PartI: General Safety Rules

6

required,see your authorized dealer for engine governor adjustments.

I. Keep combustible substancesaway fromthe engine when it ishot.

J. Never cover the machine while the muffler isstill hot.

K. Donotoperatethe enginewiththe aircleaner orthe carburetor airintakecover

removed. Removalofsuchparts couldcreateafire hazard. Donotuseflammable

solutionsto clean the airfilter.

L. The mufflerandenginebecome very hotand can cause a severeburn;do nottouch.

GeneralSafety

WARNING

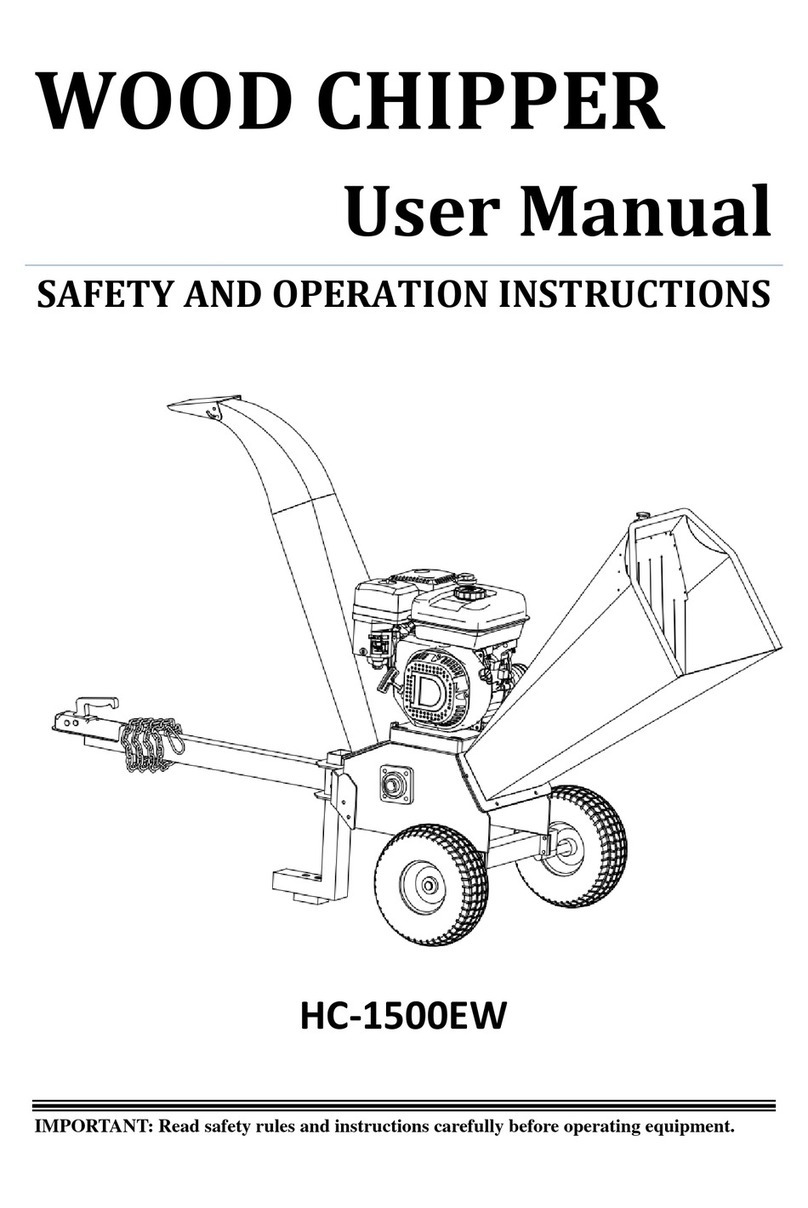

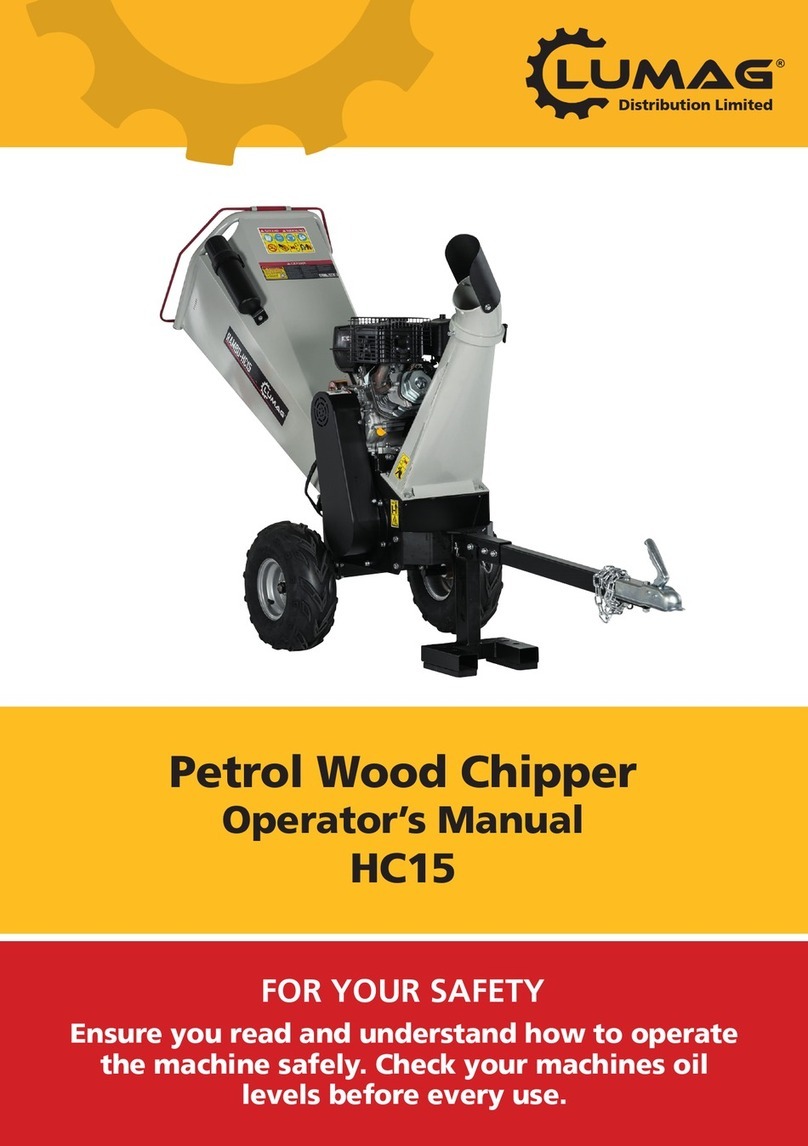

Operating thisWood Chipper safelyisnecessary topreventor minimize the riskofdeathor

seriousinjury. Unsafeoperation can createanumberofhazardsfor you. Alwaystakethe

following precautionswhen operating:

A. YourWoodChipper isapowerfultool,notaplaything. Exerciseextremecaution atall

times. The machine isdesigned toChipWoods.Do notuse it for any otherpurpose.

B. Knowhowto stop the Wood Chipper quickly.

C. Neveroperateyour unit on aslippery, wet,muddy, or icy surface. Exercisecaution to

avoid slipping or falling.

D. See manufacturer sinstructionsforproper operation and installation ofaccessories.

E. Never use the machine withoutensuring thatall guardsand shieldsare inplace.

F. Never, underanyconditions,remove,bend,cut,fit,weld,orotherwisealter standard

