.*!

3 !"#$4

The XLB-3000 Xenon lamp ballast has been designed for OEM Xenon lamp industry.

With this in mind, the Xenon lamp industry has the following requirements:

• Safe lamp operation

• Reliable short pulse lamp ignition

• Compact size

• Power factor correction to conform with CE requirements

• Low conducted electromagnetic emissions

• Low leakage for medical applications

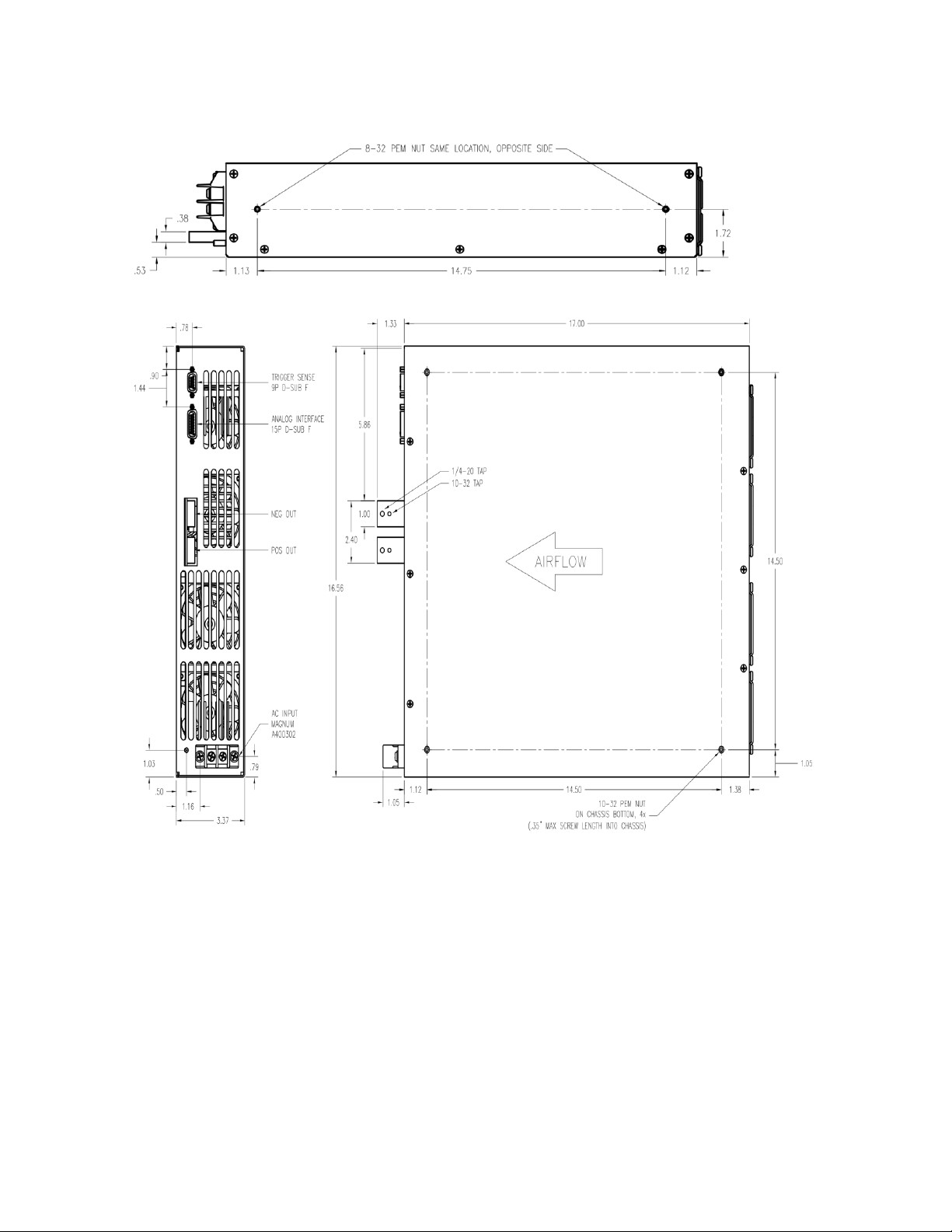

Referring to Figure 1, the XLB-3000 BLOCK DIAGRAM. The following is a brief

description of operation.

5#),!#!.

AC input power is processed through a line filter to reduce the conducted EMI to an

acceptable level. The XLB-3000 line filter has minimum capacitance to ground to

minimize leakage currents.

), !5+

The rectified input power is next applied to power factor boost inverter. This inverter

boosts the input voltage to 400VDC. In the process of boosting the input AC voltage, the

input AC current is adjusted so that is always in phase with the input AC voltage.

Without this power factor correction circuit, the AC input current would be delivered to

the power supply in high amplitude, narrow spikes, having a high harmonic content. With

power factor correction, the non- 0/60 Hz harmonics are reduced to near zero. Since only

the fundamental frequency is now used to deliver power, the efficiency of the power

supply is improved considerably.

One problem with standard input power factor correction circuits is that a high frequency

switching circuit is placed across the line in the input side of the traditional input capacitor

filter. This circuit results in substantial switching noise conducted to the line. Lumina

Power employs a proprietary soft-switching boost inverter which produces minimum

switching noise, reduces switching losses, and results in a smaller heat sink associated

with the power factor circuit.

62",!!"36245+

The ZVS inverter and the output transformer are used to step the 400VDC bus down to

the appropriate output value. The ZVS inverter is the most modern high frequency/low

loss/low noise topology utilized in power electronics today. Instead of running the

inverter in a traditional PWM mode, the inverter is run in a phase shift mode. With the

appropriate output inductor and the appropriate capacitance across each switching device -

in this case MOSFETS - there are virtually no switching losses in the inverter. The only

losses in the devices are I2R losses associated with the Drain/Source resistance of the