5

PUMP ASSEMBLY & INSTALLATION

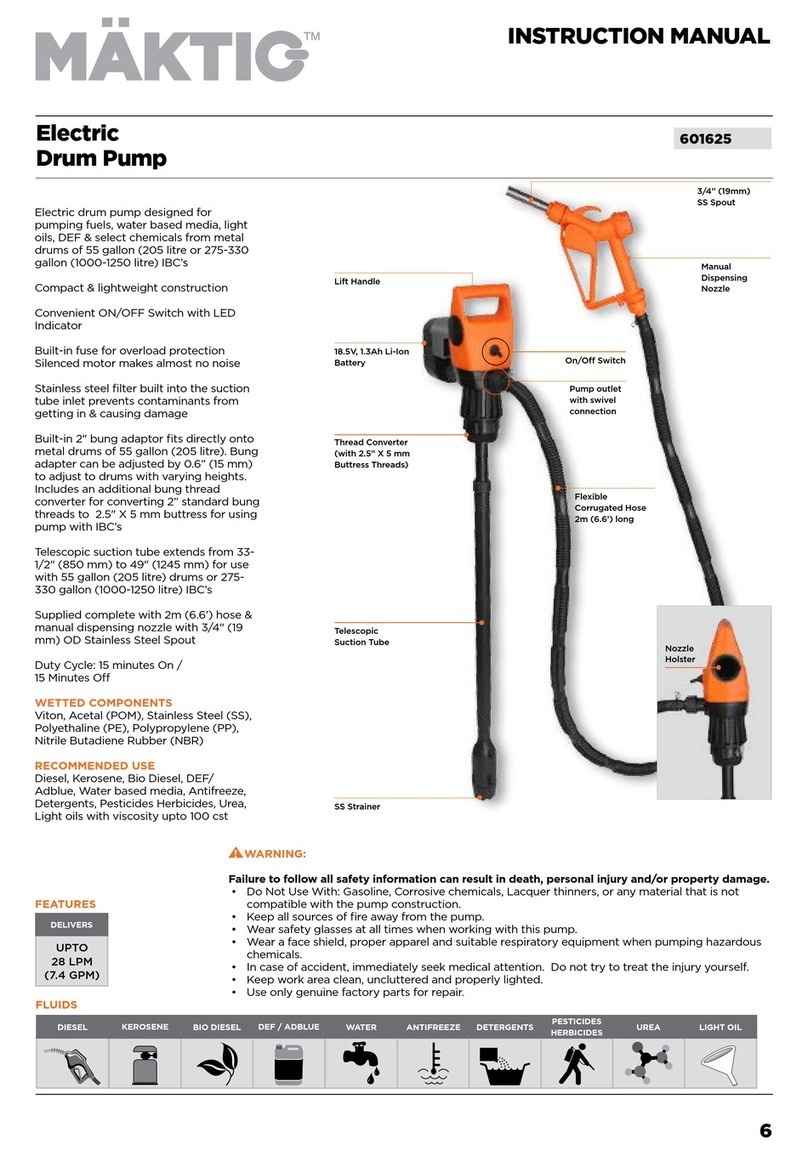

EXPLODED VIEW

Failure to follow all safety information can result in death, personal injury

and/or property damage.

• Never operate the pump near open flames or source of spark. Some

media may be flammable or explosive.

• Wear safety glasses at all times when working with this pump.

• Wear a face shield, proper apparel and suitable respiratory

equipment when pumping hazardous chemicals.

• In case of accident, immediately seek medical attention. Do not try

to treat the injury yourself.

• Keep work area clean, uncluttered and properly lighted.

• Use only genuine factory parts for repair.

Note: It is a good practice to use a sealant such as Teflon to have totally

leak-proof connection.

If the pump is about to be re-used after an extended period of time, it

may loose it’s prime & may require re-priming.

(Refer priming).

