M-Power CRB7 User manual

CRB7- COMBINATION

ROUTER BASE MK3

INSTRUCTION

MANUAL

re-cycleread version

5

2

CRB7 - COMBINATION ROUTER

BASE MK3

Thank you for purchasing the MPOWER

Combination Router Base (CRB7), we hope you

enjoy using it.

The CRB7 should give lasting performance if

used in accordance with these instructions.

SAFETY

Please read and understand the safety points at

the end of these instructions as well as the

power tool instructions before use.

Users must be competent in safe routing

practices before using this product.

FEATURES

• Adjustable Dadoing with a Clamp Guide

• Adjustable Mortising for material

2” (50mm) > 5/16” (125mm)

• Adjustable Anti-tilt support

• Adjustable Groove Copier

• Offset Baseplate

• Small Circle Router Compass:

Min. Radius 3/4” (19mm) >8.13/16”(224mm)

• Large Circle Router Compass

Min. Radius 7” (180mm) > 25” (635mm)

Note: All dimensions shown are based on a

medium sized router being used with a 1/4”

(6.3mm) router cutter.

ITEMS REQUIRED

• Router with a suitable rod size and centers.

• Router cutter / Router bit.

• Clamps.

• 2 x 1/2” (13mm) A/F open ended spanner.

• 5/16” (8mm) A/F open ended spanner.

• Hand Tools.

CONTENTS

3. Items Enclosed

4. Setting Up

Fitting the CRB7 to your router

7. The self adhesive rule

The micro adjuster

The lock bars

8. Operation

Adjustable Dadoing with a Clamp Guide

Adjustable Mortising

Anti-tilt Support

10. Adjustable Groove Copier

Offset Baseplate

11. Cutting Small Circles

Pivot Pin Storage

12. Cutting Large Circles

13. CRB7 Accessories

Maintenance

Environmental Protection

Guarantee

14. Safety Points

The following symbols are used throughout

these instructions.

Denotes risk of personal injury, loss

of life or damage to the tool in case

of non-observance of the

instructions.

Refer to the instruction manual

provided with your power tool.

