Linkoln Quicklub 223 User manual

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Quicklub®

VDC-Pumps 223 (without) and 233 (with Data Logger)

Microprocessor, Control Unit and Membrane Keypad

4354a01

810-55400-1

Page 2 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

All rights reserved.

Any duplication of this User Manual, in its entirety or in part,

by whatever means is prohibited without the prior consent in

writing of Lincoln GmbH & CO. KG.

Subject to modifications without prior notification.

©

2004 by

LINCOLN GmbH & Co. KG

Postfach 1263

D

-69183 Walldorf

Phone: +49 (6227) 33-0

Fax: +49 (6227) 33-259

Fields of Application for Quicklub Progressive Central Lubrication Pumps

Industry - Machines Pump Type

Pump:

Reservoir:

Control:

Quicklub 223, 233

2 l - 2XL1), 2XLBO1)

4 l - 4XLBO1)

8 l - 8XLBO1)

1) Filling from the bottom

4l, 8l – with lockable reservoir lid (Option)

Low-level control for all reservoir sizes

Integrated control unit with metering device

monitoring

See the respective model designation on the pump type plate e.g. P233-2XL-1K6-24-2A6.15-MDF00

or P223-2XL-1K6-24-2A6.15-MF00

Further information can be found in the following manuals:

Technical Description for „Diagnostic Software QuickData“ for pump 233 and QLS 331

Technical Description for progressive divider valves for grease and oil, model SSV, SSV M and SSV D

Installation Instructions

Parts Catalogue

Spare Parts Catalogue for pump 203

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 3 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Table of Contents

Page

Fields of Application ....................................................... 2

Introduction ..................................................................... 4

Explanation of Symbols Used ............................................ 4

User’s Responsibility.......................................................... 4

Environmental Protection .................................................. 4

Service .............................................................................. 4

Safety Instructions .......................................................... 5

Appropriate Use ................................................................ 5

Misuse................................................................................ 5

Exclusion of Liability .................................................... 5

Disposal ....................................................................... 5

Regulations of Prevention of Accidents ............................. 5

General Safety Instructions ............................................... 5

Installation ......................................................................... 6

Operation, Maintenance and Repair .................................. 5

Pump Models ................................................................... 6

Identification Code VDC .................................................. 7

P223 .................................................................................. 7

P233 .................................................................................. 8

Description ....................................................................... 9

QuickLub centralized lubrication pumps............................. 9

P223 without Datalogger ................................................... 9

Control p.c.b. MF00 ..................................................... 9

P233 with Datalogger ...................................................... 10

Control p.c.b. MDF00 ................................................. 10

Datalogger module .................................................... 10

Control Unit ..................................................................... 10

Datamemory .............................................................. 10

Operating states ........................................................ 11

Mode of Operation ......................................................... 11

Pump elements with fixed lubrication output ................... 11

Pump element B7 with bypass check valve ............... 12

Check valve................................................................ 13

Arrangement of the pump elements ........................... 13

Pump Elements with adjustable output ........................... 13

Setting of adjustable pump elements ......................... 14

- Retrofit adjustment of min. lubricant output.............. 14

- Retrofit adjustment of max. lubricant output............. 15

Pressure Relief Valve ...................................................... 15

without grease return.................................................. 15

with grease return (optional) ...................................... 15

Return Line Connection ................................................... 16

Control p.c.b. with or without data memory ..................... 16

Pause time.................................................................. 17

Operating time ........................................................... 17

Monitoring time........................................................... 17

Membrane Key Pad.......................................................... 18

Display of the membrane key pad ................................... 18

Operator Keys of the membrane key pad ........................ 19

- Acknowledging receipt of a low-level indication /

malfunction .............................................................. 19

- Additional lubrication cycle ...................................... 19

- Reset of the pause time ........................................... 20

- Changing to the different programming levels ......... 20

Monitoring relay ............................................................... 20

Page

Reading of the data memory “QuickData” (only P233)..... 21

Low-level control for grease ............................................. 21

When the reservoir is filled.......................................... 21

When the reservoir is empty ....................................... 22

Magnetic switch .......................................................... 22

Contact protection measures ........................................... 22

Setting an Operation ...................................................... 23

Factory Settings................................................................ 23

Operator Keys .................................................................. 23

External triggering of an additional lubrication cycle ........ 23

Display Mode ................................................................... 24

Programming Mode ......................................................... 26

Operating Mode ............................................................... 29

Maintenance, Repair and Tests

Maintenance .................................................................... 32

Pump filling...................................................................32

Repair............................................................................... 33

Pump .......................................................................... 33

Replace pump element ............................................... 33

Control p.c.b. .............................................................. 33

Tests ................................................................................ 34

Operational Test /

Triggering an additional lubrication cycle .................... 34

Check the pressure relief valve .................................. 34

Troubleshooting ............................................................. 35

Technical Data ................................................................ 37

Pump ............................................................................... 37

Pump elements ................................................................ 37

Pressure relief valve ........................................................ 37

Torsion torques ................................................................ 37

Weight .............................................................................. 37

Electrical Data .................................................................. 38

Input ........................................................................... 38

Output ......................................................................... 38

EMC ........................................................................... 38

Motor .......................................................................... 38

Control p.c.b. .............................................................. 38

Time setting ................................................................ 38

Operation with bayonet plug ....................................... 38

Electrical connection VDC ............................................... 39

Dimensions ...................................................................... 40

Attaching boreholes of the 2l, 4l, and 8l pump ................. 45

Lubricants ....................................................................... 45

Quicklub List of Lubricants ............................................... 46

Proven lubricants ........................................................ 46

Lubricant recommendation based on the

manufacturer’s data sheet .......................................... 46

Biodegradable lubricants ............................................ 47

Lubricants for the food & beverage industry ............... 47

Declaration by the Manufacturer .................................. 48

Page 4 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Introduction

Explanation of Symbols Used

The following description standards are used in this manual:

Safety Instructions

Structure of safety instructions:

Pictogram

Signal word

Danger text

- Danger note

- How to avoid danger

The following pictograms are used in this manual and are

combined with the corresponding signal words:

1013A94

4273a00

6001a02

- ATTENTION

- CAUTION

- WARNING

- ATTENTION

- CAUTION

- WARNING

- NOTE

- IMPORTANT

The signal words give the seriousness of danger if the follow-

ing text is not observed:

ATTENTION refers to faults or damages on

machines.

