FLUIDX W2V10 User manual

USER MANUAL

HIGH VACUUM ROTARY VANE PUMPS

W2V10 W2V20

W2V80

W2V40

W2V160

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

1. Introduction………………….....………………………………… 1

1.1 Safety Precautions

1.2 Description of W2V Pumps

2. Installation..…………………….....……………………………… 7

2.1 Unpack and Inspect

2.2 Location

2.3 Mechanical connection

2.3.1 Inlet connection

2.3.2 Outlet connection

2.4 Electrical connection

3. Operation..………………………….....………………………… 10

3.1 Gas-ballast control

3.2 Start-up procedure

3.3 Decontamination of oil

3.3.1 Checking the oil-level

3.3.2 Oil change

3.4 Switching Off/Shut down

4. Maintenance…………………………….....…………………… 12

4.1 Safety Guide

4.2 Maintenance Frequency

4.3 Maintenance of oil

4.4 Cleaning the Dirt trap

4.5 Storage and Disposal

5. Trouble Shooting………………………….....………………… 17

6. Technical Data.……………………………….....……………… 18

6.1 Dimensions of W2V10

6.2 Development gure of W2V10

6.3 Part List (BOM LIST : W2V10)

7. Service & Accessories....………………………….....………… 39

7.1 Service kit (Major Kit / Minor Kit)

7.2 Accessories List

CONTENTS

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

1. INTRODUCTION 1. INTRODUCTION

1.1 Safety precautions

Read and followbelowinstructions before you install and operate the pump.

* Notices for safe use :

Do not pump corrosive or explosive gases.

As the pump’sdrivingprinciple, you cannot pump the gases which are explosivewhen

compressed.

The standard W2V-series pumps are not designedtopreventcorrosion.

In case of pumpingstrongcorrosive gases, please contact our technical sales dept.

Do not use pump as compressor

Vacuum pump does not have any special design for withstanding inner pressure.

The accumulated pressure by compressed gases in exhaust line can break pump case,

therefore can cause both personal injury and property damage.

Do not operate the pumpswhereexplosiveprocesses are involved.

If you needto use explosion-proof motor, please contact our technical sales dept.

The pump mustbe installedandmanaged byqualifiedexpert.

Important safety information is highlighted as WARNING and CAUTION instructions.

WARNING

Indicates procedures that must be strictly observed

to preventpersonal injury.

CAUTION

Indicates procedures that must be strictly observed

to preventdamage to pump orsystem.

Additional safety information

Danger of

electric

shock

Danger of

hot

surface

Danger of

explosion

Danger of

cut/crush

W 2 V10 2

-

2 Stage Pump

10

-

100 ℓ/min (pumping speed)

20

-

200 ℓ/min (pumping speed)

40

-

400 ℓ/min (pumping speed)

80

- 8

00 ℓ/min (pumping speed)

160

-

1600 ℓ/min (pumping speed)

1.2 Description of W2V Pumps

PRODUCT CODE RULE

Pumping

Speed 100 ℓ/min

(6m

3

/h, 3.5CFM)

Ultimate Pressure

Gas Ballast Closed ≤ 1X10-3 torr ( 1.3 X 10-1 Pa)

Gas Ballast Open 5X10-2 torr ( 6.7 Pa )

Power

Input Options

Standard 220VAC 1Ф 50/60Hz

Options 220/380VAC 3Ф 50/60Hz

Customer’s Request (Voltage, Frequency, Phase)

Full

Load Power 0.4kW (0.5 HP)

Motor

Speed 1,700 rpm

Inlet and Outlet

Options

Standard NW25

Option IHose Nipple (Ф12, Ф16 or Ф26 OD)

Option II PT Nipple (1/4″, 3/8″, 1/2″, 3/4″, 1 ″)

Option III User Requested Type

Oil

Capacity 500 cc (0.5ℓ)

Weight

22.5 Kg(1Ф) / 19.2 Kg (3Ф)

Ambient

Temp 7~40°C / 45~104°F

Overall

Dimension (mm) 150(W) X 392(L) X 250(H)

W2V10

1

-Inlet end fitting 2 -Gas

ballast control

3 -Exhaust end fitting

4

-Oil filling-plug 5 -Oil drain-plug 6 -Oil level sight glass

7

-Oil case 8 -Electric motor 9 -Terminal box

1 2

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

1. INTRODUCTION

1

-Inlet end fitting 2 -Gas

ballast control

3 -Exhaust end fitting

4

-Oil filling-plug 5 -Oil drain-plug 6 -Oil level sight glass

7

-Oil case 8 -Electric motor 9 -Terminal box

1. INTRODUCTION

1

-Inlet end fitting 2 -Gas

ballast control

3 -Exhaust end fitting

4

-Oil filling-plug 5 -Oil drain-plug 6 -Oil level sight glass

7

-Oil case 8 -Electric motor 9 -Terminal box

Pumping

Speed 200 ℓ/min

(12m

3

/h, 7.1CFM)

Ultimate Pressure

Gas Ballast Closed ≤ 1X10-3 torr ( 1.3 X 10-1 Pa)

Gas Ballast Open 5X10-2 torr ( 6.7 Pa )

Power

Input Options

Standard 220VAC 1Ф 50/60Hz

Options 220/380VAC 3Ф 50/60Hz

Customer’s Request (Voltage, Frequency, Phase)

Full

Load Power 0.4kW (0.5 HP)

Motor

Speed 1,700 rpm

Inlet and Outlet

Options

Standard NW25

Option IHose Nipple (Ф12, Ф16 or Ф26 OD)

Option II PT Nipple (1/4″, 3/8″, 1/2″, 3/4″, 1 ″)

Option III User Requested Type

Oil

Capacity 600 cc (0.6ℓ)

Weight

23.3 Kg(1Ф) / 20 Kg(3Ф)

Ambient

Temp 7~40°C / 45~104°F

Overall

Dimension (mm) 150(W) X 423(L) X 250(H)

W2V20

Pumping

Speed 400 ℓ/min

(24m

3

/h, 14.1CFM)

Ultimate Pressure

Gas Ballast Closed ≤ 1X10-3 torr ( 1.3 X 10-1 Pa)

Gas Ballast Open 5X10-2 torr ( 6.7 Pa )

Power

Input Options

Standard 220VAC 1Ф 50/60Hz

Options 220/380VAC 3Ф 50/60Hz

Customer’s Request (Voltage, Frequency, Phase)

Full

Load Power 0.75kW (1 HP)

Motor

Speed 1,700 rpm

Inlet and Outlet

Options

Standard NW25

Option IHose Nipple (Ф12, Ф16 or Ф26 OD)

Option II PT Nipple (1/4″, 3/8″, 1/2″, 3/4″, 1 ″)

Option III User Requested Type

Oil

Capacity 1500 cc (1.5ℓ)

Weight

34.8 Kg(1Ф) / 31.6 Kg(3Ф)

Ambient

Temp 7~40°C / 45~104°F

Overall

Dimension (mm) 170(W) X 484(L) X 287(H)

W2V40

3 4

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

1. INTRODUCTION

1

-Inlet end fitting 2 -Gas

ballast control

3 -Exhaust end fitting

4

-Oil filling-plug 5 -Oil drain-plug 6 -Oil level sight glass

7

-Oil case 8 -Electric motor 9 -Terminal box

1. INTRODUCTION

1

-Inlet end fitting 2 -Gas

ballast control

3 -Exhaust end fitting

4

-Oil filling-plug 5 -Oil drain-plug 6 -Oil level sight glass

7

-Oil case 8 -Electric motor 9 -Terminal box

Pumping

Speed 800 ℓ/min

(48m

3

/h, 28.3CFM)

Ultimate Pressure

Gas Ballast Closed ≤ 1X10-3 torr ( 1.3 X 10-1 Pa)

Gas Ballast Open 5X10-2 torr ( 6.7 Pa )

Power

Input Options

Standard 220/380VAC 3Ф 50/60Hz

Options 220VAC 1Ф 50/60Hz

Customer’s Request (Voltage, Frequency, Phase)

Full

Load Power 1.5kW (2 HP)

Motor

Speed 1,700 rpm

Inlet and Outlet

Options

Standard NW40

*Change to NW25 available

Option I+ Hose Nipple (Ф36 OD) for NW40

Option II + PT Nipple :1&1/4″ for NW40

Option III User Requested Type

Oil

Capacity 2700 cc (2.7ℓ)

Weight

68.5 Kg (1Ф) / 65.1 Kg(3Ф)

Ambient

Temp 7~40°C / 45~104°F

Overall

Dimension (mm) 226(W) X 624(L) X 346(H)

W2V80

Pumping

Speed 1600 ℓ/min

(96m

3

/h, 56.5CFM)

Ultimate Pressure

Gas Ballast Closed ≤ 1X10-3 torr ( 1.3 X 10-1 Pa)

Gas Ballast Open 5X10-2 torr ( 6.7 Pa )

Power

Input Options

Standard 220/380VAC 3Ф 50/60Hz

Customer’s Request (Voltage, Frequency, Phase)

Full

Load Power 3.7kW (5HP)

Motor

Speed 1,700 rpm

Inlet and Outlet

Options

Standard NW40

Option I+ Hose Nipple (Ф36 OD) for NW40

Option II + PT Nipple :1&1/4″ for NW40

Option III User Requested Type

Oil

Capacity 6200 cc (6.2ℓ)

Weight

101.5 Kg(3Ф)

Ambient

Temp 7~40°C / 45~104°F

Overall

Dimension (mm) 264(W) X 777.5(L) X 442(H)

W2V160

5 6

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

2. INSTALLATION 2. INSTALLATION

2.3.1 Inlet port Connection

* Connection Tip : To achieve specifiedpumping speed, make the lengthof pipeline between

vacuum chamber and the pump as short as possible.Alsothe internal diameter ofthe pipeline is

at leastthe same as inlet port; the narrow inlet line can reduce pumpingspeed.

