3 (9)

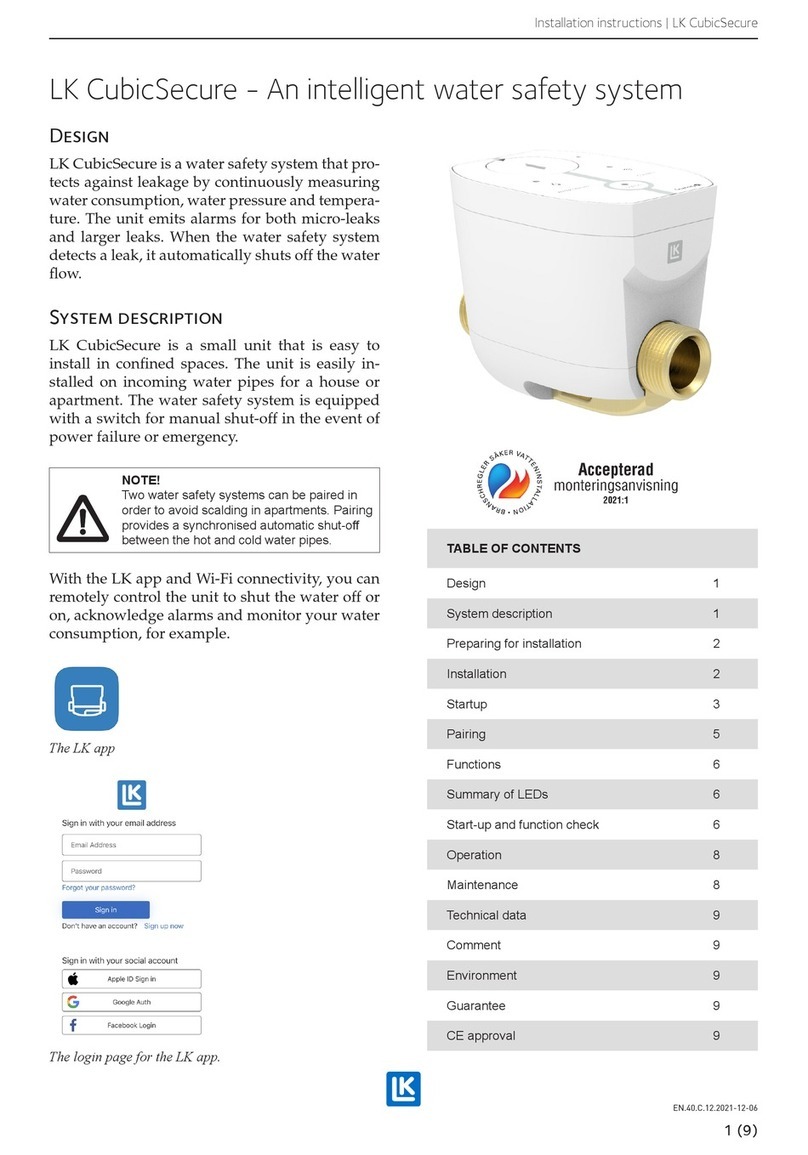

Connecting a PIR Sensor

Power supply for a PIR Sensor

A PIR Sensor can be supplied with power by either:

1. Connecting the PIR Sensor (+) to the LK WSS

master unit terminal (6+) or terminal (7+).

Connecting the PIR Sensor (-) to the LK WSS mas-

ter unit terminal (4-).

2. External separate 12V connection.

Connect power supply in parallel if connecting

several PIR Sensors to the same LK WSS master

unit

Connecting PIR Sensor NC inputs

Connect one PIR Sensor (NC) to the LK WSS mas-

ter unit terminal (5+).

Connect the other PIR Sensor (NC) to the LK WSS

master unit terminal (5-).

Connect several PIR Sensors in parallel with regard

to NC inputs (power supply must be connected

in parallel).

Example with three PIR Sensors.

Bus connection for leak detector

If units such as leak detectors are to be connected

by cable for bus communication, connect them to

the master unit's terminal 4.

Connect the cable to D and - in the master unit.

The equivalent marking is found on the units to be

connected. Use 2-wire twisted cable 2 x 0.5 mm2,

telecom cable type. Units can be connected in a

star network or in series using bus communication.

+ D -

D -

Connecting sensors

If leak detection is required at the master unit, con-

nect a sensor to the master unit’s contact 2. Sensors

are available as accessories.

Power supply

Power supply to the master unit is provided using

the supplied network adapter. Connect to the unit's

contact 1.

Cable penetrations

Remove the required number of holes in the rub-

ber gasket for cable penetration. Use the cable ties

supplied for strain relief. Secure the cable tie in the

hole pattern in the black rubber gasket.

Replace the cover

Screw the cover back onto the main unit. Ensure

the exible cable is not twisted. When all of the

units to be connected with bus communication

have been connected, connect the master unit's

network adapter to a wall socket.

Installing a PIR Sensor

Place a PIR sensor where motion detection is

required to control the water supply. Screw onto

the wall with suitable screws.

Installing a leak detector

Place a leak detector where possible water leaks

need to be detected. Suitable locations include the

kitchen sink unit cupboard, under a dishwasher

or other household appliances such as coffee

machines, water coolers or ice-makers. Other pos-

sibilities are in the utility room and under washing

machines, toilets and in the bathroom. Two sen-

sors are included with each leak detector. More

sensors can be added with LK Sensor and branch

cable WSS or LK Splitter Cable and LK Extension

Cable if required. See under Accessories. The leak

detector has a built in temperature monitor. If the

temperature is below +5 °C (default value, can be

changed via LK Webserver), the unit will set off an

alarm and transmit a signal to the master unit to

tell it to shut off the water. Place the sensor where

any potential water leak can be detected at an early

stage. Attach sensor using the Velcro tape supplied.

Try to keep the sensor as at as possible for rapid

Installation guide | LK Water Safety System WSS PIR

EN.40.C.9.1911