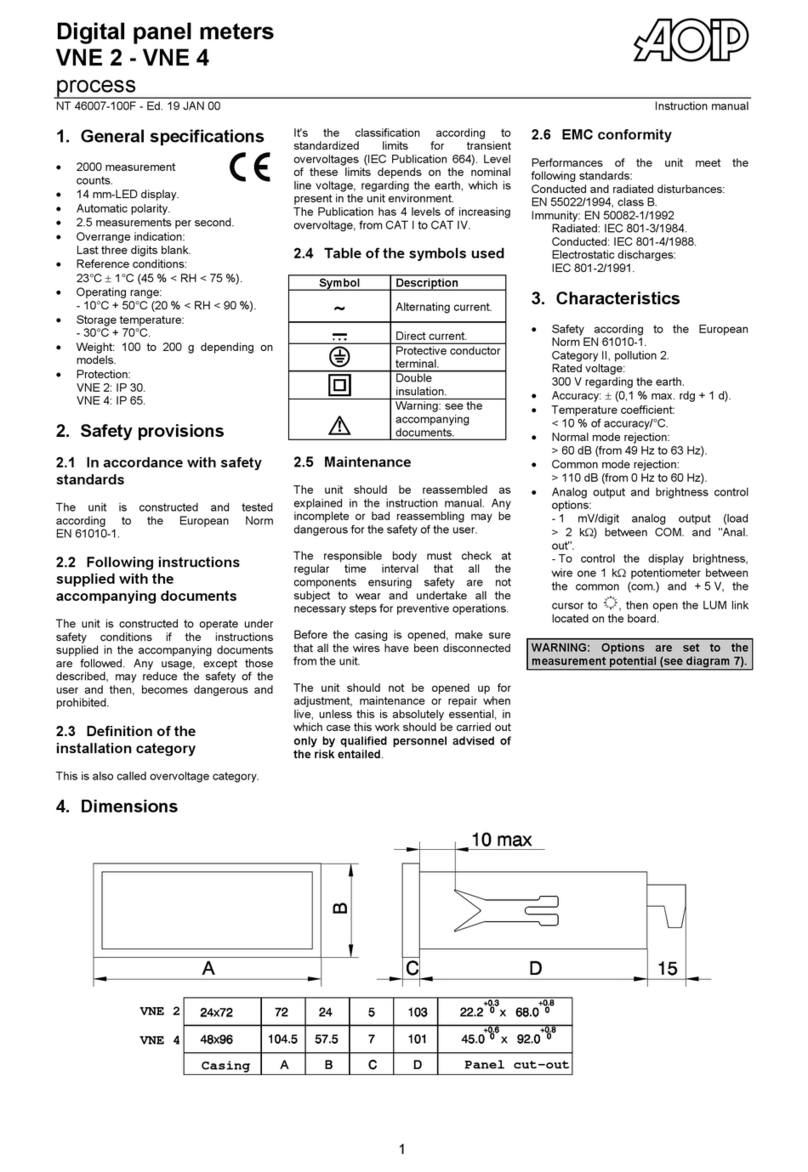

CONTENT

A. GENERAL ...................................................................................................................................................................................................................................................................................6

A.1 INTRODUCTION..................................................................................................................................................................................................................................................................................6

A.2 APPLICATIONS...................................................................................................................................................................................................................................................................................6

A.3 MAIN CHARACTERISTICS...................................................................................................................................................................................................................................................................7

A.4 SAFETY PROVISIONS..........................................................................................................................................................................................................................................................................7

Compliance with Safety Standards .............................................................................................................................................................................................................................................7A.4.1 Following Instructions supplied with the accompanying Documents ..........................................................................................................................................................................................7A.4.2 Taking Measurements ................................................................................................................................................................................................................................................................7A.4.3 Instructions to be followed before Use........................................................................................................................................................................................................................................7A.4.4 Faults and abnormal Constraints...............................................................................................................................................................................................................................................8A.4.5 Table of Symbols used................................................................................................................................................................................................................................................................8A.4.6 Maintenance ..............................................................................................................................................................................................................................................................................8A.4.7

