Lister Petter LPP Series Service manual

LPP PetroL genset

oPerators' Handbook

ORIGINAL INSTRUCTIONS

P027-10760

LPP SERIES

2

Statement of Indemnity

P027-10760

WARNING

WARNING

WARNING

WARNING

3

CONTENTS

4

12

1

16

18

22

2

31

32

33

3

4

LPP PETROL GENSET OPERATORS' HANDBOOK

Read the information in this section carefully and follow all the advice given. Pay

special attention to the cautions and warnings demonstrated below, which are

used throughout this handbook.

DANGER

WARNING

CAUTION

SAFETY INFORMATION

LPP PETROL GENSET OPERATORS' HANDBOOK

WARNING

1. Read carefully and understand operator manual prior to operation of this product.

Follow all warnings and instructions.

2. Know your equipment. Consider the applications, limitations, and the potential

power supply such as frequency, voltage, AC wave shape etc.

generator at least 1m (3 ft) away from buildings or other equipment when

operating the generator. If the generator is tilted, fuel spillage and bad lubrication

may result.

SAFETY AND OPERATION RULES

4. Load must be kept within rating stated on generator nameplate. Overloading

will damage the unit or shorten its life.

5. Engine must not be run at excessive speeds. Operating an engine at excessive

speeds increases the hazards of personal injury. Do not tamper with parts which

may increase or decrease the governed speed.

6. To prevent accidental starting, always remove the spark plug or cable from the

spark plug before maintaining the generator or engine.

7. Units with broken or missing parts, or without protective

housing or covers, should never be operated. Contact your

service center or local dealer for replacement parts.

6

LPP PETROL GENSET OPERATORS' HANDBOOK

8. Units should not be operated or stored in wet or damp

conditions or on highly conductive locations such as metal

decking and steel work.

9. Keep the generator clean and free of oil, mud, and other foreign matter.

10. Extension cords, power cords, and all electrical equipment must be in good

condition. Never operate electrical equipment with damaged or defective

cords.

fuel tank empty. Fuel should not be stored near the

generator.

12. Your generator should never be operated under these conditions:

a. Uncontrolled change in engine speed.

b. Electrical output loss.

c. Overheating in connected equipment.

e. Damaged receptacles.

g. Excessive vibration.

h. Flame or smoke.

i. Enclosed area.

j. Rain or inclement weather. Do not let the unit get wet when operating.

13. Check the fuel system periodically for leaks or signs of deterioration such as

chafed or spongy hose, loose or missing clamps, or damaged tank or cap.

All defects should be corrected before operation.

14. The generator should be operated, serviced, and refueled only under the

following conditions:

the generator in an enclosed area, even if doors or

windows are open; avoid areas where vapors may be

trapped such as pits, garages, cellars, excavations

and boat bilges.

7

LPP PETROL GENSET OPERATORS' HANDBOOK

DANGER - CARBON MONOXIDE HAZARD: The engine exhaust contains

carbon monoxide, a poisonous, odourless, invisible gas which, if breathed, may

cause death or serious personal injury. If you start to feel sick, dizzy or weak

while using the generator, shut it off and get to fresh air right away; you may

have carbon monoxide poisoning.

cooled units. Temperatures should not exceed ambient 40°C (104°F).

c.Refuel the generator in a well lighted area. Avoid fuel spills and never refuel

while the generator is running. Allow engine to cool for two minutes prior to

refueling.

as power tools, welders, and grinders .

8

LPP PETROL GENSET OPERATORS' HANDBOOK

f. Do not smoke near the generator.

15. Ensure that generator is properly grounded.

16. Do not wear loose clothing, jewelry, or anything that may be caught in the

starter or other rotating parts.

17. Unit must reach operating speed before electrical loads are connected.

Disconnect loads before turning off engine.

18. To prevent surging that may possibly damage equipment, do not allow engine

to run out of fuel when electrical loads are applied.

19. Do not stick anything through ventilating slots, even when the generator is

not operating. This can damage the generator or cause personal injury.

20. Before transporting the generator in a vehicle, drain all fuel to prevent leakage

that may occur.

21. Use proper lifting techniques when transporting the generator from site to

site. Improper lifting techniques may result in personal injury.

9

LPP PETROL GENSET OPERATORS' HANDBOOK

surfaces which became hot during operation.

23. Know how to stop the generator quickly and understand operation of all

the controls. Never permit anyone to operate the generator without proper

instructions.