1

5

4

1D

6E

3

4B

5B

5D 5E

6

6B

6D 6F

1B

1C

2 2B

16 4 3 27 1 2 3 4 5 6 7

123 1 2 3

cm

Inches

5

11

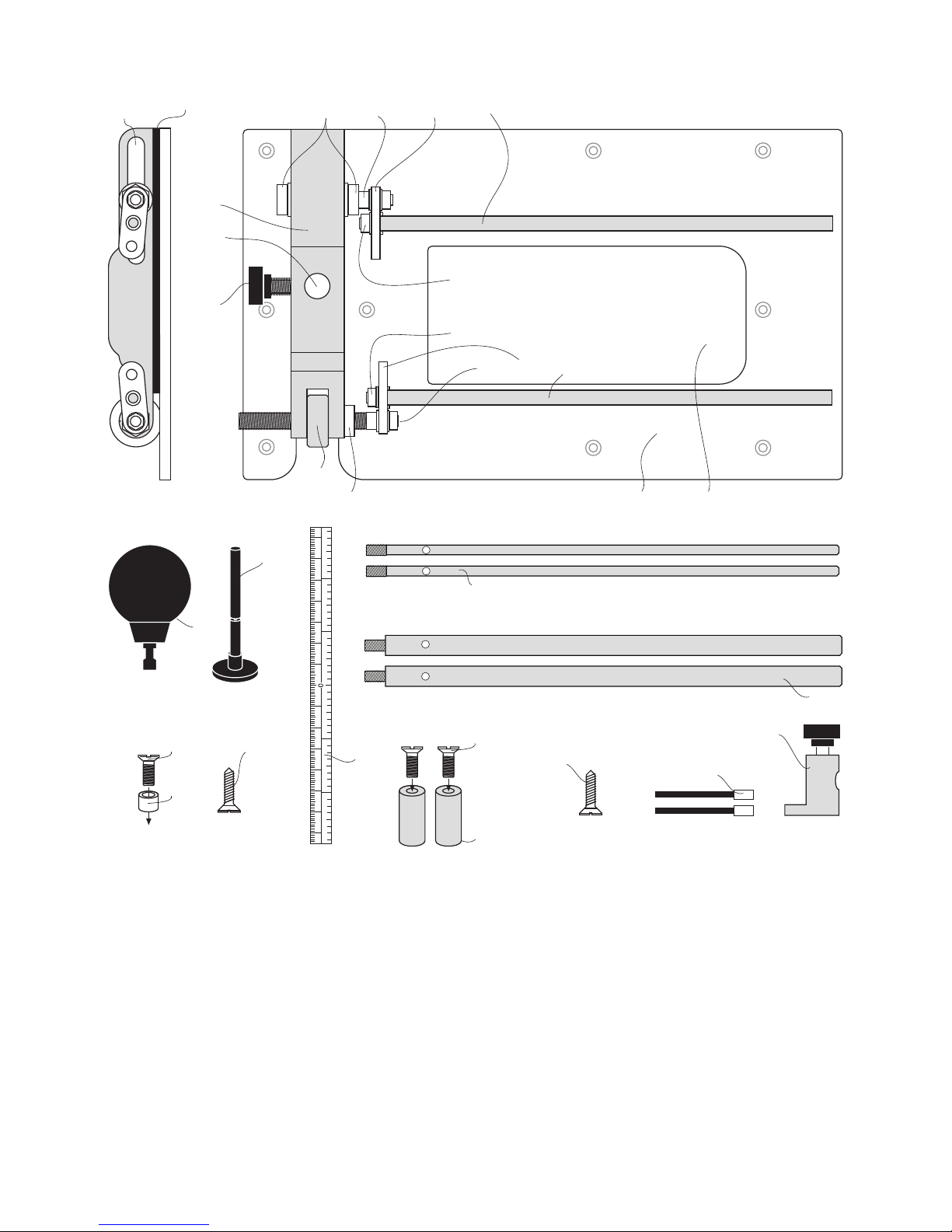

1 Bridge

1B Bridge Spacer

1C Bridge Slot

1D Bridge pinch bolt hole

2 Baseplate

2B Baseplate Letterbox

3 Bridge Pinchbolt

4 Micro Adjuster

4B Micro Adjuster Lock Nut

5 Adjuster Guide Rod 5/16” (8mm)

5B Adjuster Guide Rod M5 Locknut

5D Adjuster Rod

5E Adjuster Rod Crank Plate

6 Fixed Guide Rod 5/16” (8mm)

6B Fixed Guide Rod M5 Locknut

3

ITEMS ENCLOSED

6D Fixed Rod

6E Fixed Rod M8 Locknut x 2

6F Fixed Rod Crank Plate

7 Offset Handle

8 Anti-tilt Leg

9 Pivot Pin

10 Mortise Pillars

11 Self adhesive Rule

12 No.6 x 1/2” Woodscrews x 6

13 M4 x 25/64’ (10mm) Screws x 3

14 9/32” (7mm) Guide Rods

15 Compass Pivot Hub

16 25/64” (10mm) Compass Rods x 2

17 No.6 x 1/2” Woodscrews x 3

18 Lock Bars X 2

(not to scale)

