M-Power Diamond Cross User manual

Circular Sawblades

Suggested: Single Handle File

Fine: For regular maintenance

Coarse: For dull blades

TECHNICAL DATA

Code Grade Grit Micron

Router Bit Fine 600 25

Sharpener Coarse 300 50

Credit Card Fine 600 25

Stone Coarse 300 50

Single Fine 600 25

Handle File Coarse 300 50

Twin Handle Coarse 300 50

File X/C Ex. Coarse 100 140

Twin Handle Fine 600 25

File C/F Coarse 300 50

8” Bench Stone Super Fine 1000 15

Coarse 300 50

MOUNTING THE 8” BENCH STONE ON

THE DIAMOND STONE HOLDER

The 8” bench Stone comes with two

diamond stone holders.

Attach one diamond

holder to the underside

at each end of the

stone using the

magnetic lock to secure

in position.

To prevent skidding ensure

worksurface is dry, flat and

clean of debris.

ROUTER BIT SHARPENER

CREDIT CARD STONE

SINGLE HANDLE FILE

TWIN HANDLE FILES

BENCH STONE

followed to ensure that the stone will give

lasting performance under normal

conditions.

Follow the hints and tips explained here

to help maximise the life of your Diamond

Cross Stone:

All tooling should be cleaned before

sharpening. Resin build-up should be

removed with Resin Cleaner and a wire

brush.

Use with Diamond Abrasive Lapping

Fluid (water can be used if necessary),

this will prevent the diamonds

becoming clogged with swarf.

Diamond Cross Stones require a

'break-in' period. Initially the diamond

will feel coarse and will smooth

overtime.

Do not apply too much pressure.

The diamond is extremely abrasive so

what would normally take 5-10 minutes

on an oilstone may take approximately

20 seconds on the Diamond stone.

Dry the Diamond Cross stone

thoroughly after use. Any wet steel

filings left on the stone will cause

surface rust to form.

DIAMOND CROSS

Thank you for purchasing this product.

The following symbols are used

throughout these instructions.

Denotes risk of personal injury, loss

of life or damage to the tool in case

of non-observance of these instructions.

Refer to Power Tool instructions.

INTENDED USE

This product is intended to be used to

sharpen steel, tungsten carbide & high

speed steel tools. For both professional

and domestic use.

SAFETY

Please read and understand these

instructions before use.

Users must be competent in using

Woodworking equipment before using our

products.

All cutting edges are very sharp and care

must be taken to prevent injury.

GUIDELINES

Diamond Cross stones allow fast, clean

stock removal,with less effort and time

required and can be used on a variety of

cutting edges.

