Linx Technologies 250 Series User manual

250 Series

Master Development System

User's Guide

Warning: Linx radio frequency ("RF") products may be

used to control machinery or devices remotely, including machinery

or devices that can cause death, bodily injuries, and/or property

damage if improperly or inadvertently triggered, particularly in industrial

settings or other applications implicating life-safety concerns. No Linx

Technologies product is intended for use in any application without

redundancies where the safety of life or property is at risk.

The customers and users of devices and machinery controlled with

RF products must understand and must use all appropriate safety

procedures in connection with the devices, including without limitation,

using appropriate safety procedures to prevent inadvertent triggering by

the user of the device and using appropriate security codes to prevent

triggering of the remote controlled machine or device by users of other

remote controllers.

Do not use this or any Linx product to trigger an action directly

from the data line or RSSI lines without a protocol or encoder/

decoder to validate the data. Without validation, any signal from

another unrelated transmitter in the environment received by the module

could inadvertently trigger the action.

All RF products are susceptible to RF interference that can prevent

communication. RF products without frequency agility or hopping

implemented are more subject to interference. This module does have

a frequency hopping protocol built in, but the developer should still be

aware of the risk of interference.

Do not use any Linx product over the limits in this data guide.

Excessive voltage or extended operation at the maximum voltage could

cause product failure. Exceeding the reflow temperature profile could

cause product failure which is not immediately evident.

Do not make any physical or electrical modifications to any Linx

product. This will void the warranty and regulatory and UL certifications

and may cause product failure which is not immediately evident.

!

Table of Contents

1 Introduction

2 Ordering Information

2 250 Series Transceiver Development Board

3 250 Series Transceiver Evaluation Module

3 Using the Development Boards

4 Using the Development Boards

12 Troubleshooting

13 The Prototyping Area

14 Range Testing

15 Master Development Software

21 About Antennas

21 In Closing

23 250 Series Master Development Board Schematic

––

1

250 Series Master Development

System

User's Guide

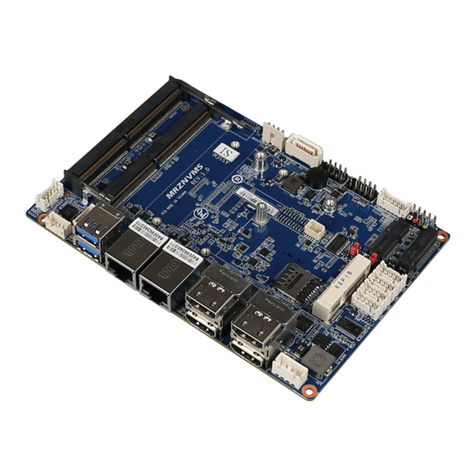

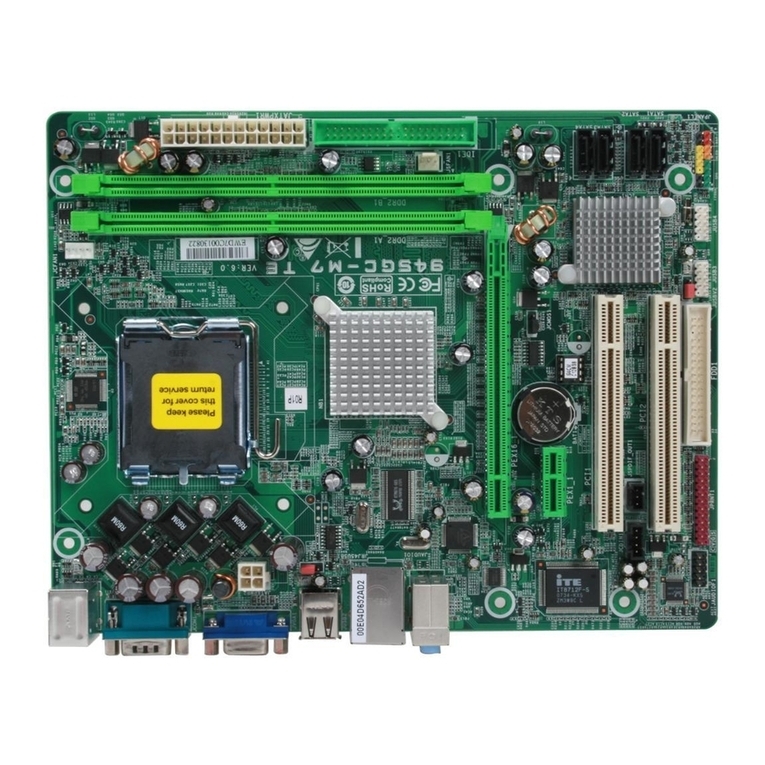

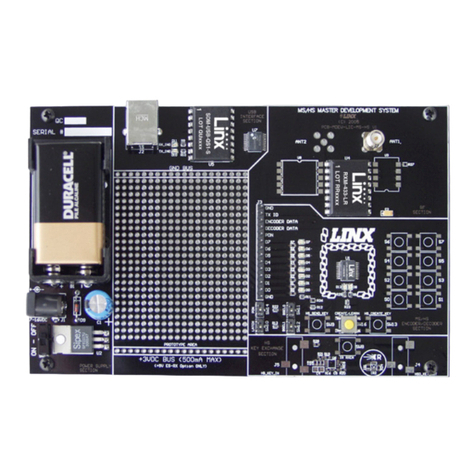

Figure 1: 250 Series Master Development System

Revised 2/7/14

Introduction

The Linx 250 Series RF modules offer a simple, efficient and cost-effective

method of adding wireless communication capabilities to any product. The

Master Development System gives a designer all the tools necessary to

correctly and legally incorporate the 250 Series into an end product. The

development boards serve several important functions:

• Rapid Module Evaluation: The boards allow the performance of the 250

Series modules to be quickly evaluated in a user’s environment.

• Range Testing: Windows-based demonstration software is included,

which allows for a variety of tests. A pair of development boards can

be used to evaluate the range performance of the modules.

• Design Benchmark: The boards provide a known benchmark against

which the performance of a custom design may be judged.

• Application Development: An onboard prototyping area allows for the

development of custom circuits directly on the development board. All

signal lines are available on a header for easy access.

The Master Development System includes two development boards, two

250 Series evaluation modules, two 250 Series transceivers, two CW

Series antennas, two RH Series antennas, six AAA batteries, USB cables,

demonstration software and full documentation.

––

2

Ordering Information

Ordering Information

Part Number Description

MDEV-915-250 250 Series Master Development System

Figure 2: Ordering Information

250 Series Transceiver Development Board

1. Prototyping Area

2. Batteries (3xAAA)

3. On-Off Switch

4. Power LED

5. USB Connector

6. USB Jumpers

7. RS-232 Connector

8. RS-232 Jumpers

9. Breakout Header

10. EVM Module Socket

11. Serial Port Indicators

Figure 3: 250 Series Transceiver Development Board

12

3

4

5

6

7

8

9

10

11

––

3

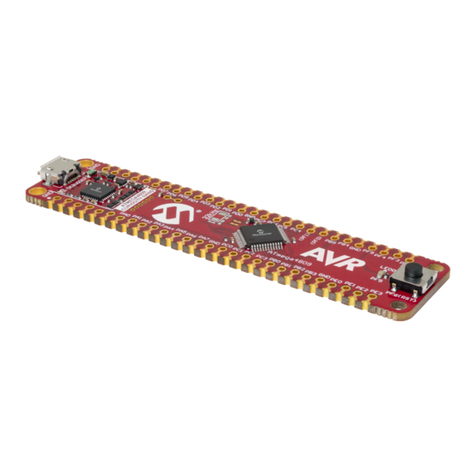

250 Series Transceiver Evaluation Module

Using the Development Boards

The development system provides a stable platform to test and evaluate

the performance of the modules. Everything required for basic testing is

included in the box.

The system includes two identical development boards and two

evaluation modules. These are used to set up a bi-directional data link.

The development boards have USB and RS-232 interfaces to connect to

computers or peripheral devices. Windows-based software is included that

is used to configure the modules and to establish a wireless chat that can

send text between the modules.

Figure 4: 250 Series Transceiver Evaluation Module

––

4

Using the Development Boards

After unpacking the development system, the following steps are used to

get started.

1. Insert an EVM module into the evaluation boards, observing the correct

orientation. The antenna connector should be closest to the edge

of the development board (Figure 5). Make sure it is seated fully and

correctly.

2. Screw an antenna onto each EVM board and install the AAA batteries.

3. Set the jumpers on the development boards. If using the USB interface

then populate the USB jumpers and remove the RS-232 jumpers

(Figure 6 A). If using the RS-232 interface then populate the RS-232

jumpers and remove the USB jumpers (Figure 6 B). Connecting both

sets of jumpers at the same time could lead to short circuits and bit

collisions, so only use one interface at a time.

4. Connect one of the development boards to a computer. USB drivers

are included on the CD, so install them if using the USB interface and

prompted by the computer. The latest drivers may be downloaded

from Silicon Labs at http://www.silabs.com/products/interface/

usbtouart/Pages/usb-to-uart-bridge.aspx

Figure 5: 250 Series Transceiver Evaluation Module on the Development Board

––

5

5. Insert the CD that is included with the kit into the computer and install

the Windows software. If already installed, skip this step.

6. Run the software, select “Wi.232FHSS-250” and click “OK” (Figure

7 A). On the next screen select the appropriate COM port and 2400

baud operation Then click “OK” (Figure 7 B). Note that if the baud

rate has been changed on the module, then the baud rate must be

changed here as well.

Figure 6: 250 Series Development Board Jumpers; (A) for USB Interface; (B) for RS-232 Interface

(A) (B)

(A)

(B)

Figure 7: 250 Series Transceiver Development System Software Setup

––

7

8. The second board can be connected to the same computer for bench

top testing or to a second computer for range testing. Open a second

instance of the software if using one computer. If two computers

are used then repeat steps 4 through 7 for the second board on the

second computer.

Figure 9: 250 Series Transceiver Development System Software Wireless Chat Tab

––

9

10. Type a message into the bottom box in one of the windows.

Figure 11: 250 Series Transceiver Development System Software Wireless Chat Tab

––

10

11. Press Enter and look for the message to appear in the top box of the

window connected to the second module (B). It appears in the middle

box of the window for the sending module (A).

Figure 12: 250 Series Transceiver Development System Software Wireless Chat Tab; (A) Sent; (B) Received

(A)

(B)

––

11

12. Chat back and forth between evaluation boards, verifying that serial

and RF communications are successful.

Figure 13: 250 Series Development System Software Wireless Chat Tab; Response (A) Received; (B) Sent

(A)

(B)

––

12

Troubleshooting

If the boards fail to work out of the box, then try the following:

• Check the batteries to make sure they are not dead.

• Make sure that the antennas are connected.

• Make sure that the jumpers are set correctly.

• Ensure that the latest USB drivers are installed.

• Test additional baud rates.

If all of these appear to be in order, then you can call 800-736-6677 or

e-mail [email protected].

––

13

The Prototyping Area

In addition to their evaluation functions, the boards may also be used

for actual product development. They feature a prototyping area for the

addition of application-specific circuitry. The prototyping area is the same

on both boards and contains a large area of plated through-holes so that

external circuitry can be placed on the board. The holes are set at 0.1" on

center with a 0.05" diameter, making it easy to add most industry-standard

SIP and DIP packages to the board. This circuitry can be interfaced with

the transceiver through the breakout header at the bottom. On the right of

this area is a row connected to the 3.3V power supply and on the left is a

row connected to ground.

Note: The on-board 3.3-volt regulator has approximately 50mA of

headroom available for additional circuitry. If added circuitry requires a

higher current, the user must power the board from an external supply.

Ground Bus

+3.3 Volt Bus

Figure 14: The Development Board Prototyping Area

Breakout

Header

––

14

Range Testing

Several complex mathematical models exist for determining path loss in

many environments. These models vary as the transmitter and receiver are

moved from indoor operation to outdoor operation. Although these models

can provide an estimation of range performance in the field, the most

reliable method is to simply perform range tests using the transmitter and

receiver in the intended operational environment.

Simple range testing can be done with the development boards. Connect

one board to a computer and set the software into Wireless Chat. Remove

all jumpers from the other board and place one between the RXD0 and

TXD0 pins on the breakout header as shown in Figure 15. This routs data

received by the module back into its transmit buffer to be sent back to the

first unit. In this way one board stays connected to a computer and the

other board is moved away to test the effective range of the link.

As the maximum range of the link in an area is approached, it is not

uncommon for the signal to cut in and out as the transmitter moves. This

is normal and can result from other interfering sources or fluctuating signal

levels due to multipath. Multipath results in cancellation of the transmitted

signal as direct and reflected signals arrive at the receiver at differing times

and phases. The areas in which this occurs are commonly called “nulls”

and simply walking a little further usually restores the signal. If this does not

restore the signal, then the maximum effective range of the link has been

reached.

To achieve maximum range, keep objects such as your hand away from

the antenna and ensure that the antenna on the transmitter has a clear and

unobstructed line-of-sight path to the receiver board. Range performance

is determined by many interdependent factors. If the range you are able to

achieve is significantly less than specified by Linx for the products you are

Figure 15: The Development Board Prototyping Area

––

15

testing, then there is likely a problem with either the board or the ambient

RF environment in which the board is operating. First, check the battery,

switch positions, and antenna connection. Next, measure the receiver’s

RSSI voltage with the transmitter turned off to determine if ambient

interference is present. If this fails to resolve the issue, please contact Linx

technical support.

Master Development Software

The development system is supplied with Windows-based software that

facilitates communication with the development boards through either a

USB or RS-232 connection. The software allows for configuration of the

modules and sends text characters in a chat format.

The development system can be used with HyperTerminal to receive and

transmit RS-232 data and send files using file transfer protocols such as

ZMODEM. HyperTerminal and many other terminal programs assert RTS

by default. On the evaluation board, the RTS line is tied to the CMD line

on the module. When the CMD line is held low (RTS line is asserted), the

module is placed in command mode.

In command mode, all UART data sent to the module is interpreted as

commands and is NOT sent to the RF engine for transmission. Additionally,

if a development board is switched on in the presence of an asserted RTS

line, it performs a full hardware and flash reset to the factory defaults.

To use the evaluation board with HyperTerminal or other terminal programs,

first remove the jumpers from between pins 7 and 8 of JP2, if using the

RS-232 interface, or JP3, if using the USB interface. Removing this jumper

disconnects the RTS line from the CMD line on the module, allowing

normal operation.

The development software has three tabs for configuring and using the

mdoule: Volatile Registers, Non-Volatile Registers and Wireless Chat. The

Volatile Registers and Non-Volatile Registers tabs are used to configure the

operation of the module. The Wireless Chat tab is a demonstration using

the module.

––

16

The Volatile Registers Tab

The Volatile Registers tab tab displays all of the items that can be

configured in volatile memory. Values programmed into these registers are

lost on power-down, but have an immediate effect on module operation.

If the Data Rate register is changed here, then the software needs to be

restarted and the new baud rate selected. Please see the 250 Series

Transceiver Data Guide for details on the register settings.

Figure 16: 250 Series Transceiver Development System Software Volatile Registers Tab

This manual suits for next models

1

Table of contents

Other Linx Technologies Motherboard manuals

Linx Technologies

Linx Technologies LT Series User manual

Linx Technologies

Linx Technologies ES Series User manual

Linx Technologies

Linx Technologies EVAL-KH3 Series User manual

Linx Technologies

Linx Technologies HumPRO MDEV-900-PRO Service manual

Linx Technologies

Linx Technologies HS Series User manual

Linx Technologies

Linx Technologies KH3 Series User manual