24. Keep children and pets away from the generator when the generator is

running.

25. Avoid placing any flammable materials near the exhaust outlet during

operation.

26. Never touch the machine with wet hands or electrical shock will occur.

ELECTRICAL SAFETY

Every year many people injured through electrical shock. Portable, electrically

operated tools account for the second largest number of injuries, with the plug or

cord at fault in two-thirds of the incidents. Insurance company statistics indicates

that rental equipment is involved in a high percentage of such accidents, and it

is important to realized that the rental operator is liable for those defects of which

he is aware, as well as those which would have been disclosed by a reasonable

investigation.

10

LPP PETROL GENSET OPERATORS' HANDBOOK

LEAKAGE CURRENT

One of the most important checks to be sure a tool is safe is for excessive leakage

equipment housing or enclosure.

exceeds about 48 volts that hazards exists. At a common supply voltage of 120V

pass through the body.

One milliampere (1/1000 of an ampere) will

be felt by most individuals as a slight tingling

sensation. A defective hand drill or floor

polisher might allow this amount of current

to use the equipment, until he happens to

touch a water connection, heating register,

metal window sash or other grounded metal

object. He has now completed the circuit to

through his body.

required to operate a 25-watt lamp) flow

through his body, it will result in a violet

muscle reaction, throwing him away from the

equipment.

If the current is much above 10 milliamperes,

the person will lose his ability to release his grip

on the electricity equipment. While the heart

normally can continue to function, fatigue sets

in, followed by death if no help is available.

11

LPP PETROL GENSET OPERATORS' HANDBOOK

At about 100 milliamperes (less than half that

heart is no longer able to pump blood.

When a tool is operating normally, electricity

passes through one wire the tool and back out

the second wire. Little or no current should

travel down the ground wire.

If a tool’s insulation becomes defective, some

of the electrical current will pass through the

tool’s case to the ground wire and back to the

ground. The person holding the tool will not be

line fuse will open. The only problem is that

this depends on a good ground path all the

way back to the ground itself.

If the ground wire doesn’t make a perfect

contact all the way back to the ground, the

to the ground. The amount of shock the person

receives will depend on how defective the

tool’s insulation is and how well grounded

the main is.

12

LPP PETROL GENSET OPERATORS' HANDBOOK

WATTAGE CALCULATION

The biggest problem in selecting a generator is determining the power requirements

that must be met under operating conditions.

Under-sizing of the generator is the single most common mistake and can be

avoided by considering all the loads to be connected to the generator. Additionally,

calculating the starting requirements of any electric motor operated equipment is

a very important consideration.

An estimate of the total load that will be connected to the generator can be made

by getting the nameplate amperage of all equipment or tools to be used. The

nameplate, showing the electrical requirements, is found on all electric powered

tools, appliances, electric motors or devices. It lists such information as running

amperage, the speed at which the tool operates; hertz,or frequency; phase; and

Once the total amperage draw for all tools and equipment is known, the following

can be used to establish starting wattage required:

If the equipment is for heating or lighting and contains no electric motors, multiply

the running amperage requirement times 1, times the voltage rating or requirement.

The result will tell the wattage required for this application. Heaters, light bulbs,

coffee makers, hot plates, are refered to as resistive loads. This type of equipment

draws a constant amount of current while operating.

If the equipment to be powered consists of hand tools, such as saws, drills or

other, handheld type of equipment; multiply the running amperage times 2, times

the voltage requirement. Again, the result will tell the wattage required for this

application. These types of equipment typically draw twice their normal, free running

amperage when used at full capacity or when starting the motor.

If the equipment being run is stationary equipment or appliances containing electric

motors, multiply the running amperage times 3, times the voltage requirement.

Once again, the result will tell the wattage required for this application. Electric

motor driven stationary equipment typically requires up to three times the running

amperage when starting, until the machine’s motor comes up to operating

speed.

Generator wattage required = (amps) x (volts) x (1, 2, or 3)

This example will help to explain these requirements.

A customer wants to operate the following equipment on a generator:

and (5) Four sixty-watt light bulbs.

SELECTING A GENERATOR

13

LPP PETROL GENSET OPERATORS' HANDBOOK

Tools / Equipment Nameplate Running Watts Times (x)

1, 2, 3 Starting Watts

Radiant heater 1250 1 1250

Freezer 400 3 1200

Small refrigerator 400 3 1200

Microwave Oven 750 1 750

4 Sixty-watt Light Bulbs 240 1 240

Total 3840 4640

A total of 4640 starting watts are required if all the items were started simultaneously.