7

8

10

13

13

9

12

Accessories

15

18

16

14

X 6

17

X3

4

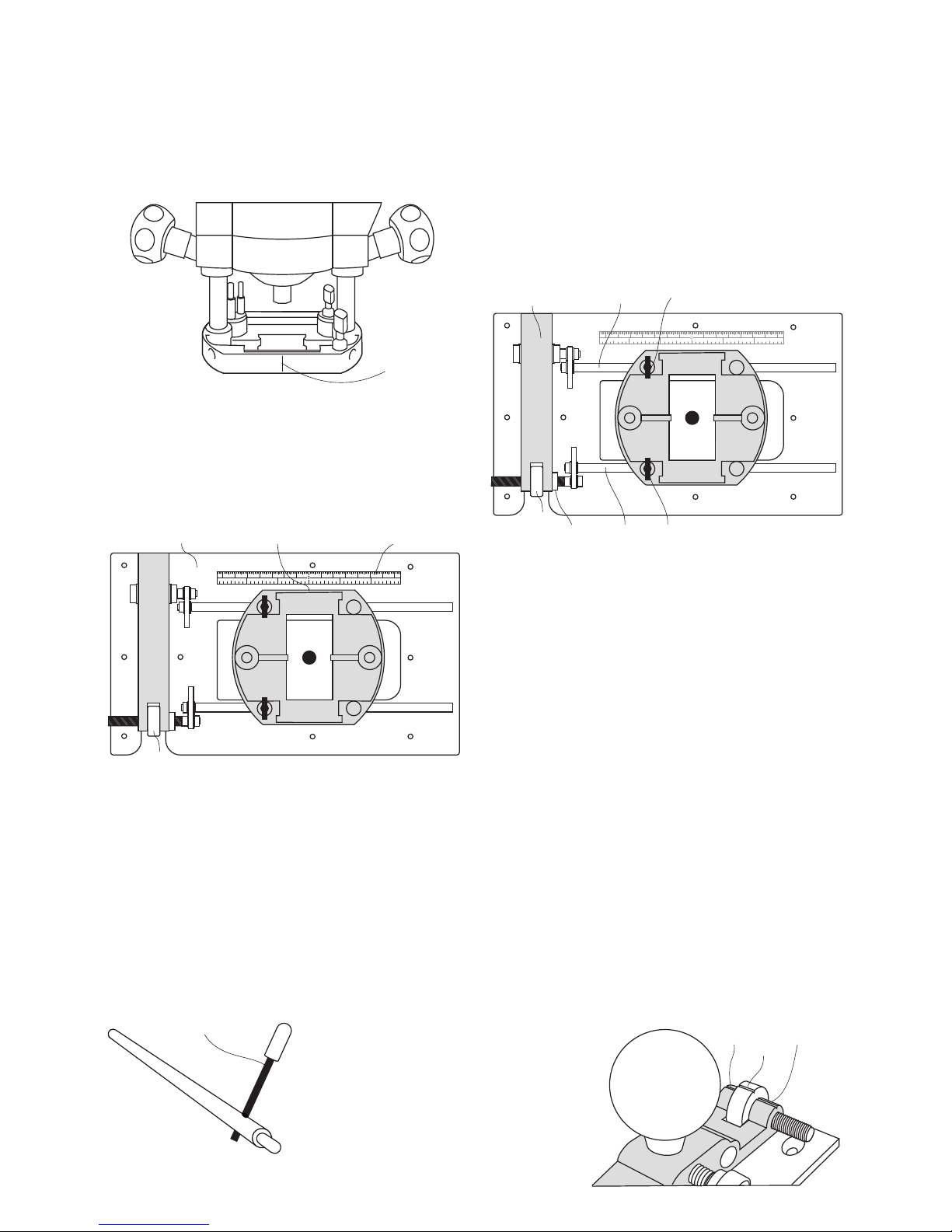

FITTING THE CRB7 TO YOUR ROUTER

1. Guide Rod selection

5

6

6E

4B

3. Initial alignment

Aligned

5

Router base

wing bolt

A

SETTING UP

Letterbox

The CRB7 is fitted with 5/16” (8mm) diameter

guide rods (5 & 6).

If the router base rod drillings are smaller, fit

the 9/32” (7mm) guide rods.

2. Loosen the Lock Nuts

Using 1 x 1/2” (13mm) spanner, slightly loosen

fixed rod nut (6E) and micro adjuster nut (4B).

Position the router in front of the CRB7.

Align the router base rod drilling (A) with

Adjuster Rod (5).

IMPORTANT

IT IS NOT ESSENTIAL TO CENTER THE

ROUTER CUTTER PRECISELY WITHIN

THE CRB7’S LETTERBOX FOR ANY

OPERATION.

5. Guide Rod adjustment4. Cutter alignment

Router

cutter

Letterbox

Router cutter

path

* 1/4”

Clearance *

X

X5

5E2

6E2

5B

5

5E1

5E2

Check that the router cutter will safely align

within the letterbox cross hatch area.

IF IT WILL, GO TO STEP 7.

IF IT WILL NOT, GO TO STEP 5.

Loosen the M5 nut (5B) using a 5/16” spanner.

