Linx Technologies HS Series User manual

HS Series

Master Development System

User's Guide

Warning: Linx radio frequency ("RF") products may be

used to control machinery or devices remotely, including machinery

or devices that can cause death, bodily injuries, and/or property

damage if improperly or inadvertently triggered, particularly in industrial

settings or other applications implicating life-safety concerns. No Linx

Technologies product is intended for use in any application without

redundancies where the safety of life or property is at risk.

The customers and users of devices and machinery controlled with

RF products must understand and must use all appropriate safety

procedures in connection with the devices, including without limitation,

using appropriate safety procedures to prevent inadvertent triggering by

the user of the device and using appropriate security codes to prevent

triggering of the remote controlled machine or device by users of other

remote controllers.

Do not use this or any Linx product to trigger an action directly

from the data line or RSSI lines without a protocol or encoder/

decoder to validate the data. Without validation, any signal from

another unrelated transmitter in the environment received by the module

could inadvertently trigger the action. This module does not have data

validation built in.

All RF products are susceptible to RF interference that can prevent

communication. RF products without frequency agility or hopping

implemented are more subject to interference. This module does

not have frequency agility built in, but the developer can implement

frequency agility with a microcontroller and the example code in Linx

Reference Guide RG-00101.

Do not use any Linx product over the limits in this data guide.

Excessive voltage or extended operation at the maximum voltage could

cause product failure. Exceeding the reflow temperature profile could

cause product failure which is not immediately evident.

Do not make any physical or electrical modifications to any Linx

product. This will void the warranty and regulatory and UL certifications

and may cause product failure which is not immediately evident.

!

Table of Contents

1Introduction

2Ordering Information

2HS Series Encoder Development Board

3HS Series Decoder Development Board

4Using the Development Boards

4Troubleshooting

5The Prototyping Area

6The Power Supply

6The Encoder Board

6 The Encoder Area

8 The Encoder Board RF Area

8 The Encoder Board Key Exchange Area

10 The Decoder Board

10 The Decoder Area

11 The Decoder Board RF Area

12 The Decoder Board USB Area

13 The Decoder Board Key Exchange Area

14 HS Series Master Development Software

15 Installing the Software Drivers

19 Resources

––

1

Introduction

The HS Series encoders and decoders are ideal for remote control and

command, security, keyless entry, status monitoring, and a host of similar

applications. They encode the status of up to eight buttons or contacts into

a highly secure serial output intended for transmission via an RF or infrared

link. The Master Development System is intended to give a designer all the

tools necessary to incorporate the encoder and decoder into a product.

This guide will show how to take full advantage of the development

boards included with the system. Data Guides for the encoder and

decoder are included with the system or may be downloaded from the

Linx Technologies website at www.linxtechnologies.com. The Master

Development System serves several important functions:

• Rapid Evaluation: It allows the performance and features of the HS

Series encoder and decoder to be quickly evaluated.

• Design: It shows how to design with the encoder and decoder and

how to interface with other components. It also demonstrates the

overall system function, making it easy to develop the initial system

design.

• Prototype Development: It allows for additional circuitry to be placed

directly on the board so that it can act as the first prototype of the

product. All of the signals are available on a wire-wrap header for easy

connection to external circuitry.

HS Series Master Development

System

User's Guide

Figure 1: Package Dimensions

Revised 11/23/12

––

2

Ordering Information

Ordering Information

Part Number Description

MDEV-LICAL-HS HS Series Master Development System with LR Series

MDEV-LICAL-HS-ES HS Series Master Development System with ES Series

Figure 2: Ordering Information

The Master Development System includes 2 development boards, one set

up for the encoder and the other for the decoder, 2 HS Series encoders*,

2 HS Series decoders*, and two CW Series antennas. The boards may

be populated with either the LR Series or the ES Series RF modules. The

decoder board is also populated with 1 QS Series USB module.

*One part is soldered to the board, one extra is for use on your first prototype board.

HS Series Encoder Development Board

1

2

3

4

56

7

8

9

10

11 12

1. 9V Battery

2. Power Jack

3. On-Off Switch

4. Voltage Regulator

5. Prototype Area

6. Break-Out Header

7. Reverse-Polarity SMA Antenna

Connector

8. LR Series Transmitter Module

9. HS Series Encoder

10. Indicator LEDs

11. Function Switches

12. CREATE Button

13. Data Line Buttons

14. Key Input Jack

15. IR Receiver Enable Button

16. IR Key Transfer Phototransistor

Figure 3: MS Series Encoder Development Board

13

14 15

16

––

3

HS Series Deccoder Development Board

Figure 4: MS Series Deccoder Development Board

1. 9V Battery

2. Power Jack

3. On-Off Switch

4. Voltage Regulator

5. QS Series USB Module

6. Prototype Area

7. Break-Out Header

8. Reverse-Polarity SMA Antenna

Connector

9. LR Series Transmitter Module

10. HS Series Decoder

11. Data Line LEDs

12. Indicator LEDs

13. Function Switches

14. LEARN Button

15. SEND_KEY Button

16. CREATE_KEY Button

17. Key Input Jack

18. IR Receiver Enable Button

19. IR Key Transfer Phototransistor

and Diode

20. Key Output Jack

1

2

3

4

5

6

7

8

9

10

11

12

13 14

15 16

17

18

19 20

––

4

Using the Development Boards

After unpacking the development system, attach an antenna to each

board, install the supplied 9V battery, and turn on the power switches. The

encoder and decoder will be set at the factory and will work straight out of

the box. To create a new operational setup, follow these steps:

1. On the decoder board, press the LEARN button and then the

CREATE_KEY button to enter Create Key Mode. Release the LEARN

button and press the CREATE_KEY button ten times to generate the

KEY.

2. To use the infrared key transfer, press the IR_RXEN button on the

encoder board to activate the infrared receiver. Hold the encoder and

decoder boards close until the MODE_IND LEDs on both boards light

up.

3. To set Control Permissions, press the LEARN button on the decoder

board.

4. While the decoder’s MODE_IND line is flashing, press each data line

button on the encoder that is needed for the application.

5. After all the desired data lines have been transmitted, press the

LEARN button again, or wait until the 15 second time-out occurs. The

permissions will now be saved in the decoder.

6. Transmit with one or all the data lines held high to confirm that the learn

process was successful.

Troubleshooting

If the boards fail to work out of the box, then try the following:

• Check the battery to make sure it is not dead.

• Make sure that the baud rate switches are set the same on both

boards.

• Make sure that the antenna is connected.

• Check to see if the PDN switch is on, placing the encoder and decoder

into Power Down Mode. In most cases, the encoder PDN switch

should be on.

• Make sure that you set the Encryption Key correctly. This key is created

by the decoder and needs to be sent to the encoder before they will

communicate.

––

5

The Prototyping Area

The prototyping area is the same on both boards and contains a large

area of plated through holes so that external circuitry can be placed on

the board. This circuitry can be interfaced with the HS encoder or decoder

through the breakout header to the right. At the bottom of this area is a row

connected to the 3V power supply and at the top is a row connected to

ground.

All of the data lines are connected to a wire-wrap header to the right,

allowing easy access from the prototyping area. The DATA_IN, DATA_OUT,

and TX_ID lines are also available on the header, as well as the PDN lines

from the RF modules. This allows complete control of the entire system

from the prototyping area, giving the designer a great deal of flexibility in

using the boards.

• Make sure that you set your Control Permissions correctly. If you have

not set the encoder to use a particular line, then when you press a

button on the encoder board, the MODE_IND LED on the decoder

board will light up, but the data line LED will not light up.

If all of these appear to be in order, then you can call +1 800 736 6677 or

Figure 5: The Prototyping Area and Power Supply

––

6

The Encoder Board

The encoder board has two sections that are of primary interest: the

encoder area and the transmitter area.

The Encoder Area

Figure 6 shows the encoder area of the development board.

The encoder is located in the center beneath the Linx logo. To the right are

buttons that will pull the encoder data lines high when pressed. Button S0

corresponds to data line D0, button S1 to data line D1 and so forth.

The diodes to the left isolate the data lines from each other while allowing

any line to activate the SEND line.

Beneath the encoder are two LEDs. D12 is connected to the MODE_IND

line and will light up as described in the MS Encoder Data Guide. D8 is

connected to the TX_CNTL line and will provide visual feedback by lighting

up when the encoder sends a word.

Figure 6: The Encoder Area

The Power Supply

The power supply is the same on both boards and consists of a standard

9V battery and a power jack connected to a 3.0V voltage regulator. The

regulator can provide approximately 500mA of current to the prototyping

area. If the added circuitry will need more than this, then the designer

must add an external supply. If the circuit will consistently draw more than

100mA of current, it might be better to use the power jack, as the battery

may run down fairly quickly, reducing testing and development time.

