Page 1of 19

Contents

GENERAL.....................................................................................................................................................................3

Drawing 1 Boiler terminal locations.........................................................................................................................4

Table 1 Boiler terminal locations .............................................................................................................................4

Table 2 risk assesment ............................................................................................................................................5

Boiler flue information............................................................................................................................................6

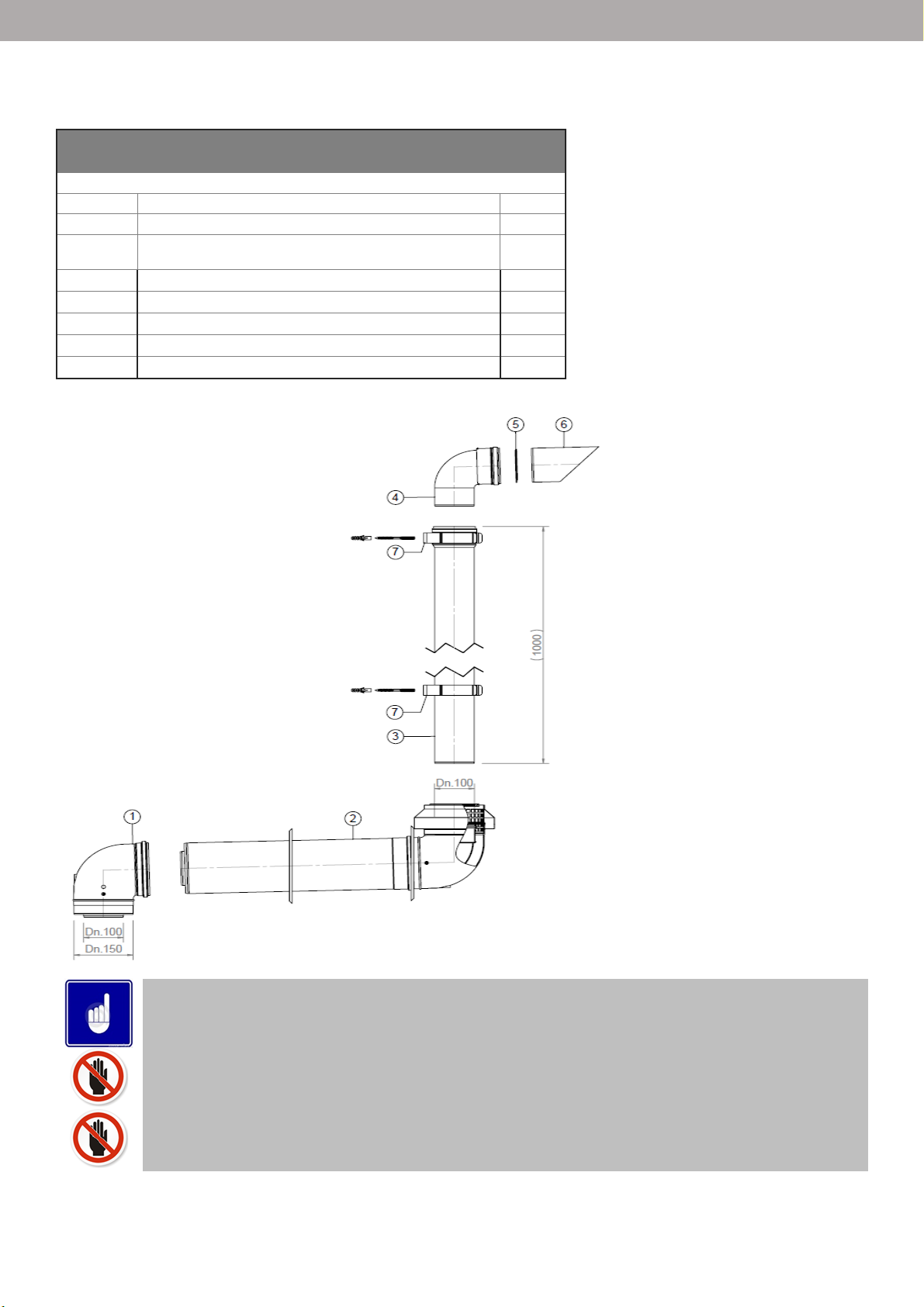

CONCENTRIC FLUE SYSTEMS .......................................................................................................................................7

Horizontal Type C13 .................................................................................................................................................7

Plume Management Kits .........................................................................................................................................8

Vertical Type C33......................................................................................................................................................9

Concentric Flue Sizing Calculations........................................................................................................................10

TWIN-PIPE FLUE SYSTEMS TYPE C53 ...........................................................................................................................11

Twin-Pipe Flue Sizing Calculations .........................................................................................................................12

CONVENTIONAL (EXHAUST ONLY) FLUE SYSTEMS TYPE B23........................................................................................14

Conventional Flue Sizing Calculations....................................................................................................................15

COMMON FLUE SYSTEMS .........................................................................................................................................17

ORDER FORM AND NOTES .................................................................................................................................18