Load Cell Systems TX-2 User manual

HANDHELD FORCE MEASURING INDICATOR

HHI

Contents

Specifications and Parameters……………………………………………… 2

Appearance and Dimensions ……………………………………………… 4

Test Benches ……………………………………………………………… 5

Precautions ………………………………………………………………… 6

Functions …………………………………………………………………… 7

Main Features ……………………………………………………………… 7

Parts & Buttons and Their Functions ……………………………………… 8

Interfaces and Their Functions………………………………………………12

Test Description ……………………………………………………………19

Software …………………………………………………………………… 21

Maintenance and After-Sales Service ………………………………………26

Battery Use and Maintenance ………………………………………………27

Packing List …………………………………………………………………28

Load Cell Systems reserves the right to change specifications without notice. ©2018

Web: https://loadcellsys.com

Email: [email protected]

Phone: 607-426-1467

Specifications andParameters (for EmbeddedProducts)

TX-500

500N

0.1N

1Mpa

Embedded sensor

1%~100%F.S

±0.5%F.S

N、kg、lb

2.8-inch true color

20±10℃

15%~80%RH

No vibration sources or corrosive materials exist.

1kg

TX-200

200N

0.1N

TX-100

100N

0.05N

0.1Mpa

TX-50

50N

0.01N

TX-20

20N

0.01N

TX-10

10N

0.005N

0.01Mpa

TX-5

5N

0.001N

TX-2

2N

0.001N

Model

Range

C

alibration

Calibration

f P

S

ensor

Measuring

R

Indication

E

Units

D

isplay

Working

Tt

R

elative

H idit

Working

Conditions

Weight

- 2 -

Specifications and Parameters (for External Products)

Model

TX-1K

TX-2K

TX-5K

TX-10K

TX-20K

TX-50K

TX-100K

TX-200K

TX-500K

TX-1000K

TX-2000K

Range

1000 N

2000 N

5000 N

10kN

20 kN

50 kN

100 kN

200 kN

500 kN

1000 kN

2000 kN

C

alibration

0.5 N

1 N

1 N

0.005kN

0.01 kN

0.01 kN

0.05 kN

0.1 kN

0.1 kN

0.5 kN

1 kN

Sense

E

xternal S

-shaped

sensor

External spoke

sensor

Measuring

Range

1%~100%F.S

Indication

Error

±1%F.S

(depending

on the

sensor

configured)

- 3 -

Appearance and Dimensions

mm

Output Port Wiring

- 4 -

Test Benches (Optional)

- 5 -

Precautions

Misoperation may cause damage to the force

gauge and even result in serious accidents.

This manual describes precautions against

accidents and operation methods of this

product. Make sure to read this manual carefully and safe keep it after the

reading. For impact test, select a force gauge whose maximum measurable value

is doubled the impact load to be applied. Effective measuring range of this

product is 10% ~ 100%.

1、Before the impact test, wear mask and gloves; avoiding personal injury in

case of object splash.

2、Do not use damaged or bent fixture; avoiding personal injury in case of

fixture fall or break.

3、If “Warning: test load exceeds measurement” appears on the LCD display, it

indicates that the test load the sensor measures is 110% larger than the rated

load. Decrease the load immediately. Make sure the load applied is smaller

than 105% the rated load after the force gauge is restarted.

4、Make sure the force gauge is not overloaded. Overload, excessive impact

force, and forces other than pull force and push force may damage the

sensor.

5、Do not use sharp tools to press buttons.

6、Avoid the force gauge from water, oil, and other liquids. Put it in a cool, dry,

and vibration-free place.

7、Use the charger delivered with the force gauge for charging; otherwise,

Notes

Warning

- 6 -

circuit failure even fire may be caused.

8、Follow this document to wire ports; otherwise, circuit failure even PC fault

may be caused.

9、Make sure the AC charger is securely inserted into a socket if the product

needs to be charged. Looseness may cause short circuit, resulting in electric

shock or fire.

10、Remove the power adapter after the charging; avoiding accidents.

11、Do not touch the power adapter with wet hands; otherwise, electric shock

may occur.

12、This product is for measuring pull and push forces only. Do not bend or

twist the test head. See the following figure for correct operation method.