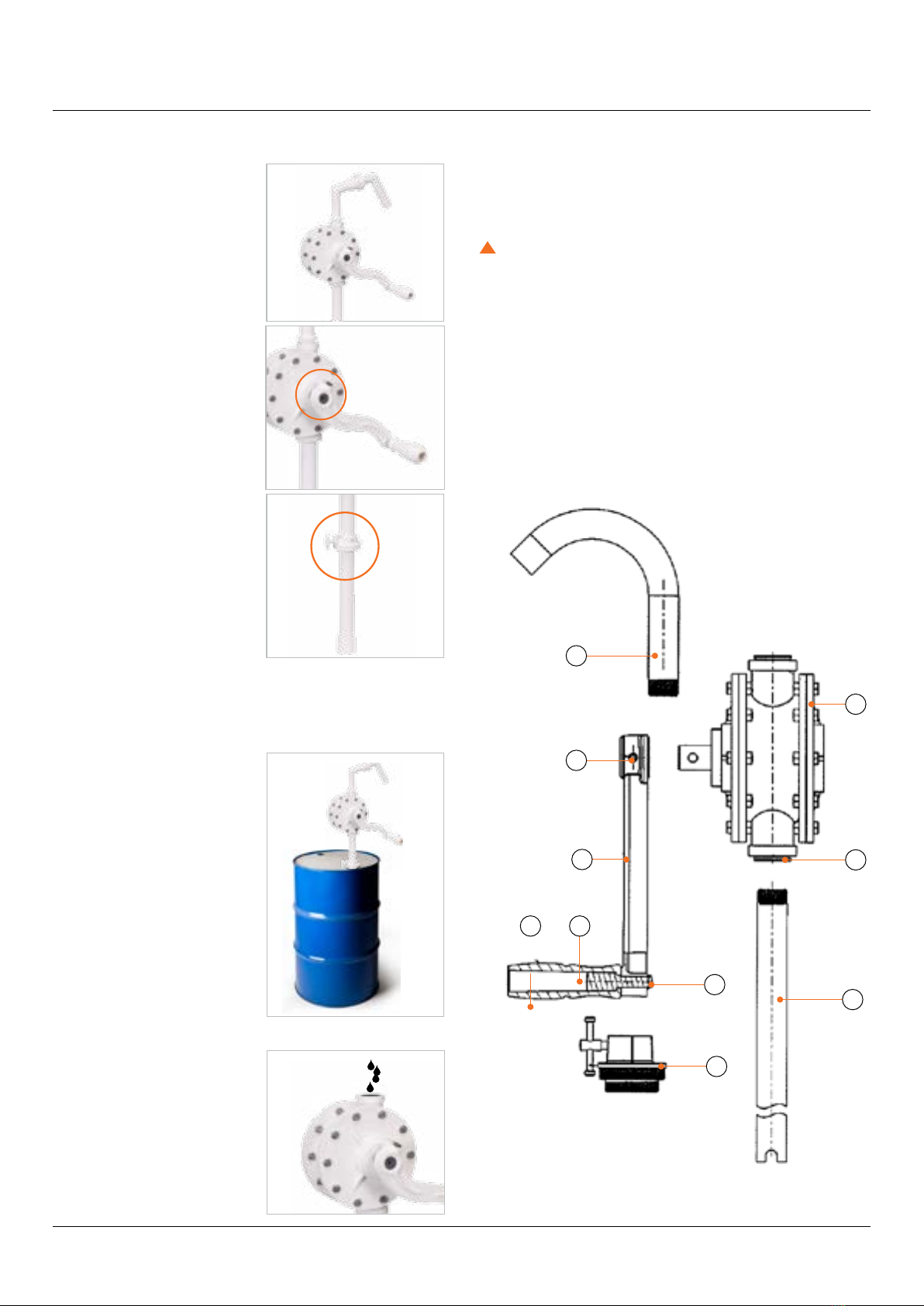

1. Assemble the 2 parts of the

Discharge spout together

& fasten the assembly onto

the outlet on the main pump

body. Use PTFE tape or

equivalent sealant tape.

Note: Do not use paste pipe

sealant.

2. Insert the pump handle shaft

through the pump shaft. Fix

the pump handle onto the

crank arm & connect the

crank to the crankshaft on

the pump body. Secure the

connection using the hex

bolt & hex nut provided.

Make sure that the bolt fits

onto the depression in the

crankshaft.

3. Assemble the suction tube

parts, depending upon the

drum size on which the

pump is to be installed.

The tail pipe with the

strainer may be connected

direct onto the pump inlet

or assembled with one

extension or both extensions,

depending upon drum

size. All 3 parts must be

connected for use with 55

gallon / 205 litre drums.