CAUTION refers to bad damages and possi-

ble injuries.

WARNING refers to possible dangerous inju-

ries.

NOTE refers to improvements in handling

of systems.

IMPORTANT refers to considerable disadvan-

tages in handling of systems.

Example:

1013A94

ATTENTION!

When making use of other than the tested

spare parts, serious damage may affect

your device.

Therefore, for the operation of your device

always use original spare parts made by

Lincoln GmbH & Co. KG.

Furthermore, you will find the following text symbols in this

manual:

Listing of applicable statements

- Subpoint of applicable statements

1. Determination of the number or sequence of contents

Procedural instruction

User's Responsibility

To ensure the safe operation of the unit, the user is responsi-

ble for the following:

1. The pump / system shall be operated only for the in-

tended use (see next chapter "Safety Instructions") and

its design shall neither be modified nor transformed.

2. The pump / system shall be operated only if it is in a

proper functioning condition and if it is operated in accor-

dance with the maintenance requirements.

3. The operatin

g

personnel must be familiar with this Owner

Manual and the safety instructions mentioned within and

observe these carefully.

The correct installation and connection of tubes and hoses, if

not specified by Lincoln GmbH & Co. KG, is the user's re-

sponsibility. Lincoln GmbH & Co. KG will gladly assist you

with any questions pertaining to the installation.

Environmental Protection

Waste (e.g. used oil, detergents, lubricants) must be dis-

posed of in accordance with relevant environmental regula-

tions.

Service

The personnel responsible for the handling of the pump /

system must be suitably qualified. If required, Lincoln GmbH

& Co. KG offers you full service in the form of advice, on-site

installation assistance, training, etc. We will be pleased to

inform you about our possibilities to support you purposefully.

In the event of inquiries pertaining to maintenance, repairs

and spare parts, we require model specific data to enable us

to clearly identify the components of your pump / system.

Therefore, always indicate the part, model and series number

of your pump / system.

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 5 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Safety Instructions

Appropriate Use

Use the 223 and 233 pumps only for dispensing lubricants

in centralized lubrication systems. The pump is designed

for intermittent operation.

Misuse

Any use of the 223 and 233 pumps that is not expressly men-

tioned in this User Manual will be regarded as misuse.

If the 223 and 233 pumps are used or operated in a different

manner other than specified, any claim for warranty or liability

will be null and void.

6001a02

NOTE

If personal injury or material damage

occurs as a result of inappropriate opera-

tion, e.g. if the safety instructions are

ignored or resulting from an incorrect

installation of the 223 and 233 pumps, no

claims or legal actions may be taken

against Lincoln GmbH & Co. KG.

Exclusion of Liability

The manufacturer of the pumps 223 and 233 will not accept

any liability for damages:

caused by a lack of lubricant due to an irregular refilling of

the pump;

caused by the use of contaminated lubricants;

caused by the use of greases which are not or only condi-

tionally pumpable in centralized lubrication systems (see

page 45 and 46);

caused by chemical or biological modifications of the

lubricant used;

caused by inadequate disposal of used or contaminated

lubricants as well as of components that have been in

touch with lubricant;

caused by unauthorized modification of the system com-

ponents;

caused by the use of unapproved parts.

Disposal

Dispose of used or contaminated lubricants as well as of

parts that were in touch with lubricant according to the legal

regulations pertaining to environmental protection. Make sure

to observe the safety data sheets of the lubricants used.

Regulations for Prevention of Accidents

To prevent accidents, observe all city, state and federal

safety regulation of the country in which the product will

be used.

Avoid the operation with

unapproved parts.

insufficient or contaminated lubricants.

General Safety Instructions

Lincoln Quicklub centralized lubrication systems

- are designed state-of-the-art.

- can be assembled for safe operation.

Incorrect use may result in bearing damage caused by

poor or over-lubrication.

Unauthorized modifications or changes to an installed

system are not admissible. Any modification must be sub-

ject to prior consultation with the manufacturer of the lu-

brication system.

Installation

Any safety equipment already fitted to the vehicle or the

machine:

- should not be modified or made ineffective;

- should only be removed for the purpose of fitting the

system;

- must be reinstalled after fitting the system.

Keep Quicklub centralized lubrication systems away from

sources of heat. Adhere to the operating temperature.

Use only original Lincoln spare parts (see Parts Catalog)

or parts approved by Lincoln.

Adhere to:

- the installation instructions of the vehicle or machine

manufacturer as regards all drilling and welding proce-

dures.

- the specified minimum distances between the boreholes

and the upper/lower rim of the frame or between two

boreholes.

Operation, Maintenance and Repair

4273a00

CAUTION!

The centralized lubrication system may be

installed by qualified personnel only. Be-

fore beginning with the installation or

service work, disconnect the power

supply!

4273a00

ATTENTION!

Consider residual ripple of max.

±

5 % to

connect pumps with direct current version

(in relation to the operating voltage acc. to

DIN 41755).

Suitably pack defective printed circuit boards and return to

the factory (see page 33, paragraph „Printed Circuit

Boards“).

Page 6 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Safety Instructions, continuation

Operation, Maintenance and Repair, continuation

1013A94

ATTENTION!

Risk of bursting if the reservoir is overfilled!

When filling the reservoir by means of

pumps with a large delivery volume do not

exceed the max. filling mark.

CAUTION!

It is not allowed to use the pump in poten-

tially explosive fields.

Repair should only be performed by authorized and in-

structed personnel who are familiar with the instructions.

Lincoln Quicklub centralized lubrication systems

- must be operated only with installed pressure relief val-

ve.

- must be refilled in regular intervals with clean lubricant

recommended by the manufacturer without air entrap-

ments.

- operate automatically. However, a regular check (ap-

prox. every 2 days) should be made to ensure that

lubricant is emerging from all lubrication points.

Pump Models

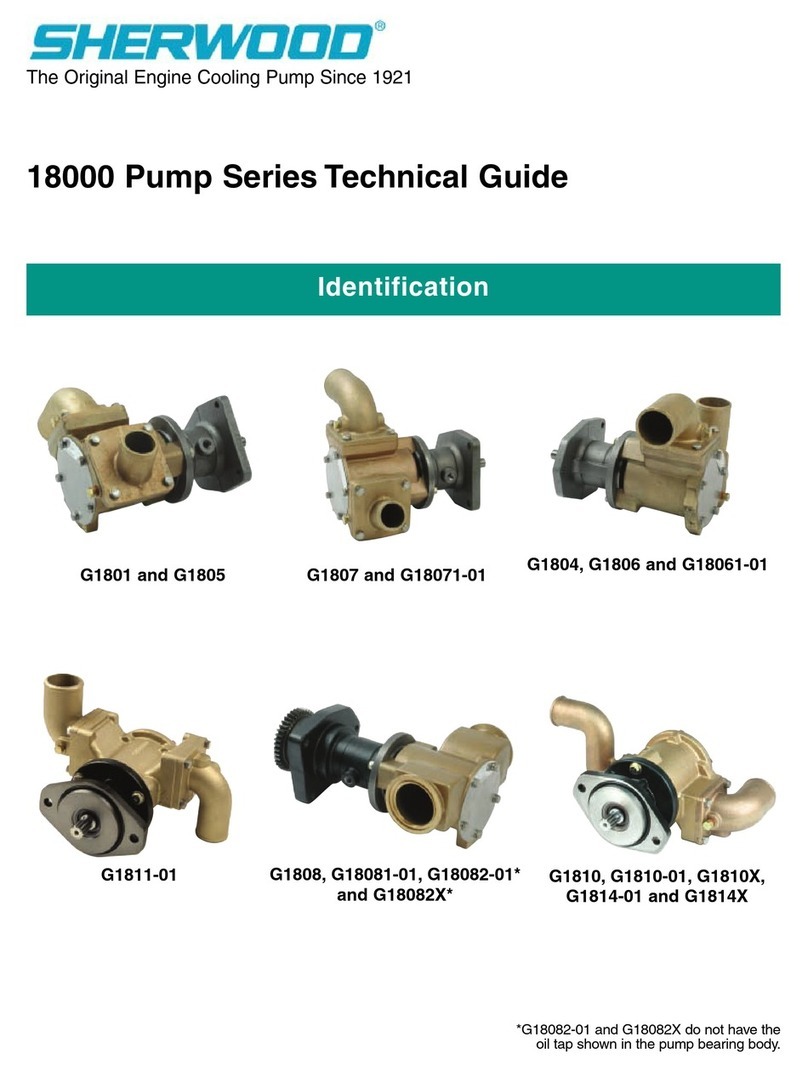

1173a04

Fig. 1 Different models of pumps 223 (without) and 233 (with reading window)

Pumps 223 and 233 basically differ by the read-out function

((P223 without; P233 with). However, both pumps are avail-

able with all reservoir variants.

Reservoir sizes

2 l transparent plastic reservoir

4 l transparent plastic reservoir

8 l transparent plastic reservoir

Control unit models 223, 233

Pumps 223, 233 can be used with integrated control pa-

nels with monitoring of the metering device; pumps 233

additionally with data logger for the data transmission to

the Lincoln diagnostic software QuickData.

1) Refer to the designation on the pump type plate, e.g.

P233 -2XLBO- 1 K6 - 24 - 2A6.15- MDF00 (see also chap-

ter “Identification Code” page 7 and 8).

For the following features of distinction please see the identi-

fication code on pages 7 and 8:

motor voltage

type of control unit (if any)

remote control for triggering an additional lubrication cycle

design and number of pump elements

design and number of pressure relief valves

filling type

use of return line connections

low-level control

Electrical connection

Pumps model 223, 233 may be equipped with a 10 m electric

cable.

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 7 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Identification Code – DC Pump Models P223

Examples of model designations

P223 - 4 - X - L - 1 - K6 - 24 - 2A - 6. - 15 - MF00

P223 - 2 - X - L - BO 1 - K7 - 24 - 2A - 6. - 15 MF00

P223 - 8 - X - L - BO 1 - K6 - 12 - 2A - 6. - 15 - MF00

6001a02

NOTE

Any pump combinations other than the follow-

ing standard pumps can be composed and

ordered in accordance with the valid model

identification code. P223 - 4 - X - L - BO - 1 - K6 - 24 - 2A - 6. - 15 MF00

Basic pump model for grease

with 1-3 outlets and 12 VDC or 24 VDC motor

Reservoir design

2 = 2 l transparent plastic reservoir

4= 4 l transparent plastic reservoir

8= 8 l transparent plastic reservoir

X = Reservoir for grease

L = Low-level control

without designation = Standard reservoir (2 liters)

BO = Filling from top

Pump elements

1-3 = Number of the use elements

K 5 = Piston diameter = 5 mm

K 6 = Piston diameter = 6 mm

K 7 = Piston diameter = 7 mm

KR = Pump element, adjustable, Piston diameter = 7 mm

Connecting voltage

12 or 24 VDC motor

Number of electric connecting possibilities (on pump housing only)

2A = 2 connections:

- connection for power supply on the left, external illuminated pushbutton for

additional lubrication and malfunction

- piston detector on the right

Type of connection 1)

6= Bayonet plug, 7/5-core, DIN 72585-1

1)

other types of connection on request possible

Connection outside the pump

00 = without socket-outlet, without cable

15 = Bayonet socket with 10 m cable, 7/5-wire

Control p. c. b. s. 12V / 24 V

MF00 = with microprocessor control and membrane key pad

Page 8 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Identification Code – DC Pump Models P233

Examples of model designations

P233 - 4 - X - L - 1 - K6 - 24 - 2A - 6. - 15 - MDF00

P233 - 2 - X - L - BO 1 - K7 - 24 - 2A - 6. - 15 MDF00

P233 - 8 - X - L - BO 1 - K6 - 12 - 2A - 6. - 15 - MDF00

6001a02

NOTE

Any pump combinations other than the follow-

ing standard pumps can be composed and

ordered in accordance with the valid model

identification code. P233 - 4 - X - L - BO - 1 - K6 - 24 - 2A - 6. - 15 MDF00

Basic pump model for grease

with 1-3 outlets and 12 VDC or 24 VDC motor

Reservoir design

2 = 2 l transparent plastic reservoir

4= 4 l transparent plastic reservoir

8= 8 l transparent plastic reservoir

X = Reservoir for grease

L = = Low-level control

without designation = Standard reservoir (2 liters)

BO = Filling from top

Pump elements

1-3 = Number of elements used

K 5 = Piston diameter = 5 mm

K 6 = Piston diameter = 6 mm

K 7 = Piston diameter = 7 mm

KR = Pump element, adjustable, Piston diameter = 7 mm

Connecting voltage

12 or 24 VDC motor

Number of electric connecting possibilities (on pump housing only)

2A = 2 connections:

- connection for power supply on the left, external illuminated pushbutton for

additional lubrication and malfunction

- piston detector on the right

Type of connection 1)

6= Bayonet plug, 7/5-core, DIN 72585-1

1)

other types of connection possible on request

Connection outside the pump

00 = without socket-outlet, without cable

15 = Bayonet socket with 10 m cable, 7/5-wire

Control p. c. b. s. 12V / 24 V

MDF00 = with microprocessor control, data logger and membrane keypad

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 9 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Description

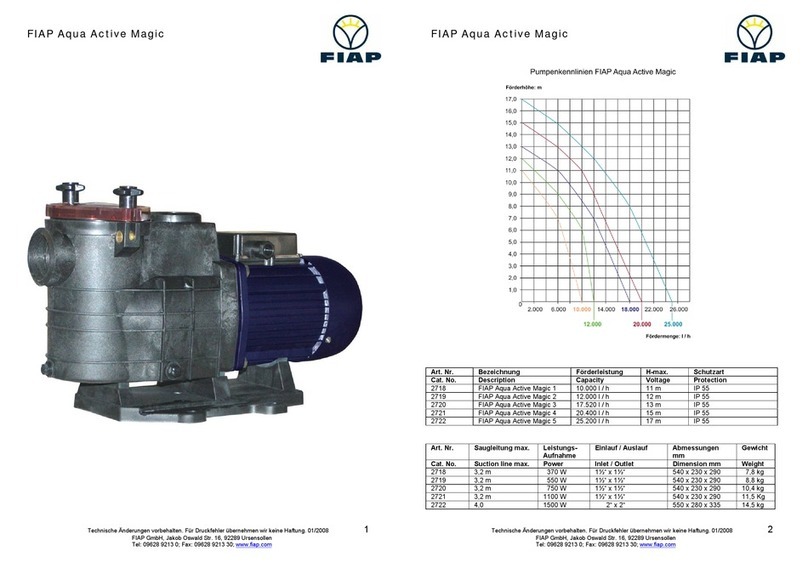

4355a01

Fig. 2 Components of pump 223, 233

1 - Reservoir

2 - Pump element

3 - Pressure relief valve

4 - Filling nipple, system

emergency lubrication

possible

5 - Fillilng nipple, pump

6 - Adaptor for piston detec-

tor

7 - Display

8 - Momentary-contact

switch for indication or

setting of pause time

9 - Reading window for Datalog-

ger (only P233)

10 - Momentary-contact switch for

additional lubrication

11 - Membrane key pad

12 - Piston detector

13 - Covering to the p.c.b.

14 - Adaptor for power supply

15 - Closure plug for the use of a

pump element

Quicklub centralized lubrication pumps

Are compact multi-line pumps consisting of the following

components:

- Housing with integrated motor

- Reservoir with stirring paddle and fixed paddle

- P223: Control printed circuit board (p.c.b.)

P233: Data logger (control p.c.b. with readable

data memory)

- Pump element

- Accessories:

- Pressure relief valve

- Refilling unit

- Electrical connection parts

6001a02

NOTE

Pressure relief valve are not part of the

pump components and have to be or-

dered separately. Accessories for refilling

of the reservoir (see parts catalogue).

can drive up to 3 pump elements

operate according to lubrication cycles (pause and operat-

ing times)

can be equipped with a low-level control

can supply up to 100 lubrication points depending on the

line lengths

are designed for the automatic lubrication of the con-

nected lubrication points

are designed for the delivery of greases up to NLGI 2 at

temperatures from - 25° C to 70° C

can be used at low temperatures down to - 40° C

During the operating time the pump dispenses lubricant to the

connected lubrication points via one or several metering de-

vices.

6288b04

Fig. 3 Control p.c.b. MF00 (P223)

P223 without data logger

Control p.c.b. MF00

The control unit is installed in the housing of the pump

behind the membrane keypad (see pos. 11, fig. 2) as an

integrated p.c.b. MF00.