This would require the use of generator with a minimum continuous rating of 5000

watts.

TYPICAL EQUIPMENT REQUIREMENTS

Appliance Watts Appliance Watts

Light bulb See bulb Coffee makers 400-700

Clothes dryer 5000-10,000 Window fan 200

Iron(Hand) 500-1500 Radio 50-200

Portable heater 600-4800 Air conditioner

(10000 BTU) 2000-3000

Toaster 900-1650 Automatic washer 150-1500

0-1/2 inch hand saw 1000-2500 Refrigerator 600-2000

Water heater 3000-5000 Television 100-500

Water pump 1000-3000 Vacuum cleaner 200-300

Sump pump 400-3000 Electric drill 225-100

Food freezer 300-500 Hot plate 330-1100

ELECTRIC MOTOR LOADS

It is characteristic of common electric motors in normal operation to draw up to

six times their running current while starting. The following table shows the watts

required to start motors, however if an electric motor fails to start or reach running

speed, turn off the appliance or tool immediately to avoid equipment damage.

Always check the requirements of the tool or appliance being used compared to

the rated output of the generator.

14

LPP PETROL GENSET OPERATORS' HANDBOOK

Motor size (HP) Running watts Watts required to start motor

Repulsion induction Capacitor Split phase

1/8 275 600 850 1200

1/6 275 600 850 2050

1/4 400 850 1050 2400

1/3 450 975 1350 2700

1/2 600 1300 1800 3600

3/4 850 1900 2600

1 1100 2500 3300

LPP PETROL GENSET OPERATORS' HANDBOOK

OPERATING VOLTAGE

CAUTION

A power line conditioner should be used when running one or more of the following

solid state equipments:

Televisions

Personal computer

Copy machines

Telephone equipment

Kitchen appliances with digital displays

Garage door openers

Stereos

Quartz clocks

Other solid state equipment may require a power line conditioner.

16

LPP PETROL GENSET OPERATORS' HANDBOOK

INSTALLATION

WARNING

To avoid backfeeding into utility systems, isolation of the residence electrical

system is required. Before temporary connection of the generator to the residence

electrical system, turn off the main service / disconnect.

If your generator is to be used as a stand-by power source in case of utility power

failure, it should be installed by a registered electrician and in compliance with all

applicable local electrical codes.

Proper use requires that a double throw transfer switch be installed by a licensed

between utility power and the generator’s output, thereby preventing backfeed

into the power utility’s electrical system.

17

LPP PETROL GENSET OPERATORS' HANDBOOK

WARNING

Always follow local codes and regulations that apply to the installation of any item

that concerns this product.

EXTENSION CORD

Maximum recommended lengths (in feet)

Amps

Dia.

0.1285in

(3.26mm)

Wire

Dia.

0.1019in

(2.59mm)

Wire

Dia.

0.0808in

(2.05mm)

Wire

Dia.

0.0641in

(1.63mm)

Wire

Dia.

0.0508in

(1.29mm)

Wire

2.5 1000 600 375 250

5 500 300 200 125

7.5 350 200 125 100

10 250 150 100 50

15 150 100 65

20 175 125 75 50

25 150 100 60

30 125 65

40 90

245) or the equivalent to withstand mechanical stresses.

LINE TRANSFER SWITCH

If this generator is used for standby service, it must have a transfer switch

between the utility power service and the generator. The transfer switch not only

prevents the utility power from feeding into the generator, but it also prevents the

generator from feeding into the utility company’s lines. This is intended to protect

a serviceman who may be working on a damaged line. THIS INSTALLATION

MUST BE DONE BY A LINCENSED ELECTRICIAN AND ALL LOCAL CODES

MUST BE FOLLOWED.

18

LPP PETROL GENSET OPERATORS' HANDBOOK

PRE-OPERATION CHECK

GROUNDING

Be sure to ground (earth) the generator.

The ground terminal connected to the frame of the generator has been provided

for grounding purpose.

(1) Ground wire diameter: 0.12 mm (0.005in) per ampere

The ground wire should be made of 0.1285 in dia (AWG#8) copper wire. Do not

use wire with a higher gauge number. Higher gauge numbers indicate thinner

wire, which may not provide an adequate ground path.

generator frame. Tighten the lock nut on top of the ground wire end terminal.