You can p rotect the p ump with applying proper accessories such as separators, filters and cooling

traps etc.between vacuum chamber and pump.However, the conductance val ue of the accessory

could cause areduction inpumpingspeed.

Connection

Connect the intake and exhaust lines with a clamp and centering each.

-Default : Connect to the NW25 flange suppliedonthe pump;use the clamp andcentering.

-Option 1 : The hose nipple canbe provided upon request. Applicableto vacuum hose.

(Ф 12 OD, Ф16 OD, Ф26 OD for NW25, Ф36 OD for NW40 available depending on hose size.)

-Option 2 : Screw nipple canbe used.Applicabletoscrewvalves etc.

(1/4″,3/8″,1/2″,3/4″, 1″for NW25, 1&1/4” for NW40; available depending on connecting devices.)

Inlet filters canbe installedfor very dusty applicationsorpumpingcondensable vapor.

Valve s can be used for isolating the pum p from the vacuum system;to maintain vacuum when the

pump isswitched off.Werecommend to install the Angle Valve.(refer section 7.2)

2.3.2 Outlet port Connection

WARNING

If the exhaust gases from the vacuumpump are harmful to human

body, these must be safely lead away and subjected to post-treatment

as required

* Connection Tip : Designing the exhaust line lower than the pump can prevent condensate

from flowing back into the pump.

Oil vapors can be discharged from the exhaust port in low vacuum section(760 Torr~10 Torr)

since the large amount of air is suckedinto the vacuum pump.In order toreduce the emissionof

oil vapors, we recommendthe installation of an additional exhaust filter (WSA oil misttrap : refer

section7.2)especiallywhenthe oil mistcannot be leadout by separate hood or duct system.

Contact WSA for the detailedinquiry.

Connection

Exhaust connecting options are the same asInlet Connection

*Connection Tip :Ensure that the internal diameter of the exhaust line is at least the same as outlet

port;the narrow exhaust l i ne can accumulate the inner pressure in the p ump and it can damage

the pump se als therefore cause oil leaks.The maximum pressure in the oil case m ust not exceed 1.5

bar (absolute).

CAUTION

If the temperature of the pump-body exceeds 70°C (158 °F),

you must fit suitable guards to prevent contact with hot surfaces.

7 8

1. Unpack and Inspect

Remove all packingmaterials and protectivecovers.

Leave the inlet and outlet lids on before connection of the pump.

(The pump issuppliedfilledwithoil.)

①Check the pump and accessories if they are the same type you have ordered.

②Check the oil level contained through the sight glass.

③Check the pump ifit has any sign of loose bolts,spiltoil, and broken/loose parts.

④Do not use the pump ifit is damaged;notify WSA withyour order and serialnumber.

2. Location

The pump canbe usedfree-standing on its baseplate.

To firmlyinstall the pump inplace,use bolts andfasten it to the ground or to a secure object

through holes in the baseplate.It is recommended to use anti-vibration pads betweenbase plate

and fixingsurface.

Locate the pump where youcan check the oil level sight-glass and access the controls including

oil filling-plug, oil drain-plug, and gas-ballast.

When installingthe pump ina closedhousing, make sure there is sufficient air circulation.

We use vacuum oil, ‘MR-200’ as our default vacuum oil and it isrecommended to use the pump

over 7 °C (45 °F)

WSA standard pump isnot suitedfor installationin explosion hazard areas.

If you needto apply the pump to such area, please contact us first.

2.3 Mechanical connection

Before connecting the WAS pump, remove the shipping seals from the inlet and exhaust

connection flanges. (WSA pumpsare sealedwithwhite PEseals for domestic and ocean transport

and metal blank clampedfor air shipmenttomaintainoil inside)

WSA pumpsare shippedwithoil contained inside, so take extra care not to spill it

Retain shipping seals in case you needto store the pump in the future.

Ensure that sealing surfaces are clean and scratch-free prior to assembly.

WARNING

Do not carry out any unauthorized conversions or

modifications on the pump

CAUTION

The pump should be set up on a flat, horizontal surface.

Ter m inal box should not to exposed to excessive moisture.

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

2. INSTALLATION 3. OPERATION

380V Connection

220V Connection

230V Connection

4 5 6

1 2 3

7 8 9

R S T

460V Connection

456

789

123

R S T

3.1 Gas-ballast control

The gas ballast introduces a small amount of air(or inert gas) during the compression stage in order

to adjust the saturationpressureof the vapor and it can prevent condensation of vapors in the

pump;the condensates cause contamination of the oil.

In general use,itisrecommended to use the pump with gas-ballastclosed.

Operating pump withGBcontrol openwill lower ultimate vacuum level and raise the temperature

of the pump body. Also it will increase the speed of oil loss from the pump.

3.2 Start-up procedure

GB control closed GB control open

to achieve ultimatevacuum to pump high concentrations of

condensable vapor

to pump dry gases to decontaminatethe oil

WARNING

Never operate the pump with a sealed exhaust line.

There is the danger of injury.

Ensure all vacuum connections are completely sealedbefore switch on the pump.

Operating pump withbeingexposed to normal pressureinlongperiodof time cancause serious

mechanical troubles.

Do not operate the pump with inlet port open. It would overload the pump andcause oil loss.

Neverexposeanypart of the body to the vacuum. It mightcause personal injury.

* In case of Emergencystop or Power failure

There is no need of a particular procedureto prevent from loosing vacuum incase ofan emergency

stop or power failure.

The oil regulator builtinside ofthe pump prevents Back-Flow of oil when the pump stops.

However,it ismore recommendedtovent the inlet side of the pump ifit stops accidentally.

Procedure

①Check that the pump oil-level is between the H and L marks through the oil-levelsight-

glass; if it is not, refer to sec 4.3 (Neveroperate the pump with the oil level belowLmark.)

②Turn the gas-ballastcontrol to the requiredposition if you pump condensable vapor.

③Switch on the electricalsupply to the pump.

④For 3 phase pump,check the direction of rotation of the motor.

When starting-up ap um p after prolonged storage period, the actual vacuum level might not be

able to reach to the ultimate pressure, specified on the p ump .It is ge nerall y because of the

contaminationof the oil inside.Replacewith new vacuum oil.

9 10

(Fig) Examples of 3 phase power connection

380V, 460Vat 3phase :high voltage connection /220V, 230Vat 3phase :low voltage connection.

④After wiring the motor, c he ck its direction of rotati on by ope rati ng the pum p for short time(2~3

sec) before connecting the pump to your vacuum system.If the rotation is the opposite to the

direction of the arrow on the motor cap, change the c ode s from outside (e x. 1 2 3 -> 1 3 2) and

checkthe directionagain.

Depending on the type of applicationorthe kind of pumpedmedia,the corresponding regulations

and informationsheets must be observed.

2.4 Electrical connection

If you don’t haveknowledge of 3 phase power connection, please inquire of WSA.

WSA can notbe responsible for any trouble caused by electrical connection.

* For 1 phase pump,no specificconnection process is needed.

Simplyconnect the plugto the power.

Connection (3 phase)

①Open the cover of terminal box.You cansee 6 or 9 electriccords needto be connected.

②For 3 phase motor, 3 external power cords and 1 extra electric cord to earth shouldbe supplied.

③With referringto the diagram on the back of terminal c ove r, connect the motor to the power.

WARNING

ELB(Earth leakage breaker) must be installed to prevent electrical accident.

Electrical connections for 3 phase must be done by a qualifiedelectrician.

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

4. MAINTENANCE3. OPERATION

When the pump hasbeenpumpingcorrosivemedia,we recommend to perform any possibly

planned maintenance work immediately in order to prevent corrosion of the pump.

After maintenance is completed and reconnect the power of 3 phase pump,

recheckthe pump rotation direction.

Do not reuse o-ring and seals if they are damaged.

4.2 Maintenance Frequency

The plan shown in the below Table details the r outi ne maintenance op e rati ons necessary to

maintainthe pump innormal use.

More frequent m ai nte nance may be required if the pump is used to p rocess corrosive or ab rasive

gases and vapors;in these circumstances, we recommend that you replace the p um p seals every

year.Ifnecessary, adjust the maintenance planaccordingto your experience.

When you maintainthe pump, use WAS spares and service kits;

there contain all of the components necessary to complete maintenance operations successfully.

The Item Numbers of the spares and kits are given in Section 7.1.

*WSA provides 2kinds of Service kits(Repair kits)

‘Minor Repair Kit is for the general use for overhaul and consists of various metal andrubber

parts. It contains mainly disposable parts which need to be periodicallyreplaced.

‘Major Repair Kit contains major parts(ex.vanes) which should be replacedfor repair process in

addition to all Minor parts.(refer sec 7.1)

4.1 Safety Guide

WARNING

Obey the safety instruction given below.

If you do not, you can cause personal injury and property damage

Allowthe pump to cool to a safe temperaturebeforeyoustart maintenance work.

WARNING

Disconnect the electrical connection before disassembling the pump.

Make absolutely sure that the pump cannot be accidentally started.

(pull the main plug)

A suitablytrained and supervised technician must maintainthe pump.

Obey your local and national safety requirements.

If the pump haspumpedharmful substances, ascertain the nature of hazard and take adequate

safetymeasures.

CAUTION

When disposing of used oil,

you must observe the applicable environmental regulation.

11 12

3. Decontamination of Oil

As the oil is gradually contaminatedduring operation by dissolved gases and vapors, the degas

process is necessary to prevent corrosion of the pump.Allowthe pump to continue operating with

inlet port closedand gas ballast control open until the oil is free of condensed vapors.

It is recommendedtoleave the pump being operating inthis mode for about 30 min after finishing

the process. To attain the ultimate pressure, close the gas ballast after this process.

4. SwitchingOff &Shutdown

You cansimplyswitch off to stop the pump,under normal circumstances.

* When motor is switched off while the gas ballast is open, the system pressurecan be risen slowly.

(Close the gas ballast to maintain vacuum level.)

If the pump is to be shutdown for an extendedperiodafterpumpingaggressive or corrosive media

or if the pump has to be stored, proceed as follows;

①Drain the oil through oil drain-plug.

②Add cleanoil until the oil-level is at the H mark and let the pump operate for some time.

③Drain the oil again and add clean oil until the oil level is at the H mark.

④Seal the connection ports.

WARNING

When pumping harmful substance, take adequate safety precautions.

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

4. MAINTENANCE 4. MAINTENANCE

4.3 Maintenanceof oil

4.3.1 Checking the oil-level

During operati on of the pump, the oil level must al ways remain between marks Hand Lon the oil-

level glass.The amount of oil must be checkedand toppedup as required.

Note :The p ump must be s witc he d off before topping up the oil.It is recommended to p ower off

other components connected to pump for safety reason.

If gases of liquids dissolved in the oil re sult in adeterioration of the ultimate pressure, the oil can be

degassed by allowi ng the p ump to run for approx.30 min.wi th the i nt ake port closed and the gas

ballastvalve open.

Replace the oil 2,500 operation hours

Inspect and clean the inlet-filter Every oil change

Clean or replace the gas-ballast o-ring Every oil change

Clean the motor fan-cover Yearly

Clean and overhaul the pump 15,000 operation hours

Fit new blades 30,000 operation hours

Test the motor condition 15,000 operation hours

Oil change

Frequency

Application Frequency(hrs)

High

Vacuum in Lab environment, or system seldom exposed to the air 2,500

High

Vacuum in manufacturing environment, often exposed to the air 1,200

Vacuum

furnace, large gas-exhaust diffusion system, system with booster pump 600

Vacuum drier,

vacuum molding, vacuum packing 200

Vacuum

distillation, low vacuum tank 120

Overhaul is a process of dismantlementthe pump,cleaningall parts and reassembling.

It ishighly importantto improve the performance and elongate lifetime of the pump.

WSA recommendsusers to do overhaul at leasteveryother year.

Maintenance Frequency

Operation Frequency

Check the oil-level Daily

4.3.2 Oil change

For proper operation of the pump,itisessentialthat the pump has an adequate supply ofthe

correct and clean oil at all times.

Clean vacuum oil isbasicallyodorlessandtransparent. (MR-200 ha s pale yellow color.)

As operatingpumps, the color of vacuum oil turns from yellow through orange into red brown.

This discoloration is causedby gases and foreign materials pumped in and this mixture would

impairsthe vacuum level anddamage the interior of pump.

Change vacuum oil when discoloration is dark yellow to red brown. (4 in above pictu re.)

When the color reach 6~7 with deterioration, the interior of pump woul d be damaged and

overhaul process is necessarybefore operating the pump again.

If the vacuum oil becomes cloudyasmilkcolor,it is causedbymoisture flowed in.

In this case, stop the pump and wait until the fluid is divided into two layers; vacuum oil and water.

Then drain the water layer completely throughoil drain plug.

Design the process so as moisture not to be pumpedinand install a coldtrap if necessary.

Before and after a prolonged storage, additional change of oil is required.

If the speedof deterioration of oil is too fast, applydustfilter or oil filter tothe pump.

(refer to sec 7.4 : WMT-250/400)

Contact WSA for further information.

Caution

Only change the oil after the pump has been switched off and

while the pump is still warm..

Procedure

①Remove the oil-drainplugandletthe used oil drain into a suitable container.

②When the flow of oil slows down, screw the oil-drainplugbackin,brieflyswitchon the pump

(max. 10 sec) and then switch it off again. Remove the oil-drainplugonce more and drain out the

remainingoil.

③Screw the oil-drain plug back in (check the gasket and reinstall a new one if necessary.)

④Remove the oil-fill plugandfill in with fresh oil.

⑤Screw the oil-fill plugbackin.

* Recommended Vacuum oil : NEOVAC MR 200

Caution

We can only guarantee that the pump operates as specified by the

technical data if the vacuumoil recommended by us is used.

13 14

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

4. MAINTENANCE 4. MAINTENANCE

The ultimate pressure is determined by the saturationvapor pressure, viscosity andsolubilityof

gases of the vacuum oil used.

Use suitable vacuum oil for the pump.

* MSDS report of MR-200 is available to download on WSA web site.

(http://www.wsavac.com/eng/sub/products/accessories.asp#)

NEO VAC MR-200 (Moresco corp.)

Color (ASTM) bright yellow (L0.5)

Pour point -17.5°C

Boiling point 195°C / 0.1 Torr

Flash point 256°C min. (COC)

Viscosity 71.0 (40°C, mm2 /sec(cSt))

Vapor pressure 1 X 10-5 (50°C)

4.4 Cleaning the Dirt Trap

WSA pump hasdirt trap in the inlet port; a wire mesh structure which is designedtosieve coarse

particles.To keep the pumpingspeedasspecified,the dirt trap shouldbe cleanedup regularly.

Take out the dirt trap from the inlet port and rinse itin a suitable container with sol vent

Dry it completelywith compressed air.

Check the status of dirt trap and replaceitifdamaged.

Caution

The cleaning intervals depend on the application.If the pump is exposed to

large amounts of abrasivematerials, a dust filter should be fitted into the

intake line.

4.5 Storage and Disposal

When a pump is put into operation after over one year of storage, standardmaintenance shouldbe

run on the pump and the oil should also be exchanged.

4.5.2 Disposal

Dispose of the pump,the oil and any components removed from the pump safely in accordance

withall local and national safety and environmental requirements.

Take particular care with the following:

-Components which have come into contact with the vacuum oil.

-Components which have been contaminated with dangerous process substances.

* Do not incinerate fluoroelastomerseals and o-rings. (eg.viton)

15 16

Caution

Observe the storage temperature: -30~70 °C (-22~158 °F)

Storagebelow -30°C (-22°F) will permanently damage the pump seals.

4.5.1 Storage

The pump shouldbe stored in a dry place preferablyat room temperature20 °C (68 °F).

All other components and connections to vacuum system must be properly removed and purged

the pump with dry nitrogen if possible.

The used oil should be changed to prevent corrosion during the idle period. (refer 3.4)

The inlets and outlets of the pump must be sealed.(Use the seals provided upon delivery.)

The gas ballast switch must be tightly closed and it is recommended to put the pump in aPE bag

withsilicagel(desiccant) for prolonged storage.

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

5. TROUBLE SHOOTING 6. TECHNICAL DATA

Symtom Possible cause Corrective actions

The motor is noisy

and does not rotate

voltage ofpowerand

connection.

Correctvoltage or its

connections.

Any foreignmaterialinthe

pump.

Removethe

substanceand/orchangeoil.

Motor

(Openinternalcircuit)

Replaceopen

windings.

The pump isn oisy

and over-heated.

Any foreignmaterialblocks the

exhaust

valve.

Removethe foreign

material.

Leakageinthe

system

Fine the partandfix the

leakage.

If leakagevalve is

opne

Closethe

valve.

All valves in the vacuum

line

Closeiffound

open.

Vacuumlevel

drops

continuously.

Lowoil

level

Top

vacuum oilup.

Leakageonthe

connecteddevice

Closetheintakeand

recheck.

Condensed

moistureinoil

Change

oil.

Oil regulator

failure

Replacetheoil

regulator.

Gas ballast

open

Closethegas

ballast.

Motor rotates but

pump doesn’t run.

Worn

outcoupling

Replacecoupling

parts.

Worn

outkey betweenmotorandpump

Replacethekey and set

screws

Any foreignmaterialblocks the

pump

Overhaul the

pump

The pump fails

to start

Status

of connectedvoltage

Align the voltage with motor

specification.

Wiringis

malfunctioning

Checkand repair

wiring.

Too

viscous oil.

Userecommendedoilandchange

if

contaminated.

Oil temperatureis below

7°C

Warm

upthe pumpandoil.

Any foreignmaterial

blocked

Overhaul the

pump.

Motor is

malfuncioning

Overhaul or replacethe

motor.

Failure to reach

ultimate vacuum

Leakageinthe

system

Do leak

test.

Measurementrangeofthe

gauge

Usesuitablegaugeforthevacuum

level.

Incorrectway ofmeasuring

vacuum

learnhowto usethegauge

correctly.

Type

ofoil or contaminationlevel

Userecommendedoilandchangeit

if

contaminated.

Valve

failure

Repairor replacethe

valve

Insufficientpump

capacity

Replacethepumpwithsufficient

capacity.

Pumping speed is

too slow

Contaminationofdirt

trap

Cleanor replacethedirt

trap.

Designofpiping

system.

Make the

connectedpipes biggerthan

pumpandhave minimum

length.

