2CAREANDUSE/INSTALLATION

NOTE

!CAUTION

Safety information ...............................................................2

Unpacking your appliance ..................................................3

Warranty registration .....................................................3

Installing your appliance ......................................................4

Cabinet clearances .........................................................4

Leveling the appliance ....................................................4

Electrical connection ......................................................5

Product dimensions ............................................................6

Using your Electronic control .............................................8

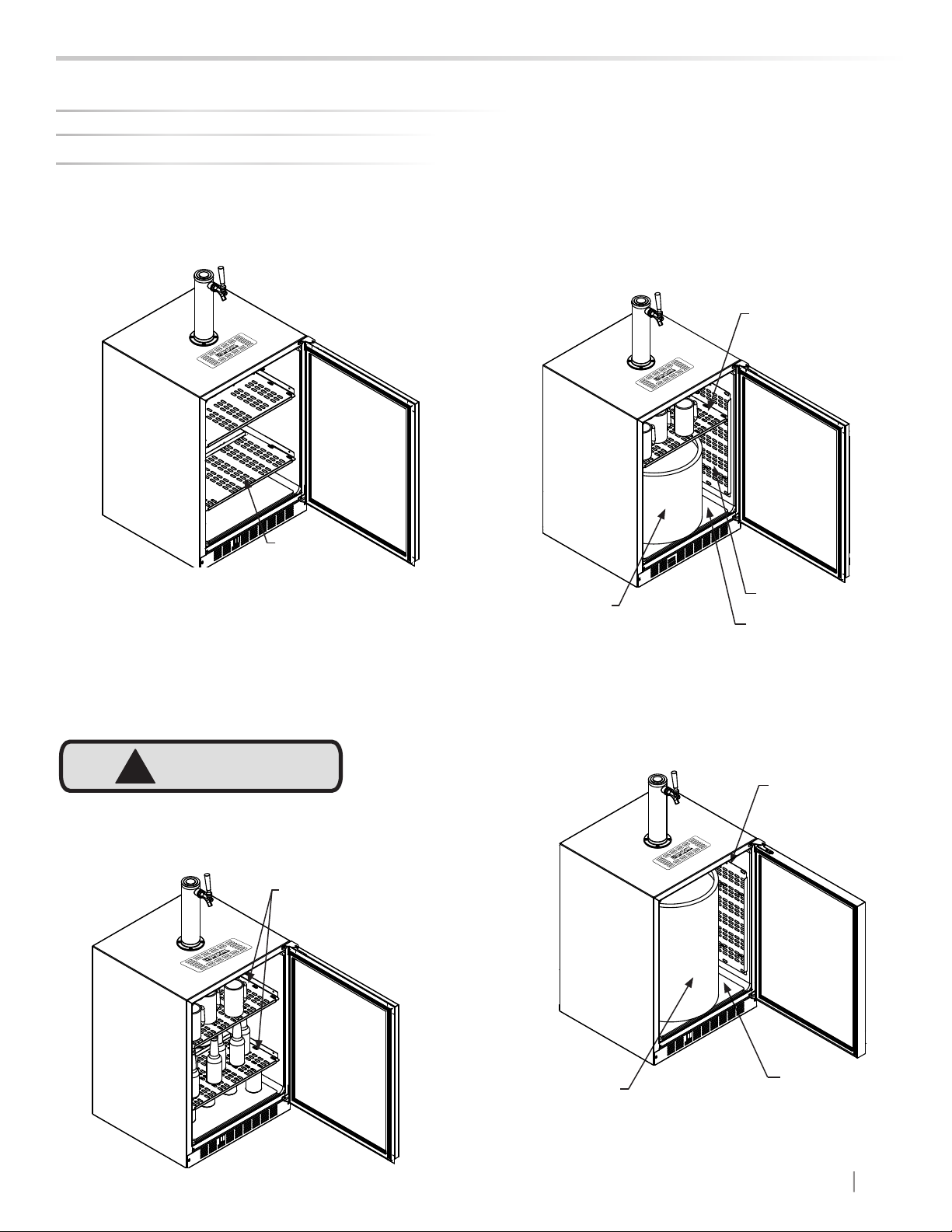

Using your beverage dispenser........................................10

Shelving .......................................................................10

Tap equipment and assembly......................................11

Gas regulator ...............................................................15

Drainkit .........................................................................16

Care and cleaning ............................................................16

Cleaning the drain sump ...............................................16

Keg coupler cleaning ....................................................17

Faucet cleaning ............................................................17

Tap cleaning kit .............................................................18

Cleaning the beverage line ...........................................18

Front grille .....................................................................18

Cabinet .........................................................................18

Interior ..........................................................................18

Long term storage / winterization .................................19

Stainless steel maintenance ............................................20

Energy saving tips ...........................................................20

Obtaining service .............................................................21

Troubleshooting ................................................................22

Important Safety Instructions

Contents

!WARNING

WARNING - This unit contains R600a (Isobutane)

which is a ammable hydrocarbon. It is safe for regular

use. Do not use sharp objects to expedite defrosting.

Do not damage refrigerant circuit.

Warnings and safety instructions appearing in this guide

are not meant to cover all possible conditions and situa-

tions that may occur. Common sense, caution, and care

must be exercised when installing, maintaining, or operat-

ing this appliance.

Recognize Safety Symbols,

Words, and Labels.

!WARNING

WARNING - You can be killed or seriously injured

if you do not follow these instructions.

CAUTION-Hazards or unsafe practices which could re-

sult in personal injury or property / product damage.

NOTE-Important information to help assure a problem

free installation and operation.

CONTENTS

Warranty ...........................................................................23