6

MAINTENANCE

1. The pump has been designed and built to require a minimal

amount of maintenance.

2. All maintenance must be performed by qualified personnel.

PRIMING

When using the pump for the first time or if using after a long

period of time, the pump may need priming. Priming is done by

stroking the handle 4-5 times.

Note: If the pump is not used for a long period of time, it may

lose its prime and may need re-priming.

1. Take out the pump body from the box and adjust the height

of bung assembly (16) to be threaded onto the drum.

2. Connect grounding wire

3. Screw the outlet spout (12) onto the pump head (1) along

with the teflon seal placed in the kit (17).

4. Start operating the T-Handle (7) by moving it up and

down. Within a maximum of 4 strokes, the pump will start

dispensing media. The higher the lift of the handle, the

greater the discharge will be per stroke.

5. Pump comes with 5 flow control tubes in the kit (17) which

can be inserted between spring (6) & nut (3) according to

the flow requirement.

STEPS ON HOW TO REPLACE THE DAMAGED SEAL

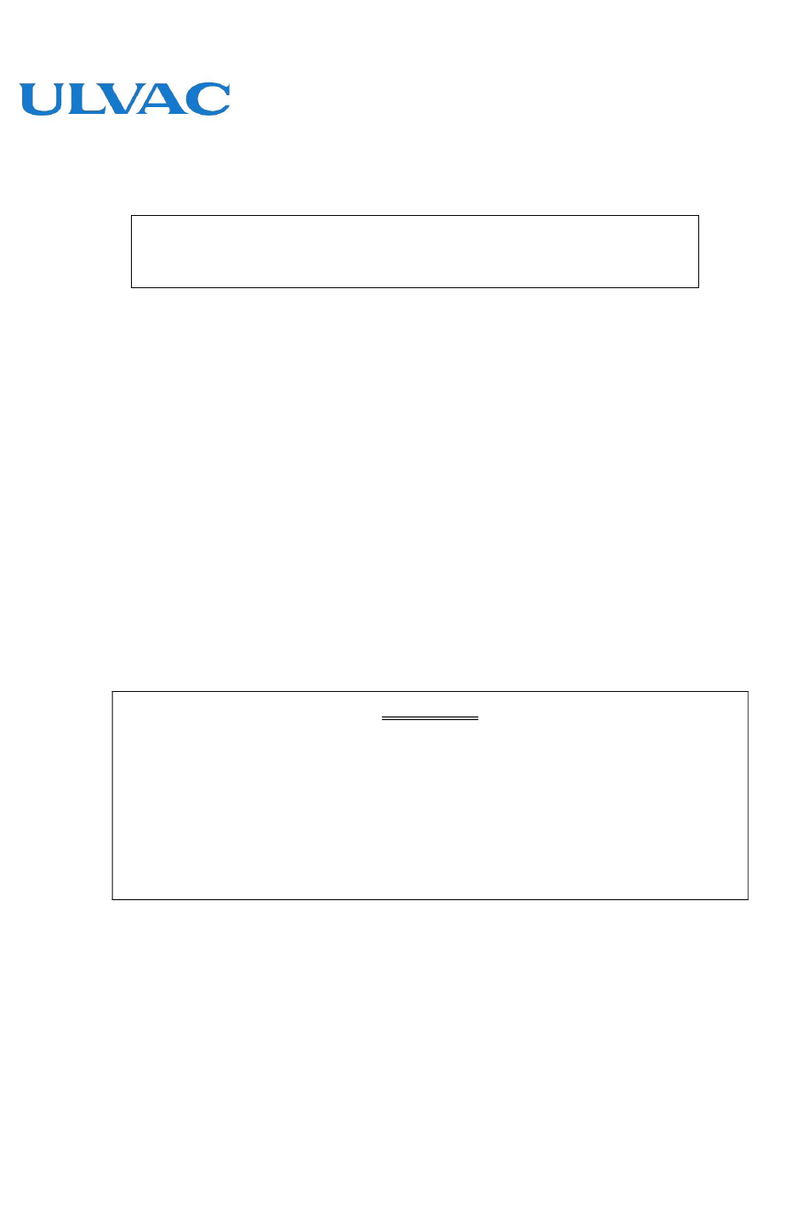

ASSEMBLY AND OPERATION

Failure to follow all safety information can result in death, personal injury

and/or property damage.

• Dispensing media can lead to a buildup of static electric charge

that could spark and ignite flammable fumes. Always connect a

grounding wire from the pump’s treaded stud and locknut to an

electrical system grounding point.

• Keep all sources of fire away from the pump.

• Never let a body part come in front of, or in contact with the pump

outlet.

• Wear safety glasses at all times when working with this pump.

• Wear a face shield, proper apparel and suitable respiratory

equipment when pumping hazardous chemicals.

• In case of accident, immediately seek medical attention. Do not try

to treat the injury yourself.

• Keep work area clean, uncluttered and properly lighted.

• Use only genuine factory parts for repair.

Note: The flow control tubes will restrict the flow and each tube will

approximately reduce the flow rate by 100 ml (3.4 oz.). Combination of

tubes can be used together, but the discharge will reduce.

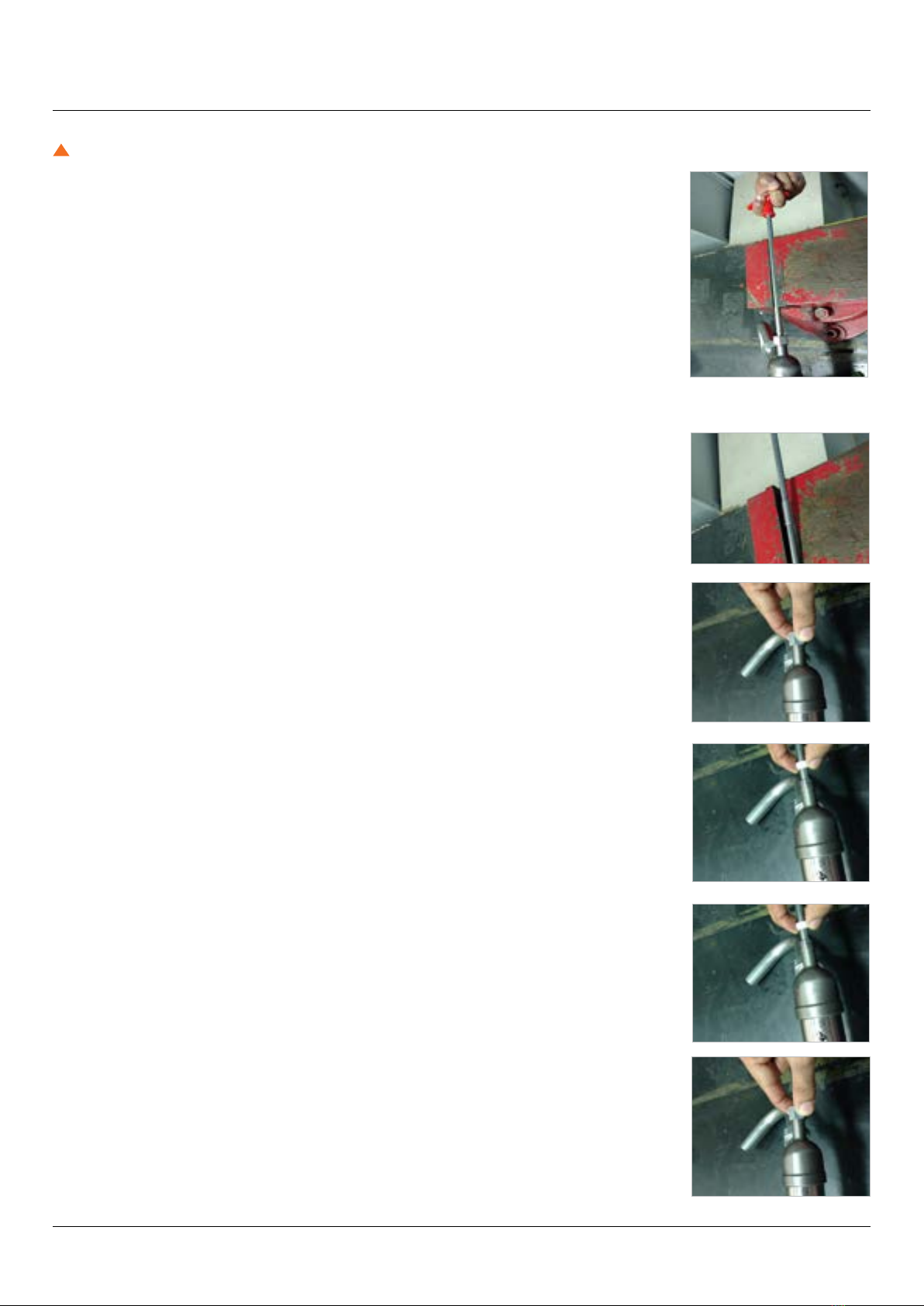

1. Hold the rod (5) into a vice

and rotate the T-Handle (7)

anticlockwise to disassemble

it from the rod (5).

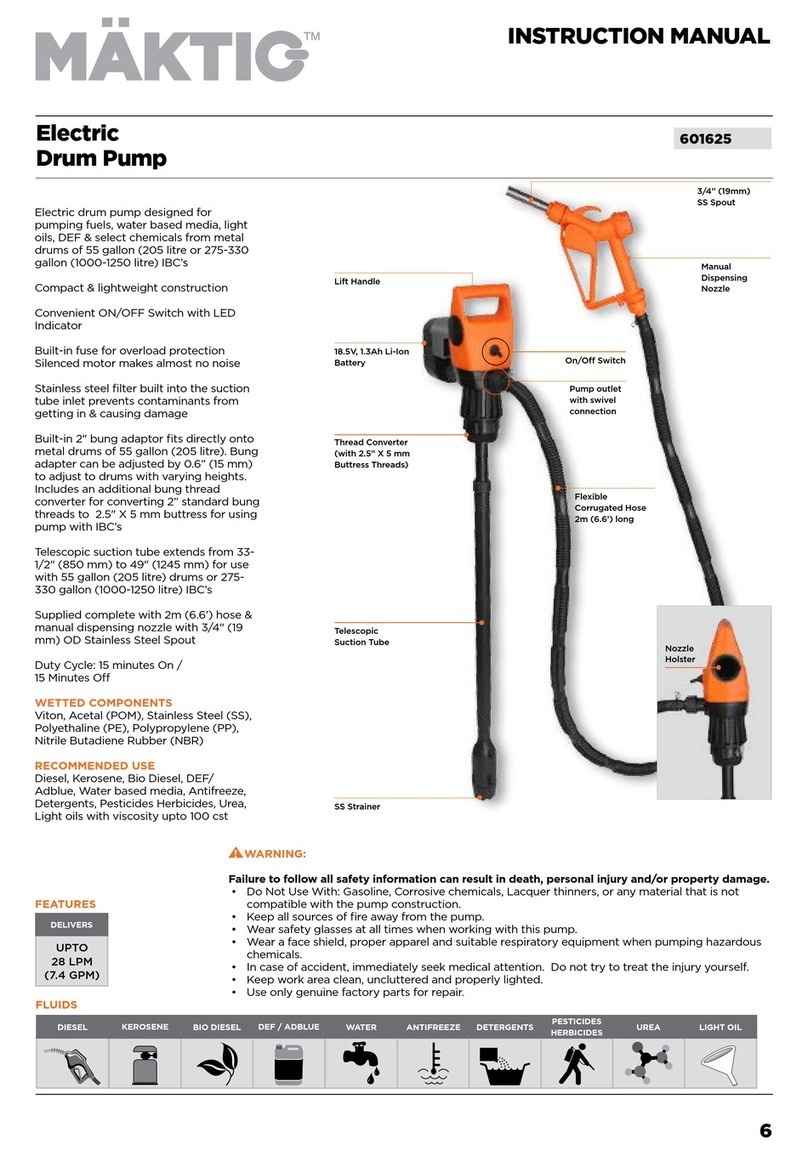

2. Now, remove the spring

(6) from the rod (5).

3. Unscrew the nut (3) from

the rod (5).