parts on theWoodChipper. Thisincludesall shieldsand guards.Modificationstoyour

machine couldcausepersonalinjuriesand propertydamage and will invalidyour

warranty.

G. Ifthemachine starttomakean unusualnoiseorvibrate, shutdowntheengine,

disconnectthesparkplugwire, keeping it awayfromthesparkplug toprevent

accidentalstarting, wait5minutesfor enginetocooldown,theninspectfordamage.

Vibration isgenerallyawarning oftrouble. Checkdamaged parts and clean,repair

and/or replace asnecessary.

H. Never tamper with safety devices. Checktheir proper operation regularly.

I. Beforeperforming anymaintenanceorinspection procedure,shutdownthe engine,

disconnectthe sparkplug wire keeping it away fromthe sparkplug toprevent

accidentalstarting, wait 5 minutesfor machine to cooldown.

J. Neverallowpeople who areunfamiliar withtheseinstructionstousethe Wood Chipper.

Allowonlyresponsibleindividualswhoare familiar withtheserulesofsafeoperation to

use your machine.

K. Neveroverload or attempttochipwoodsbeyond the manufacturer srecommendation.

It could result inpersonalinjury ordamage to the machine.

L. Whileusing,don't hurry or takethingsfor granted. When indoubtaboutthe

equipmentor your surroundingsstop the machine and take time to lookthingsover.

M. Never operate the machine when under the influenceofalcohol, drugs,or medication.