The other end of the ground wire must be securely fastened to an approved

ground source. The examples given below illustrate a few of the ways in which

a good ground source may be established.

A metal underground water pipe in direct contact with the earth for at least 10

feet canbe used as a grounding source. If an underground pipe is unavailable,

an 8 foot length of pipe or rod may be used as the ground source. The pipe

should be 3/4 inch diameter or larger and the outer surface must be noncorrosive.

If a steel or iron rod is used it should be at least 5/8 inch diameter and if a

nonferrous rod is used it should be at least 1/2 inch diameter and be listed

as material for grounding. Drive the rod or pipe to a depth of 8 feet. If a rock

bottom is encountered less than 4 feet down , bury the rod or pipe in a trench.

All electrical tools and appliances operated from this generator, must be properly

grounded by use of a third wire or be "Double insulated".

19

LPP PETROL GENSET OPERATORS' HANDBOOK

It is recommended to:

1. Use electrical devices with 3 prong power cords.

2. Use an extension cord with a 3 hole receptacle and a 3 prong plug at opposite

ends to ensure continuity of the ground protection from the generator to

appliance.

For the approved ground sources, refer to the local laws and regulations. If not

LUBRICATION

amount and type of oil. Your generator has been shipped from the factory

without oil in the crankcase. Operating the generator without oil can damage

the engine.

35(23(5$7,21&+(&.