6.1 Dimensions ofW2V10

17 18

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

6.2 Development figure ofW2V10

6.1 Dimensions of W2V20

19 20

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

6.2 Development gure of W2V20 6.1 Dimensions of W2V40

21 22

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

6.2 Development gure of W2V40 6.1 Dimensions of W2V80

23 24

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

6.2 Development gure of W2V80 6.1 Dimensions of W2V160

주

WSA

16

0

㎌ ㎌

MOTOR

2.2Kw

25 26

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

Parts List (BOM LIST: W2V10) Parts List (BOM LIST: W2V10)

Part

No. Code No. Description Specification Qty

241

WPRE024101YW

SIDE

COVER (WSA)

ABS(YELLOW)

2

301

WPMI03010100

1ST

STAGE STATOR

FC

-25 1

302

WPMC03022100

TAPER

PIN

Ø5.9 X Ø6.5 X

7 2

303

WPRV03030700

OIL

SEAL(for block)

Ø25/35 X

7 1

304

WPMI03041300

VALVE

GUIDE PIN(SPRING PIN)

Ø3 X

20 2

305

WPRV03050100

1ST

STAGE VALVE

24 X 36 X

2t(VITON) 1

306

WPMI03060100

1ST

VALVE BACK PLATE

25 X 36 X

1.6t 1

307

WPMS03071300

1ST

VALVE SPACER

Ø8/6.3 X

13(SUS) 1

311

WPMI03111300

1ST

VALVE SPRING

W1 X Φ9/11 X

15.5L 1

312

WPMSW5N0000

WASHER

Ø5(SUS

FLAT) 1

313

WPMIM5X22HN

BOLT

M5 X

22 1

314

WPRSP6000000

DISTRIBUTER SLEEVE

O-Ring

P

-6(SILICON) 2

315

WPME03152100

DISTRIBUTER SLEEVE

ASSEMBLY 1

319

WPRV03192100

DISTRIBUTER

VALVE

Ø45 X 9 X

1.5(VITON) 1

320

WPMI03202101

DISTRIBRTER

SPACER

Ø15 X 16(S45C,NEW

TYPE) 1

321

WPMC03212100

DISTRIBUTER

WEIGHT

Ø44 X

4.7t 1

322

WPMI03222100

DISTRIBUTER

SPRING

W0.6 X Ø8.3/9.5 X

17L 1

323

WPMA03232100

DISTRIBUTER

CAP

Ø50 X

20 1

324

WPMA03242100

TUBE

FITTING

Ø8 x

1/8”PC 1

325

WPRE03250100

HOSE

73MM

1

327

WPMIM5X50HN

BOLT

M5 X

50 1

328

WPMI03280300

OIL

FILTER ASSEMBLY 1

332

WPMI03320300

OIL

FILTER FIXTURE

t2.0(PRESS)

1

333

WPMIM4X8HN0

BOLT

M4 X

8 2

335

WPRSS8000000

O

-RING

S

-80(SILICON) 1

336

WPMI03360100

1ST

VALVE OIL BAFFLE

52 X 46 X

1.2t 1

337

WPMIM4X8HN0

BOLT

M4 X

8 2

338

WPMIM6X25HN

BOLT

M6 X

25 3

401

WPMI04010100

ROTOR

ASSEMBLY(NEW TYPE)

FCD

-64 1

409

WPMI04090700

KEY

5 X 5 X 11 X

17.5L 1

410

WPME04100700

OIL PUMP

BLADE

8 X 6 X

21 1

411

WPME04110100

1ST

STAGE BLADE

25 X 32 X 6t(ROUND

28x70x6.5) 2

412

WPMS04122100

1ST

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS) 2

413

WPMI04132100

1ST

STAGE BLADE SPRING GUIDE

Ø1.8/3 X

26(Ø2/3 x26) 2

414

WPME04140100

2ND

STAGE BLADE

22 X 22 X 6t(ROUND

25x50x6.5) 2

415

WPMS04152100

2ND

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS) 2

416

WPMI04162100

2ND

STAGE BLADE SPRING

Ø1.8/3 X

26(Ø2/3 x26) 2

501

WPMI05010100

2ND

STAGE STATOR

FC

-25(Φ49x42t) 1

502

WPMI05022100

VALVE

GUIDE PIN (spring pin)

Ø3 X

20 2

503

WPRV05032100

2ND

STAGE VALVE

Ø14.5 X

7(VITON) 1

504

WPMI05042100

2ND

VALVE SPRING

W0.6 X Ø7.3/8.5 X

17L 1

506

WPMI05060300

SPRING

SUPPORT(for 2nd valve)

DIECAST(SMALL)

1

507

WPMIW5G00000

WASHER

Ø5(GEAR,

SPRING) 1

508

WPMIM5X20HN

BOLT

M5 X

20 1

509

WPRSP6000000

O

-RING

P

-6(SILICON) 1

510

WPMI05102100

TAPER

PIN(ONE SCREW)

Ø7 X

25L(M6) 2

511

WPMIM6000000

NUT

M6

2

512

WPMIM6X25HN

BOLT

M6 X

25 5

Part

No. Code No. Description Specification Qty

241

WPRE024101YW

SIDE

COVER (WSA)

ABS(YELLOW)

2

301

WPMI03010100

1ST

STAGE STATOR

FC

-25 1

302

WPMC03022100

TAPER

PIN

Ø5.9 X Ø6.5 X

7 2

303

WPRV03030700

OIL

SEAL(for block)

Ø25/35 X

7 1

304

WPMI03041300

VALVE

GUIDE PIN(SPRING PIN)

Ø3 X

20 2

305

WPRV03050100

1ST

STAGE VALVE

24 X 36 X

2t(VITON) 1

306

WPMI03060100

1ST

VALVE BACK PLATE

25 X 36 X

1.6t 1

307

WPMS03071300

1ST

VALVE SPACER

Ø8/6.3 X

13(SUS) 1

311

WPMI03111300

1ST

VALVE SPRING

W1 X Φ9/11 X

15.5L 1

312

WPMSW5N0000

WASHER

Ø5(SUS

FLAT) 1

313

WPMIM5X22HN

BOLT

M5 X

22 1

314

WPRSP6000000

DISTRIBUTER SLEEVE

O-Ring

P

-6(SILICON) 2

315

WPME03152100

DISTRIBUTER SLEEVE

ASSEMBLY 1

319

WPRV03192100

DISTRIBUTER

VALVE

Ø45 X 9 X

1.5(VITON) 1

320

WPMI03202101

DISTRIBRTER

SPACER

Ø15 X 16(S45C,NEW

TYPE) 1

321

WPMC03212100

DISTRIBUTER

WEIGHT

Ø44 X

4.7t 1

322

WPMI03222100

DISTRIBUTER

SPRING

W0.6 X Ø8.3/9.5 X

17L 1

323

WPMA03232100

DISTRIBUTER

CAP

Ø50 X

20 1

324

WPMA03242100

TUBE

FITTING

Ø8 x

1/8”PC 1

325

WPRE03250100

HOSE

73MM

1

327

WPMIM5X50HN

BOLT

M5 X

50 1

328

WPMI03280300

OIL

FILTER ASSEMBLY 1

332

WPMI03320300

OIL

FILTER FIXTURE

t2.0(PRESS)

1

333

WPMIM4X8HN0

BOLT

M4 X

8 2

335

WPRSS8000000

O

-RING

S

-80(SILICON) 1

336

WPMI03360100

1ST

VALVE OIL BAFFLE

52 X 46 X

1.2t 1

337

WPMIM4X8HN0

BOLT

M4 X

8 2

338

WPMIM6X25HN

BOLT

M6 X

25 3

401

WPMI04010100

ROTOR

ASSEMBLY(NEW TYPE)

FCD

-64 1

409

WPMI04090700

KEY

5 X 5 X 11 X

17.5L 1

410

WPME04100700

OIL PUMP

BLADE

8 X 6 X

21 1

411

WPME04110100

1ST

STAGE BLADE

25 X 32 X 6t(ROUND

28x70x6.5) 2

412

WPMS04122100

1ST

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS) 2

413

WPMI04132100

1ST

STAGE BLADE SPRING GUIDE

Ø1.8/3 X

26(Ø2/3 x26) 2

414

WPME04140100

2ND

STAGE BLADE

22 X 22 X 6t(ROUND

25x50x6.5) 2

415

WPMS04152100

2ND

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS) 2

416

WPMI04162100

2ND

STAGE BLADE SPRING

Ø1.8/3 X

26(Ø2/3 x26) 2

501

WPMI05010100

2ND

STAGE STATOR

FC

-25(Φ49x42t) 1

502

WPMI05022100

VALVE

GUIDE PIN (spring pin)

Ø3 X

20 2

503

WPRV05032100

2ND

STAGE VALVE

Ø14.5 X

7(VITON) 1

504

WPMI05042100

2ND

VALVE SPRING

W0.6 X Ø7.3/8.5 X

17L 1

506

WPMI05060300

SPRING

SUPPORT(for 2nd valve)

DIECAST(SMALL)

1

507

WPMIW5G00000

WASHER

Ø5(GEAR,

SPRING) 1

508

WPMIM5X20HN

BOLT

M5 X

20 1

509

WPRSP6000000

O

-RING

P

-6(SILICON) 1

510

WPMI05102100

TAPER

PIN(ONE SCREW)

Ø7 X

25L(M6) 2

511

WPMIM6000000

NUT

M6

2

512

WPMIM6X25HN

BOLT

M6 X

25 5

27 28

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

Parts List (BOM LIST: W2V10) Parts List (BOM LIST: W2V20)

Part

No. Code No. Description Specification Qty

513

WPRSG5500000

O

-RING

G

-55(SILICON) 1

601

WPMI06010300

END

PLATE

FC

-25 1

603

WPMC06030300

TAPER

PIN

Ø3.5 X Ø2.9 X

6.0 1

607

WPMIM6X30HN

BOLT

M6 X

30 4

608

WPMI06080100

2ND DISCHARGE

BAFFLE

100 X 140 X

1.2t 1

701

WPMA07010100

OIL

BOX

DIECAST

1

703

WPRS07030300

O

-RING(for oil box)

167 X 126 X

2t(SILICON) 1

704

WPMS07041500

OIL LEVEL

PLATE SUS

10 X 95 X

0.2t 1

705

WPRS07052100

O

-RING(for oil window)

112.5x2(S

-75,SILICON) 1

706

WPRE07062100

OIL LEVEL

WINDOW

34 X 122 X 3,

PC 1

707

WPMZ07072100

OIL LEVEL

BACK PLATE

DIECAST

1

708

WPMIM35X11C

BOLT

M3.5 X

11(CROSS, Ni-PLATED) 10

709

WPMC07091300

OIL DRAIN

PLUG

M10(BRASS)

1

710

WPRSAN109000

O

-RING(for drain plug)

