P a g e 2 | 11

LPS-Lasersysteme Siegmund Ruff / CEO Haidschwaerze 18 72131 Ofterdingen Germany

Foreword

Thank you for purchasing an LPS product.

Before you operate this product the first time, please read this manual carefully.

Our systems are equipped with high sensitive electronics and mechanics.

Strong shocks can cause significant damage to the system.

CAUTION!

Should an error occur due to improper handling or maintenance, there is no warranty.

Contents

Foreword.........................................................................................................................................................2

Contents..........................................................................................................................................................2

1. Commissioning....................................................................................................................................3

1.1 Areas of use ........................................................................................................................................3

1.2 Electrical Connection ..........................................................................................................................3

1.3 Installation ..........................................................................................................................................3

1.4 Operation............................................................................................................................................3

1.5 Unpack and connect ...........................................................................................................................4

2. Technical Specification .......................................................................................................................5

3. Overview.............................................................................................................................................7

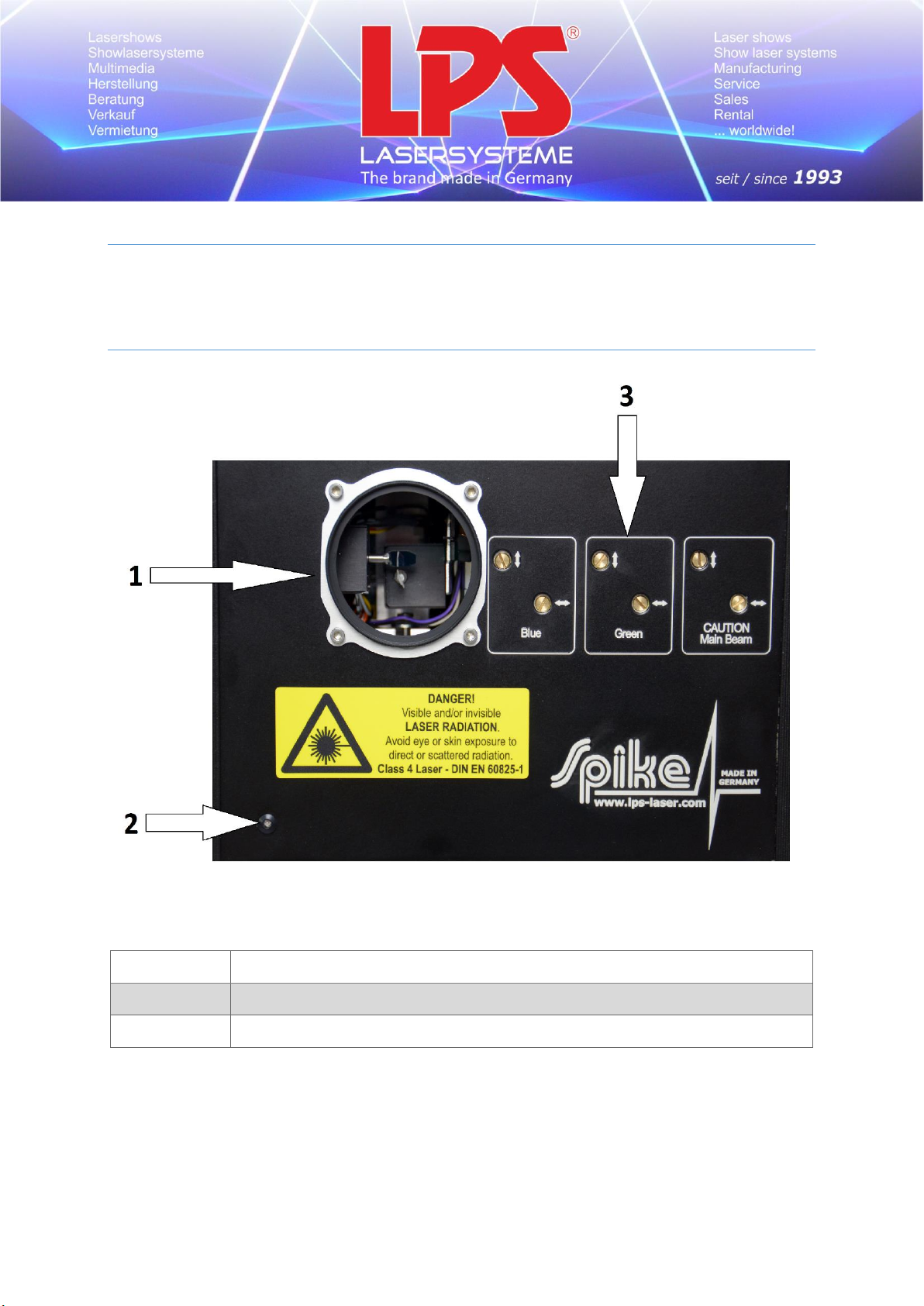

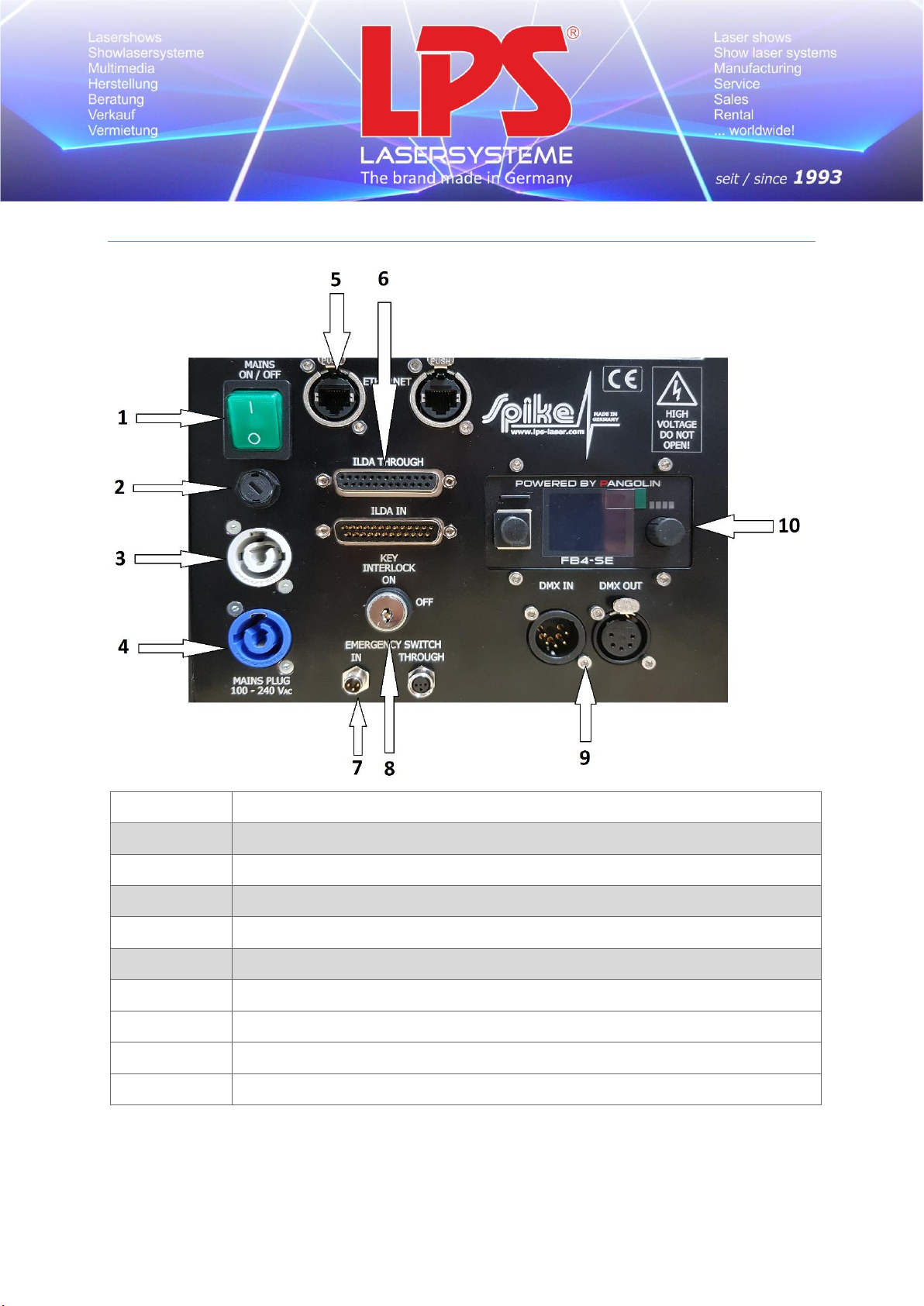

3.1 Housing front view..............................................................................................................................7

3.2 Housing back view ..............................................................................................................................8

3.3 Power switch ......................................................................................................................................9

3.4 Key switch...........................................................................................................................................9

3.5 Emergency Off ....................................................................................................................................9

3.5.1 Emergency in ......................................................................................................................................9

3.5.2 Emergency through ............................................................................................................................9

3.6 ILDA In / Through..............................................................................................................................10

3.7 Emission LED.....................................................................................................................................10

4. Maintenance.....................................................................................................................................10

5. Beam Adjustment.............................................................................................................................11