FOR INSTRUCTION /

DETERMINATIONS

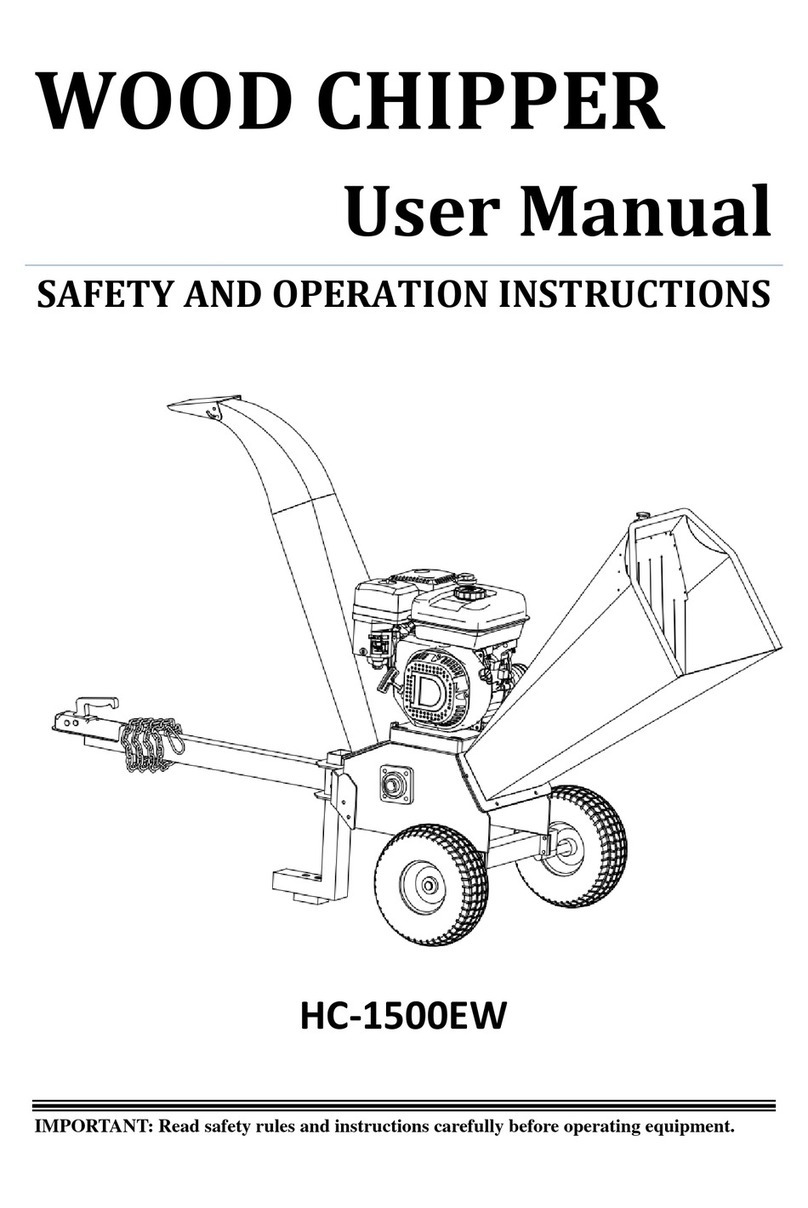

designation machine

The term machine replaces the commercial

designation of the object to which these operating

instructions - see cover sheet - applies.

copyright

All documents are protected under copyright law. A

transmission and reproduction of documents, even

in extracts and releases the contents are not

permitted unless expressly agreed.

Reservations

Information on specifications, dimensions and

illustrations of the device as well as changes of

safety standards are subject to further development

and are therefore not in any case for the supply

binding.

Printing and typographical errors.

WATCH

OUT!

The machine is supplied without engine oil.

For th e f irs t tim e must

ENGI N E OIL w i ll b e

fille d !

Second IN SHAPEATION

FOR INSTRUCTION

This manual describes functions, operation,

maintenance and care of your new harvester.

Please read it carefully and follow the instructions

carefully to ensure your shredder a long life and

give you a safe operation. Observe the safety

information and instructions as well as for the local

accident prevention regulations and general safety

regulations.

Read Before carrying out any work with the

machine, the operating manual, especially the

Safety chapter and the relevant safety information.

You must fully understand the read and observe.

These are basic instructions and suggestions to

prevent accidents. Errors in operation, inspection

and maintenance can cause injury or even death.

Third

USE

The shredder is intended exclusively for chopping

brushwood, shrubs, bark, branches to a branch

thickness of 12 cm.

The machine is not suitable for garden soil

prepare.

Roots with soil, stones, glass, metal, textiles, kitchen

waste, cardboard or plastic may be crushed in no

case with the machine.

Cuttings of conifers or similar dense

clippings can lead to blockages!

Any other or additional use is not considered to

comply with regulations. The manufacturer is not

liable for any resulting damage. The risk is borne

solely by the user.

Observance of the operating and maintenance

instructions and carrying out the maintenance, and

compliance with the maintenance intervals, are

intended for use.

WATCH

OUT!

Persons who are not familiar with the operating

instructions, children, youth and persons with

alcohol, drugs and medication influence may not

operate the machine.

3