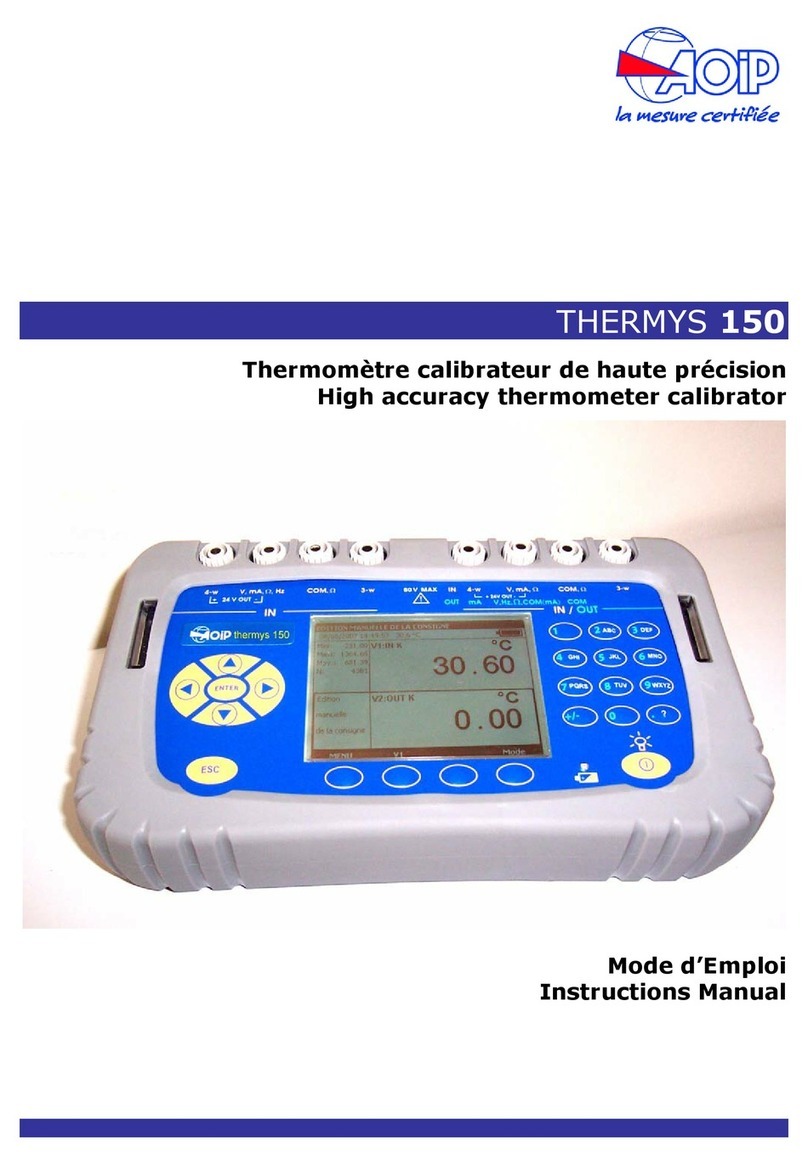

B. DESCRIPTION............................................................................................................................................................................................................................................................................9

B.1 General View..........................................................................................................................................................................................................................................................9

B.2 DISPLAY ..........................................................................................................................................................................................................................................................................................10

B.3 ACCESSORIES ..................................................................................................................................................................................................................................................................................11

Delivered with the Unit............................................................................................................................................................................................................................................................11B.3.1 Options delivered to order .......................................................................................................................................................................................................................................................11B.3.2

C. OPERATION.............................................................................................................................................................................................................................................................................12

C.1 REMINDERS OF THE 4-WIRE PRINCIPLE............................................................................................................................................................................................................................................12

C.2 PERFORMING A MEASUREMENT ......................................................................................................................................................................................................................................................12

Switching On .........................................................................................................................................................................................................................................................................14C.2.1 Selecting the Range ...............................................................................................................................................................................................................................................................14C.2.2 Selecting the Measurement Mode.............................................................................................................................................................................................................................................14C.2.3 Ambient temperature compensation ......................................................................................................................................................................................................................................18C.2.4 Setting Alarms .......................................................................................................................................................................................................................................................................19C.2.5 Connecting to Connectors........................................................................................................................................................................................................................................................19C.2.6 Standby (STBY) Position ........................................................................................................................................................................................................................................................20C.2.7

C.3 LIST OF ERROR MESSAGES ..............................................................................................................................................................................................................................................................21

C.4 CONFIGURING THE UNIT ...............................................................................................................................................................................................................................................................22

Principle..................................................................................................................................................................................................................................................................................22C.4.1 Direct Access Key....................................................................................................................................................................................................................................................................22C.4.2 Entering a Number ..................................................................................................................................................................................................................................................................22C.4.3 Programming Menu Table.......................................................................................................................................................................................................................................................23C.4.4 Managing an Alarm Threshold: ALAr......................................................................................................................................................................................................................................24C.4.5 Using the DB9 Connector: rS ..................................................................................................................................................................................................................................................24C.4.6 Managing and printing Memory Content: mEm.......................................................................................................................................................................................................................24C.4.7 Programming the temperature compensated measurement Value.......................................................................................................................................................................................28A.1.1

CONFIGURATION AND OPERATION COMMANDS USING THE RS232 SERIAL LINK..................................................................................................................................................29

C.5 INTRODUCTION................................................................................................................................................................................................................................................................................29

Command Errors...............................................................................................................................................................................................................................................................30A.1.2

C.6 LIST OF COMMANDS ........................................................................................................................................................................................................................................................................31

C.7 GENERAL COMMANDS.....................................................................................................................................................................................................................................................................32

C.8 PROGRAMMING COMMANDS ...........................................................................................................................................................................................................................................................33

C.9 MEMORY USAGE COMMANDS .........................................................................................................................................................................................................................................................36

C.10 OTHER INFORMATION COMMANDS................................................................................................................................................................................................................................................38

C.11 LOGOM PROGRAM .......................................................................................................................................................................................................................................................................38

Installation ........................................................................................................................................................................................................................................................................38A.1.3 Use....................................................................................................................................................................................................................................................................................38A.1.4

D. MAINTENANCE.......................................................................................................................................................................................................................................................................40

D.1 OPENING/CLOSING THE UNIT ..........................................................................................................................................................................................................................................................40

D.2 BATTERY PACK...............................................................................................................................................................................................................................................................................42

Charging.................................................................................................................................................................................................................................................................................42D.2.1 Replacing the Battery ..............................................................................................................................................................................................................................................................42D.2.2

D.3 FUSES ..............................................................................................................................................................................................................................................................................................42

D.4 CHECKING PERFORMANCE ..............................................................................................................................................................................................................................................................43

D.5 MANAGING MAINTENANCE.............................................................................................................................................................................................................................................................43

D.6 UPDATING THE ON-BOARD SOFTWARE ...........................................................................................................................................................................................................................................44

D.7 ADJUSTMENT...................................................................................................................................................................................................................................................................................45

Environment............................................................................................................................................................................................................................................................................45D.7.1 Adjusting the Unit....................................................................................................................................................................................................................................................................45D.7.2

D.8 WARRANTY.....................................................................................................................................................................................................................................................................................46

E. SPECIFICATIONS....................................................................................................................................................................................................................................................................47

E.1 APPLICABLE STANDARDS ................................................................................................................................................................................................................................................................47

Safety Class .............................................................................................................................................................................................................................................................................47E.1.1 EMC Conformity......................................................................................................................................................................................................................................................................47E.1.2 Ambient Conditions..................................................................................................................................................................................................................................................................47E.1.3 Mechanical Conditions ............................................................................................................................................................................................................................................................47E.1.4 Measurement under Reference Conditions ...............................................................................................................................................................................................................................47E.1.5

E.2 CHARACTERISTICS...........................................................................................................................................................................................................................................................................48

General....................................................................................................................................................................................................................................................................................48E.2.1 Resistance measuring function.................................................................................................................................................................................................................................................48E.2.2 Protections...............................................................................................................................................................................................................................................................................48E.2.3

E.3 END OF UNIT SERVICE LIFE .............................................................................................................................................................................................................................................................49

Waste Generated by the Unit....................................................................................................................................................................................................................................................49E.3.1 Unit Destruction Procedure .....................................................................................................................................................................................................................................................49E.3.2

F. ANNEXES..................................................................................................................................................................................................................................................................................50

F.1 UNIT MAINTENANCE PROGRAMMING DIAGRAM..............................................................................................................................................................................................................................51

F.2 DIAGRAMME DE PROGRAMMATION ET DE LECTURE DE L'APPAREIL.................................................................................................................................................................................................52