The jack accepts a standard 5.5mm plug with the tip ground and the outer

shell 7 to 16VDC positive supply. A reverse voltage protection diode has

been included on the board to protect the circuitry in case the voltage on

the plug is reversed, but it is still a good idea to double-check the polarity.

––

7

Beneath the LEDs is a button that is connected to the CREATE line. This

button is used to create the Code Word and set the Control Permissions as

described in the MS Series Encoder Data Guide.

There are three function switches to the left of the CREATE button. BSEL0

and BSEL1 are used to set the baud rate of the encoder as described in

the Figure 7 below.

The maximum baud rate for the LR Series is 10,000bps, so only 2,400 and

9,600bps can be used on boards populated with these modules. The ES

Series can use all four baud rates.

The PDN switch will connect the TX_CNTL line of the encoder to the PDN

line of the transmitter so that the TX Control Mode of the encoder can be

tested. This mode is described in the HS Series Encoder Data Guide.

If a BSEL switch is up, then the line is high (1, VCC); if down, then the line is

low (0, GND). If the PDN switch is up, then the encoder’s TX_CNTL line is

connected to the transmitter’s PDN line; if down, it is not connected and

the LR Series transmitter will not be activated unless the PDN line is pulled

high externally. The ES Series transmitter has an internal pull-up, so will be

active unless pulled low.

Baud Rate Selection Table

SEL_BAUD1 SEL_BAUD0 Baud Rate (bps)

0 0 2,400

0 1 9,600

1 0 19,200

1 1 28,800

Figure 7: Baud Rate Selection Table

Note: The decoder board must be set to the same baud rate in order for

the signal to be received correctly.

––

8

The Encoder Board RF Area

Figure 8 shows the RF area of the development board.

This board can be populated with either the LR Series transmitter (as

shown) or the ES Series transmitter. The LR Series transmitter will be

placed on the right side and the ANT1 connector will be populated. The

ES Series transmitter will be placed on the left and the ANT2 connector will

be populated. R27 is connected to the LADJ line of the LR transmitter to

reduce the output power to approximately 0dBm. The LR Series transmitter

is capable of producing more output power than may be legally acceptable,

so by reducing the output power, the range experienced with the evaluation

kit will more closely resemble the range that can be achieved with a final

certified product.

The Encoder Board Key Exchange Area

Figure 9 below shows the key exchange area of the development board.

This section allows for both a wire and infrared transfer of the Encryption

Key. The encoder can only receive a key, so only the infrared receiver

and KEY_IN jack are populated. The jack is simply connected directly to

the KEY_IN line on the encoder. The infrared receiver is more complex. A

schematic diagram of this circuit is shown in Figure 10.

Figure 8: Baud Rate Selection Table

Figure 9: The Encoder Board Key Exchange Area

––

9

G

N

D

R21

1

00k

V

CC

R1

8

9

.1

M

R2

0

5

1

k

V

CC

V

CC

G

N

D

G

N

D

G

N

D

C4

4.7

uF

R1

6

9

.1

M

R1

5

9

.1

M

R

1

9

1

0k

R14

5

.1

M

R17

9

.1

M

G

N

D

To KEY

_

I

N

C5

0

.

0

1u

F

G

N

D

+

-

G

N

D

V

CC

+

-

S

W

8

U

6

U

6

IR

1

Figure 10: The Infrared Receiver Circuit

The left side of the circuit consists of an op-amp that is set up as a timer to

feed current into the phototransistor for a specific amount of time after the

button is pressed. Since the phototransistor can pick up infrared radiation

from many sources, including lights, this keeps the output from randomly

switching and keeping the encoder awake. This circuit will keep the

phototransistor from constantly pulling current and will allow the encoder to

enter sleep mode, preventing it from also constantly pulling full current.

The circuit works in the following way: when SW8 is pressed, capacitor C4

will discharge and pull the negative input of the op amp low. This will make

the output of the op amp go high and supply current to the phototransistor

(IR1). C4 will begin to recharge through R14 as soon as SW8 is released.

At 5.1MΩ, it will take approximately 20 seconds for the voltage to get high

enough to make the output of the op amp go low and deactivate IR1.

The right half of the circuit uses a comparator as a data slicer to make

the output of the phototransistor into a square wave that is easier for the

encoder to read. The output of the comparator is then connected to the

KEY_IN line on the encoder. The Master Development board has a 10kΩ

resistor in series to prevent the jack from shorting the comparator out, but

it may not be necessary in a custom design.

––

10

The Decoder Board

The decoder board has three main sections of interest: the decoder area,

the receiver area, and the USB area.

The Decoder Area

Figure 11 shows the decoder area of the development board.

The decoder is placed in the center beneath the Linx logo. To the left are

LEDs that are connected to the decoder data lines. These will light up

when the decoder receives a signal from the encoder to take the data line

high. LED D0 corresponds to data line D0 and so forth.

Beneath the decoder is an LED that is connected to the MODE_IND line.

This will light up as described in the HS Series Decoder Data Guide.

Beneath the LED are three buttons. The one on the left labeled HS_SEND_

KEY is connected to the SEND_COPY line on the decoder. The one in

the middle is connected to the LEARN line, and the one on the right is

connected to the CREATE_KEY line. The HS_SEND_KEY button will cause

the decoder to begin sending a copy of its User Data when pressed at the

same time as the LEARN button. The LEARN button is used to learn the

Code Word from the encoder and, with the other two buttons, to make

the decoder enter special modes. The CREATE_KEY button will cause the

decoder to create a new key when pressed at the same time as the LEARN

button. All of these functions are described in detail in the HS Series

Decoder Data Guide.

There is one function switch to the left of the CREATE button. BSEL0 is

used to set the baud rate of the decoder as described in Figure 7.

Figure 11: The Decoder Area

––

11

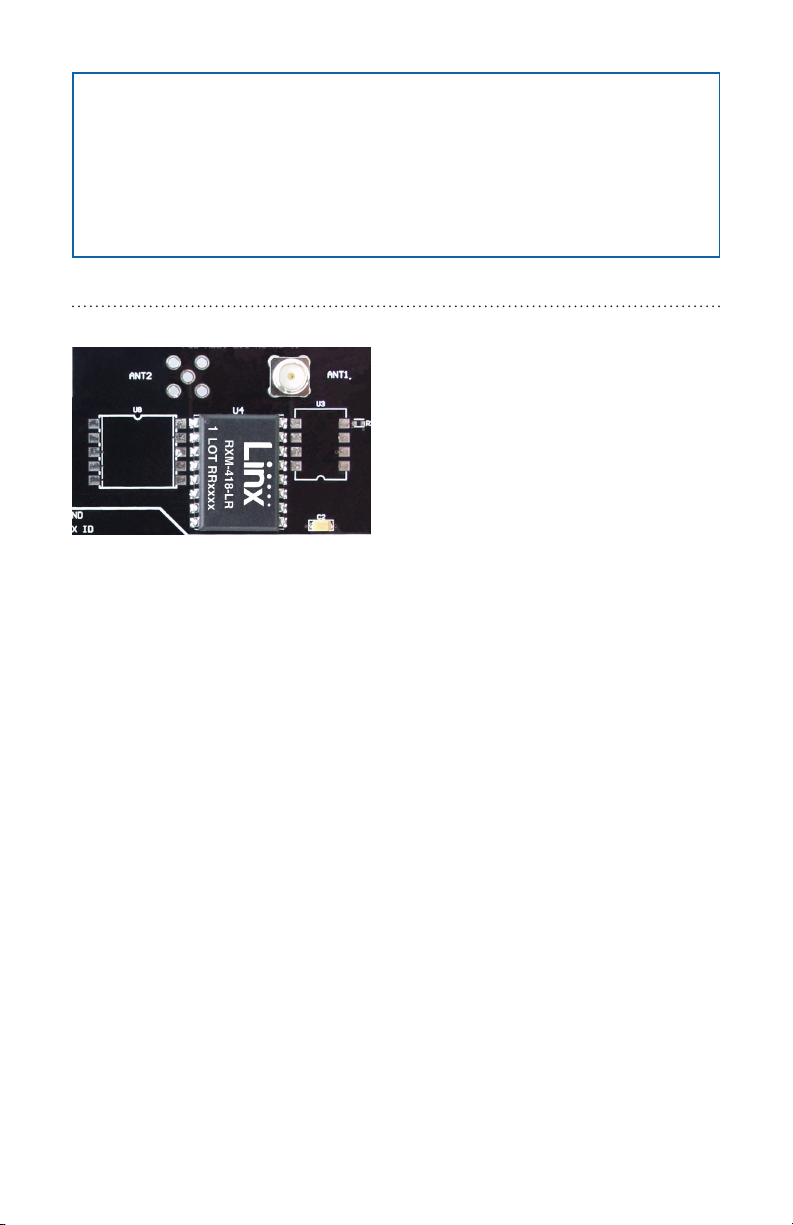

The Decoder Board RF Area

Figure 12 below shows the RF area of the development board.

