC2974.

The system tree on the left hand side should look

like this:

Figure 2. Connecting DC1809A/DC1810A Boards and the DC1613 I2C/SMBus/PMBus Controller

DC1978a F02

5

dc1978af

DEMO MANUAL DC1978A

QUICK START PROCEDURE

b. A green message box shows for a few seconds in the

lower left hand corner, confirming that the LTC2974

is communicating:

9. You are now ready to view one of the LTC2974 demo

videos embedded in the LTpowerPlay GUI or experi-

ment with the part on your own. To view a video or

more LTC2974 information and application notes, visit

the LTpowerPlay online help website from the GUI as

shown here:

c. In the Toolbar, click the R icon to read the RAM from

the LTC2974. This reads the configuration from the

RAM of LTC2974 and loads it into the GUI.

d. Save the demo board configuration to a (*.proj) file.

Clickthe Save iconand save thefile. Name itwhatever

you want.

8. The control switches SW0 to SW3 are configured to

control channels CH0 to CH3. Slide the switches to HI/

GND to enable/disable the individual channels.

LOADING A LTC2974 CONFIGURATION (*.proj) FILE

WITH THE GUI

1. In the upper left hand corner of the GUI, File > Open >

browse to your *.proj file. This will load the file into

the GUI.

2. Click on the arrow. This loads the configura-

tion into LTC2974 RAM.

3. To store the configuration in EEPROM, click on the

STORE button. It is the button on the left below.

6

dc1978af

DEMO MANUAL DC1978A

DC1978A DETAILS TOP SIDE

Figure 3. DC1978A Top Details

DC1978a F03

7

dc1978af

DEMO MANUAL DC1978A

COMMON DEMO BOARD OPERATIONS

SELECTING I2C ADDRESS

The I2C/SMBus address of the LTC2974 equals the base

address + N, where N is a number from 0 to 8. N can be

configured by setting the ASEL0 and ASEL1 pins to VDD33,

GND or FLOAT. See Table 3. Using one base address and

the nine values of N, nine LTC2974s can be connected

together to control thirty six outputs. The base address

is stored in the MFR_I2C_BASE_ADDRESS register. The

base address can be written to any value, but generally

should not be changed unless the desired range of ad-

dressesoverlapexistingaddresses.Watchthattheaddress

range does not overlap with other I2C/SMBus device or

global addresses, including I2C/SMBus multiplexers and

bus buffers.

RESET THE LTC2974

To reset the LTC2974 and reload the EEPROM contents

into operating memory (RAM), press SW4 on DC1809A.

Table 3. Device Address Lookup Table

ADDRESS

DESCRIPTION

HEX DEVICE ADDRESS BINARY DEVICE ADDRESS BITS ADDRESS PINS

7-Bit 8-Bit 6 5 4 3 2 1 0 R/W ASEL1 ASEL0

ALERT RESPONSE 0C 19 00011001 X X

GLOBAL 5B B6 10110110 X X

N=0 5C* B8 10111000 L L

N=1 5D BA 10111010 L NC

N=2 5E BC 10111100 L H

N=3 5F BE 10111110 NC L

N=4 60 C0 11000000 NC NC

N=5 61 C2 11000010 NC H

N=6 62 C4 11000100 H L

N=7 63 C6 11000110 H NC

N=8 64 C8 11001000 H H

H = Tie to VDD33, NC = No Connect = Open or Float, L = Tie to GND, X = Don’t Care

* MFR_I2C_BASE_ADDRESS = 7-Bit 0x5C (Factory Default)

DC1978A LEDS

The red LEDs on ALERTB, FAULTB0, FAULTB1 and AUX-

FAULTB (D3, D4, D5, D2) indicate a fault has occurred.

The green LED (D6) next to them is the LTC2974 PWRGD

signal. Each individual channel on DC1810A also has

its own green PWR GOOD LED (PG0, PG1, PG2, PG3).

When the USB to I2C/SMBus/PMBus controller power or

external power is applied, the green LED D1 will illuminate,

indicating that the LTC2974 is powered.