Move the adjuster rod (5) to the other crank

plate drilling (5E2).

Replace washers and nuts and tighten.

For further adjustment fit the rods in the other

crank plate drillings (5E2 & 6E2).

Flip cranked adjuster rod (5) to its outer

position.

6. Crank Plate adjustment

5

7. Fitting the router 8. Setting the Fixed Rod

Aligned

6

Bridge

B

A

6E

B

Hold Still

Align fixed rod (6) with the router base rod

drilling (B), so that both rods are aligned.

Slide the router onto both rods until it stops at

the Bridge end of the CRB7 assembly.

Using 2 x 1/2” (13mm) open ended spanners,

tighten both fixed rod nuts.

Tip: Using two spanners when tightening the

fixed rod nuts will prevent the rod setting being

disturbed.

Both guide rod positions are now set.

Important - Before attempting any

machining pass:

Ensure that the router is securely fitted to the

CRB7 by checking ALL CRB7 fixings, including

router base wing bolts and micro adjuster lock

nut.

IMPORTANT

Follow the below steps in order:

1. Tighten router base wing bolt (A).

2. Finger-tighten fixed rod nut (6E).

3. Tighten router base wing bolt (B).

6

Tip: Positioning the router base Wing Bolts

towards the bridge end of the CRB7 will increase

micro adjuster accuracy.

Using the index markings

The micro adjuster and bridge have

corresponding red index lines. (1A & 4A)

1 x Micro adjuster rotation = 5/100” (1.25mm).

4 x Rotations = 3/16” (5mm).

Removing the slack from the adjuster

thread.

• Loosen both router base wing bolts and turn

the adjuster (4) in the desired direction to

engage the thread.

• Rotate until index markings (1A & 4A) align.

• Re-tighten the wing bolt on the adjuster guide

rod.

• Should the router cutter need to be adjusted

in the opposite direction repeat the above

step.

Once happy with the rule location:

• Ensure that the baseplate (2) is clean.

• Peel off the self adhesive backing paper.

• Stick in position.

THE LOCK BARS

Use the lock bars (18) to help tighten and

loosed the guide rods.

THE SELF ADHESIVE RULE

11A

16 4327 1234567

123 1 2 3

cm

Inches

5

11

11A2

4

THE MICRO ADJUSTER

• Plunge the router cutter to a level just above

the workpiece and lock in position.

• Loosen the router base wing bolt (I6) on the

fixed guide rod (6).

• Lock the router base wing bolt (I5) on the

adjuster guide rod (5).

• Rotate the micro adjuster (4) to move the

router and cutter into position.

• Lock the adjustment in position by tightening

the adjuster nut (4B) against the bridge (1).

4B

Many routers are manufactured with a cast

index line (11A).

• If the router has no index line, draw one

on the base using a fine tip marker pen.

7

18

With the router fitted to the CRB7:

• Position the rule (11) along the edge of the

router base.

A measurement can then be taken as the router

is moved.

16 4327 1234567

123 1 2 3

cm

Inches

5

61 I6

I5

4

1A 1A

5

4A

• Fit the cutter to the router and re-fit the

router onto the CRB7.

• Position the CRB7 with a mortise pillar (10)

either side of the work piece.

• Rotate the CRB7 clockwise until both mortise

pillars contact the sides of the workpiece.

• Adjust the cutter position to the mortise

markings, use the micro adjuster if required.

• Lock the router position on both guides rods

using the router wing bolts.

For a deep rebate, several light cutting

passes may be preferred.

Before use, check that the router is firmly

secured to the CRB.

Adjustable Mortising

Material widths between:

2” (50mm) > 4. 7/8” (125mm)

Fit the mortise pillars through hole locations F

Material widths between:

4 7/8” (125mm) - 8 5/8” (219mm)

Fit the mortise pillars through holes C-D or C-H

OPERATION

Adjustable Dadoing with a Clamp

Guide

• Fix the clamp guide (J) on the workpiece.

• Butt the bridge end of the CRB7 up against

the clamp guide.

• Slide the router along the guide rods to

position the cutter.

• Use the micro adjuster (4) if required.