This board can be populated with either the LR Series receiver (as shown)

or the ES Series receiver. Both modules can be placed on the same pads

in the center of the section, but the ANT1 connector will be populated

for the LR receiver and the ANT2 connector will be populated for the ES

receiver.

Figure 12: The Decoder Board RF Area

Note: The encoder board must be set to the same baud rate in order

for the signal to be received correctly. The maximum baud rate for the

LR Series is 10,000bps, so only 2,400 and 9,600bps can be used on

boards populated with these modules. The ES Series receiver can use

all four baud rates. If the switch is up, then the line is high, if it is down,

then the line is low.

––

12

The Decoder Board USB Area

The development boards have a Linx SDM-USB-QS-S module for use

with the included development software. This module is powered by the

USB bus so will not pull any current from the battery. Figure 13 shows this

section.

The microcontroller on the right monitors the decoder data lines and

generates commands that are sent to the development software on the PC

via the QS Series USB module. The RX_IND LED to the left of the module

will flash to indicate that data is being received from the microcontroller.

Figure 13: The Decoder Board USB Area

––

13

The Decoder Board Key Exchange Area

Figure 14 below shows the key exchange area of the development board.

The KEY_IN jack and the IR receiver circuit are identical to the encoder

board. Since the decoder must also send a key to an encoder and / or

another decoder, the KEY_OUT jack is populated. The infrared portion

consists of an infrared diode (IR2) that is modulated by the KEY_OUT line

of the decoder. When the SEND_KEY and LEARN buttons are pressed

and released, the decoder will begin sending the key to the jack and diode.

Simply plug a wire into the KEY_OUT jack on the decoder board and the

KEY_IN jack on the encoder board or activate the infrared receiver on the

encoder board to send the key across.

Figure 14: The Decoder Board Key Exchange Area

––

14

HS Series Master Development System Software

The MS Series Master Development System software can be used in one

of two modes. The default mode is as a simulation of the system. This

is a good way of showing how the MS Series can work in a system for

activating lights and doors.

The second mode is for use with the development system. When the

decoder board is plugged into the USB port, the kit can be used to activate

the features in the software. When a data line goes high on the decoder,

the microcontroller will send a command to the computer to control the

functions in the software. Please see the documentation included with the

software for details.

Figure 15: The HS Series Master Development Software

––

15

Installing the Software and Drivers

The software included with the Master Development System uses the QS

Series Direct Drivers and cannot be used with the Virtual COM Port Drivers.

For this reason, only the Direct Drivers are included on the CD with the

software.

The first time a QS module is plugged into a computer, Windows

will display the Found New Hardware Wizard, which will guide you

through installing the drivers. Application Note AN-00201 “Installing the

SDM-USB-QS-S Drivers” describes the installation of the drivers in detail.

The drivers should be installed before running the development software.

The HS Series Master Development System Software will automatically

start when the CD is inserted and the player in Figure 16 will appear.

Pressing the Install Software button will start the Installation Wizard, which

will guide you through the installation of the development software. The

View Documentation button will show a list of the application notes and

manuals related to the HS Series. Selecting one of these will open the file

in Adobe Acrobat. The Play Movie button will play a short video about Linx

on the Player Screen, which can be controlled with the Selection Keypad.

Clicking the button on the bottom right of the player will open the Linx

Technologies homepage in the computer’s default browser.

The View Documentation list also allows for the installation of Adobe

Acrobat Reader so that the documents may be viewed. There is also the

Install Software

View Documentation Play Movie

Exit

Go to the

Linx Website

Selection Keypad

Player Screen

Figure 16: Software Installer

––

16

option of installing Flash, which may be required if the Linx video does not

play correctly.

The Read Me file found in the View Documentation list will have extra

information on the software that may not be in the software documentation,

so it is a good idea to read this file before using the software.

This manual suits for next models

2

Table of contents

Other Linx Technologies Motherboard manuals

Linx Technologies

Linx Technologies HumPRO MDEV-900-PRO Service manual

Linx Technologies

Linx Technologies KH3 Series User manual

Linx Technologies

Linx Technologies 250 Series User manual

Linx Technologies

Linx Technologies EVAL-KH3 Series User manual

Linx Technologies

Linx Technologies ES Series User manual

Linx Technologies

Linx Technologies LT Series User manual