FAULTING AN OUTPUT

The outputs of the power supplies CH0 to CH3 may be

shorted indefinitely. This is a good way to induce UV faults.

Use a jumper wire or a coin to short any output.

8

dc1978af

DEMO MANUAL DC1978A

FAULT SHARING SETUP IN THE GUI

Use the fault sharing setup tool to configure the fault

sharing in the GUI. Before doing so, view the fault sharing

demo in the GUI. Go to Tools > Fault Sharing Diagram.

Also, read the section on fault sharing in the data sheet.

“WHY AM I OFF?” TOOL

Use the “Why am I Off?” tool in the LTpowerPlay GUI to

diagnose the reason a power supply channel is turned off.

The tool can be located in the top right corner of the GUI,

next to the Register Information tab.

TRACKING BASED SEQUENCING

The LTC2974 supports tracking power supplies that are

equipped with a tracking pin and configured for tracking.

A tracking power supply uses a secondary feedback ter-

minal (TRACK) to allow its output voltage to be scaled to

an external master voltage. Typically, the external voltage

is generated by the supply with the highest voltage in the

system, which is fed to the slave track pins (see Figure 6).

Any supplies that track a master supply must be enabled

before the master supply comes up and disabled after the

master supply comes down. Enabling the slave supplies

COMMON DEMO BOARD OPERATIONS

Figure 4. Fault Sharing Utility in LTpowerPlay GUI

Figure 5. “Why am I Off?” tool in the LTpowerPlay GUI

DC1978a F04

DC1978a F05

9

dc1978af

DEMO MANUAL DC1978A

when the master is down requires supervisors monitoring

theslaves to disable UV detection.Slave UC detection must

also be disabled when the slaves are tracking the master

down to prevent false UC events. All channels configured

for tracking must track off together in response to a fault

on any channel or any other condition that can bring one

or more of the channels down. Prematurely disabling a

slave channel via its run pin may cause that channel to

shut down out of sequence. The LTC2974 supports the

following tracking features:

• Track channels on and off without issuing false UV/

UC events when the slave channels are tracking up or

down.

• Track all channels down in response to a fault from a

slave or master.

• Track all channels down when VIN_SNS drops below

VIN_OFF, share clock is held low or RESTORE_USER_

ALL is issued.

• Ability to reconfigure selected channels that are part of

a tracking group to sequence up after the group has

tracked up or sequence down before the group has

tracked down.

Todemonstrate the tracking features ofLTC2974, DC1810A

has three jumpers (JP1, JP2 and JP3) that can be set to

connect resistive dividers from the 1.8V master supply

(CH0) to the TRACK pins of channels 1 to 3.

The required timing settings and diagrams in order to

enable tracking with LTC2974 are listed in the data sheet,

and a brief summary is shown below:

Master channel 0

• TON_DELAY = Ton_delay_master

• TON_RISE = Ton_rise_master

• TOFF_DELAY = Toff_delay_master

• Mfr_track_en_chan0 = 0

COMMON DEMO BOARD OPERATIONS

Figure 6. LTC2974 Configured to Control, Supervise and Monitor Power Supplies Equipped with Tracking Pin

VOUTP

RUN

VOUTM

VSENSEP0

VSENSEM0

TRACK

FAULTB0FAULTB0

LTC2974

CONTROL0

VOUT_EN0

CONTROL0

DC/DC LOAD

VOUTP

RUN

VOUTM

VSENSEP1

VSENSEM1

TRACK

VOUT_EN1

DC/DC LOAD

VOUTP

RUN

VOUTM

VSENSEP2

VSENSEM2

TRACK

VOUT_EN2

DC/DC LOAD

VOUTP

RUN

VOUTM

VSENSEP3

VSENSEM3

TRACK

VFB

VDAC0

VFB

VDAC1

VDAC3

VFB

VDAC2

VFB

VOUT_EN3

VSENSEP0

VSENSEP1

VSENSEP2

VSENSEM0

VSENSEM1

VSENSEM3

VSENSEM2

VSENSEP3

DC/DC LOAD

DC1978a F06

R2_3

R1_3

R2_2

R1_2

R2_1

R1_1

PWRGD

10

dc1978af

DEMO MANUAL DC1978A

Slave channel n

• TON_DELAY = Ton_delay_slave

• TON_RISE = Ton_delay_master + Ton_rise_slave

• TOFF_DELAY = Toff_delay_master + T_off_delay_slave

• Mfr_track_en_chan0 = 1

Where:

Ton_delay_master – Ton_delay_slave > RUN to TRACK

setup time

Toff_delay_slave > time for master supply to fall.