Functions

BIN-106 series digital force gauges are new-generation universal portable

instruments for testing pull and push forces. They are characterized by

compactness, lightness, portability, versatility, high precision, and curve capture,

applicable to pull & push test, insertion & extraction test, and impact test of

various products. They can be also designed into small-sized test machines for

various purposes when they are combined with different test benches and

fixtures.

Main Features

1、2.8-inch TFT true color display; both direction buttons and display can be

rotated 180°.

2、Built-in real time clock;USB interface; hot swappable.

- 7 -

3、Peak values, real-time values, and test curves can be displayed on the same

screen; enabling procedural monitor and reproduction of the test.

4、Free setting of fracture alarm value, fracture alarm dead zone, and

upper/lower offset; selection of fracture alarm, alarm for not excess of limit,

and alarm for excess of limit. When alarm values are exceeded, the buzzer

acts while the display shows alarm information. The two SC open-collector

level outputs drive the DC 12V relay or the solenoid to act, each output

being 50mA. To use output ports, connect the power adapter first.

5、Enable automatic unit conversion: N, kg, and lb; pressure unit MPa can be

converted as well.

6、Peaks can be held or cleared; clearing time can be set.

7、A maximum of 100 groups of test reports can be saved permanently. The

saved content includes test time, peak, and average valley. One group of test

curves can be saved(Automatically cleared after shutdown) as well for

reproducing the test procedure.

8、Material strength can be calculated based on sectional area input.

9、Shutdown and backlight can be set to perform automatically.

10、Chinese/English switchover; pictures and literary descriptions make various

operations easy to understand and learn.

11、Relying on the PC dedicated test software, the force gauge can realize

unlimited storage, transmission, and reproduction of test curve data.

12、Installed on different test benches, the force gauge can implement various

tests.

- 8 -

Parts & Buttons and Their Functions (for Embedded Products)

- 9 -

Parts & Buttons and Their Functions (for External Products)

W

iring methods of

the sensor:

1

——

V

+;

2

——

V

-;

3

——

S

+;

4

——

S

-;

5

——

P

- 10 -

Buttons and Their Functions

Button Standalone

Test Mode

Capture

Mode

Online Test

Mode

Storage &

Query Mode

Menu Operation

Mode

Shutdown Invalid Shutdown Invalid Invalid

Invalid Quit

capture Invalid Exit

Quit parameter

modification or

exit

Zero set Invalid Zero set Invalid Invalid

Test

output

Invalid Invalid Up Up

Enter

storage &

query

mode

Invalid Invalid

Switch to

upper

window

Down

Enter

parameter

setting

mode

Capture

stop

Invalid

View report

and output

test value

Confirm

parameter

modification

Curve

capture

start

Invalid

Curve

capture

start

Move the blinking number

leftward by one unit

Peak

clearing

Invalid Peak

clearing

Move the blinking number

rightward by one unit

-11 -

Interfaces and Their Functions

1、Test Interface:

Press and hold the "ON/OFF" button to start the force gauge. The following

interface appears.

⑦、Number of reports saved

⑧、Sampling Speed

⑨、Upper limit alarm

⑩、Peak hold time

、Peak-to-peak

①、Battery level

②、Curve

③、Real-time force

④、Lower limit alarm

⑤、First peak

⑥、Valley-to-peak

- 12 -

Test Functions

①、Battery level: real-time display. In case of power shortage, this icon blinks

and an alarm is reported.

②、Curve: force-to-time curve.

③、Force: real-time display. A maximum of 5 digits can be shown. Its unit can

be converted on the setting interface.

④、Lower limit alarm: values can be specified on the setting interface.

⑤、First peak: the first peak value after the test starts.

⑥、Valley-to-peak: the minimum force that is smaller than the initial value.

⑦、Number of reports saved: a maximum of 100 groups of reports can be saved

and the latest group of test curves can be saved as well.

⑧、Display sampling speed.

⑨、Upper limit alarm: values can be specified on the setting interface.

⑩、Peak hold time: this parameter can be set on the setting interface and

manually cleared.

、Peak-to-peak: the maximum positive peak.

2、Interface Setting

On the test interface, press "OK" to enter the setting interface. The setting

interface falls into 2 pages.

- 13 -

【Display Unit】

When the main unit is set to "g", available values of [Display Unit] include:

"g", "mlb", "mN", and "Pa".

When the main unit is set to "kg", available values of [Display Unit] include:

"kg", "lb", "N", and "KPa".

When the main unit is set to "t", available values of [Display Unit] include:

"t", "klb", "kN", and "MPa".

【Force Area】

When [Display Unit] is set to "Pa", "KPa", or "MPa", [Force Area] will

involve in calculation.

Note: Pressure test result will be accurate only when [Force Area] is set.

【Zero Tracking】

Available values include "shutdown", "1d", "2d", "3d", "4d", and "5d".

Before the zero point becomes stable, values smaller than [Zero Tracking]

are automatically cleared. After the test values become stable, test frequency is

once per second. Variants of the test values that are smaller than [Zero Tracking]

are automatically cleared, to hold the displayed values.

【Sampling Speed】

When it is set to "6Hz ~ 1600Hz", it indicates force sampling speed per

second.

Note: The higher the sampling speed, the lower the test accuracy. Higher

sampling speed applies to dynamic and transient test; and lower sampling speed

applies to static and slow test.

【Calibrate Grav】The Gravity of calibration place adding speed

【User Gravity】The Gravity of Using place adding the speed

Its value is "9.600 ~ 9.900" N/Kg.

This parameter is used for gravity correction. The displayed value = test

value + test value * ([Calibrate Grav] –[User Gravity]).

【Alarm Upper LV】For setting alarm upper limit value.

【Alarm Lower LV】For setting alarm lower limit value.

- 14 -

【Alarm mode】

Values of this parameter include "Within", "Beyond", "Fracture", and "Shut

Off"; they are indicative of within limit alarm, beyond limit alarm, fracture alarm,

and shutoff alarm.

If the value is set to "Within" or "Beyond", when the alarm value is

exceeded, the buzzer acts while the display shows alarm information. Meanwhile,

the Boolean value is output. The following figure shows differences between

within limit alarm and beyond limit alarm.

If the value is set to "Fracture", [Alarm Upper LV]and [Alarm Lower LV]

will be automatically switched to [Fracture Alarm] and [Fracture Dead]. Set

these two parameters. When the force variation is reduced to the set value, the

buzzer acts while the display shows alarm information. Meanwhile, the upper

Boolean value is output.

Note: To use output ports, connect the power adapter first. The two SC

open-collector level outputs drive the DC 12V relay or the solenoid to act, each

output being 50mA.

【Peak V. Hold】a switch for enabling peak hold function

Its values include "on" and "off".

If this parameter is set to "off", the peak value will not be displayed on the

interface.

【External Input】external switch for enabling capture

Its values include "on" and "off".

- 15 -

When this parameter is set to "on", enabling the external switch (equivalent

to the "curve capture" button or the "curve capture" instruction) to be turned on,

the force gauge will enter curve capture mode. Note: capture time length is

subject to the sampling speed. Capture time (unit: second) = number of captured

data / sampling speed

【Peak Hold Time】

Its values include "Clr by Key" and "1 ~ 60 sec".

When this parameter is set to "Clr by Key", the peak remains unchanged

until users press the "Peak Clearing" button or "Zero Set" button. When this

parameter is set to "1 ~ 60 sec", the peak will be automatically re-measured after

the set time is up. The peak can also be re-measured by manually pressing the

"Peak Clearing" button or "Zero Set" button.

【Capture Lenght】

Set range: 1 ~ 1280 seconds

This parameter indicates the curve capture time in capture mode. The

capture time depends on the sampling speed: 60Hz: 1 ~ 1280sec; 12Hz: 1 ~

640sec; 25Hz: 1 ~ 320sec; 50Hz: 1 ~ 160sec; 100Hz: 1 ~ 80sec; 200Hz: 1 ~

40sec; 400Hz: 1 ~ 20sec; 800Hz: 1 ~ 10sec; 1600Hz: 1 ~ 5sec.

【Capture Trigge】

Set range: –99999 ~ +99999

The [F/P Boundary] parameter serves as a condition of triggering capture

after the force gauge enters the curve capture mode. If the number of data

captured reaches utmost or capture is stopped in advance, a capture report will be

generated and saved. The curve will be cleared after the force gauge exits the

capture mode.

【F/P Bounbary】first peak boundary

Set range: 1 ~ 99999

This parameter is used for determining first peak during peak test. Take the

assumption that the criteria for determining a peak is 10. After users press the

"Peak Re-measuring" button, a new peak test is started. During the test,

- 16 -

peak-to-peak (Vmax), valley-to-peak (Vmin), and new peak (Vnew) are updated

continuously. If the absolute value of (Vmax –Vnew) or (Vmin –Vnew) is

larger than 10, Vmax or Vmin is considered the first peak.

【Buad Rate】serial port baud rate

Set range: 4800 ~ 230400bps

Format: 1 initial bit; 8 data bits; 1 stop bit. No parity bit. This parameter will

take effect after users restart the force gauge.

Note: In order to ensure that each data is sampled during communication

with a PC, baud rate is recommended to set as follows: 6Hz: ≥4800bps; 12Hz: ≥

9600bps; 25Hz: ≥14400bps; 50Hz: ≥19200bps; 100Hz: ≥28800bps; 200Hz: ≥

38400bps; 400Hz: ≥57600bps; 800Hz: ≥115200bps; 1600Hz: ≥230400bps.

Due to speed limits of serial ports, if the sampling speed is larger than 400Hz,

data will be lost when it is transmitted to a PC. Instrument reading results prevail.

【Serial Port】serial port output way

This parameter is used for controlling real-time data transmission.

Parameter values and meanings are as follows:

Prohibit: The serial port is forbidden to transmit real-time data.

Key/Order:When the button is pressed or an output command is

received, output is performed once. If the force gauge is connected to a PC, PC

programs will automatically forbid the output function.

Change: When test data changes, output is performed once.

Stabilize: When test data becomes stable, output is performed once.

Consecutive: Test data is transmitted uninterruptedly.

【Display Angle】

This parameter is used for changing display angle. Available values are 0°

and 180°.

【Auto Power Off】

This is an energy-saving design. When the force gauge is idled for a

specified period, it will automatically shut down.

- 17 -

【Auto Backlight】

This is an energy-saving design. When the force gauge is idled for a

specified period, it will automatically adjust backlight brightness.

【Clear Storage】clearing stored data

This parameter is used for clearing stored test reports and curves. When

stored data is overflowed, the system will automatically clear all data and begin

storing new captured data.

【Reset User Set】reset parameters

this parameter is used for restoring factory settings in case of wrong setting

or other setting problems.

【Language】Chinese/English switchover

【Factory Set A\B\C】【Factory adjustment and self-test】

This parameter is used only during factory setting. Users are not authorized

to set this parameter.

【Connection】

This parameter is provided to users for connector wiring. Users can refer to

it during connector wiring.

【S/N】local sequence number

This parameter indicates internal sequence number of the machine. Users

are not authorized to set this parameter.

3、Calibrate:

①Press "↑", "↓", "←", or "→" to move the cursor to [Calibrate] and press

"OK" for confirmation. Then, press any button to enter the calibration

interface, as shown in figure a.

②Press "↑", "↓", "←", or "→" to move the cursor to [Input Weight] and

press "OK" for confirmation. Press "↑" or "↓" to change "NO" to "YES" and

press "OK" for confirmation.

③Press "↑", "↓", "←", or "→" to move the cursor to [CAL Point] and press

"OK" for confirmation. Press "↑" or "↓" to set the number of a calibration

point to a desired value and press "OK" for confirmation. (The maximum

- 18 -

value of the calibration point is 6.)

④Press "↑", "↓", "←", "→", or "OK" to change values of other calibration

points and press "OK" for confirmation.

⑤Press "↑", "↓", "←", or "→" to move the cursor to [No.0 A/D Code]. After

the internal code becomes stable, press "OK" for confirmation. The cursor

automatically moves to [No.1 A/D Code] and the system loads weight that is

equivalent to one calibration point. After it becomes stable, press "OK". The

cursor moves on to the next calibration point….After the last calibration

point is confirmed, the cursor moves on to [Save Calibrate]. Press "OK"

and then press "Back" to exit.

4、Figures b and c show report content

(a maximum of 100 groups of reports and 1 group of curves can be saved).

Test Description

After understanding interfaces and functions, you are expected to start test:

1、Install a head for test. Choose a proper head accessory or fixture for test and

install it onto a rod. Note that do not screw the head with excessive force;

otherwise, the sensor may be damaged.

2、Connect the sensor to the force gauge and install a fixture. Use a wire to

connect the sensor connector with the force gauge in a proper manner.

figure a

figure b

figure c

- 19 -

Choose a proper fixture and install in onto the sensor. Note that do not screw

the sensor with excessive force; otherwise, the sensor may be damaged. This

step is applicable to external force gauges.

3、Power-on. Press and hold the "ON/OFF" button for 2 seconds to power on

the force gauge. The test interface appears. Check the battery level in the

right upper corner of the interface. If battery level is low, connect the force

gauge to the delivered power adapter for charging. The force gauge can be

charged in both startup mode and shutdown mode. During charging, the

force gauge can be tested as well. When the force gauge is fully charged, the

system will display a prompt. Remove the power adapter immediately.

4、Set parameters. On the test interface, press "OK" to enter the setting interface.

Set such parameters as unit, force area, zero track, sampling speed, fracture

alarm, upper limit alarm, lower limit alarm, peak hold, capture trigger, and

capture length. After the setting, press "Back" to go back to the test interface.

5、Test. Install the sensor onto a proper bench for test. Press the "Zero Set"

button and the "Peak Clearing" button. Two test methods are available: one is

direct test. In this case, real-time forces, peaks, and other parameter values

are obtained which will not be saved. These values will be cleared once a

new test is performed. The other method is curve capture. On the test

interface, press the "Curve Capture" button to enter the capture mode. The

system will automatically start test when the capture trigger condition is met.

If users press "OK" or the capture time is up, the test is completed. Peaks,

curves and other parameter values will be obtained.

6、Report query. Test performed in capture mode will be saved, including test

curves and test results. Only 1 group of curves can be saved and it can be

queried by pressing the "Query" button. If users restart the force gauge or

perform a new test, the curves will be cleared. A maximum of 100 groups of

reports can be saved and they can be queried by pressing the "Query" button.

7、Shutdown. Press the "Back" button to go back to the test interface and then

press the "ON/OFF" button to shut down the force gauge. The "ON/OFF"

- 20 -

This manual suits for next models

7

Table of contents

Other Load Cell Systems Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Greenheck

Greenheck Sure-Aire 384986 Installation, operation and maintenance manual

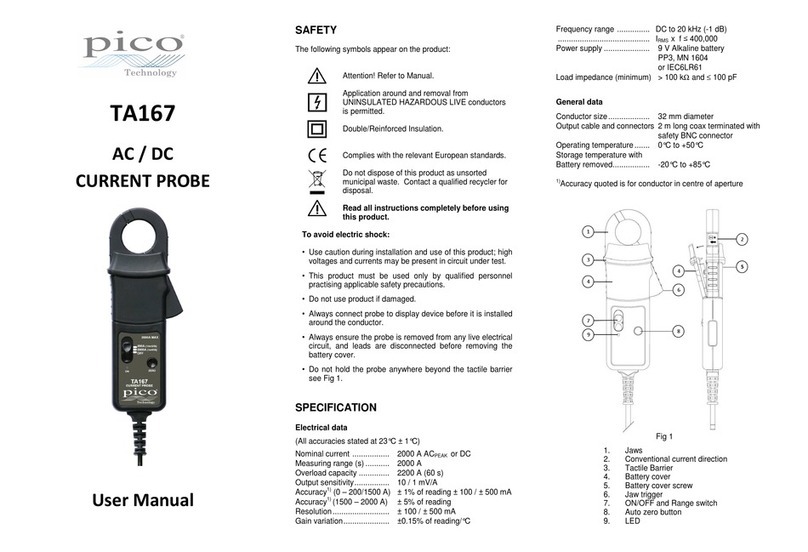

pico Technology

pico Technology TA167 user manual

Keysight Technologies

Keysight Technologies UXA N9040B manual

PCE Instruments

PCE Instruments PCE-TG 300-P5EE user manual

HW Group

HW Group Poseidon2 3266 user manual

EET

EET PMC-53M-A user manual