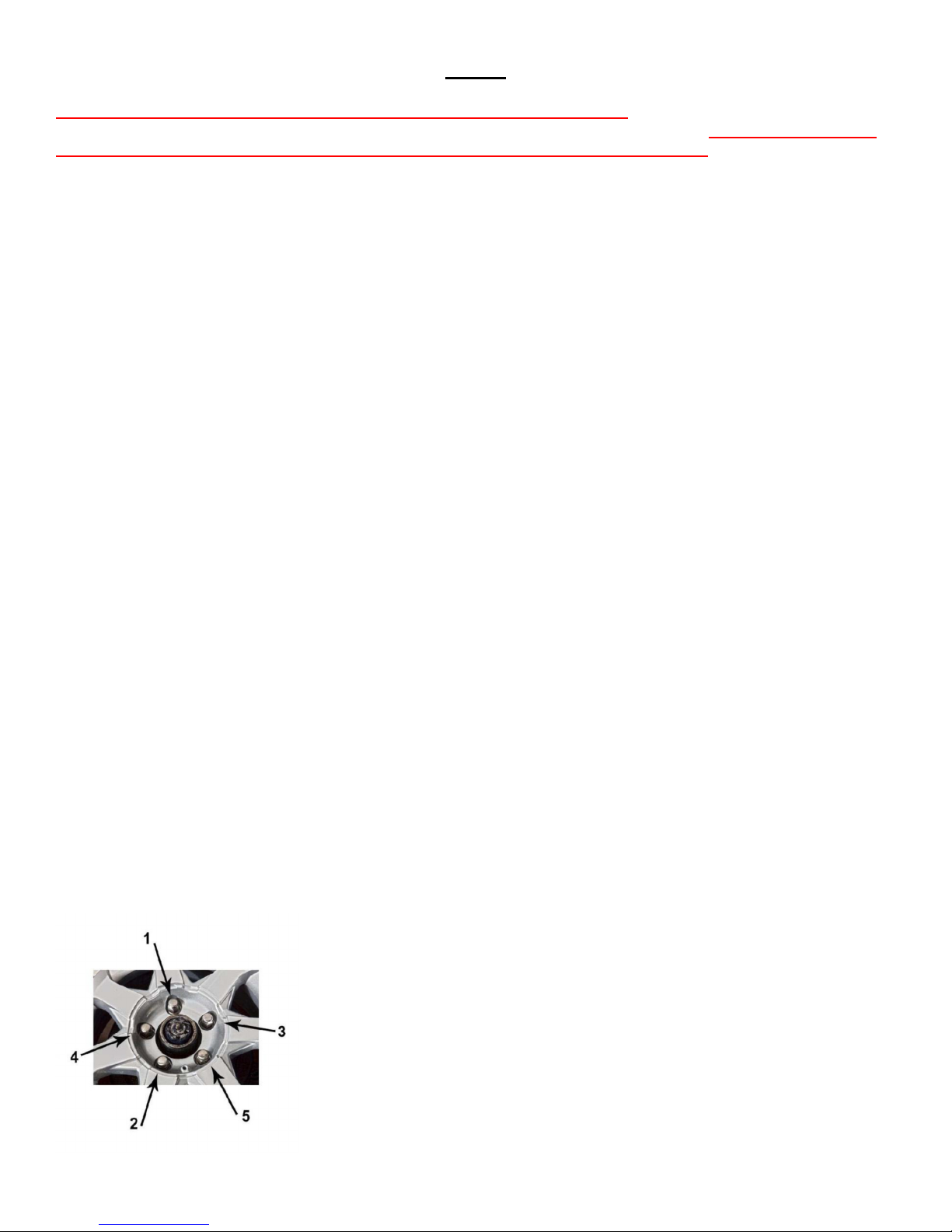

Bearing Inspection:

Wash all grease and oil from the earing and cone using a suita le solvent. Dry the earing with a clean, lint free cloth and

completely inspect each roller. Replace the earing cone and cup if there are any signs of pitting, wear, or corrosion. Repeat the

inspection procedure for the inner earing cone. ALWAYS REPLACE THE BEARING CONE AND CUP AS A PAIR.

**IMPORTANT**

DO NOT MIX LITHIUM, CALCIUM, SODIUM, OR BARIUM COMPLEX GREASES DUE TO POTENTIAL COMPATIBILITY PROBLEMS. WHEN

CHANGING FROM ONE TYPE OF GREASE TO ANOTHER, IT IS NECESSARY TO INSURE THAT ALL OF THE OLD GREASE HAS BEEN

REMOVED.

Bearing Lu rication:

Proper adjustment and adequate lu rication of the earings are essential to the longevity and performance of your trailer axle. The

earings should e lu ricated every 6000 miles or 6 months.

Procedure:

•Remove the ru er plug from grease cap.

•Insert grease gun on the grease zerk.

•Pump until new grease egins to appear.

•Replace ru er plug.

Frame

The new main frame mem ers are 2.0” x 3.0” 11 gauge C-Channel steel. The old tu ular frame mem ers were either 2.0” (Rascal,

Joey, 4x8, 5x8, 5x10) or 3.0” (4-Wide, 5-Wide, 6-Wide, Sport, 6x10, RT, 6x10 RT) 12 gauge ox channel steel.

The Rough Rider has an additional 12 gauge ox channel steel frame with skid plates supporting the main frame. The T@B has the

larger 2.0” x 6.0” 11 gauge C-Channel Steel. All C-Channel frames have een E-Coated; whereas, all others have een powder coated

to produce a high specification coating which is relatively harder and more a rasion resistant.

No normal maintenance is required, ut if the welds or scratches need attention, first remove any rust, dirt, or grease and coat with

gloss lack touch up paint. There is a receiver located on the rear umper (except for Rascal, Joey and RT) for optional equipment.

This receiver is designed for light weight cargo with the load positioned close to the receiver and umper. DO NOT EXCEED 125

POUNDS total weight on the receiver.

Coupler

Your coupler needs no adjusting or maintenance other than periodic oiling to ensure smooth operation. All models use a coupler

that receives a 2” all. Set the hitch height of the tow vehicle so that the trailer is eing pulled in a horizontal position. The height

listed elow is the optimal height after the tongue weight is resting on the hitch. Trailers must e towed as level as possi le for

proper handling and weight distri ution.

All Little Guy, RT and Silver Shadow Trailers T@B

Set all height at 16” from ground to top of all. Set all height at 16” from ground to top of all

Attaching the Trailer to the Tow Vehicle

Position the receiver over the all, and lift the ta handle of the hitch upward as you lower the jack. After the all is seated, allow

the handle to return ack down parallel to the frame. It will click, indicating that it has locked onto the all. Attach the safety chains,

insert the camper plug into the towing vehicle receptacle, and test the signal lighting. Raise the jack as far as it will go y turning the

crank handle clockwise. Remove the castor wheel y removing locking pin and sliding the wheel assem ly downward. The locking

pin can e inserted into the hitch locking mechanism for storage and added security. **The Rascal does not have a wheel jack, ut

rather a spring loaded, flip down tongue jack. ** Do not tow the vehicle with the front jack in the lowered position.

Stabilizers

All trailers are equipped with lightweight sta ilizer jacks. The T@B, Rough Rider and 6x10, are eefier and include a ¾” speed crank

handle for quick response of oth the up and down movement. The high strength design allows for increased load sta ilization and

fine leveling.

** All Little Guy and Silver Shadows have two rear sta ilizers only. Oil the jacks periodically to ensure smooth operation.

Never use the sta ilizers to raise the camper tires off the ground – unless changing a flat. Always raise the sta ilizers completely

efore travel.