• Lock the router position on both guides rods

using the router wing bolts (I)

Workpiece

I

J

J

4

2

Workpiece

10

2

10

C

H

2

D

F

F

Workpiece

10

10

K

C

l

o

c

k

w

i

s

e

F

• Fit the mortise pillars (10) to the underside

of the baseplate (2).

8

• Slide the anti-tilt leg (8) into the bridge

from the underside.

• Tighten the bridge pinch bolt (3) to lock it in

position.

• Slide the router onto the CRB7 rods and lock

in position using the wing bolts (I)

• Rest the CRB7 and router on the work piece

(M), then release the bridge pinchbolt (3) to

set the anti-tilt Leg depth.

• Lock the anti-tilt Leg in position.

Before routing, check that the bench

surrounding the work piece is smooth, even

and clear of obstacles.

Anti-Tilt Support

The Anti tilt leg is a two part assembly.

Max. Support height = 3 1/8” (80mm)

Min. support height = 5/16” (8mm)

If the mortise is positioned at the end of

the work piece, clamp extended battens (L)

to either side.

L

Workpiece

L

L

L

K

10

10

Workpiece

4

C

l

o

c

k

w

i

s

e

Check that the mortise pillars can complete

the mortise without running off the end of

the battens.

For a deep mortise, several light cutting

passes may be preferred.

9

8

3

8

3M

I

When cutting the mortise, ensure an even

pressure is maintained between the

mortise pillars and workpiece.

To avoid splitting the batten, pilot drill and

screw into position by hand.

• Fit the CRB7 to the router.

• Check that the batten (N) slides into the

first groove and moves smoothly along its

length.

• Set the required distance between the router

cutter and batten.

• Use the micro adjuster (4) to finely adjust cutter

position if required.

• Lock the router in position using the router base

wing bolts (I)

The second groove can now be routed.

• Slot the batten into the second groove to rout

the 3rd groove.

Adjustable Groove Copier

N

2

5

4

1

Workpiece

K

Workpiece

C

E

E

• Make copy batten (N) Min. Length 6. 5/16”

(160mm) in timber or solid plastic i.e. nylon or

polyethylene.

Note: The batten profile should copy the size and

shape of the router cutter.

• Test the batten in a sample groove to ensure a

good but not over-tight fit.

• Rout the first groove into the workpiece. Use a

clamp guide or side fence.

• Using 3 x No.6 woodscrews (12) fix the batten to

the underside of the baseplate via hole E & C.

10

• Slide the router onto the CRB7 guide rods.

• Position the router at the opposite end from

the Bridge (1).

• Lock the router in position using the wing

bolts (I)

The router cutter should just sit safely

within the baseplate ‘letterbox’.

• Fit the offset handle (7) into the bridge and

lock in position using the bridge pinchbolt (3).

Ensure that the CRB7 handle end remains

over the work piece.

7

3

I

2

1

Workpiece K

Apply

Pressure

Offset Baseplate

12

N

I

Cutting Small Circles.

Circle Sizes:

Maximum Radius 8. 13/16” (224mm)

Minimum Radius 3/4” (19mm)

Pivot Pin Locations H and C:

Maximum Radius Setup:

8.13/16” (224mm) Hole H

Minimum Radius Setup:

3/4” (19mm) Hole C

9

H

Cutter

8 13/16”

210mm

4

9

C

3/4”

19mm

11

• Mark out the circle on the work piece.

• Drill a 1/4“ (6mm) hole, a 1/4” (6mm)

deep at the center of the circle.

• Fit the pivot pin (9) to the underside of the

baseplate.

913

1

The pivot pin (9) can be stored in the back of

the bridge (1). The M4 screw (13) must be fully

screwed into the pivot pin (9) for the magnet to

work.

9

Baseplate

C

H

You can replace the pivot pin (9) with a

No.6 woodscrew (12).

• Attach the router to the CRB7.

• Position the CRB7 so that the pivot pin (9)

fits in the center drilling.

• Position the router and cutter as required.

• Lock in position using the router wing bolts.

Tip: To avoid a central drilling in the workpiece,

use a 1/4” (6.35mm) thick overlay secured by

double sided tape. Rout through the overlay and

into the workpiece beneath.

Pivot Pin Storage

12

Cutting Large Circles

Circle Sizes:

Maximum R25” (635mm)

Minimum Radius 7” (180mm)

• Measure and mark out the position, size

and center point of the circle.

• Line up the Compass Hub (15) drilling with

the center point of the circle.

• Screw the Hub into position.

Ensure that the Hub is secured tightly but

still free enough to rotate.

lock

lock

6D

Center/pivot point marking

15

Workpiece

Router cutter

Circle perimeter

Max. Radius 25” (635mm)

• Slide the CRB7 rod assembly through the hub.

• Position the router and cutter using the micro

adjuster if required.

• Lock the router in position using the router

base wing bolts (I).

• Lock the hub pinchbolt (15B)

• Assemble the 10mm compass rods and

tighten using the lock bars.

• Screw the rod assembly into the back of the

CRB fixed guide rod (6D) and tighten using

1 x lock bar.

Min. Radius 7” (180mm)

Before routing the circle ensure that:

The hub and rods are securely fastened.

The center and outer section of the

workpiece are supported.

Tip: To ensure a consistent cutting path always

apply a slight pressure away from the Compass

Hub when routing. If it helps, imagine the rods

are a piece of string and you need to keep the

string tensioned to maintain the distance

between pivot point and router.

15B

I

I

13

Combines with the fine adjustment of the CRB7

to improve router control and offer greater edge

to rebate range.

13/32” (10mm) GUIDE ROD PAIR

For routers bases with 13/32” rod drillings.

EDGE GUIDE PARALLEL SIDE FENCE

15/32” (12mm) GUIDE ROD PAIR

For router bases with 15/32” rod drillings.

MAINTENANCE

The accessory has been designed to operate

over a long period of time, with the minimum

amount of maintenance. Continual satisfactory

operation depends upon proper tool care and

regular cleaning.

Cleaning

• Regularly clean jig with a soft cloth.

Lubrication

• The CRB7 requires no additional lubrication.

Storage

• The CRB7 can be stored in its packaging, or

can be hung on a wall hook.

ENVIRONMENTAL PROTECTION

Recycle raw materials instead of disposing as

waste.

Packaging should be sorted for environmental

friendly recycling.

The product and its accessories at the end of its

life should be sorted for environmental-friendly

recycling.

GUARANTEE

All MPOWER products are guaranteed against

any defects in either workmanship or material,

except products that have been damaged due to

improper use or maintenance.

Our policy of continuous improvement means

that specifications may change without notice.

MPOWER Tools Limited cannot be held liable for

any material rendered unusable, or for any form

of consequential loss.

CRB7 ACCESSORIES

Please only use MPOWER original accessories.

MORTISE, HINGE, LOCK & FLUTE

The solution to the serious issue of controlled

cutter access into the edge of a board.

Cutting Mortises, Hinges, Lock Rebates and

Fluting is now safer, quicker and more accurate

than before.

EDGING AND DOWEL TRIM KIT

A fast and accurate method of consistently

trimming solid hardwood and iron on edging

flush to its core panel. The kit can also be used

to trim off the excess wood when using dowel

plugs.

14

SAFETY POINTS

1. Disconnect power tool and attachment

from power supply when not in use,

before servicing, when making

adjustments and when changing

accessories such as cutters. Ensure

switch is in “off” position. Always

ensure cutter has stopped rotating.

2. Read and understand instructions

supplied with power tool, attachment

and cutter.

3. Current Personal Protective Equipment

(PPE) for eye, ear and respiratory

protection must be worn. Keep hands,

hair and clothes clear of the cutter.

4. Before each use check cutter is sharp

and free from damage. Do not use if

cutter is dull, broken or cracked or if

any damage is noticeable or suspected.

5. The maximum speed (nmax) marked on

tool or in instructions or on packaging

shall not be exceeded. Where stated,

the speed range should be adhered to.

6. Insert the shank into the router collet

at least all the way to the marked line

indicated on the shank. This ensures at

least 3/4 of shank length is held in

collet. Ensure clamping surfaces are

clean.

7. Check all fixing and fastening nuts,

bolts and screws on power tool,

attachment and cutting tools are

correctly assembled, tight and to

correct torque setting before use.

8. Ensure all visors, guards and dust

extraction is fitted.

9. The direction of routing must always be

opposite to the cutter’s direction of

rotation.

10. Do not switch power tool on with the

cutter touching the workpiece.

11. Trial cuts should be made in waste

material before starting any project.

12. Repair of tools is only allowed

according to tool manufacturers

instructions.

13. Do not take deep cuts in one pass; take

several shallow passes to reduce the

side load applied to the cutter.

Manufactured by MPOWER Tools Ltd

Tel: 0044 (0)1980 629 526

Email: [email protected]

Email: [email protected]

Web: www.m-powertools.com

Manor Farm Reserve - Newton Tony - Salisbury - Wiltshire - SP4 0HA - UK

© Copyright MPOWER Tools Ltd 2018

50365

Other manuals for CRB7

3

Table of contents

Other M-Power Power Tools manuals

Popular Power Tools manuals by other brands

Hytorc

Hytorc LION GUN Basic operation manual

Bosch

Bosch GWS Professional 7-115 E Original instructions

Mitsubishi Electric

Mitsubishi Electric MELDAS 600M Series instruction manual

Bravo

Bravo SCOPREGA GE 20-2 instruction manual

Makita

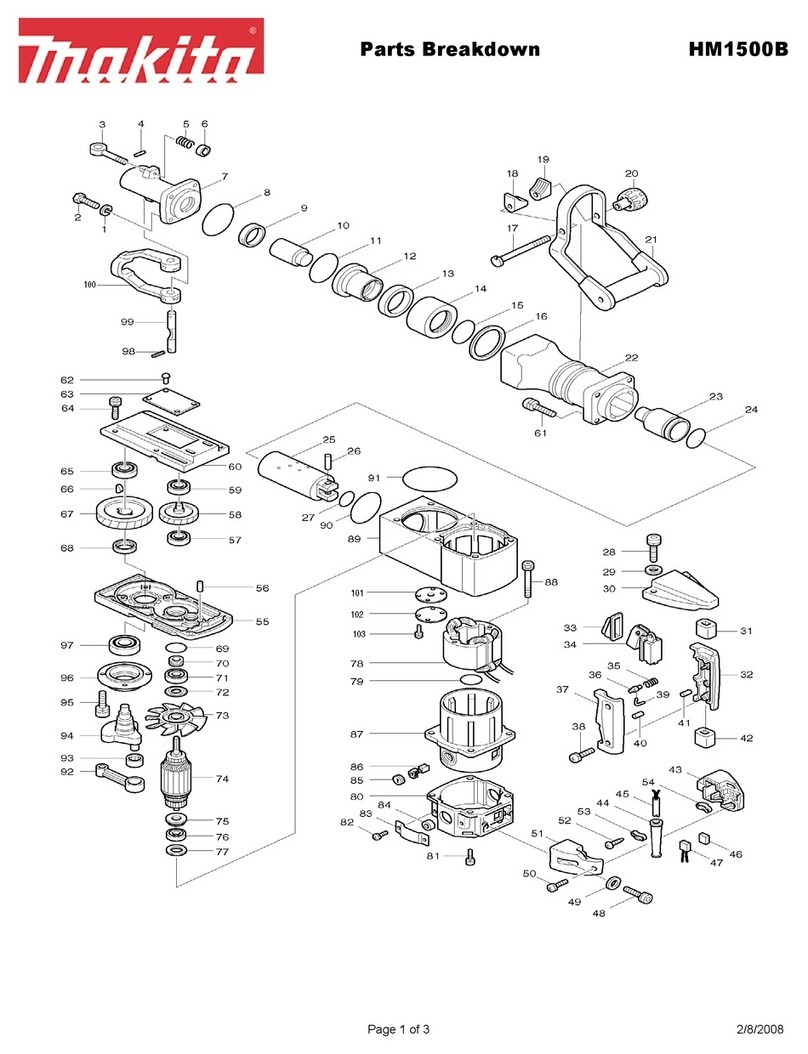

Makita HM1500B Parts Breakdown

Parkside

Parkside PPHSS 730 SE Operation and safety notes