8 (8)

Assembly instructions | LK Wallbox UNI Push AX16 V2 and AX20

EN.29.C.46.20200318

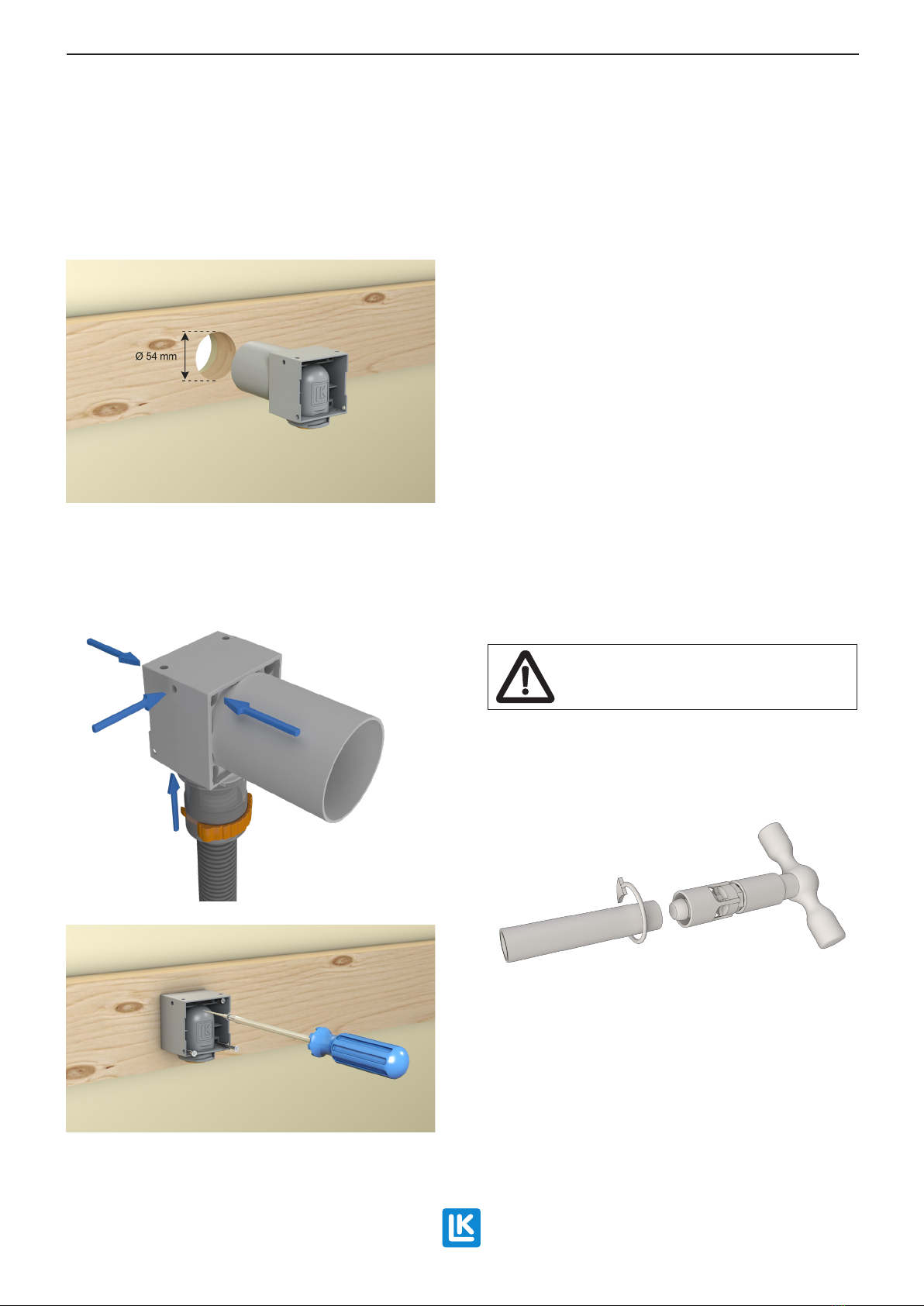

After wall covering

6.1. The wall box is cut down to approximately

2 mm from the completed wall with LK Wall Box

Cutter UNI (Article no. 187 64 94).

If the wall cladding is to have a vinyl covering

then the LK Wall Box Cutter UNI UTV (Article

no. 188 21 54) can be used.

LK Connection couplings

7.1.1 For assembly of tap mixer in accordance with

Swedish standards, LK Connection coupling M26

(Article no. 188 18 45) should be assembled. The

length of the connection should be adjusted and

the thread joint against the angle tting should be

sealed with, for example, ax and thread paste.

Tightening is done with a combination wrench or

a 14 mm Allen key.

NOTE!

Thread tape should not be used on the con-

nection coupling.

7.1.2 For assembly of tap mixer in accordance with

international standards, LK Connection coupling

¾”/ ½” (Article no. 188 18 48) should be assembled.

The length of the connection coupling should be

adjusted so that approximately 10 mm of the ¾”

pipe thread is exposed when the cover plate is tigh

-

tened against the wall. The thread joint against the

angle tting should be sealed with, for example,

ax and thread paste. Thread tape should not be

used. Tightening is done with a 14 mm Allen key.

NOTE!

Thread tape should not be used on the con-

nection coupling.

For more variants of connection couplings, visit:

https://www.lksystems.se/en/products/lk-uni-

versal/products/installation-components/angle-

wall-box-mounting/connection-couplings/

Replacement of PE-X pipe to

LK Wallbox Push

For replacement of LK PE-X Universal Pipe X,

refer to assembly instructions for LK PEX, PAL

and PE-RT.

Accessories for LK Wallbox UNI Push

Reinforcement for Wallbox

LK Reinforcement for Wallbox UNI (Article no.

188 10 66), see picture below, is used when the

mixer needs maximum support. The reinforcement

has a female ½” thread which is screwed onto a

connection coupling. The connection coupling is

then threaded on the wallbox angle tting.

LK Systems AB, Box 66, 161 26 Bromma, Sweden | www.lksystems.se/en