Page 10 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Description, continuation

P233 with data logger

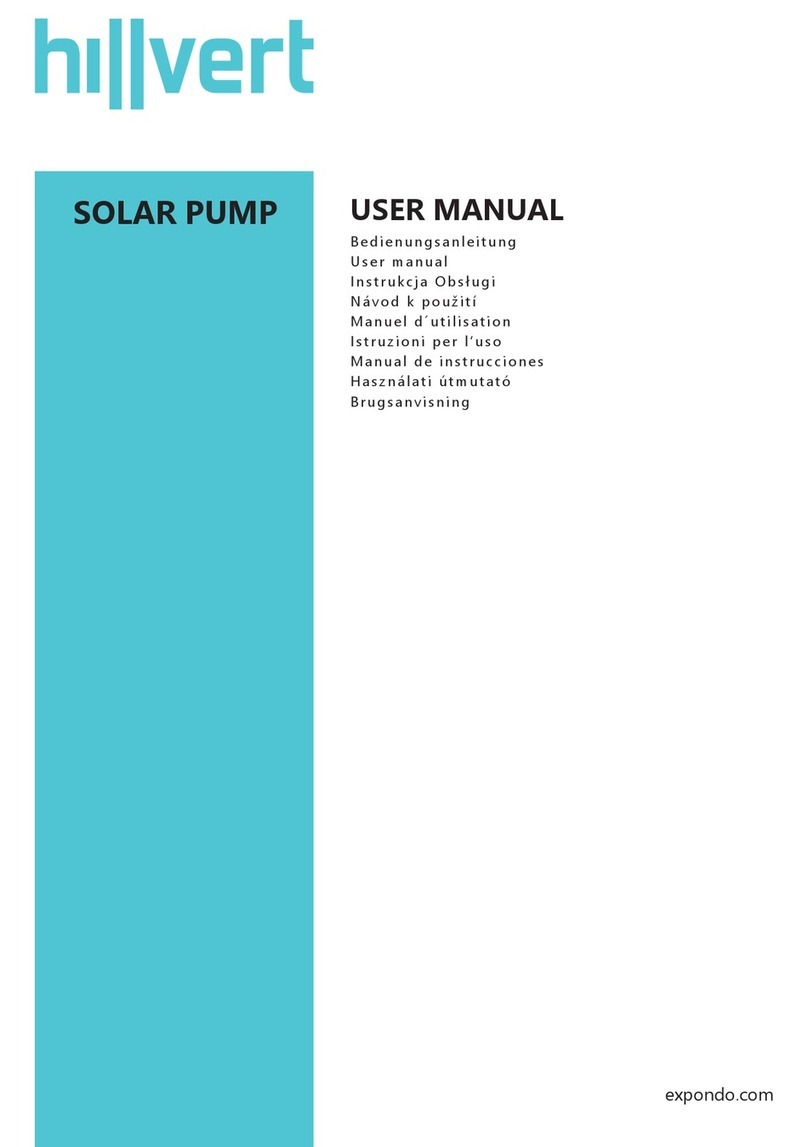

6288a01

Fig. 4 Control p.c.b. MDF00 with built-on data logger

1 - Data logger

2 - IR interface

3 - Control p.c.b.

Control p.c.b. MDF00

The control unit is installed in the housing of the pump

behind the membrane keypad (see pos. 11, fig. 2, page 9)

as an integrated p.c.b. MDF00.

The data logger (fig. 4, pos. 1) is fixed onto the p.c.b.

Control and monitoring system QuickData®

The control and monitoring system consists of:

- control p.c.b. MDF00 (pos. 3, fig. 4)

- built-on data logger module with IR interface

(pos. 2, fig. 4)

- membrane keypad with display (pos. 3, fig. 2)

- IR interface module RS 232 (COM) for laptops, PDA

and Palm

- Lincoln diagnostic software QuickData®

- monitored metering device model SSV with integrated

piston detector (comp. fig. 22, page 17)

4357a01

Fig. 5 Data logger module

Data logger module

Pump 233 is equipped with a readable data memory (data

logger) QuickData®.

The data logger renders information regarding system

settings, events such as low-level indications, malfunc-

tions, operating times and lubrication cycles.

By means of the Lincoln diagnostic software QuickData®

the above-mentioned data can be read on a suitable lap-

top via an infrared interface (see User Manual “Diagnostic

Software QuickData®).

Control Unit

Control p.c.b.

The centralized lubrication system is monitored, i.e.

events such as malfunctions of the centralized lubrication

system, faults in the elapse of the operating time, low-

level indications, pause time, residual pause times of the

pump are displayed in the display window of the mem-

brane keypad.

Version P233 additionally transmits data into the data

logger.

Data memory

The following events are memorized in the EEPROM of

printed circuit boards MF00 (P223) or MDF00 (P233). How-

ever, they can be read and analyzed only out of pumps 233

via the Lincoln diagnostic software QuickData®:

Malfunctions (start, end and duration) in the centralized

lubrication system

faults in the elapse of the operating time

low-level indication (start, end and duration)

number of connections and disconnections of the power

supply

automatically triggered lube cycles

manually triggered lube cycles

operating data

customer related data

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 11 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Description, continuation

Control Unit, continuation

Operating states

Functions, processes, settings, faults or malfunctions of the

pump are indicated on a membrane keypad as shown on the

survey:

6001a02

NOTE

The fault indication „LL“ appears

whenever the solenoid fixed to the stir-

ring paddle has passed the proximity

switch six times. Appearing „LL“ on the

display, the lubrication cycle is being

completed fully. Afterwards, the control

unit does not switch the pump on auto-

matically any longer.

Pump Display

Failure in the power supply no indication

Power supply ON right segment

illuminated

Failure in the membrane key pad EP

Operating time elapses Rotating segment

Pump element does not dis-

pense Er

Reservoir empty LL

Pause time PP

Residual pause time rP

Lubrication point or divider valve

blocked Er

Leakage in the main line from

the pump to the monitored di-

vider valve

Er

Air entrapments in the grease Er

Failure in one lube cycle (de-

pending on the installation of the

monitored divider valve)

Er

Mode of Operation

Pump elements with fixed lubrication output

20002068

Fig. 6 Pump element, sectional drawing

1 - Piston

2 - Return spring

3 - Check valve

The electric motor drives the eccentric (pos. 1, fig. 7-8,

page 12).

During the operating time:

- piston (pos. 2) sucks in lubricant from the reservoir (re-

fer to fig. 7).

- piston 2 dispenses the lubricant to the connected lubri-

cation points via the metering device (see fig. 8).

The following designs are available:

Piston diameter, K5 ................................................. 5 mm

Lubricant output ................................... approx. 2 cm³/min

Piston diameter, K6 (Standard) ............................... 6 mm

Lubricant output ................................ approx. 2,8 cm³/min

Piston diameter, K7 ................................................. 7 mm

Lubricant output ................................... approx. 4 cm³/min

Tightening torques ................................................... 25

Nm

Page 12 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Pump elements with fixed lubrication output, continuation

1003a95

Fig. 7 The pump element sucks in lubricant

1004a95

Fig. 8 The pump element dispenses lubricant

1 - Eccentric 2 - Piston 3 - Spring 4 - Check valve

Pump element B7 with bypass check valve

6251b04

Fig. 9 Pump element B7

6250b04

Fig. 10 Sectional diagram - pump element B7

Pump element B7 suits especially applications in con-

taminated environments as the supplied lubricant is pass-

ing through a bypass bore (pos. 2) on the check valve

(Pos. 1).

The output is 2 cm³/min.

1 - Check valve

2 - Bypass

3 - Pump piston

4 - Return spring

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 13 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Pump elements with fixed lubrication output, continuation

Check valve

1164b95

Fig. 11 Hydraulic diagram of the pump

1 - Reservoir with stirring paddle

2 - Pump

3 - Check valve, spring-loaded

4 - Pressure relief valve

R - Return line

p - Pressure line

The check valve

- closes the pressure line during suction stroke.

- prevents the lubricant from flowing back to the housing

or reservoir.

Arrangement of the pump elements

1163a95

Fig. 12 Arrangement of the pump elements

If several pump elements are to be installed, the installa-

tion arrangement shown in Fig. 12 must be adhered to.

If there is only one pump element, it can be installed in

any position. Standard position is no. 3.

If there are two elements, install one in position 3 and the

other in position 1.

Pump elements with adjustable lubricant output

4158a99

Fig. 13 Adjustable pump element

The mode of operation (suction and supply phase) is the

same as that of the pump elements with an invariable lu-

bricant output.

Lubricant outputs are adjustable from 0.04 to

0.18m3/stroke, or 0.7 to 3cm3/min.

The pump elements are factory-set to the maximum lubri-

cant output; the adjusting dimensions “S” should be

29 ± 0.1 mm (see fig. 14, page 14).

Page 14 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Pump elements with adjustable lubricant output, continuation

4159a98

Fig. 14 Sectional view: adjustable element

1 - adjusting spindle SW 16

(SW ~ with over flats)

2 - counternut SW 24

3 - pump element body

4 - gasket

5 - pump cylinder

6 - control piston

7 - delivery piston

S - setting dimension

Setting of adjustable pump elements

Unscrew the coupling nut for fixing the pressure relief

valve.

Loosen counter nut (pos.21)) while holding in position

pump element body (pos.3) by means of a second

wrench.

Change the position of the adjusting spindle (pos.1) by

means of a wrench, see supply diagram (fig. 13).

The dimension “S” (fig. 14) for the desired lubricant output

can be ascertained by using the supply diagram (fig. 15).

1) All indications of positions refer to fig. 14.

Retrofit adjustment of min. lubricant output

Before the pump element can be adjusted to a small lubri-

cant output, the dimension “S” for max lubricant output

must be ascertained, and the difference from the nominal

value 29 must be transferred to any desired settings be-

tween 25.5 ... 28.5.

Dimension “S” must be adjusted to the desired value in

accordance with the delivery diagram (fig. 15).

6001a02

NOTE

At maximum setting “S“ is 29 ±0.1 mm.

4179a99

Fig. 15 Supply diagram

A - Lubricant output cm3/min

B - Lubricant output cm3/stroke

S - Setting dimension

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 15 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Setting of adjustable pump elements, continuation

Retrofit adjustment of max. lubricant output

6001a02

NOTE

In order to ensure that the lubricant out-

put setting will be as exact as possible,

first the actual dimensions “S” of the

max. lubricant output must be ascer-

tained as follows. The measured differ-

ence from the nominal value 29 must be

considered for all other settings values

(e.g. ± 0.1).

Unscrew the adjusting spindle (pos.11)) from the pump

element body (pos.3) until “S” is approx. 30 mm.

Screw counter nut (Pos.2) onto stop collar of the adjusting

spindle (pos.1).

Screw adjusting spindle (pos.1) with counter nut (pos.2)

into pump element body (pos.3) until stop.

1) All indications of positions refer to fig. 14, page 14.

Pressure Relief Valve

10022618a

Fig. 16 Pressure relief valve

6001a02

IMPORTANT

Each pump element must be secured

with a pressure-limiting valve.

The pressure relief valve is not contained

in the scope of supply of the pumps 223,

233. Therefore it is to be ordered sepa-

rately (see Spare Parts Catalogue).

without grease return

The pressure relief valve

- limits the pressure build-up in the system.

- opens, if the specific overpressure is reached.

- is to be selected according to the requirements to the

lubrication plant (see different opening pressures; 200,

270, 350 bar).

If lubricant is leaking at the pressure relief valve, this indi-

cates that the system is malfunctioning.

Despite existing fault monitoring devices a regular visual

and function control must be carried out on the lubrication

system.

6001a02

NOTE

Between a malfunction (blockage) and the

following fault indication (lubricant leak-

age; monitoring intermittent LED display)

there may be a longer time delay.

The duration of the delay depends on the

type and length of the lines, the type of

lubricant, the ambient temperature and

other influences.

6336b04

Fig. 17 Pressure relief valve with grease return

with grease return (optional)

If the system is blocked, grease will leak from the pres-

sure relief valve. This grease quantity is returned to the

reservoir.