/XEULFDWLRQ

'RQRWDWWHPSWWRVWDUWWKHHQJLQHZLWKRXW

ILOOLQJ WKH FUDQNFDVH ZLWK WKH SURSHU

DPRXQW DQG W\SH RI RLO <RXU JHQHUDWRU

KDV EHHQ VKLSSHG IURP WKH IDFWRU\

ZLWKRXWRLOLQWKHFUDQNFDVH2SHUDWLQJ

WKH JHQHUDWRU ZLWKRXW RLO FDQ GDPDJH

WKHHQJLQH

)LOO WKH HQJLQH ZLWK RLO DFFRUGLQJ WR WKH

RSHUDWRUPDQXDO)RUXQLWVZLWKDGLSVWLFN

ILOORLOWRWKHSURSHUOHYHO8QLWVZLWKRXWD

GLSVWLFN VKRXOG EH ILOOHG WR WKH WRS RI WKH

RSHQLQJRIWKHRLOILOO'RQRWRYHUILOO'RQRWVFUHZWKHRLOGLSVWLFNLQWRWKHRLOILOOHUQHFNWRFKHFN

RLOOHYHO

(QJLQHRLOUHFRPPHQGDWLRQV

Ƶ 2LOLVDPDMRUIDFWRUDIIHFWLQJSHUIRUPDQFHDQGVHUYLFHOLIH

Ƶ 8VLQJ VWURNH DXWRPRWLYH GHWHUJHQW RLO 6$( : LV UHFRPPHQGHG IRU JHQHUDO

XVH

Ƶ 6HOHFWLQJWKHYLVFRVLW\LVEDVHGRQWKHDLUWHPSHUDWXUHDWWKHWLPHRIRSHUDWLRQ

Ƶ 5HFRPPHQGHGHQJLQHRLOFODVVLILFDWLRQ$3,VHUYLFH³6(´RUKLJKHUJUDGH

/RZRLOZDUQLQJV\VWHP

0RVWRIJHQHUDWRUVDUHHTXLSSHGZLWKDORZRLOVHQVRU,IWKHRLOOHYHOEHFRPHVORZHUWKDQUHTXLUHG

WKHVHQVRUZLOODFWLYDWHDZDUQLQJGHYLFHRUVWRSWKHHQJLQH

,IWKHJHQHUDWRUVWRSVDQGWKHRLOOHYHOLVZLWKLQVSHFLILFDWLRQVFKHFNWRVHHLIJHQHUDWRULVVLWWLQJDW

DQDQJOHWKDWIRUFHVRLOWRVKLIW3ODFHRQDQHYHQVXUIDFHWRFRUUHFWWKLV,IHQJLQHIDLOVWRVWDUWWKH

RLOOHYHOPD\QRWEHVXIILFLHQWWRGHDFWLYDWHORZRLOOHYHOVZLWFK0DNHVXUHWKHVXPSLVFRPSOHWHO\

IXOORIRLO

)XHOUHFRPPHQGDWLRQV

6WURNH(QJLQH

8VLQJXQOHDGHGSHWUROZLWKDSXPSRFWDQHUDWLQJRIRUKLJKHU8QOHDGHGSHWUROSURGXFHV

IHZHU HQJLQH DQG VSDUN SOXJ GHSRVLWV DQG H[WHQGV H[KDXVW V\VWHP OLIH 1HYHU XVH VWDOH RU

FRQWDPLQDWHGSHWURORUDQRLOSHWUROPL[WXUH$YRLGJHWWLQJGLUWRUZDWHULQWKHIXHOWDQN

2FFDVLRQDOO\ \RX PD\ KHDU D OLJKW ³ VSDUN NQRFN´ RU ³SLQJLQJ´ PHWDOOLF UDSSLQJ QRLVH ZKLOH

RSHUDWLQJXQGHUKHDY\ORDGV7KLVLVQRFDXVHIRUFRQFHUQ

,IVSDUNNQRFNRUSLQJLQJRFFXUVDWDVWHDG\HQJLQHVSHHGXQGHUQRUPDOORDGFKDQJHEUDQGVRISHWURO

1RWLFH

5XQQLQJ WKH HQJLQH ZLWK SHUVLVWHQW VSDUN NQRFN RU SLQJLQJ FDQ FDXVH HQJLQH GDPDJH

5XQQLQJWKHHQJLQHZLWKSHUVLVWHQWVSDUNNQRFNRUSLQJLQJLVFRQVLGHUHGPLVXVH

Fill the engine with oil according to the operator manual. For units with a dipstick,

WARNING

20

LPP PETROL GENSET OPERATORS' HANDBOOK

ENGINE OIL RECOMMENDATIONS

Oil is a major factor affecting performance and service life.

general use.

operation.

LOW OIL WARNING SYSTEM

Most of generators are equipped with a low oil sensor. If the oil level becomes lower

than required, the sensor will activate a warning device or stop the engine.

generator is sitting at an angle that forces oil to shift. Place on an even surface to

low oil level switch. Make sure the sump is completely full of oil.

FUEL RECOMMENDATIONS

4-Stroke Engine

Using unleaded petrol with a pump octane rating of 86 or higher. Unleaded petrol

produces fewer engine and spark plug deposits and extends exhaust system life.

Never use stale or contaminated petrol or an oil/petrol mixture. Avoid getting dirt

or water in the fuel tank.

Occasionally you may hear a light "spark knock" or "pinging" (metallic rapping

noise) while operating under heavy loads. This is no cause for concern.

If spark knock or pinging occurs at a steady engine speed, under normal load,

change brands of petrol.

Note:

2-Stroke Engine

Use oil-mixed petrol. If not, engine will be overheated. Usually the petrol and oil