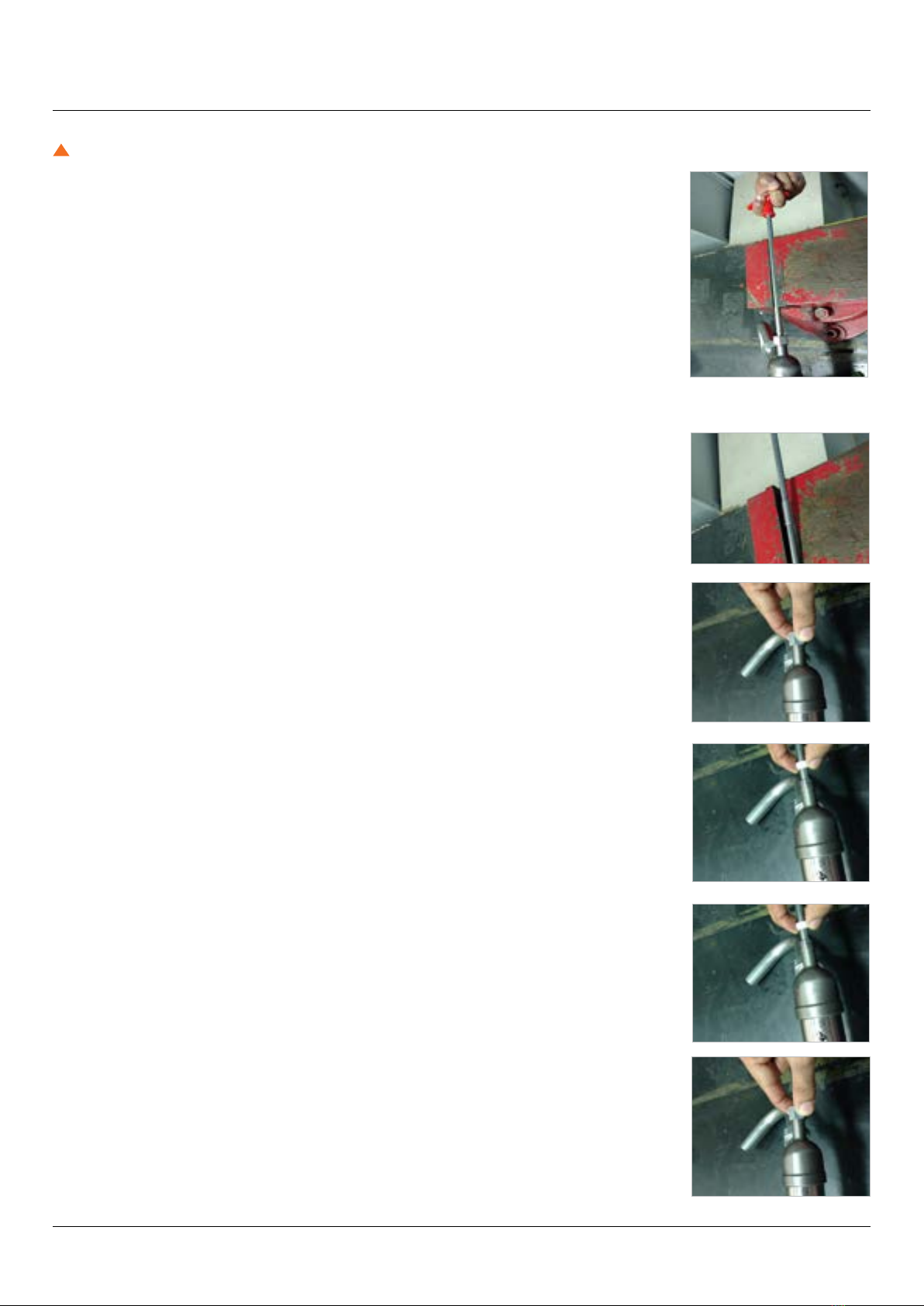

4. Pull out the damaged

seal (4).

5. Now take the seal (4)

to be replaced from the

repair kit and slide it

over the rod (5).

6. Assemble the pump by

repeating the steps

(1-3) in the reverse

order.

! WARNING: