Mäktig 601625 User manual

6

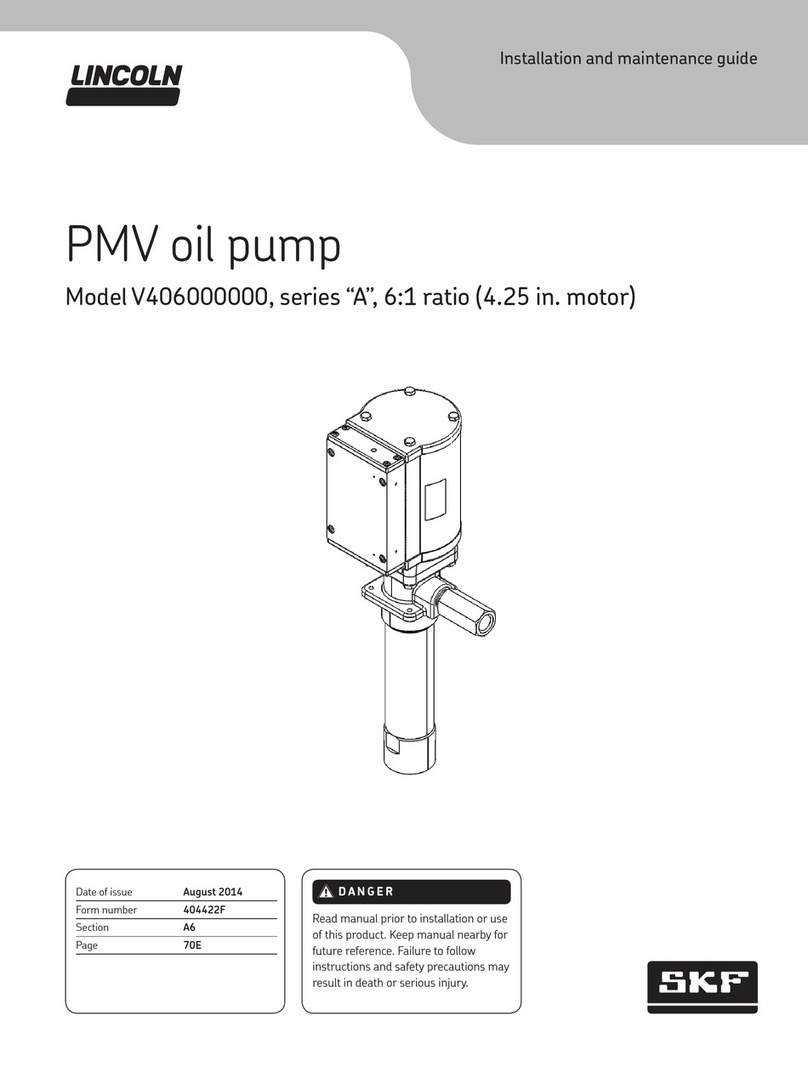

Lift Handle

Thread Converter

(with 2.5" X 5 mm

Buttress Threads)

Telescopic

Suction Tube

SS Strainer

3/4” (19mm)

SS Spout

Manual

Dispensing

Nozzle

Flexible

Corrugated Hose

2m (6.6’) long

On/O Switch

Pump outlet

with swivel

connection

18.5V, 1.3Ah Li-Ion

Battery

Nozzle

Holster

Electric

Drum Pump

Electric drum pump designed for

pumping fuels, water based media, light

oils, DEF & select chemicals from metal

drums of 55 gallon (205 litre or 275-330

gallon (1000-1250 litre) IBC’s

Compact & lightweight construction

Convenient ON/OFF Switch with LED

Indicator

Built-in fuse for overload protection

Silenced motor makes almost no noise

Stainless steel filter built into the suction

tube inlet prevents contaminants from

getting in & causing damage

Built-in 2" bung adaptor fits directly onto

metal drums of 55 gallon (205 litre). Bung

adapter can be adjusted by 0.6” (15 mm)

to adjust to drums with varying heights.

Includes an additional bung thread

converter for converting 2” standard bung

threads to 2.5" X 5 mm buttress for using

pump with IBC’s

Telescopic suction tube extends from 33-

1/2" (850 mm) to 49" (1245 mm) for use

with 55 gallon (205 litre) drums or 275-

330 gallon (1000-1250 litre) IBC’s

Supplied complete with 2m (6.6’) hose &

manual dispensing nozzle with 3/4" (19

mm) OD Stainless Steel Spout

Duty Cycle: 15 minutes On /

15 Minutes O

WETTED COMPONENTS

Viton, Acetal (POM), Stainless Steel (SS),

Polyethaline (PE), Polypropylene (PP),

Nitrile Butadiene Rubber (NBR)

RECOMMENDED USE

Diesel, Kerosene, Bio Diesel, DEF/

Adblue, Water based media, Antifreeze,

Detergents, Pesticides Herbicides, Urea,

Light oils with viscosity upto 100 cst

UPTO

28 LPM

(7.4 GPM)

DELIVERS

FEATURES

601625

FLUIDS

DIESEL LIGHT OIL

KEROSENE UREA

WATER ANTIFREEZE PESTICIDES

HERBICIDES

DETERGENTS

BIO DIESEL DEF / ADBLUE

! WARNING:

Failure to follow all safety information can result in death, personal injury and/or property damage.

• Do Not Use With: Gasoline, Corrosive chemicals, Lacquer thinners, or any material that is not

compatible with the pump construction.

• Keep all sources of fire away from the pump.

• Wear safety glasses at all times when working with this pump.

• Wear a face shield, proper apparel and suitable respiratory equipment when pumping hazardous

chemicals.

• In case of accident, immediately seek medical attention. Do not try to treat the injury yourself.

• Keep work area clean, uncluttered and properly lighted.

• Use only genuine factory parts for repair.

INSTRUCTION MANUAL

7

INSTALLATION

SPECIFICATION

POWER SOURCE

MOTOR TYPE DC Brush Motor (5 Pole)

TEMPERATURE 5° to 40°C (41° to 104°F)

MAX. VISCOSITY OF MEDIA 100 cst

POWER SOURCE RECHARGEABLE (Li-Ion)

Power Cord Rechargeable 1.3 Ah Li Ion Battery with

1 hour Quick Charger

Voltage 18.5V Battery & AC charger

(110V or 220V)

Max. Discharge 28 LPM (7.4 GPM)

3. Clamp the hose with the

nozzle using the Hose

clamp.

4. Clamp the other end of

the Hose with the outlet

Hose barb on the pump

outlet.

5. Place the Nozzle inside

the Nozzle Holster

provided on the side of

the pump.

1. Insert the Pump into the

Drum through the Drum

Hole.

2. Screw the Bung adaptor

with the Drum hole.

Note: Buttress thread

adaptor can be used with

2.5" x 5mm thread IBC’s.

OPERATION

BATTERY CONNECTION

1. Pull out the Nozzle from

the Nozzle Holster

2. Place the Nozzle into the

receiving container to

transfer the liquid.

3. Switch On the Toggle

switch (Up) and pull the

Nozzle Trigger.

4. After Dispensing Switch

O the Toggle switch

(Down) and lift the

Nozzle upward allowing

all the liquid in the line to

flow back into the Drum.

1. Connect the Battery

holder plug with the

pump socket and mount

the Battery holder on to

the pump by screwing

the holder into the pump

body. (Refer to Exploded

View point 50 & 51)

2. Push a fully charged

battery into the Battery

holder.

Note: Press the side

buttons on the battery

while removing it or else it

will not come out.

3. Turn the toggle switch to ‘ON’ position to start the pump.

5. Place the Nozzle back

into the Holster to

prevent any damage

to the Hose or to the

Nozzle.

8

HOW TO EXTEND TELESCOPIC SUCTION TUBE ?

1. Rotate the joint nut anti

clockwise and then pull

the strainer end of the

suction tube away from

the bung.

2. After extending the

suction tube rotate the

joint nut clockwise to fix

the suction tube in the

extended position.

HOW TO CHARGE THE PUMP BATTERY ?

1. Push the Battery inside

the charger as shown in

the picture

Note: Press the side

buttons on the battery while

removing it or it will not

come out.

2. Connect the charger to the power supply and switch it ‘ON’

a. At the time of charging

both lights remain steady.

b. When battery is fully

charged, only green light

remain steady and red

light turns o.