mixing ratio: 50:1

Table of contents

Other Lister Petter Portable Generator manuals

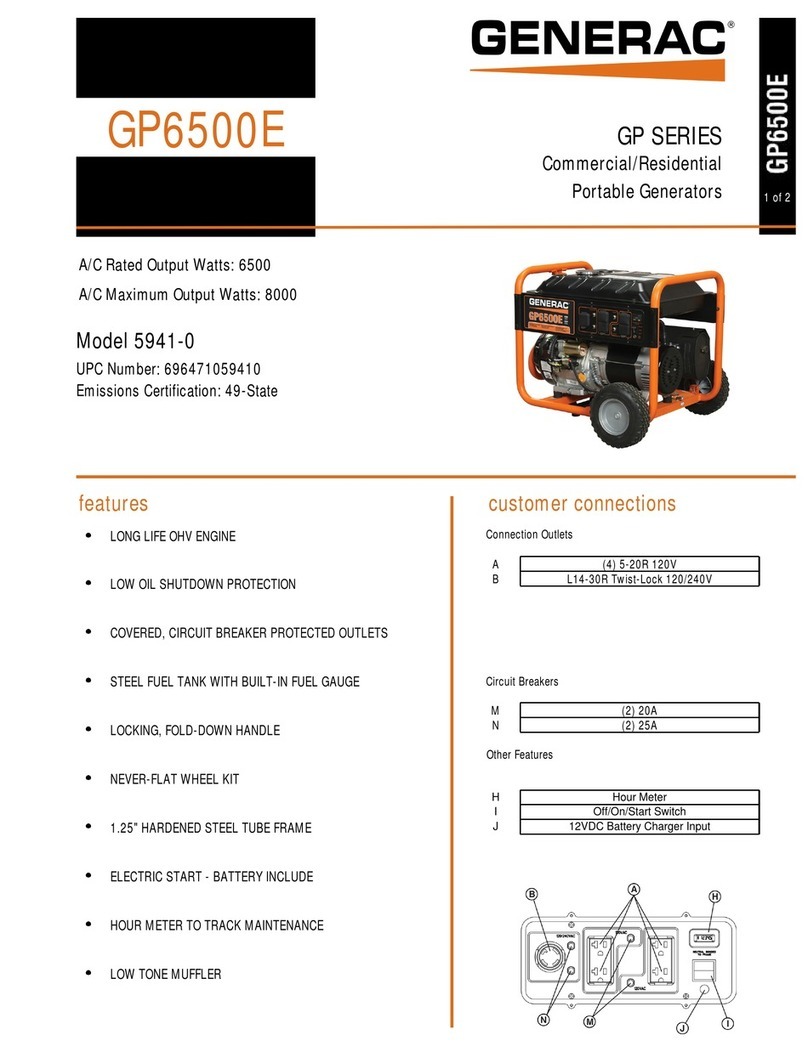

Popular Portable Generator manuals by other brands

YSONIC

YSONIC YS4000i user manual

Westerbeke

Westerbeke 20.0KW sbeg Operator's manual

Olympus

Olympus USG-410 Quick reference guide

Rohde & Schwarz

Rohde & Schwarz SMB100A quick start guide

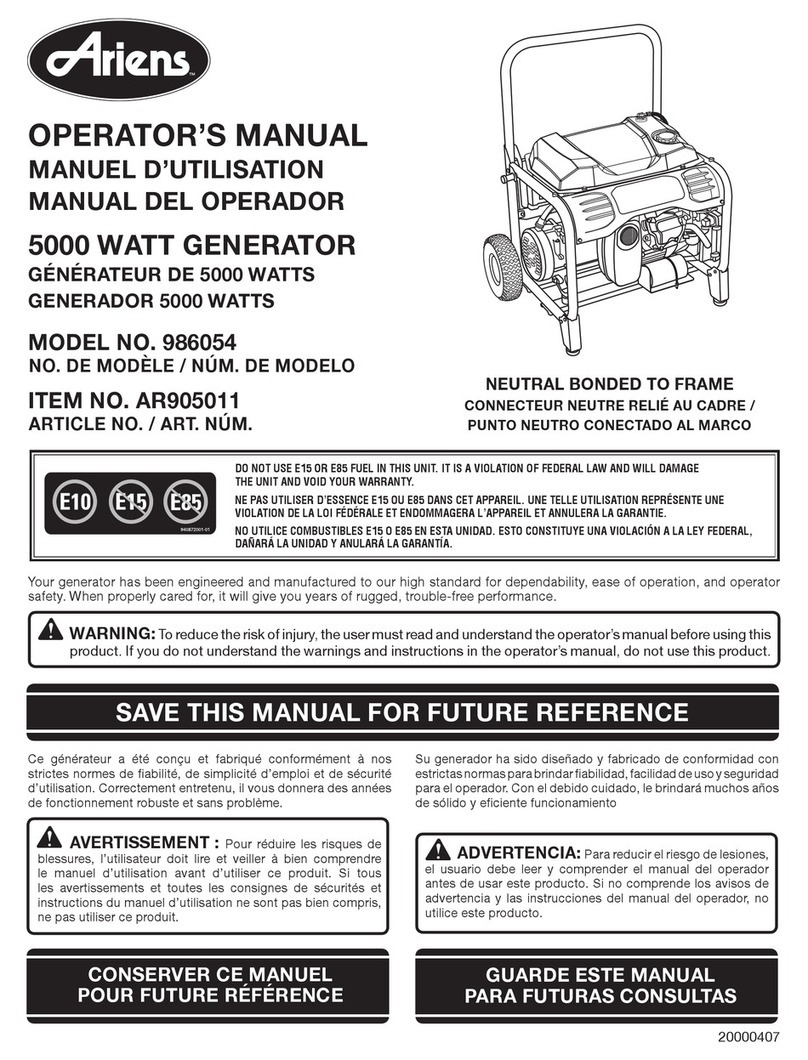

Ariens

Ariens 5000 Watt Generator Operator's manual

Keysight Technologies

Keysight Technologies X Series Getting started guide