Page 16 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

00002629a

Fig. 18 Fault indication in the case of a blockage

Pressure relief valve with grease return (optional),

continuation

Fault indication

In the case of a blockage in the system, the grease

pushes out the red pin at the pressure relief valve, thus

indicating that there is a fault.

10032618

Fig. 19 Return line connection

Return Line Connection

The lubricant quantities, which cannot be dispensed by

the metering device, must be returned to the pump via the

return line connection.

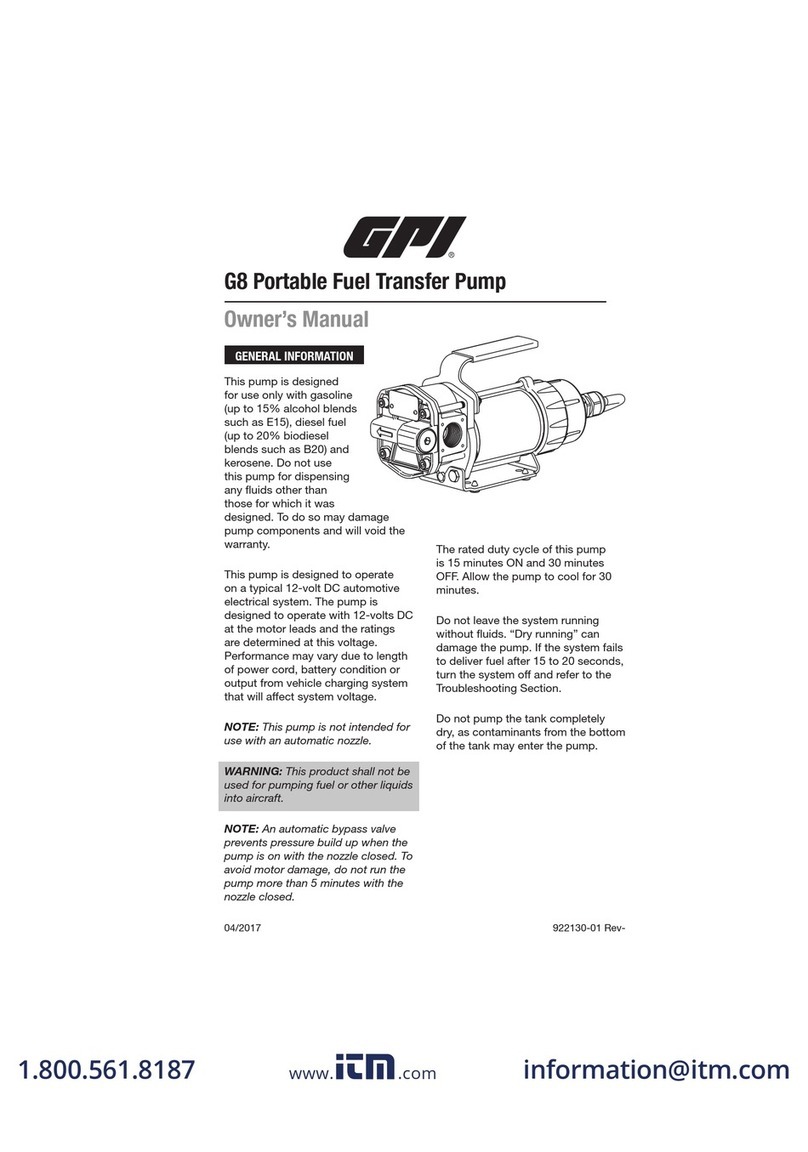

Control p.c.b. with or without data memory

1059a95

Fig. 20 Time sequence diagram

tB- working hours T - lubrication cycle

tP- individual pause time T1 - stored pause time

T2 - operating times

The control p.c.b. controls the sequence of the pause and

operating times of the 223 and 233 centralized lubrication

pumps as a function of the vehicle or machine working

hours tB(see fig. 20).

The sequence of the pause and operating times is acti-

vated when the machine contact or driving switch is

switched on, i.e. the centralized lubrication pump is ready

for operation.

A lubrication cycle consists of one pause time and one

operating time. Once the pause time has elapsed, the op-

erating time starts to run. This lubrication cycle is re-

peated permanently after the machine or vehicle has been

put into operation.

During the operating time the pump element dispenses

the lubricant to the lubrication points via progressive me-

tering devices.

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 17 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Control p.c.b. with or without data memory, continuation

Pause time

4205a01

Fig. 21 Schema of the centralized lubrication pump

1 - low-level control 4 - control p.c.b.

2 - piston detector 5 - pump

3 - membrane key pad 6 - divider block model SSV N

Factory setting of the pause time ....................... 6 hours

The pause time

- determines the frequency of the lubrication cycles within

a working cycle.

- is started and stopped with the power supply via the

machine contact or the driving switch.

- is adjustable

When the machine contact ort he driving switch is

switched off, the pause times which have already elapse

are stored and added up by an electronic data memory

(EEPROM) until the time which has been set on the

membrane key pad is reached.

After the machine contact or driving switch is switched on

again, the control p.c.b. operates from the point where it

had been interrupted.

If the setting is modified within the pause time, the control

p.c.b. takes over the new value automatically on comple-

tion of the programming procedure (see paragraph “Pro-

gramming Mode”, page 26).

The pause time setting may be different for each applica-

tion. It must be adjusted in accordance with the respective

lubrication cycle (see paragraph “Programming Mode”,

page 26).

Operating time

0002634

Fig. 22 Divider block SSV 6 with piston detector

The operating time depends on the system’s lubricant

requirement and on the location of the piston detector (ei-

ther on the main metering device or on the secondary me-

tering device).

A piston detector (initiator) which has been installed on a

metering device instead of a piston closure plug, monitors

and brings he pump operating time to a close after all the

pistons of this metering device have dispensed their lubri-

cant quantity once.

During the pump operating time a circulating segment

appears in the display of the membrane keypad (see

paragraph “Display of the membrane key pad, page 18).

After an interruption of the operating time, e.g. by switch-

ing off the power supply, the operating time continues

from the point where it had been interrupted.

When the machine contact ort he driving switch is

switched off, the pause times, which have already

elapsed, are stored and added up by an electronic data

memory (EEPROM) until the piston detector stops the op-

erating time.

Monitoring time

6001a02

NOTE

Only one lubrication cycle can be moni-

tored.

NOTE

Normally, the monitoring time ends at the

same time as the operating time.

A fixed monitoring time of a maximum of 30 minutes runs

in parallel to the operating time.

If there is no switching off signal from the piston detector

(fig. 22) to the control p.c.b. within 30 minutes a fault sig-

nal will occur (see paragraph “Display of the membrane

key pad”, page 18).

An external signal lamp flashes continuously in case of a

fault.

Page 18 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Membrane keypad

4360a04

Fig. 23 P223 membrane keypad

4360a01

Fig. 24 P233 membrane keypad with display and reading window

1 - Display 2 - Key for acknowledgment of fault

indications and setting of time (shift

key)

3 - Reading window for

”QuickData“ 4 - Key for triggering an addi-

tional lubrication and for

setting the time values

(setting key)

Display of the membrane keypad

4208a04

Fig. 25 Green segment, pause time, voltage applied

As soon as voltage is applied (On), the lower right-hand

segment in the display window flashes (pause time runs).

If the power supply is interrupted during the pause time,

after switching it on again, the pause time continues at the

point of interruption.

4209a99

Fig. 26 Green circulating illuminated segment, operating time

During the operating time of the pump, a circulating illumi-

nated segment appears in the display window of the

membrane keypad.

If the power supply is interrupted during the operating

time, after switching it on again, the operating time contin-

ues at the point of interruption.

Low-level control

6262b04

6263b04

6264b04

Fig. 27 Announcement of a low-level indication

In the display mode, a low-level is announced by an

intermittent display of * L8 *,* L7 *, * L6 *, … * L1 *.

Finally the intermittent * LL * appears for a low-level

indication that had not been confirmed (see fig. 28,

page 19).

Subject to modifications

User Manual

OperationInstructions

2.1A-30008-A04

Page 19 of 48

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Display of the membrane keypad, continuation

Monitoring time / Malfunction

4211a99

4210a99

Fig. 28 Display of an low-level indication or malfunction

If there is no feedback from the piston detector (initiator)

within 30 minutes (monitoring time) from completion of

the pause time or from triggering an additional lubrication,

the jump switches off immediately. One of the fault signals

* Er * (Error) or * LL * (Low-Level) is displayed as a flash-

ing light in the display of the membrane keypad.

6001a02

IMPORTANT

If a malfunction * Er * or low-level indica-

tion * LL * is present, the pump does not

switch on automatically any longer.

Operator keys of the membrane keypad

Operator keys of the membrane keypad in the display mode

< 2 sec.

4214a99

Fig. 29 Acknowledging receipt of a flashing low-level or fault

indication

Acknowledging receipt of a

low-level indication / malfunction

By pressing the key (fig. 26, < 2 sec.) the flashing * Er *

changes into a permanent light.

Fault indications that have been confirmed but not been

remedied yet will flash again after switching the power

supply off and on again.

Operator keys of the membrane keypad in the operating mode

> 2 sec.

4222a99

Fig. 30 Operator key to trigger an additional lubrication cycle

6001a02

NOTE

External triggering of an additional lubrica-

tion cycle (see fig. 38, page 23).

Additional lubrication cycle

An additional lubrication cycle is triggered via the button

(fig. 30). Press the button for 2 seconds.

It can be initiated at any time, provided that the power

supply is applied.

If a fault signal (malfunction) is present, it will be cancelled

as soon as the system is operating properly, again.

6001a02

NOTE

If a malfunction is present (flashing dis-

play * ER *), it can be acknowledged

before triggering an additional lubrication

cycle (see fig. 29). However, this is not

compelling.

> 2 sec.

4214a99

Fig. 31 Information regarding the set pause time and residual

pause time

Display of information regarding the set pause time and

residual pause time

Press key > 2 seconds.

Page 20 of 48

User Manual

OperationInstructions

Subject to modifications

2.1A-30008-A04

LINCOLN GmbH & Co. KG • Postfach 1263 • D-69183 Walldorf • Tel +49 (6227) 33-0 • Fax +49 (6227) 33-259

Mode of Operation, continuation

Operator keys of the membrane keypad

Operator keys of the keypad in the programming mode

4222a99

Fig. 32 Settings in the programming mode

Reset of the pause time

Setting of the pause time by

- single key activation for one hour/ minute

- permanent activation for quick run

Settings of the monitoring relay

How to set the metering device cycles:

The monitoring relay signalizes a malfunction over an

external lamp Lampe via the optional connection “X2“

(see connection diagrams).

In case of the standard setting “normally open contact

(NO)“ a malfunction is signalized by a permanently lit

lamp.

In case of the standard setting “normally closed contact

(NC)” the malfunction is signalized by a lamp that stopped

burning.

For VDC version ……………………………. 1 to 5 cycles

Termination of the programming mode

Terminate the programming mode.

4222a99

4214a99

4214a99

Fig. 33 Changing to the different programming levels

1. Changing to the different programming levels

Press key to change into the programming mode.

Settings: hours ……………………………. P1

minutes …………………………….. P2

metering device cycles………… P3

output potential-free contact …. P4

Termination of programming

Monitoring relay

The monitoring relay signalizes a malfunction (only in

combination with optional connector “X2”; see electrical

connection diagrams pages 39 ff).

In the first case the relay picks up (normally open con-

tact).

In the second case the relay releases (normally closed

contact, broken-wire interlock).

The signal is available via a potential free contact.

When the fault indication is confirmed, the relay releases.

The flashing display changes into a permanent display.

This manual suits for next models

1

Table of contents