PROCEDURE TO DEMONSTRATE TRACKING WITH

DC1978A

1. Start with the default LTC2974 EEPROM and jumper

settings for DC1978A. Set the jumpers JP1, JP2 and

JP3 to TRACK CH0 position. This connects the TRACK

pins of the slave supply channels to the output voltage

of the master channel through resistive dividers (see

Figure 6).

2. Set DC1809A jumper JP4 to SW0 position to propagate

theCONTROL0switchtotheCONTROL0pinof LTC2974.

3. Set the preload (100mA) of CH0 (SW1 to ON) and the

preloads of the slave channels CH1 to CH3 to OFF (SW2

to SW4 to OFF). The absence of load for the slave chan-

nels makes improper sequencing down behavior more

obvious.

4. Configure all power supplies to respond to CONTROL0,

by setting the appropriate bit in the paged MFR_CONFIG

register. In this case U0:0, U0:1, U0:2 and U0:3 are all

controlled by CONTROL0.

COMMON DEMO BOARD OPERATIONS

11

dc1978af

DEMO MANUAL DC1978A

5. Set the TON_DELAY of all slaves (CH1, CH2 and CH3)

to 0ms and the TON_DELAY for the master channel to

20ms.

COMMON DEMO BOARD OPERATIONS

6. Set the TOFF_DELAY of all slaves (CH1, CH2 and CH3)

to 20ms and the TOFF_DELAY for the master channel

to 0ms.

7. Set the TON_RISE of all slaves (CH1, CH2 and CH3)

to 30ms and the TON_RISE for the master channel to

10ms.

12

dc1978af

DEMO MANUAL DC1978A

COMMON DEMO BOARD OPERATIONS

Figure 7. Tracking Supplies Up with DC1978A Figure 8. Tracking Supplies Down with DC1978A

8. Set the track_en_chan1, track_en_chan2 and track_

en_chan3 bits in MFR_CONFIG3 to 1.

9. Toggle the CONTROL0 switch and observe the synchro-

nized tracking behavior of the power supplies.

DC1978a F08

DC1978a F07

13

dc1978af

DEMO MANUAL DC1978A

COMMON DEMO BOARD OPERATIONS

CASCADE SEQUENCING

Cascade sequence ON allows a master power supply to

sequence ON a series of slave supplies by connecting

each power supply’s power good output to the control

pin of the next power supply in the chain. Please note

that the power good signal is that of the power supply

and not derived from the LTC2974’s internal power good

processing. Power good based cascade sequence OFF is

not supported, OFF sequencing must be managed using

immediate or time based sequence OFF. See also Tracking

Based Sequencing.

Cascade sequence ON is illustrated in Figure 9. For each

slave channel Mfr_config_cascade_on bit is asserted

Figure 9. LTC2974 Configured to Cascade Sequence ON and Time Base Sequence OFF

high and the associated control input is connected to the

power good output of the previous power supply. In this

configuration each slave channel’s startup is delayed until

the previous supply has powered up.

Cascade sequence OFF is not directly supported. Options

for reversing the sequence when turning the supplies off

include:

• Using the OPERATION command to turn off all the

channels with an appropriate off delay.

• Using the FAULT pin to bring all the channels down im-

mediately or in sequence with an appropriate off delay.

VOUTP

RUN

VOUTM

VSENSEP0

VSENSEM0

POWERGOOD0

FAULTB0FAULTB0

LTC2974

SLAVES

MASTER

CONTROL0

RECOMMENDED CONNECTION

WHEN HARDWARE ON/OFF

CONTROL IS REQUIRED

VOUT_EN0

CONTROL1

CONTROL0

DC/DC LOAD

VOUTP

RUN

VOUTM

VSENSEP1

VSENSEM1

POWERGOOD1

VOUT_EN1

CONTROL2

DC/DC LOAD

VOUTP

RUN

VOUTM

VSENSEP2

VSENSEM2

POWERGOOD2

VOUT_EN2

CONTROL3

DC/DC LOAD

TO NEXT CONTROL PIN

VOUTP

RUN

VOUTM

VSENSEP3

VSENSEM3

POWERGOOD3

VOUT_EN3

DC/DC LOAD

DC1978a F09

14

dc1978af

DEMO MANUAL DC1978A

COMMON DEMO BOARD OPERATIONS

PROCEDURE TO DEMONSTRATE CASCADE

SEQUENCING WITH DC1978A

1. Start with the default LTC2974 EEPROM and jumper

settings for DC1978A. Set the DC1809A power good

cascading jumpers JP4, JP5, JP6 and JP7 to SW0,

PG_0, PG_1, PG_2 positions. This connects the power

good and control pins as shown in Figure 9.

2. Enable all output supply preloads on DC1810A by slid-

ing the DC1810A switches SW1, SW2, SW3 and SW4

to ON position.

3. Set the TON_DELAY of all channels to 0ms

4. SettheTOFF_DELAY for the inverse shutdownsequence.

15

dc1978af

DEMO MANUAL DC1978A

COMMON DEMO BOARD OPERATIONS

5. Set the cascade_on bit in MFR_CONFIG register for

CH1, CH2 and CH3. The master channel has this bit

cleared.

6. Use Group Operation On to power up all supplies

16

dc1978af

DEMO MANUAL DC1978A

Figure 10. Cascade Sequencing Up with DC1978A Figure 11. Time Based Sequencing Down with DC1978A

COMMON DEMO BOARD OPERATIONS

7. Use Group Operation “Sequence Off” to power down

all supplies

8. ThepowersuppliescascadeON/OFFasshown in Figures

10 and 11 below.

DC1978a F10 DC1978a F11

17

dc1978af

DEMO MANUAL DC1978A

SETUP PROCEDURE FOR MULTIBOARD ARRAYS

Figure 12. Array of Multiple DC1978A Demo Boards

Multiple DC1978As can be combined to control up to 36

independent power supplies. This demonstrates the co-

ordinated fault responses and accurate time base shared

across multiple LTC2974 chips.

Procedure:

1. Stack the boards together by plugging J1 of the second

DC1809A board into J3 of the first DC1809A board.

2. Connect the 12V VIN across the boards using the ba-

nana cables as shown in Figure 12 below. Preserve the

correct polarity (connect VIN to VIN and GND to GND).

3. The USB to I2C/SMBus/PMBus controller may be

pluggedintoeitherboard. Ifboth LTC2974s do not show

up in the GUI, click the hourglass icon to enumerate

the I2C bus and find the addresses of the parts. Make

sure to set different addresses for each LTC2974.

4. The addresses of the LTC2974 are set by the jumpers

JP1 and JP2 on DC1809A and the settings have to be

unique for each board in the array.

5. Since the individual control lines are connected across

the boards (CONTRL0 is a common bus across all

boards in the array, as are CONTROL1 CONTROL2

and CONTROL3), make sure that all control pins on all

DC1809A boards are set to the selected active state.

6. Relaunch LTpowerPlay. After launching, LTpowerPay

will enumerate the entire board array and build a rep-

resentative system tree and read all hardware settings

into the GUI.

18

dc1978af

DEMO MANUAL DC1978A

DC1809A DETAILS TOP

Table 4. DC1809A Default Jumper and Switch Configuration (Default Position Shown in Grey in the Figure Above)

REFERENCE

DESIGNATOR SIGNAL NAME USAGE DEFAULT

JP1, JP2 ASEL0, ASEL1 Set the address offset of LTC2974 LOW, LOW

JP3 WRITE PROTECT Write protect the LTC2974 EEPROM

memory

OFF

JP4, JP5, JP6, JP7 CONTROL0, CONTROL1,

CONTROL2, CONTROL3

Implement cascade sequencing by

connecting power good signals to the

control pins, or connect the control pins

directly to the SW0 to SW3 switches

SW0, SW1, SW2,

SW3

SW0, SW1, SW2,

SW3

CONTROL0, CONTROL1

CONTROL2, CONTROL3

Switches that can be routed to the

individual CONTROL input pins of

LTC2974

HI, HI, HI, HI

19

dc1978af

DEMO MANUAL DC1978A

DC1809A DETAILS BOTTOM

Table of contents

Other Linear Technology Power Supply manuals

Popular Power Supply manuals by other brands

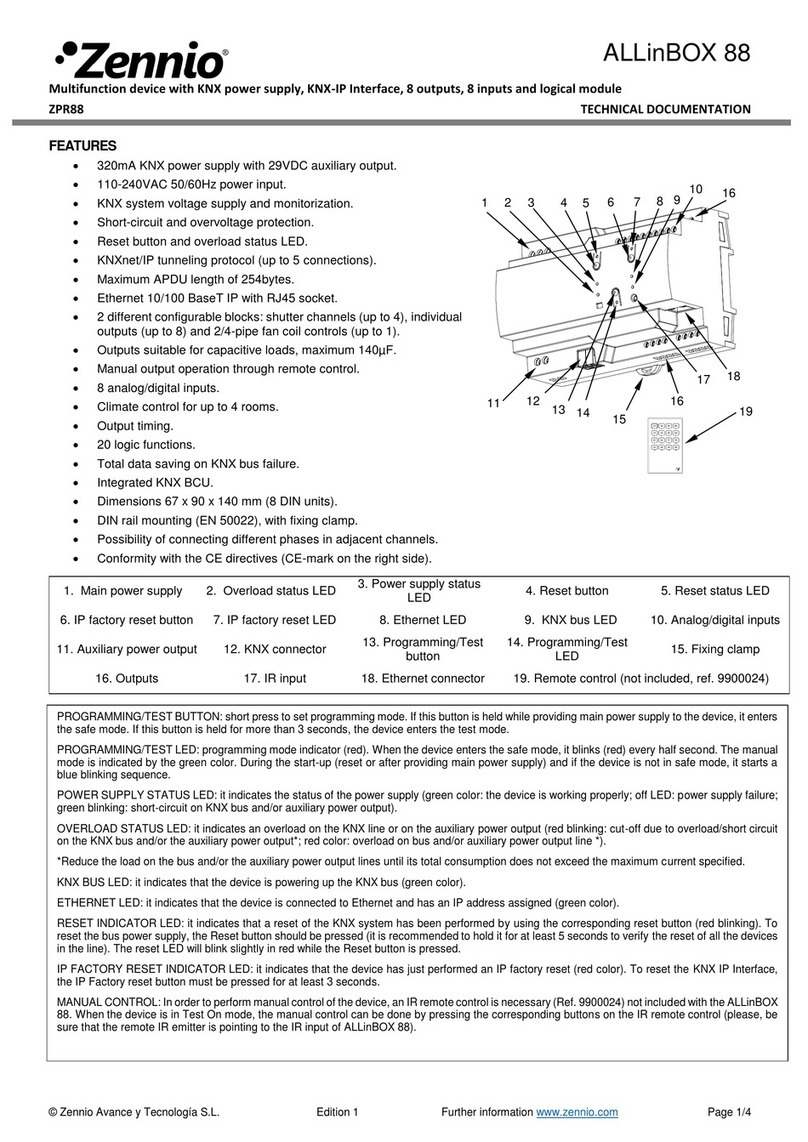

Zennio

Zennio ALLinBOX 88 Technical documentation

CAMBRIONIX

CAMBRIONIX SyncPad54 user manual

KUSSMAUL

KUSSMAUL 091-115 instruction manual

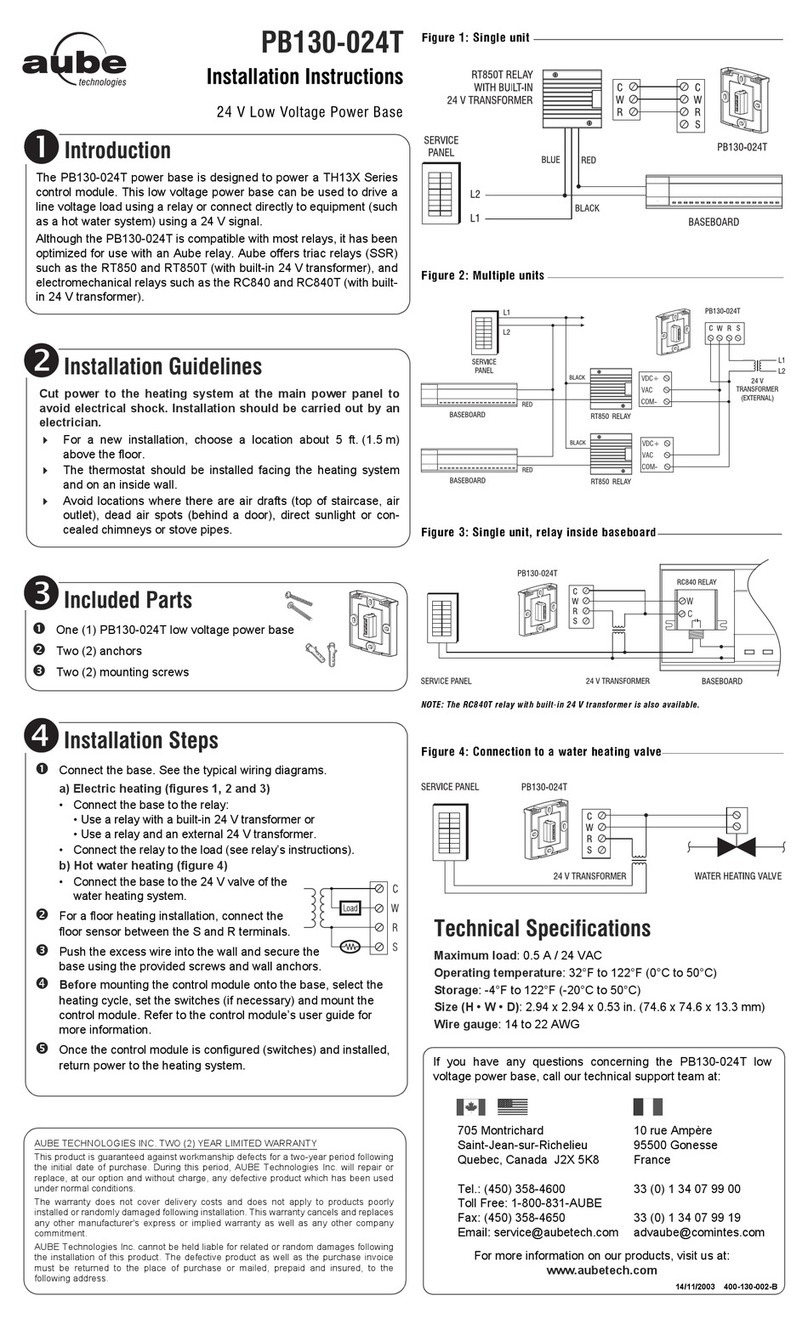

Aube Technologies

Aube Technologies Power Base PB1 30-024T installation instructions

SLAT

SLAT AES 28V/8A operating instructions

SAled Australia

SAled Australia BYG-60B-12 manual

GW Instek

GW Instek ASD Series user manual

Telemark

Telemark TT CHEETAH Series instruction manual

Husqvarna

Husqvarna PP 480 HF Operator's manual

Ruckus Wireless

Ruckus Wireless SmartZone 300 Quick setup guide

Siemens

Siemens SITOP PSU8600 manual

Rockwell Automation

Rockwell Automation Allen-Bradley 1606-XLERED20 installation instructions