Linyang Photovoltaic BP60T User manual

PV MODULE INSTALLATION MANUAL

Jiangsu Linyang Photovoltaic Technology Co., Ltd

No.612 Huashi Rd, Qidong, Jiangsu, 226200

1 Introduction .............................................................................................................................. 2

2 Disclaimer ................................................................................................................................. 2

3 General ...................................................................................................................................... 2

4. Cautions ................................................................................................................................... 3

5 Installation ................................................................................................................................. 4

5.1 Installation safety ........................................................................................................... 4

5.2 Selection of installation conditions ................................................................................ 5

5.2.1 Working conditions ............................................................................................. 5

5.2.2 Geographical conditions ..................................................................................... 5

5.2.3 Selection of angle of inclination ......................................................................... 5

5.3 Mode of installation ....................................................................................................... 6

5.3.1 Frameless solar PV module installation .............................................................. 6

5.3.2 Frame solar PV moudue installation ................................................................. 12

5.4 Installation requirements .............................................................................................. 14

6 Electrical Installation .............................................................................................................. 15

6.1 Wiring and connection ................................................................................................. 15

6.2 PV module connector ................................................................................................... 15

6.3 Use appropriate components ........................................................................................ 15

6.4 Diodes .......................................................................................................................... 16

6.5 Cable protection ........................................................................................................... 16

7 Grounding ............................................................................................................................... 16

8 Cleaning and Maintenance ...................................................................................................... 17

Version No.................................................................................................................................. 17

Contents

1 Introduction

Thank you for choosing the product of Jiangsu Linyang Photovoltaic Technology Co., Ltd

(“Linyang Photovoltaic”). This installation manual applies to the operation and maintenance of

bifacial modules manufactured by Linyang Photovoltaic.

Linyang Photovoltaic modules have passed testing by international testing and certification

organizations. Please feel relaxed in using our products as long as you observe the terms and

conditions defined in this installation manual.

Please carefully read this Manual before operating and installing the module. This manual

covers the basic information on mechanical and electric installation and vital safety information,

which you must understand.

A “module” or “solar PV module” herein means one or several series solar modules. Please

retain this Manual for possible future use.

This manual applies exclusively to solar PV modules manufactured by Linyang Photovoltaic.

2 Disclaimer

Linyang Photovoltaic reserves the right to modify this installation manual without any prior

notice. Linyang Photovoltaic holds no liability for any damage or hurt whatsoever, including but not

limited to any personal injury, hurt or property arising from any module operation, system

installation or compliance or non-compliance with any instruction herein.

A client’s failure in observing instructions listed herein during any module installation will

result in expiry of the limited warranty of product provided to the client.

3 General

Linyang Photovoltaic designs its module according to IEC61730-1, conforming to the standard

for Application Class A.

A module conforming to Application Class A means that, the module may be used in systems

operating at greater than 50V DC or 240W where general contact access is anticipated. (If such an

application module passes IEC61730-1 and IEC61730-2, it shall be regarded as conforming to Class

II safety requirements.

All installation work must comply with the local codes and the relevant international electrical

standards.

The installation, operation and maintenance of module require high-level technical capacities

and experience, thus requiring qualified engineers with such skills and relevant basic electrical,

electronic and mechanical knowledge to implement.

4 Cautions

An improper operation may result in injury or death; the installation and commissioning of

solar PV system require specialized skills and knowledge. The installer shall, prior to the

installation, read and understand any and all safety measures described herein.

The following safety instructions and warnings are important integral parts of this Manual, as a

guidance. For any question, please contact our Customer Service for further help.

a) When a module is exposed to sunlight or any other light source, direct current is generated

inside the module, when contact with any electrical part of module may result in electric

shock.

b) Do not focus sunlight with a mirror or lens to shine on the solar PV module.

c) The front glass and back glass of solar PV module protect the module. A damaged solar

PV module is with electric hazard (electric shock and fire); such a module can not be

restored or repaired and shall be immediately replaced.

d) Under normal outdoor conditions, the current and voltage generated from the module are

somehow different from those listed in the parameter list. The parameter list is based on

testing under standard testing conditions. Therefore, when determining the parameters of

other components in the PV generation system related to the module power output, such as

rated voltage, conductor capacity, fuse capacity and controller capacity, design and install

such components based on 125% of the values of short-circuit current and open-circuit

voltage labeled on the module.