When using Diamond Cross stones,

certain general guidelines should be

OPERATION

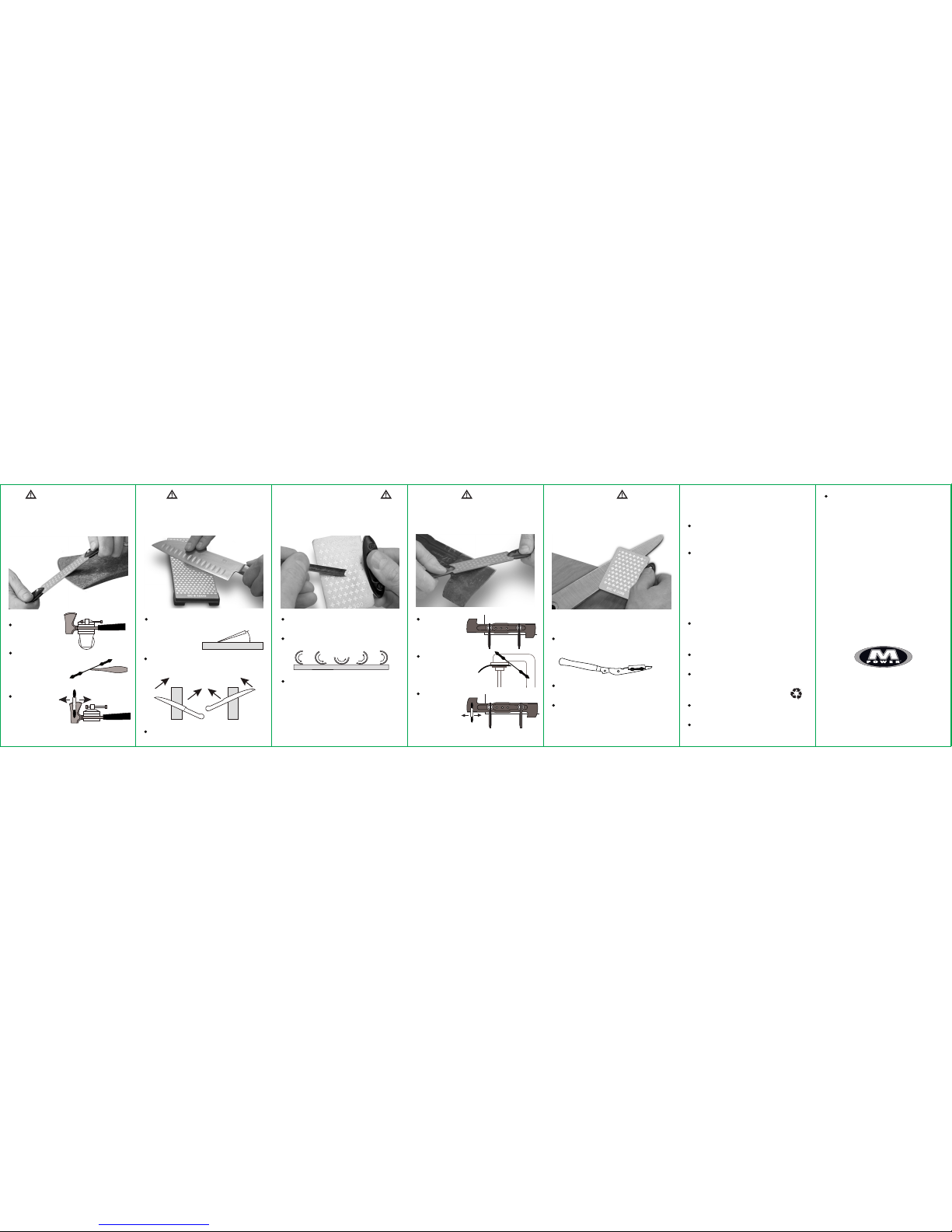

Router Bits/Cutters

Suggested: Router Bit Sharpener

Fine: For Tungsten Carbide.

Coarse: For High Speed Steel.

Always sharpen the flat face,

never the profile/relief.

Slide the cutter with slight

pressure along the whetstone.

Repeat same number of strokes

on each cutting edge.

Chisel/Plane Irons

Suggested: 8” Bench Stone

Fine: For edge honing

Coarse: Areas of minor damage

Finish with one light stroke on

the back of the chisel.

It is recommended to use a figure of eight

motion when sharpening chisels.

Keep the bevel of the chisel/plane

iron flat on the stone.

Keep the diamond

surface flat to

the face of saw

tooth.

Use a few light,

smooth, back

and forth strokes

on each tooth.

Repeat the same

number of strokes on

each tooth.

Mark the first tooth sharpened

with chalk or masking tape to

avoid honing a second time.

UNIVERSAL

INSTRUCTION MANUAL

re-cycleread version

2

Axes

Suggested: Twin Handle File C/F

Fine: To hone the edge

Coarse: To prepare the edge

Knives

Suggested: 8 “ Bench Stone

Fine: To keep a razor edge

Coarse: To restore an edge

Small pointed tools and gouges

Suggested: Credit Card Stone

Fine: To maintain an edge

Coarse: To restore a dull edge

Mower Blades

Suggested: Twin Handle File X/C

Fine: To hone the edge

Coarse: To prepare the edge

Shears and Scissors

Suggested: Credit Card Stone

Fine: To hone the edge

Coarse: To prepare the edge

Mount the axe

in a vice.

Keep the same angle as the knife

bevel on the diamond stone.

The angle is 20˚

for most knives.

Keep the bevel on the back of the

gouge flat on the diamond stone.

Roll the tool gently to hone.

Fix the

mower blade

position using

two clamps.

Dismantle the shears to work on the

cutting blade.

Lay the diamond stone flat on the

cutting edge bevel.

Stroke smoothly towards the tip of the

blade.

Lay the stone flat on the sliding face

and remove the burr with a light stroke

(as per the main image above).

Keep the diamond

surface flat to the

face of the blade

edge.

Perform light

strokes back

and forth.

Small tools should be honed as per

chisels, pointed tools should be

honed as per gouges.

Keep the diamond

surface flat to the tip

of the Axe blade

edge.

Perform light

strokes back

and forth on

both sides.

20˚

ACCESSORIES

Non-slip magnetic Diamond Stone

Holder (pair) - Ref 21

Suitable for use with Diamond Cross

Router Cutter Sharpener, Credit

Card & 8” Bench Stones.

Also fits all other brands of credit card

and bench diamond stones.

DIAMOND STONE MAINTENANCE

Continual satisfactory operation depends

upon proper tool care and regular

cleaning.

Cleaning

Clean with a damp cloth or cleaning

(eraser) block.

Storage

Ensure diamond stones are stored

separately.

Do not store the diamond stones in

damp conditions.

ENVIRONMENTAL PROTECTION

Re-cylce raw materials instead of

disposing as waste.

Packaging should be sorted for

environmental-friendly re-cylcing.

300

Stroke away from the body, alternating

on each said of the knife.

Light strokes will produce a finer edge.

300

The product and its accessories at the

end of its life should be sorted

for environmental-friendly recycling.

GUARANTEE

All MPOWER products are guaranteed

against any defects in either

workmanship or material, except

products that have been damaged due to

improper use or maintenance.

POLICY

Our policy of continuous improvement

means that specifications may change

without notice. MPOWER Tools Limited

cannot be held liable for any material

rendered unusable, or for any form of

consequential loss.

Manufactured by MPOWER Tools Ltd

Tel: 0044 (0)1980 629 526

Email: [email protected]

Email: [email protected]

Web: www.m-powertools.com

Manor Farm Reserve - Newton Tony - Salisbury

Wiltshire - SP4 0HA - UK

© Copyright MPOWER Tools Ltd 2018

50117

Other M-Power Power Tools manuals

Popular Power Tools manuals by other brands

Harbor Freight Tools

Harbor Freight Tools CENTRAL MACHINERY 46199 ASSEMBLY AND Operating information

Hakko Electronics

Hakko Electronics FU-600 instruction manual

Milwaukee

Milwaukee M12 FUEL 2556-20 Operator's manual

Gardol

Gardol GGSI 180 operating instructions

Makita

Makita JV0600 instruction manual

AGP

AGP EV21 instruction manual