1245 mm (49")

850 mm (33.5")

Green

Light

Red

Light

HOW TO REPLACE THE FUSE ?

1. Remove the Hose Barb

from the Outlet.

2. Unscrew all the bolts to

Remove the Hose Barb

from the Outlet.

3. Replace the older fuse

with a new one.

4. Upper body must be

perfectly seated while

assembling the pump

again.

5. Make sure that the

Nozzle holster is

perfectly seated as

shown in the picture.

6. Screw all the bolts to

assemble the pump.

7. Screw back the Hose barb onto the outlet.

9

10-3

53-1 53-2

10-2 10-1

10

EXPLODED VIEW

10

PARTS LIST

REF NO. PARTS DESCRIPTION QTY.

1Front Cover 1

2Back Cover 1

3Nozzle Holder 1

4Holder Cover 1

5Nozzle Hook 1

6Screw 6

7Toggle Switch 1

8Waterproof Cap 1

9LED Lamp 1

10 PCB Assembly 1

10-1 Resistor 1

10-2 Fuse Holder 2

10-3 Fuse 1

11 Connector Wire 2

12 Connector Pin 2

13 Motor Wire Packing 2

14 Wire Clamp 2

15 Body 1

16 O-ring (Body) 1

17 Drum Bung Adapter 1

18 Inner Pipe 1

19 Suction Pipe Packing 1

20 Suction Pipe (Upper) 1

21 O-ring (Pipe) 1

22 Suction Pipe (Lower) 1

23 Motor Wire 1

24 Motor Cover 1

25 O-ring (Motor Cover, Handle) 2

26 Motor 1

PROBLEM CAUSE SOLUTION

Pump not creating suction Strainer clogged Clean the strainer

Pump not working 1. Wire damaged inside the pump.

2. Electricity supply problem

3. Fuse damaged

4. AC adaptor not working (only in AC version)

5. Battery not charged (only in Battery version)

6. Motor not working

1. Send the pump to the service centre.

2. Check the electricity supply.

3. Replace the Fuse.

4. Replace the AC adaptor.

5. Fully recharge the Battery.

6. Send the pump to the service centre

Fluid not coming out of the Nozzle Nozzle or the Hose may be blocked Clean or replace the Nozzle or the Hose.

Leakage in Hose Hose Damaged Cut the Hose from the next slot and use again.

REF NO. PARTS DESCRIPTION QTY.

27 Motor Packing 1

28 Motor Case 1

29 Impeller 1

30 Impeller Casing 1

31 Filter 1

32 End Cap 1

33 O-ring (Hose Adapter, Spout) 3

34 Hose Adapter 1

35 Joint Nut 3

36 Hose Clamp 2

37 Discharge Hose 1

38 Handle 1

39 Nozzle Cap 1

40 Nozzle Spring 1

41 Nozzle Piston 1

42 O-ring (Piston L) 1

43 O-ring (Piston S) 1

44 Nozzle Lever 1

45 Spout (Stainless Steel) 1

46 O-ring (Stainless Nozzle) 1

47 Spout Adapter 1

48 Screw 1

49 Cable Clamp 1

50 Battery Adapter 1

51 Screw 2

52 Cable Connector 1

53-1 Terminal 1

53-2 Terminal Bracket 1

TROUBLESHOOTING

Table of contents

Other Mäktig Water Pump manuals

Popular Water Pump manuals by other brands

Grundfos

Grundfos PF Series Installation and operating instructions

Profi-pumpe

Profi-pumpe INNO-TEC 550-9 operating instructions

KSB

KSB Calio 25-100 manual

aermotor

aermotor HNAS Series Installation and operation manual

Grundfos

Grundfos DMH 25X Installation and operating instructions

Sandpiper

Sandpiper SB1-A Service and operating manual

Bison

Bison BPH-125SW2 installation instructions

Pro Series Pumps

Pro Series Pumps PHCC-1850 Instruction manual & safety warnings

Aurora

Aurora 442 Installation & operating instructions

Wilo

Wilo Wilo-E 15/1-5 Installation and operating instructions

onga

onga Dominator 7535 owner's manual

vacuubrand

vacuubrand PC 3002 VARIO select Instructions for use