e) To reduce hazards of electric shock or combustion, opaque materials may be applied to

cover the module surface when installing a solar PV module.

f) The installation of a module array shall be conducted with devices to isolate sunlight;

module installation and/or maintenance shall be conducted by qualified professionals only.

g) If any accumulator is used in the PV system, its configuration with the module shall be

subject to the guidance of accumulator manufacturer.

h) No module shall be installed in any area with possible inflammable gas.

i) Strictly do not touch any electrical part of module directly with hand; use insulating tools

for electrical connections.

j) Do not dismantle any part or component in a solar PV module provided by Linyang

Photovoltaic without permission.

k) Read and understand all installation guidance before install, wire or maintain a module.

l) Do not lift a module through lifting a junction box or connection line.

m) All module systems shall be grounded; unless otherwise required, please observe IEC

norms or any other international norm or standard.

n) After the module is transported to the installation site, unpack all components carefully.

o) Do not stand or walk on a module, which may damage the module and cause personal

injury.

p) Only modules of the same size, specification and model can be connected in series.

q) In transit, please ensure no transport tool or module is subject to violent vibration, which

may damage the module or cause hidden cracks in the cell sheet in the module.

r) In transit, never drop a module from a transport tool, roof or hand onto the ground, which

may damage the module or the cell sheet in the module.

s) Do not wipe a module with any corrosive chemical agent.

t) Do not disconnect a module when it is loaded.

u) Do NOT touch the terminal box or the ends of the output cables (connectors) with bare

hands under sunlight, regardless of whether the PV module is connected to or

disconnected from the system.

5 Installation

5.1 Installation safety

a) Always wear dry insulation protection equipment: insulated tools, head gear, insulated

gloves, safety belt and safety shoes (with rubber soles).

b) Do NOT install modules under rain, snow or windy conditions.

c) Do NOT wear metallic jewelry which can cause electric shock during installation.

d) In case of ground installation, choose an appropriate installation height to avoid long-time

snow cover on the upper half of module in winter in snow weather;

e) Ensure smooth ventilation at the back of module (the recommended minimal clearance

between the module and the installation surface is 40cm); in case of roof installation, the

roof to be penetrated at the installation and fixing of module shall be properly sealed up to

avoid leakage at the roof;

f) During module installation, prevent the module from contacting any pointed object, which

may scratch the module; never put any heavy object on the module surface;

g) Never drill the module or apply any operation that may change the original structure of

module, otherwise the module quality and service life may be negatively affected; the

Warranty does not cover any processed module;

h) The module shall be installed under an environment of no pressure, no external force and

no deformation;

i) The frameless module shall be fixed on a durable base (composed of aluminum sections)

with flexible cushion (composed of rubber etc, for which EPDM (Ethylene Propylene

Diene Monomer) rubber or similar material is recommended). The base shall be fixed, not

mobile. Avoid any direct contact between the module and any metallic part or component

on the base.

j) Avoid unnecessary touch on the module during installation. The module surface may be

highly hot, which may cause burns or electric shock.

5.2 Selection of installation conditions

5.2.1 Working conditions

The recommended ambient environment for module installation is -40°C to 85°C (-4°F to

185°F).

Ensure that there is sufficient clearance between modules to keep ventilated, especially at high

temperatures.

Ensure that the wind or snow pressure on the module, after installation, does not exceed the

maximal allowed load.

If a module is under a salt mist (i.e. marine environment) or sulfur-bearing (i.e. sulfur-bearing

source or volcano) environment, it may suffer corrosion.

No module shall be soaked in water (pure water or salt water), or touch water for long time

(e.g. fountain or spray).

5.2.2 Geographical conditions

Solar modules shall be installed at locations where modules receive most illumination

throughout the year. In the northern hemisphere, a module should preferably face the south, while in

the southern hemisphere, a module should preferably face the north. When choosing a location,

avoid any tree, building or other obstacle that may cast any shadow on the module. Although the

manufacturer has installed appropriate bypass diodes to minimize such losses, a shadow may still

reduce the output power.

Do not install any module near open fire or inflammable materials.

Do not install any module at any location that may be soaked in water or continuously exposed

to any water truck of fountain.

5.2.3 Selection of angle of inclination

The angle of inclination of a solar module means the included angle between the module surface

and the ground level (as in Fig. 1); the module has the biggest power output when it vertically faces

the sun.

Fig 1:Module Installation Angle

If connected to an independent PV system, the installation angle of module should achieve

maximal power output based on the season and sunlight; as for an interconnected system, the

installation angle of module should be selected based on the basic principle of maximizing the

annual total output.

5.3 Mode of installation

A brand-new bifacial power generation technology is applied in the bifacial module of

Linyang Photovoltaic. We suggest that the bifacial module installation mode be adopted to prevent

its back being sheltered, thus to maximize power generation. If the client adopts any other

installation mode, Linyang Photovoltaic shall bear no joint or several liability whatsoever for any

subsequent consequences thereof.

The installation design shall be verified by a registered professional engineer. The installation

design and process shall conform to local electrical and building norms and codes.

At a minimum, each module shall be tightened by 4 points on both long sides. Linyang

Photovoltaic suggests that, the minimal width of supporting pole should be 40mm (1600Pa/1600Pa

load requirement, 1.5 safety factor).

System designers and installers shall be responsible for the load calculation and the selection

of suitable designs of support structure.

Use suitable fasteners with corrosion resistance. All fasteners (such as bolts, elastic washers,

flat washers, nuts, etc.) shall be stainless steel.

5.3.1 Frameless solar PV module installation

Installation clamps shall aluminum alloy or any metal material with equivalent performances.

Appropriate cushions shall be placed between clamps and module glass, for which Linyang

Photovoltaic recommends EPDM.

Linyang Photovoltaic has tested a variety of clamps from different suppliers, and recommends

the use of M8 fastening bolts for clamps.

Sunlight

Module

Angle of inclination

Horizontal line

The quantity of clamps depends on the pressure intensity of local wind and snow. If the

pressure is beyond the expected value, additional clamps or brackets shall be employed to guarantee

that the module can bear that pressure. The torsion force applied for installation shall be big enough

so that the module can be properly fixed (torsion force: 17-23Nm), as shown in the figure below :

Fig A

Fig B

The maximum load of the module in the table below is for beamless installation of the module,

(maximum load :downward≤5400pa,upward≤2400pa , Installed with Beams)

The clamps and installation methods in the table 2 are recommended to match the 60 cells

transparent glass bifacial modules manufactured by Linyang Photovoltaic( In table 1) .

Tab 1 Types of modules:

5BB modules 5BB half cut modules MBB modules

BP60T QP60T MP60T

BP60TL QP60TP MP60TL

BP60TP MP60HT

BP60TPL MP60HTL

A

A

Four clamps must be installed on long

side;

(Installed without Beams);

The beam should be perpendicular to the

long side ;

(Installed with Beams)

A

B

Six clamps must be installed on long side;

(

I

nstall

ed without Beams

);

Tab 2: Clamps and installation:

No Overlapping

size

Recommended supplier Clamps type and

length

Quantity and

site

Maximum load fastener

2-A1

14.5mm

(front)

14.5mm

(contrary)

Jiangyin

Haida New

Energy

Materials

Co.Ltd

HD-008V(end clamp)

HD-008W(middle clamp)

length=150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt +

spring

2-A2

HD-008V(end clamp)

HD-008W(middle clamp)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

2-B1

11mm

(front)

14.5mm

(contrary)

Schlette

(shanghai)

Solar

Technology

co.,Ltd

132002-004(end )

132001-002(middle)

length =150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Hexagon

socket

taper bolt

2-B2

132002-004(end)

132001-002(middle)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

2-C1

14mm

(front)

14mm

(contrary)

Shanghai

Chiko Solar

Technology

co.,Ltd

CK-406-150(end)

CK-455-150(middle)

length =150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

2-C2

CK-406-100(end)

CK-455-100(middle)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

2-D1

13mm

(front)

13mm

(contrary)

JiangSu

Akcome

science &

Technology

Co.Ltd.

AG0790A0-34(end)

AG0790A0-35

(middle)

l

ength

=150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

2-D2

AG0790A0-34(end)

AG0790A0-35

(middle)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

The clamps and installation methods in the table 4 are recommended to match the 60 cells

glazed glass bifacial modules manufactured by Linyang Photovoltaic(In table 3) .

Tab 3 Types of modules:

5BB modules(glazed glass) 5BB half cut modules(glazed glass)

MBB modules(glazed glass)

BP60 QP60 MP60

BP60L QP60P MP60L

BP60P MP60H

BP60PL MP60HL

Tab 4: Clamps and installation:

No Overlapping

size

Recommended supplier Clamps type and

length

Quantity and

site

Maximum load fastener

4-A1

15mm(front)

17.5mm

(contrary)

Jiangyin

Haida New

Energy

Materials

Co.Ltd

HD-005V(end clamp)

HD-005W(middle clamp)

length =150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt +

spring

4-A2

HD-005V(end clamp)

HD-005W(middle clamp)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

4-B1

14.5mm

(front)

14.5mm

(contrary)

Jiangyin

Haida New

Energy

Materials

Co.Ltd

HD-008V(end clamp)

HD-008W(middle clamp)

length=150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt +

spring

4-B2

HD-008V(end clamp)

HD-008W(middle clamp)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

4-C1

11mm

(front)

14.5mm

(contrary)

Schlette

(shanghai)

Solar

Technology

co.,Ltd

132002-004(end )

132001-002(middle)

length =150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Hexagon

socket

taper bolt

4-C2

132002-004(end)

132001-002(middle)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

4-D1

14mm

(front)

14mm

(contrary)

Shanghai

Chiko

Colar

Technology

co.,Ltd

CK-406-150(end)

CK-455-150(middle)

length =150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

4-D2

CK-406-100(end)

CK-455-100(middle)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

4-E1

13mm

(front)

13mm

(contrary)

JiangSu

Akcome

science &

Technology

Co.Ltd.

AG0790A0-34(end)

AG0790A0-35

(middle)

l

ength

=150mm

4 clamps

A=350±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

4-E2

AG0790A0-34(end)

AG0790A0-35

(middle)

length =100mm

6 clamps

A=210±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

The clamps and installation methods in the table 6 are recommended to match the 72 cells

transparent glass bifacial modules manufactured by Linyang Photovoltaic(In table 5) .

Tab 5 Types of modules:

5BB modules 5BB half cut modules MBB modules

BP72T MP72T

BP72TP MP72HT

Tab 6: Clamps and installation:

No Overlapping

size

Recommended supplier

Clamps type and

length

Quantity

and site

Maximum load fastener

6-A1

14.5mm

(front)

14.5mm

(contrary)

Jiangyin

Haida New

Energy

Materials

Co.Ltd

HD-008V(end clamp)

HD-008W(middle clamp)

length=150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt +

spring

6-A2

HD-008V(end clamp)

HD-008W(middle clamp)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

6-B1

11mm

(front)

14.5mm

(contrary)

Schlette

(shanghai)

Solar

Technology

co.,Ltd

132002-004(end )

132001-002(middle)

length =150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Hexagon

socket

taper bolt

6-B2

132002-004(end)

132001-002(middle)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

6-C1

14mm

(front)

14mm

(contrary)

Shanghai

Chiko

Colar

Technology

co.,Ltd

CK-406-150(end)

CK-455-150(middle)

length =150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

6-C2

CK-406-150(end)

CK-455-150(middle)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

6-D1

13mm

(front)

13mm

(contrary)

JiangSu

Akcome

science &

Technology

Co.Ltd.

AG0790A0-34(end)

AG0790A0-35

(middle)

length =150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

6-D2

AG0790A0-34(end)

AG0790A0-35

(middle)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

The clamps and installation methods in the table 8 are recommended to match the 72 cells

glazed glass bifacial modules manufactured by Linyang Photovoltaic(In table 7) .

Tab 7 Types of modules:

5BB modules(glazed glass)

5BB half cut modules(glazed glass)

MBB modules(glazed glass)

BP72 MP72

BP72P MP72H

Tab 8: Clamps and installation:

No Overlapping

size

Recommended supplier Clamps type and

length

Quantity and

site

Maximum load fastener

8-A1

15mm(front)

17.5mm

(contrary)

Jiangyin

Haida New

Energy

Materials

Co.Ltd

HD-005V(end clamp)

HD-005W(middle clamp)

length =150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt +

spring

8-A2

HD-005V(end clamp)

HD-005W(middle clamp)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

8-B1

14.5mm

(front)

14.5mm

(contrary)

Jiangyin

Haida New

Energy

Materials

Co.Ltd

HD-008V(end clamp)

HD-008W(middle clamp)

length=150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt +

spring

8-B2

HD-008V(end clamp)

HD-008W(middle clamp)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

8-C1

11mm

(front)

14.5mm

(contrary)

Schlette

(shanghai)

Solar

Technology

co.,Ltd

132002-004(end )

132001-002(middle)

length =150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Hexagon

socket

taper bolt

8-C2

132002-004(end)

132001-002(middle)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

8-D1

14mm

(front)

14mm

(contrary)

Shanghai

Chiko

Colar

Technology

co.,Ltd

CK-406-150(end)

CK-455-150(middle)

length =150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

8-D2

CK-406-150(end)

CK-455-150(middle)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

8-E1

13mm

(front)

13mm

(contrary)

JiangSu

Akcome

science &

Technology

Co.Ltd.

AG0790A0-34(end)

AG0790A0-35

(middle)

l

ength

=150mm

4 clamps

A=420±20mm

Fig A

Downward≤2400pa

Upward≤2400pa

Inside

hexagonal

bolt

8-E2

AG0790A0-34(end)

AG0790A0-35

(middle)

length =150mm

6 clamps

A=260±20mm

Fig B

Downward≤5400pa

Upward≤2400pa

Take the following measures when clamps are applied to install a module:

(1) Do not bend the module;

(2) No installation component covers any solar cell;

(3) Do not scratch any module glass surface;

(4) Ensure that the overlapping width of module and clamp(including the top and bottom)is

equal or greater than 11mm;

(5) Ensure that the minimum thickness of clamp is 1.5 mm.

5.3.2 Frame solar PV moudue installation

Install the moduls according to the following examples and recommendations, if the way of

installation is different from linyang company, please consult Lin Yang for technical support and

after-sales service,and obtain Lin Yang to agree,otherwise, the warranty will expire.

The minimum spacing between the two moduls is 10mm。

The drain hole shall not be blocked under any circumstances during installation or use.

Maximum load :downward≤5400pa,upward≤5400pa。

The following table shows the types of Lin Yang 72cells framed bifacial and double-glass

modules:

5BB modules 5BB half cut modules MBB modules MBB glazed glass modules

BP72TF BP72F MP72TF MP72F

BP72TPF BP72PF MP72TFL MP72FL

BP72TFL BP72FL MP72HTF MP72HF

BP72TPFL BP72PFL MP72HTFL MP72HFL

The installation mode is divided into two types: installation of mounting hole and installation

of pressing block

5.3.2.1 Installation of mounting hole

Fix the modul on the rail with bolts through the mounting hole on the back frame of the

module:

Fig 1

Installation details are shown below:

Maximum load

72 cells framed bifacial and double-glass module

Use 4 intermediate

mounting holes

downward:≤5400Pa

upward:≤5400Pa

There are 12 mounting holes on the frame of each module. Under normal circumstances, 4 1/4

L installation holes can be used. In areas with high wind load and heavy snow, it is recommended to

add 4 additional installation points (4 outside installation holes).

Secure module in each position using bolts, washer, spring washer and nut and tighten to 16-

20N ▪M torque.

5.3.2.2 Installation of pressing block(clamping)

The fixture must have an overlap of at least 7mm to 10mm with the module frame mounting

width。

Use at least 4 clamps to attach the module to the mounting bracket.How many clamps to use

depends on the local wind and snow pressure intensity. If the pressure exceeds the expected

estimate, additional clamps or supports are required to ensure the assembly can withstand the

pressure. The torque applied during installation should be large enough for the assembly to hold

well (16-20n ▪m).

Fig 2

❶

end clamp

❷

bolt

❸

frame

❹

rail

❺

middle clamp

❻

rail

❺

❷

❷

❶

❸

❸ ❸

❹ ❻

Installation details are shown below(clamp length ≥40mm):

5.4 Installation requirements

Ensure that the module meets the overall technical requirements of the system.

Ensure that no element or component of any other system will cause any destructive

mechanical or electric property to the module.

Modules may be connected in series to increase the voltage or in parallel to increase the

current. In case of series connection, the positive electrode of module is connected to the negative

electrode of next module. In case of parallel connection, the positive electrode of module is

connected to the positive electrode of next module.

The quantity of provided bypass diodes may vary, based on the module model.

Connect an appropriate quantity of modules according to the voltage specification of inverter

applied in the system. Even under the worst local temperature conditions, the voltage of connected

modules shall not surpass the voltage value allowed by the system.

If no over-current protective device (fuse) is not used in series connection in each module

series, at most two module series may be connected in parallel. If an appropriate verified over-

current protective device is connected in series to each module series, three or more module series

may be connected in parallel.

To avoid (or reduce) the mismatch effect of array, it is suggested that modules with similar

electric properties should be connected in the same series.

To reduce risks from indirect lightning stroke, avoid loops when designing the system.

downward:≤5400Pa

upward:≤2400Pa

72 cells framed bifacial and double-glass module

A=495±50mm

For the recommended maximum rated fuse current, see the appendix.

In view of the thermal expansion effect between modules, the minimal clearance between

modules shall be 10mm, which means the minimal linear distance between the plastic corner

protectors of two neighboring modules.

Caution: Modules of Linyang Photovoltaic may be installed in the mode of installation

shown in the above figure. For any other mode of installation, please contact Linyang

Photovoltaic for further information and permission. The limited warranty provided by

Linyang Photovoltaic shall become invalid if any mode of installation deviates from the

guidance in this Manual.

6 Electrical Installation

6.1 Wiring and connection

Please confirm whether wiring connection is correct prior to power generation, in order to

reduce lightning stroke and short-circuit risks. A wiring error may exist if the measured open-circuit

voltage and short-circuit current are different from those in the technical specifications.

In case of series connection, select solar modules with current at the same level to connect; the

voltage generated by modules in series connection shall not surpass the maximum voltage allowed

in the system. The quantity of modules in each series depends on the system design, inverter type

and environment conditions.

The maximum rated fuse current value of each module series is marked on the product tag and

in the specification and parameter list. The rated fuse current corresponds to the highest reverse

current value that the module can withstand. Please apply appropriate fuses to protect the modules

in series or parallel connection in the circuit, based on the maximum fuse current and the local

electric property installation requirements.

6.2 PV module connector

Ensure that the connector is tightened and properly connected. No connector shall bear any

external pressure. The connector can only be used for circuit connection, not for turning the circuit

on or off. Keep the connector dry and clean; avoid rain or moisture. Prevent the connector from

direct sunlight or soaking in water.

6.3 Use appropriate components

All the extra conductors, adapters and plugs shall conform to outdoor application requirements.

Ensure their electrical and mechanical performances.

Ensure that all the applied materials meet the requirements of maximum voltage, current,

humidity and temperature of the system.

A module may generate greater current or voltage. Thus, multiple the parameters on the

module nameplate by 1.25, when selecting the parameters of electrical elements, such as rated

voltage, rated current and fuse capacity.

6.4 Diodes

When a module is covered by a shadow, a reverse bias voltage may occur, possibly leading to

hot spot. The function of diode is to reduce adverse effect of heating and current decrease arising

from such circumstances.

All Linyang modules are equipped with diodes, providing proper circuit protection for the

modules.

6.5 Cable protection

The permitted solar cable is single-cord cable, at the grade of 2.5-10mm2 (814 AWG), 90°C;

also, it is with proper insulation performance so that it can withstand the possible maximum open-

circuit voltage (e.g. TUV 2PfG1169). It is necessary to select appropriate conductor specifications

to reduce the voltage drop. The conductor shall be made of copper.

Apply ties with UV resistance to fix cables onto the installation system. Take proper measures

to protect exposed cables from damage (e.g. place them into plastic bushings with UV- and aging-

resistance). Avoid directly exposing cables to direct sunlight. When fixing a junction box

conductor to the bracket, the bending radius of conductor shall not be less than 60mm, and the rated

current shall exceed 10A. Special Caution: The temperature ceiling of cable is 85°C.

7 Grounding

Equipment grounding: There is no exposed conductor in the frameless double-glass PV

module; thus, grounding is not required in accordance with NEC codes.

The framed modules need to be grounded (although it has been confirmed that the modules

meet safety level 2) to ensure that the grounding method meets local electrical directives and

regulations.

Earth assembly has a pre-earthing hole in its edge of use. Correct earthing method is use of

suitable earthing conductor to connect assembly edge to all metal structural parts at the other end.

Such earthing conductor shall adopt copper, copper alloy, or other suitable material. Earthing

conductor must be connected to the soil using suitable earthing electrode. The method shown below

shall be used to ensure connection of positive electrode to assembly edge without scratching edge

oxide film.

Spring washer

Flat washer

Star washer

(SS304)

Copper wire

Hexagonal bolt

Assembly edge

Nut

All module brackets or clamps shall be properly grounded. The surface of metallic bracket

shall be electroplated to guarantee its nice electric conductivity.

8 Cleaning and Maintenance

The designed service life of module is long, so regular check and maintenance are required,

especially during the warranty period, which is under the user’s responsibility. Please timely notify

the supplier (usually within 2 weeks) once any module damage is found.

If the angle of inclination of module is not less than 5 degrees, normal rainfall under most

weather conditions is sufficient to keep the module glass surface clean. In case of excessive dust

accumulation, soft cloth and water will suffice to clean the glass surface. Never use any cleaning

agent containing acid or alkali to clean any module. In case of accumulated snow, use a soft hair

brush to clean the module surface.

It is suggested that, a module can only be cleaned at a temperature of 10°C〜30°C (in the

early morning or evening). Please do not touch the conductor; do not clean any damaged module,

which may lead to electric shock.

Version No.

First Version; Version No.:LYGF/ID.M2-JS-TS-IM-004 A/0;

This manual suits for next models

9

Table of contents

Popular Solar Panel manuals by other brands

UNIRAC

UNIRAC SUNFRAME - INSTALLATION 802 installation manual

Astronergy

Astronergy CHSM6610M manual

Lennox

Lennox SunSource installlation instructions

Qcells

Qcells Q.PEAK DUO ML-G9 Series Installation and operation manual

NDS

NDS Dometic LSE 160 BF Installation and operating manual

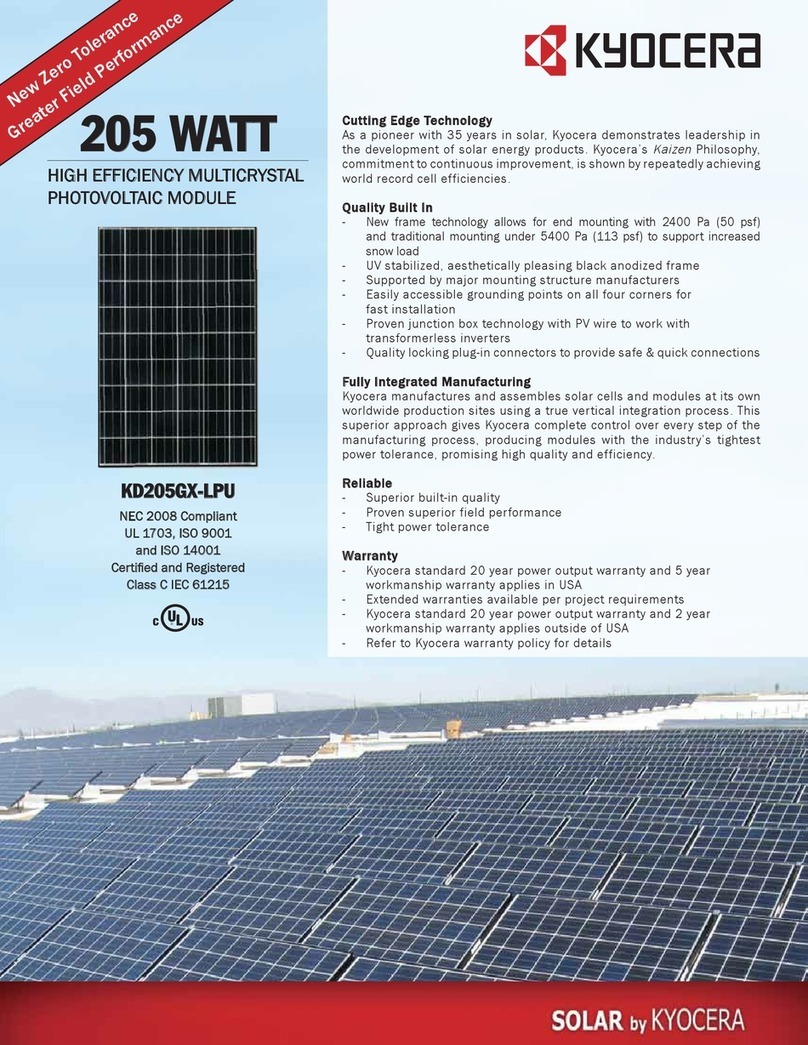

Kyocera

Kyocera KD205GX-LPU datasheet