3

With the purchase of your LOGIC TRM - ROTARY MOWER you have made an excellent

choice.

This machine should give first class service for a long time, if used correctly, and maintained as

described in this manual.

Fitted with an easy to start engine it has been designed to cope with a wide range of conditions.

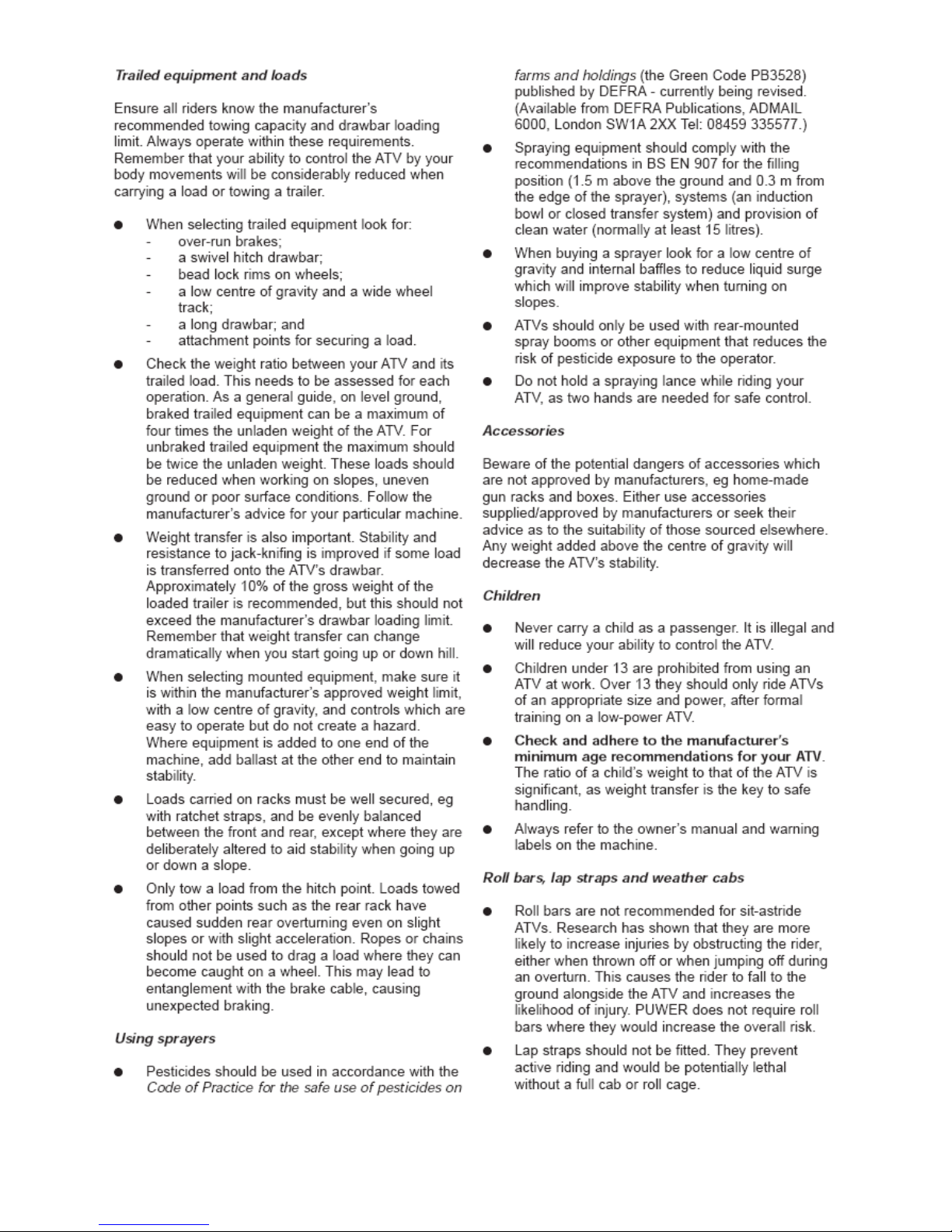

The Logic TRM - Rotary mower incorporates easy height adjustment, range of engine options

and three grass cutter blades for maximum life and durability. The Cutter blades have built in

deflectors to clean the blade and create a sucking action, all resulting in a better cutting finish

The mower incorporates a clutch to ensure the engine is protected and that the drive belts have

a longer life.

The mower deck is constructed from 4mm steel for added strength; all fittings are of high quality

to ensure years of trouble free use.

There are different wheel options available for the TRM - Rotary Mower

Engines used may vary, but all are accompanied by the maker’s usual warranty.

If after reading this manual there are any queries, please get in touch as we will be pleased to

help.

NORTH & EXPORT SOUTH

LOGIC MANUFACTURING LTD LOGIC MH LTD - New Whiteway Works,

Foundry Industrial Estate Fossecross Industrial Estate

Bridge End, Hexham Chedworth. Cheltenham

Northumberland NE46 4JL Gloucestershire GL54 4NW

Tel: 01434 606661 Fax: 01434 608143 Tel: 01285 720930 Fax:01285 720840

E-mail: sales@logic.gb.com E-mail: sales@logic.gb.com

www.logic.gb.com www.logic.gb.com