AN

-109(SILICON) 1

711

WPRSAN118000

O

-RING(for oil filling plug)

AN

-118(SILICON) 1

712

WPRE07122100

OIL FILLING

PLUG

M24

1

713

WPRN07130700

O

-RING(for exhaust flange)

Ø30/20.5 X

2.5t(NBR) 1

714

WPMZ07140700

EXHAUST ASSEMBLY(OUTLET)

NW

-25 1

715

WPRE0224N250

NW25 FLANGE

CAP

NW

-25(CAP) 1

716

WPMIM6X35HN

BOLT

M6 X

35 4

717

WPMA0717010

NAME

PLATE (WSA)

0.2t,

AL STICKER 1

Part No. Code No. Description Specification Qty

101

JWME01010310

MOTOR

(1PHASE)

1P 220V 400W 50/60Hz

±5%

1

102

WPMI01020300

KEY (FOR

MOTOR)

5X5X15R

1

103

WPMC01030300

RING (FOR

COUPLING SPACE)

Ø20/14X8.5

(BRASS)

1

104

WPMIM6X35HN

BOLT

M6X35

4

107

WPMA01070300

MOTOR

PLATE

DIECAST

1

110

WPMA01100700

HANDLE

DIECAST

1

111

WPMIM6X15HN

BOLT

M6X15

2

112

WPMIM6X20HN

BOLT

M6X20

4

114

WPMC01140700

MOTOR

PLATE GUIDE PIN

Ø6 X

13L(BRASS)

2

115

WPMIM5X8HS00

BOLT

M5X8 (SET

SCREW)

2

116

WPMIM5X8HS00

BOLT

M5X8 (SET

SCREW)

1

119

WPMA00119030

COUPLING

FAN

DIECAST(Ø14)

1

122

WPRE01222100

COUPLING

JOINT

RUBBER

1

123

WPMA01230700

COUPLING

DIECAST(Ø15)

1

201

WPMA02010300

MAIN

PLATE

DIECAST

1

202

WPMIM4X10HF0

BOLT

M4 X

10(FLATHEAD,Ni-PLATED)

3

203

WPRV02030700

OIL SEAL (FOR

HOUSING)

Ø22/32 X

7

1

204

WPMA02040700

OIL SEAL

HOUSING(SLEEVE)

Ø40/32 X

25.5

1

205

WPMI02050700

BUSHING

Ø22/18x20,SUJ2

1

206

WPRSS1800000

O

-RING

S

-18(SILICON)

2

208

WPRSG3500000

O

-RING

G

-35(SILICON)

1

209

WPMI02090700

SNAP RING (FOR

HOUSING)

R

-32

1

210

WPMIM4X80HN

BOLT

M4X8

2

211

WPMI02110300

SUCTION

FELT STRAP

1t x 92 x 13 x

R34

1

212

WPME02120700

OIL SUCTION

FELT

FELT

1

213

WPMI02132100

G/B SPRING (FOR

KNOB)

W0.9 X Ø4.5/6.3 X

33L

1

214

WPMC02142100

G/B BRASS PIN(FOR

KNOB)

Ø4.5 X 6.2 X

11.5(BRASS)

1

215

WPRSP10A0000

O

-RING

P

-10A(SILICON)

1

216

WPRE02162100

GAS BALLAST

KNOB

Ø40

1

217

WPMS02170700

STRAINER

ASSEMBLY

Ø0.2 X 32# X

Ø17

1

220

WPRSP3000000

O

-RING

P

-30(SILICON)

1

221

WPMZ02210700

INTAKE

FLANGE

NW

-25

1

223

WPMIM4X12HN

BOLT

M4 X

12

4

224

WPRE0224N250

NW25 FLANGE

CAP

NW

-25(CAP)

1

225

WPRSP2000000

O

-RING

P

-20(SILICON)

1

226

WPRSG4500000

O

-RING

G

-45(SILICON)

1

227

WPRSAN109000

O

-RING

AN

-109(SILICON)

2

228

WPRSP10A0000

O

-RING

P

-10A(SILICON)

2

229

WPMC02290200

G/B TUBE

ASSEMBLY(STANDARD)

BRASS

1

232

WPMI02322100

GAS BALLAST

CLAMP

16 X 26 X

2.0T

2

233

WPMIM4X12HN

BOLT

M4X12

2

234

WPMA02340300

BASE

PLATE

DIECAST

1

235

WPMIM6000000

NUT

M6

4

236

WPMIW6X18N0

WASHER

Ø6 X

18(FLAT)

4

237

WPMIM6X20HN

BOLT

M6 X

20

4

238

WPRE02380700

BASE

RUBBER

Ø24 X

12

4

239

WPMIM6X15HN

BOLT

M6 X

15

4

240

WPMIM4X8HB0

BOLT

M4 X 8(ROUND

HEAD,Ni-PLATED)

4

29 30

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

Parts List (BOM LIST: W2V20) Parts List (BOM LIST: W2V20)

Part No. Code No. Description Specification Qty

241

WPRE024102YW

SIDE

COVER (WSA)

ABS(YELLOW)

2

301

WPMI03010200

1ST

STAGE STATOR

FC

-25

1

302

WPMC03022100

TAPER

PIN

Ø5.9 X Ø6.5 X

7

2

303

WPRV03030700

OIL

SEAL(for block)

Ø25/35 X

7

1

304

WPMI03041300

VALVE

GUIDE PIN(SPRING PIN)

Ø3 X

20

2

305

WPRV03050200

1ST

STAGE VALVE

43 X 35 X

2t(VITON)

1

306

WPMI03060200

1ST

VALVE BACK PLATE

42 X 35 X

1.2t

1

307

WPMS03071300

1ST

VALVE SPACER

Ø8/6.3 X

13(SUS)

1

311

WPMI03111300

1ST

VALVE SPRING

W1 X Φ9/11 X

15.5L

1

312

WPMSW5N0000

WASHER

Ø5(SUS

FLAT)

1

313

WPMIM5X22HN

BOLT

M5 X

22

1

314

WPRSP6000000

DISTRIBUTER SLEEVE

O-Ring

P

-6(SILICON)

2

315

WPME03152100

DISTRIBUTER SLEEVE

ASSEMBLY

1

319

WPRV03192100

DISTRIBUTER

VALVE

Ø45 X 9 X

1.5(VITON)

1

320

WPMI03202101

DISTRIBRTER

SPACER

Ø15 X 16(S45C,NEW

TYPE)

1

321

WPMC03212100

DISTRIBUTER

WEIGHT

Ø44 X

4.7t

1

322

WPMI03222100

DISTRIBUTER

SPRING

W0.6 X Ø8.3/9.5 X

17L

1

323

WPMA03232100

DISTRIBUTER

CAP

Ø50 X

20

1

324

WPMA03242100

TUBE

FITTING

Ø8 x

1/8”PC

1

325

WPRE03250200

HOSE

95MM

1

327

WPMIM5X50HN

BOLT

M5 X

50

1

328

WPMI03280300

OIL

FILTER ASSEMBLY

1

332

WPMI03320300

OIL

FILTER FIXTURE

t2.0(PRESS)

1

333

WPMIM4X8HN0

BOLT

M4 X

8

2

335

WPRSS8000000

O

-RING

S

-80(SILICON)

1

336

WPMI03360200

1ST

VALVE OIL BAFFLE

52 X 64 X

1.2t

1

337

WPMIM4X8HN0

BOLT

M4 X

8

2

338

WPMIM6X25HN

BOLT

M6 X

25

3

401

WPMI04010200

ROTOR

ASSEMBLY(NEW TYPE)

FCD

-64

1

409

WPMI04090700

KEY

5 X 5 X 11 X

17.5L

1

410

WPME04100700

OIL PUMP

BLADE

8 X 6 X

21

1

411

WPME04110200

1ST

STAGE BLADE

42 X 32 X 6t(ROUND

45x70x6.5)

2

412

WPMS04122100

1ST

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS)

2

413

WPMI04132100

1ST

STAGE BLADE SPRING GUIDE

Ø1.8/3 X

26(Ø2/3 x26)

2

414

WPME04140200

2ND

STAGE BLADE

30 X 22 X 6t(ROUND

33x50x6.5)

2

415

WPMS04152100

2ND

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS)

2

416

WPMI04162100

2ND

STAGE BLADE SPRING

Ø1.8/3 X

26(Ø2/3 x26)

2

501

WPMI05010200

2ND

STAGE STATOR

FC

-25(Φ49x50t)

1

502

WPMI05022100

VALVE

GUIDE PIN (spring pin)

Ø3 X

20

2

503

WPRV05032100

2ND

STAGE VALVE

Ø14.5 X

7(VITON)

1

504

WPMI05042100

2ND

VALVE SPRING

W0.6 X Ø7.3/8.5 X

17L

1

506

WPMI05060300

SPRING

SUPPORT(for 2nd valve)

DIECAST(SMALL)

1

507

WPMIW5G00000

WASHER

Ø5(GEAR,

SPRING)

1

508

WPMIM5X20HN

BOLT

M5 X

20

1

509

WPRSP6000000

O

-RING

P

-6(SILICON)

1

510

WPMI05102100

TAPER

PIN(ONE SCREW)

Ø7 X

25L(M6)

2

511

WPMIM6000000

NUT

M6

2

512

WPMIM6X25HN

BOLT

M6 X

25

5

Part

No. Code No. Description Specification Qty

513

WPRSG5500000

O

-RING

G

-55(SILICON)

1

601

WPMI06010300

END

PLATE

FC

-25

1

603

WPMC06030300

TAPER

PIN

Ø3.5 X Ø2.9 X

6.0

1

607

WPMIM6X30HN

BOLT

M6 X

30

4

608

WPMI06080200

2ND DISCHARGE

BAFFLE

100 X 170 X

1.2t

1

701

WPMA07010200

OIL

BOX

DIECAST(171x166)

1

703

WPRS07030300

O

-RING(for oil box)

167 X 126 X

2t(SILICON)

1

704

WPMS07041500

OIL LEVEL

PLATE SUS

10 X 95 X

0.2t

1

705

WPRS07052100

O

-RING(for oil window)

112.5x2(S

-75,SILICON)

1

706

WPRE07062100

OIL LEVEL

WINDOW

34 X 122 X 3,

PC

1

707

WPMZ07072100

OIL LEVEL

BACK PLATE

DIECAST

1

708

WPMIM35X11C

BOLT

M3.5 X

11(CROSS, Ni-PLATED)

10

709

WPMC07091300

OIL DRAIN

PLUG

M10(BRASS)

1

710

WPRSAN109000

O

-RING(for drain plug)

AN

-109(SILICON)

1

711

WPRSAN118000

O

-RING(for oil filling plug)

AN

-118(SILICON)

1

712

WPRE07122100

OIL FILLING

PLUG

M24

1

713

WPRN07130700

O

-RING(for exhaust flange)

Ø30/20.5 X

2.5t(NBR)

1

714

WPMZ07140700

EXHAUST ASSEMBLY(OUTLET)

NW

-25

1

715

WPRE0224N250

NW25 FLANGE

CAP

NW

-25(CAP)

1

716

WPMIM6X35HN

BOLT

M6 X

35

4

717

WPMA0717020

NAME

PLATE (WSA)

0.2t,

AL STICKER

1

31 32

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

Parts List (BOM LIST: W2V40) Parts List (BOM LIST: W2V40)

Part

No. Code No. Description Specification Qty

101

JWME01010411

MOTOR

(1PHASE)

1P 220V 750W

50/60HZ 1

102

WPMI01020400

KEY (FOR

MOTOR)

6X6X15R

1

103

WPMA01030400

RING (FOR

COUPLING SPACE)

Ø25/19X24

(AL) 1

104

WPMIM6X35HN

BOLT

M6X35

4

106

WPMA01060400

MOTOR

PLATE ASSEMBLY

DIECAST

1

110

WPMA01100700

HANDLE

DIECAST

1

111

WPMIM6X20HN

BOLT

M6X20

2

112

WPMIM6X35HN

BOLT

M6X35

4

114

WPMC01140700

MOTOR

PLATE GUIDE PIN

Ø6 X

13L(BRASS) 2

115

WPMIM5X8HS00

BOLT

M5X8 (SET

SCREW) 2

116

WPMIM6X12HS0

BOLT

M6X12 (SET

SCREW) 1

119

WPMA01190400

COUPLING

FAN

DIECAST(Ø19)

1

122

WPRE01222100

COUPLING

JOINT

RUBBER

1

123

WPMA01230700

COUPLING

DIECAST(Ø15)

1

201

WPMA02010400

MAIN

PLATE

DIECAST

1

202

WPMIM4X10HF0

BOLT

M4 X

10(FLATHEAD,Ni-PLATED) 3

203

WPRV02030700

OIL SEAL (FOR

HOUSING)

Ø22/32 X

7 1

204

WPMA02040700

OIL SEAL

HOUSING(SLEEVE)

Ø40/32 X

25.5 1

205

WPMI02050700

BUSHING

Ø22/18x20,SCM415

1

206

WPRSS1800000

O

-RING

S

-18(SILICON) 2

208

WPRSG3500000

O

-RING

G

-35(SILICON) 1

209

WPMI02090700

SNAP RING (FOR

HOUSING)

R

-32 1

210

WPMIM4X80HN

BOLT

M4X8

2

211

WPMI02110400

SUCTION

FELT STRAP

1t x 92 x 13 x

R34 1

212

WPME02120700

OIL SUCTION

FELT

FELT

1

213

WPMI02132100

G/B SPRING (FOR

KNOB)

W0.9 X Ø4.5/6.3 X

33L 1

214

WPMC02142100

G/B BRASS PIN(FOR

KNOB)

Ø4.5 X 6.2 X

11.5(BRASS) 1

215

WPRSP10A0000

O

-RING

P

-10A(SILICON) 1

216

WPRE02162100

GAS BALLAST

KNOB

Ø40

1

217

WPMS02170700

STRAINER

ASSEMBLY

Ø0.2 X 32# X

Ø17 1

220

WPRSP3000000

O

-RING

P

-30(SILICON) 1

221

WPMZ02210700

INTAKE

FLANGE

NW

-25 1

223

WPMIM4X12HN

BOLT

M4 X

12 4

224

WPRE0224N250

NW25 FLANGE

CAP

NW

-25 1

225

WPRSP2200000

O

-RING

P

-22(SILICON) 1

226

WPRSG4500000

O

-RING

G

-45(SILICON) 1

227

WPRSAN109000

O

-RING

AN

-109(SILICON) 2

228

WPRSP10A0000

O

-RING

P

-10A(SILICON) 2

229

WPMC02291200

G/B TUBE

ASSEMBLY(기본)

BRASS

1

232

WPMI02322100

GAS BALLAST

CLAMP

16 X 26 X

2.0T 2

233

WPMIM4X12HN

BOLT

M4X12

2

234

WPMA02340400

BASE

PLATE

GRAVITY

CASTING 1

235

WPMIM6000000

NUT

M6

4

236

WPMIW6X18N0

WASHER

Ø6 X

18(FLAT) 4

237

WPMIM6X25HN

BOLT

M6X25

4

238

WPRE02380700

BASE

RUBBER

Ø24 X

12 4

239

WPMIM6X20HN

BOLT

M6X20

4

240

WPMIM4X8HB0

BOLT

M4 X 8(ROUND

HEAD,Ni-PLATED) 4

Part

No. Code No. Description Specification Qty

241

WPRE024101YW

SIDE

COVER (WSA)

ABS(YELLOW)

2

301

WPMI03010400

1ST

STAGE STATOR

FC

-25 1

302

WPMC03022100

TAPER

PIN

Ø5.9 X Ø6.5 X

7 2

303

WPRV03030700

OIL

SEAL(for block)

Ø25/35 X

7 1

304

WPMI03041300

VALVE

GUIDE PIN(SPRING PIN)

Ø3 X

20 2

305

WPRV03050400

1ST

STAGE VALVE

54 X 50 X

3t(VITON) 1

306

WPMI03060400

1ST

VALVE BACK PLATE

54 X 50 X

1.6t 1

307

WPMS03071300

1ST

VALVE SPACER

Ø8/6.3 X

13(SUS) 1

311

WPMI03111300

1ST

VALVE SPRING

W1 X Φ9/11 X

15.5L 1

312

WPMSW5N0000

WASHER

Ø5(SUS

FLAT) 1

313

WPMIM5X22HN

BOLT

M5 X

22 1

314

WPRSP6000000

DISTRIBUTER SLEEVE

O-Ring

P

-6(SILICON) 2

315

WPME03152100

DISTRIBUTER SLEEVE

ASSEMBLY

DIECAST

1

319

WPRV03192100

DISTRIBUTER

VALVE

Ø45 X 9 X

1.5(VITON) 1

320

WPMI03202101

DISTRIBRTER

SPACER

Ø15 X 16(S45C,NEW

TYPE) 1

321

WPMC03212100

DISTRIBUTER

WEIGHT

Ø44 X

4.7t 1

322

WPMI03222100

DISTRIBUTER

SPRING

W0.6 X Ø8.3/9.5 X

17L 1

323

WPMA03232100

DISTRIBUTER

CAP

Ø50 X

20 1

324

WPMA03242100

TUBE

FITTING

Ø8 x

1/8”PC 1

325

WPRE03250400

HOSE

130MM

1

327

WPMIM5X50HN

BOLT

M5 X

50 1

328

WPMI03281800

OIL

FILTER ASSEMBLY 1

332

WPMI03321800

OIL

FILTER FIXTURE

t2.0(PRESS)

1

333

WPMIM4X8HN0

BOLT

M4 X

8 2

334

WPRSP6000000

O

-RING

P

-6(SILICON) 1

335

WPRSS9500000

O

-RING

S

-95(SILICON) 1

336

WPMI03360400

1ST

VALVE OIL BAFFLE

112 X 147 X

1.2t 1

337

WPMIM5X10HN

BOLT

M5 X

10 4

338

WPMIM6X25HN

BOLT

M6 X

25 4

401

WPMI04010400

ROTOR

ASSEMBLY(NEW TYPE)

FCD

-64 1

409

WPMI04090700

KEY

5 X 5 X 11 X

17.5L 1

410

WPME04100700

OIL PUMP

BLADE

8 X 6 X

21 1

411

WPME04110400

1ST

STAGE BLADE

55 X 40 X 6t(Round

58x86x6.5) 2

412

WPMS04122100

1ST

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS) 2

413

WPMI04132100

1ST

STAGE BLADE SPRING GUIDE

Ø1.8/3 X

26(Ø2/3 x26) 2

414

WPME04140400

2ND

STAGE BLADE

40 X 29 X

6t(원43x63x6.5) 2

415

WPMS04152100

2ND

STAGE BLADE SPRING

W0.4 X Ø2.7/1.9 X

30L(SUS) 2

416

WPMI04162100

2ND

STAGE BLADE SPRING

Ø1.8/3 X

26(Ø2/3 x26) 2

501

WPMI05010400

2ND

STAGE STATOR

FC

-25(Φ62.5x60t) 1

502

WPMI05022100

VALVE

GUIDE PIN (spring pin)

Ø3 X

20 2

503

WPRV05032100

2ND

STAGE VALVE

Ø14.5 X

7(VITON) 2

504

WPMI05042100

2ND

VALVE SPRING

W0.6 X Ø7.3/8.5 X

17L 2

505

WPMC05051800

SPRING SUPPORT

SPACER(BRASS)

Ø17.5/10.5 X

5L 2

506

WPMI05061800

SPRING

SUPPORT(for 2nd valve)

DIECAST(Large)

2

507

WPMIW5G00000

WASHER

Ø5(GEAR,

SPRING) 2

508

WPMIM5X20HN

BOLT

M5 X

20 2

509

WPRSP6000000

O

-RING

P

-6(SILICON) 1

510

WPMI05102100

TAPER

PIN(One side Screw)

Ø7 X

25L(M6) 2

33 34

© 2020 FLUIDX, INC. © 2020 FLUIDX, INC.

FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS FLUIDX VACUUM PUMP MANUAL - HIGH VACUUM ROTARY VANE PUMPS

6. TECHNICAL DATA 6. TECHNICAL DATA

Parts List (BOM LIST: W2V40) Parts List (BOM LIST: W2V80)

Part

No. Code No. Description Specification Qty

511

WPMIM6000000

NUT

M6

2

512

WPMIM6X30HN

BOLT

M6 X

30 6

513

WPRSG7000000

O

-RING

G

-70(SILICON) 1

601

WPMI06010400

END

PLATE

FC

-25 1

602

WPMI06021000

END

PLATE BALL

Ø4(SUJ2)

1

604

WPMIM5X5HS00

BOLT

M5 x 5(SET

SCREW) 1

605

WPMI06051000

SPRING

PIN(for end plate)

Ø10 x

20 1

607

WPMIM6X30HN

BOLT

M6 X

30 5

608

WPMI06080400

2ND DISCHARGE

BAFFLE

118 X 121 X

1.2t 1

701

WPMA07010400

OIL

BOX

DIECAST

1

703

WPRS07030400

O

-RING(for oil box)

193.6 X 142.3 X

2.6t(SILICON) 1

704

WPMS07041500

OIL LEVEL

PLATE SUS

10 X 95 X

0.2t 1

705

WPRS07052100

O

-RING(for oil window)

112.5x2(S

-75,SILICON) 1

706

WPRE07062100

OIL LEVEL

WINDOW

34 X 122 X 3,

PC 1

707

WPMZ07072100

OIL LEVEL

BACK PLATE

DIECAST

1

708

WPMIM35X11C

BOLT

M3.5 X

11(CROSS, Ni-PLATED) 10

709

WPMC07091300

OIL DRAIN

PLUG

M10(BRASS)

1

710

WPRSAN109000

O

-RING(for drain plug)

AN

-109(SILICON) 1

711

WPRSAN118000

O

-RING(for oil filling plug)

AN

-118(SILICON) 1

712

WPRE07122100

OIL FILLING

PLUG

M24

1

713

WPRN07130700

O

-RING(for exhaust flange)

Ø30/20.5 X

2.5t(NBR) 1

714

WPMZ07140700

EXHAUST ASSEMBLY(OUTLET)

NW

-25 1

715

WPRE0224N250

NW25 FLANGE

CAP

NW

-25(CAP) 1

716

WPMIM6X35HN

BOLT

M6 X

35 4

717

WPMA0717040

NAME

PLATE (WSA)

0.2t,

AL STICKER 1

Part No.

Code No. Description Specification Qty

101

MOTOR

3P 220/380V 1.5KW

50/60Hz

W2V60,W2V80

1

102

WPMI01021400

KEY (FOR

MOTOR)

8X7X22R

1

103

WPMA01031400

RING (FOR

COUPLING SPACE)

Ø30/24X28

(AL)

1

104

WPMIM8X30HN

BOLT

M8X30

4

107

WPMIM8000000

NUT

M8(FLANGE NUT FOR

B5)

4

111

WPMI01111400

HOOK(EYE

BOLT)

M10X20

1

112

WPMIM8X30HN

BOLT

M8X30

4

113

WPMA01130800

FAN

COVER

258 X 226 X 1.5T (RM

:

1

114

WPMC01141400

MOTOR

PLATE GUIDE PIN

Ø8 X

20L(BRASS)

2

115

WPMIM6X12HS0

BOLT

M6X12 (SET

SCREW)

1

116

WPMIM8X10HS0

BOLT

M8X10(SET

SCREW)

1

119

WPMA01191400

COUPLING

FAN ASSEMBLY

DIECAST

1

122

WPRE01222100

COUPLING

JOINT

RUBBER

1

123

WPMI01231400

COUPLING

CR0010(Ø20)

1

201

WPMA02010800

MAIN

PLATE

DIECAST

1

202

WPMIM6X35HN

BOLT

M6 X

35

3

203

WPRV02030800

OIL

SEAL(for housing)

Ø32/45 X

7

1

204

WPMA02040800

OIL SEAL

HOUSING

Ø93/40 x

22

1

205

WPMI02050800

BUSHING

Ø32/24x20

1

206

WPRSAN021000

O

-RING

AN

-021(SILICON)

2

207

WPMI02070800

OIL PUMP

HOUSING(SLEEVE)

Ø95/32 x

16

1

208

WPRSG6000000

O

-RING

G

-60(SILICON)

1

209

WPMI02090800

SNAP RING (FOR

HOUSING)

R

-45

1

213

WPMI02132100

G/B SPRING (FOR

KNOB)

W0.9 X Ø4.5/6.3 X

33L

1

214

WPMC02142100

G/B BRASS PIN(FOR

KNOB)

Ø4.5 X 6.2 X

11.5(BRASS)

1

215

WPRSP10A0000

O

-RING

P

-10A(SILICON)

1

216

WPRE02162100

GAS BALLAST

KNOB

Ø40

1

217

WPMS02171400

STRAINER

ASSEMBLY

Ø0.2 X 32# X

Ø27

1

220

WPRSP4500000

O

-RING

P

-45(SILICON)

1

221

WPMA02211400

INTAKE

FLANGE

NW

-40(ROUND85x54),ANODIZED

1

223

WPMIM5X15HN

BOLT

M5 X

15

4

224

WPRE0224N250

NW25 FLANGE

CAP

NW

-25(CAP)

1

225

WPRSP3000000

O

-RING

P

-30(SILICON)

1

226

WPRSG1050000

O

-RING

G

-105(SILICON)

1

227

WPRSAN109000

O

-RING

AN

-109(SILICON)

2

228

WPRSP10A0000

O

-RING

P

-10A(SILICON)

2

229

WPMC02291200

G/B TUBE

ASSEMBLY(기본)

BRASS

1

232

WPMI02322100

GAS BALLAST

CLAMP

16 X 26 X

2.0T

2

233

WPMIM4X12HN

BOLT

M4X12

2

234

WPMA02341400

BASE

PLATE

DIECAST

1

239

WPMIM8X35HN

BOLT

M8X35

4

240

WPMIM5X12HB

BOLT

M5 X 12(ROUND

HEAD,Ni-PLATED))

8

241

WPRE024108YW

SIDE

COVER (WSA)

ABS(YELLOW)

2

301

WPMI03010800

1ST

STAGE STATOR

FC

-25

1

302

WPMC03022100

TAPER

PIN

Ø5.9 X Ø6.5 X

7

2

303

WPRV03030800

OIL

SEAL(for block)

Ø35/47 X

7

1

305

WPRV03050800

1ST

STAGE VALVE

Ø23 X

13(VITON)

2

306

WPMI03060800

1ST

VALVE BACK PLATE

1

35 36

This manual suits for next models

4

Table of contents

Popular Water Pump manuals by other brands

STA-RITE

STA-RITE Signature 2000 Series owner's manual

Pentair

Pentair Hydromatic P33A1 Installation and service manual

Bizon Pumps

Bizon Pumps BPN-330C installation instructions

Homa

Homa Chromatic CH 291 Series Installation and operation instruction manual

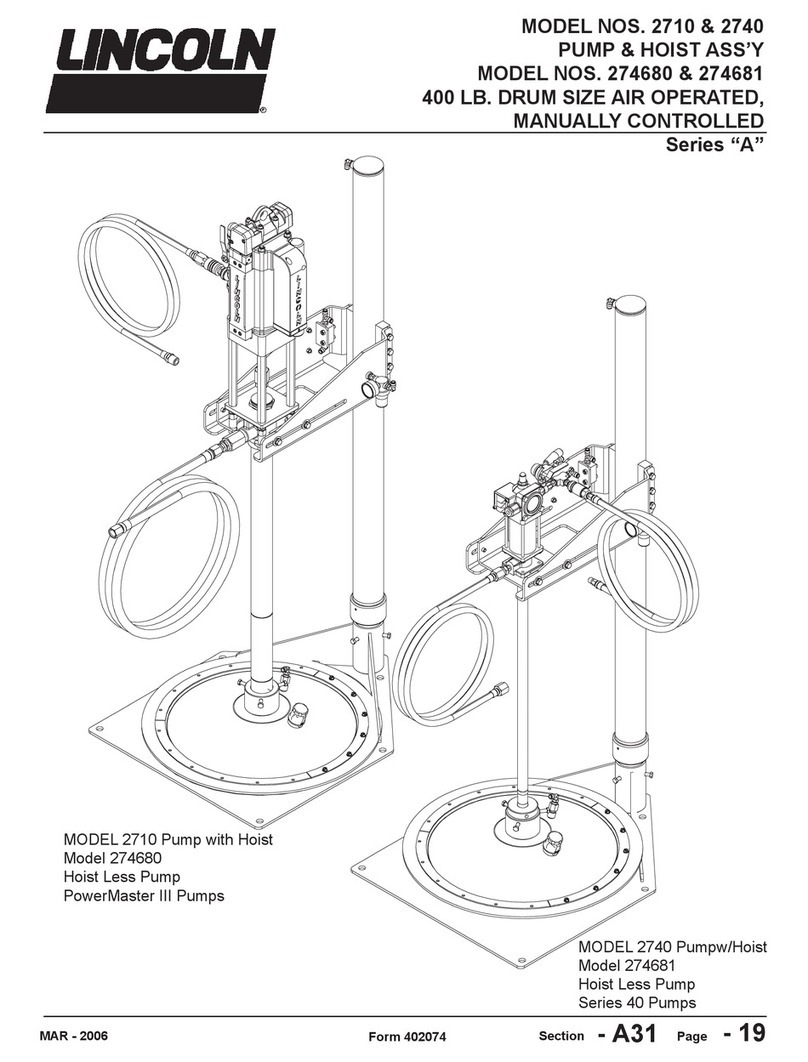

Lincoln

Lincoln 2710 manual

Pentair

Pentair Jung Pumpen DRENA-LINE Series instruction manual

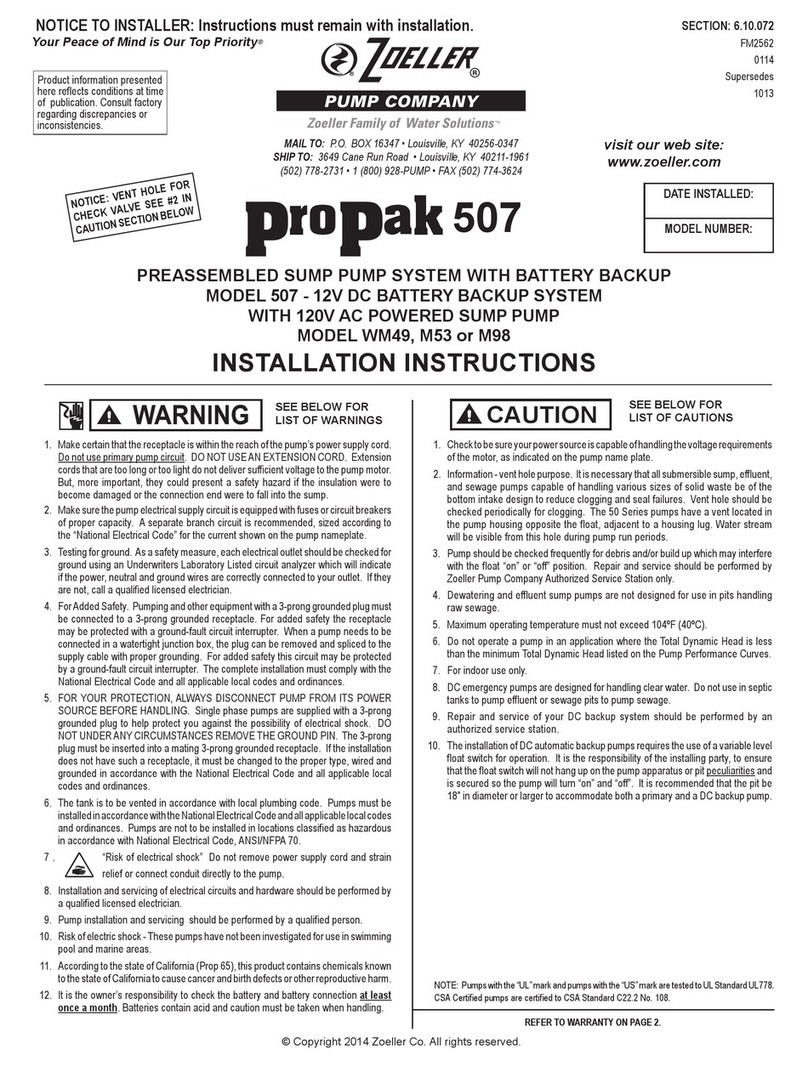

Zoeller

Zoeller ProPak 507 Series installation instructions

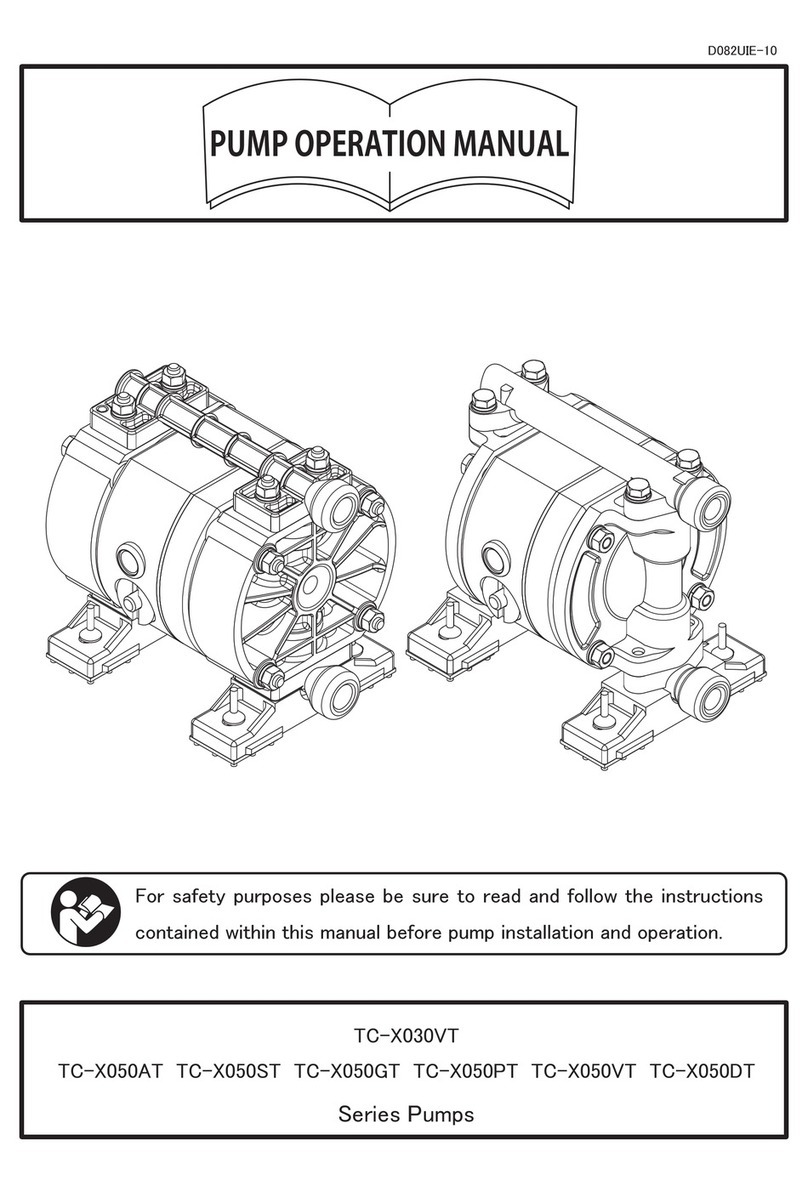

IWAKI

IWAKI TC-X030VT Series Operation manual

Reefe

Reefe RPC32E manual

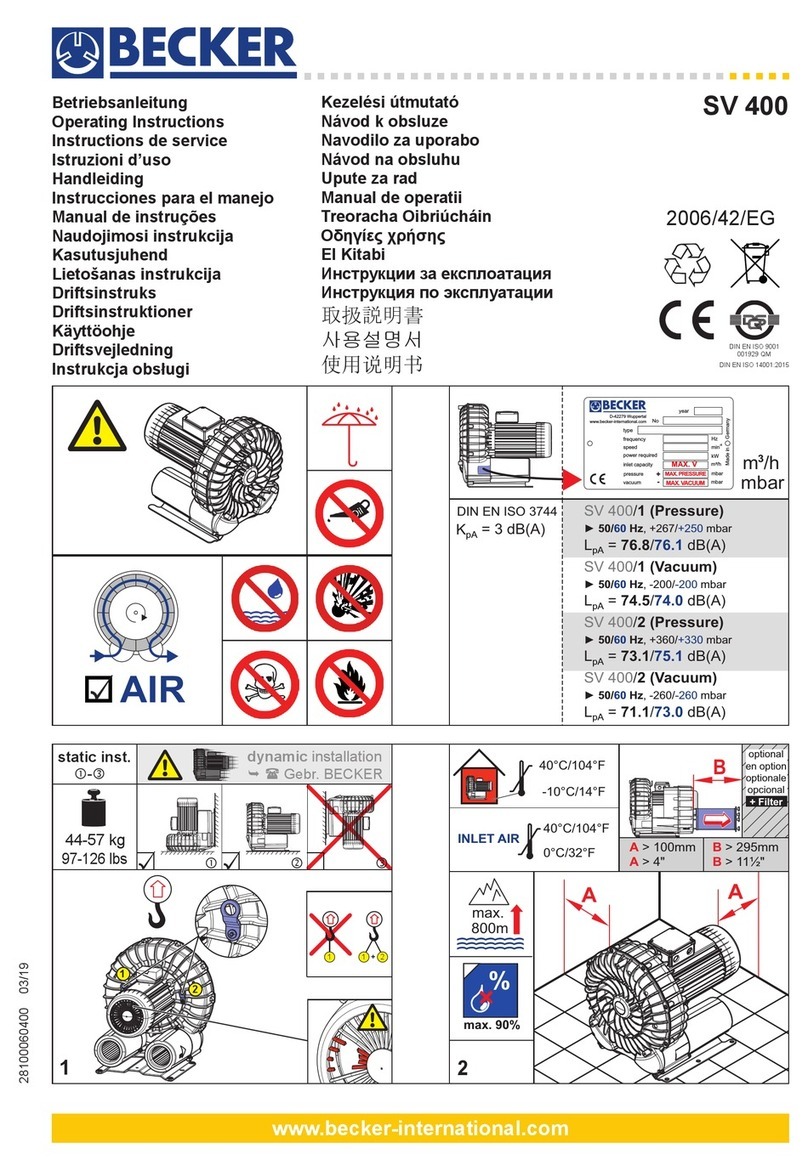

Becker

Becker SV 400 operating instructions

hp-TECHNIK

hp-TECHNIK UHE-WH4 Series Installation, maintenance and operation instructions

Denso

Denso MovinCool Condensate Pump installation manual