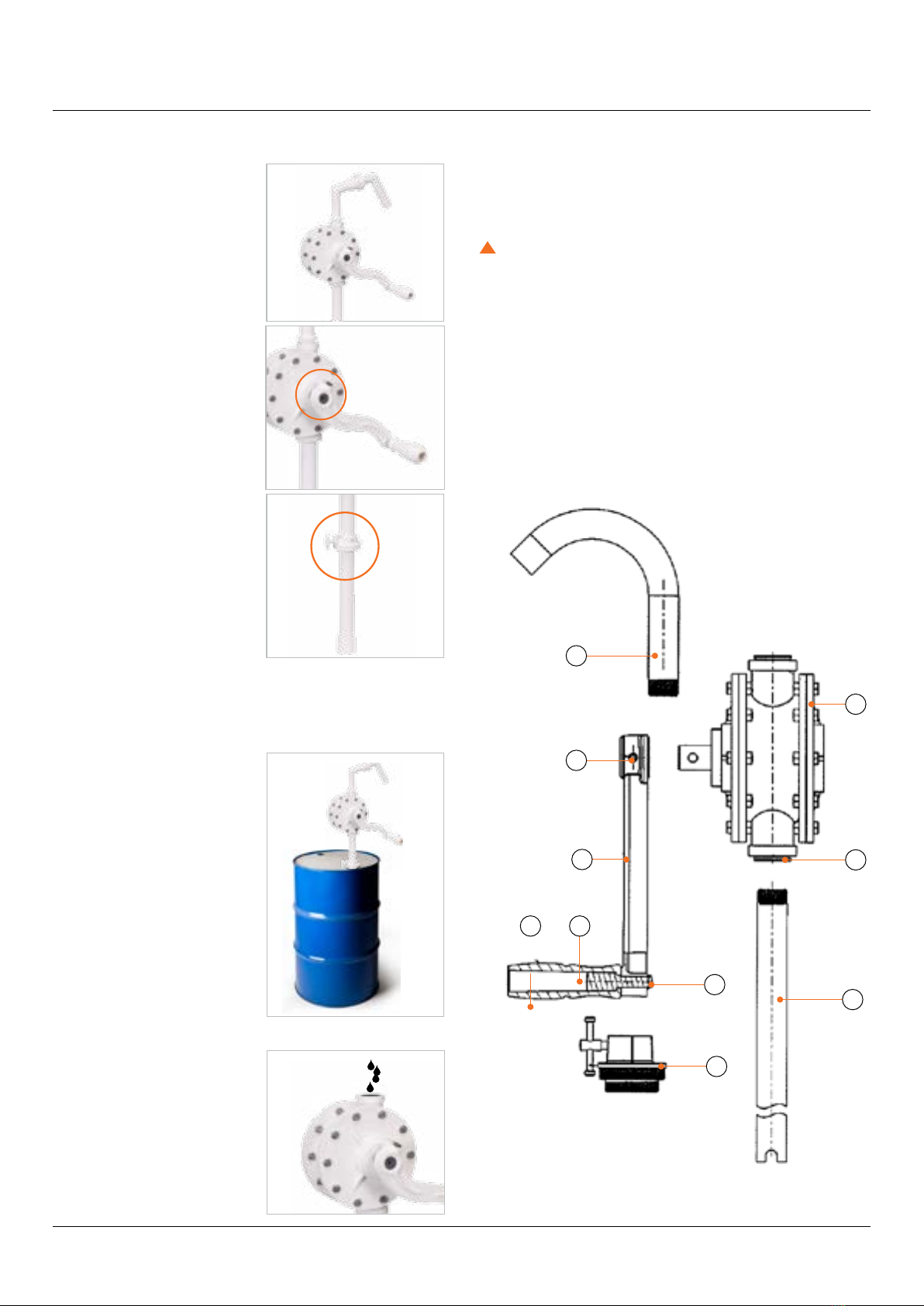

4. Choose the bung adapter

from the two that best fits

your drum. Each pack comes

with two adapters, which

have slight dierence in

the threads to suit dierent

drums. Slide the selected 2”

bung onto the tube from the

top end & tighten the suction

tube onto the inlet on the

main pump body.

5. Insert the pump assembly

into the drum from the 2”

bung opening on the drum.

6. Once the bottom of the

pump touches the base of

the drum, securely fasten the

bung onto the drum. Now

very lightly tighten the bung

cross bolt onto the suction

tube

PRIMING

In a rare case, where the pump

does not get primed, the same

can be done by removing the

discharge spout & pouring

about 30 ml (1 oz) of same liquid

being pumped into the outlet

& reassemble the discharge

spout & start operating the

pump handle till pump starts

dispensing fluid.

1

10

7

6

8

5

4

2

3

10

! WARNING: