CRB7 PARALLEL SIDE FENCE

Thank you for purchasing MPOWER’s Parallel Side Fence which

should give lasting performance if used in accordance with these

instructions.

The following symbols are used throughout these instructions

denoting risk of personal injury, loss of life or damage to the tool

in case of non-observance of the instructions.

Refer to the instruction manual of your power tool.

INTENDED USE

The Parallel Side Fence has been designed for use with

MPOWER’s Combination Router Base (CRB7), a router, and a

suitable router cutter when performing edge parallel rebates and

edge moldings.

This accessory combined with the fine adjustment of the CRB7

will improve control and offer greater edge to rebate range whilst

achieving an excellent finish.

This accessory can be used as a replacement for the much larger

and more complicated traditional fences supplied with many

makes and models of router.

SAFETY

Please read and understand the safety points at the end of this

instruction as well as the power tool instructions before use.

Please keep these instructions in a safe place. Users must be

competent in safe routing practices before using this product.

ITEMS REQUIRED

• CRB7 Router Base • Router with suitable collet fitted.

• Flat head screwdriver • 5/16” (8mm) drill bit.

• 1/2” (12mm) drill bit. • Hand tools.

• Suitable router cutter

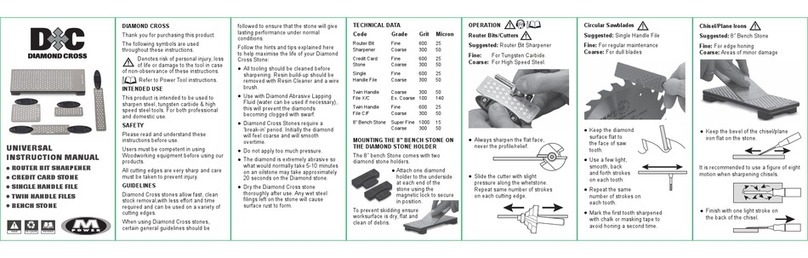

ITEMS ENCLOSED – (See Fig 1)

1) 1x Machined solid Parallel Side Fence (SKU 40051)

2) Internal Pack 10/20 (SKU 40075)

2x 25/64” (10mm) CS machine fixing screws.

2x 3/4” (20mm) CS machine screws,

The Side Fence fixing position is determined by the desired

distance of the routing pass from the edge of the workpiece (See

Fig 3)

Note: Dimensions may vary according to the size and shape of

the router base being used.

*distance between the cutter centre and the edge of the

workpiece.

ASSEMBLY

FITTING THE SIDE FENCE – (See fig 4)

After deciding on the Fence fixing position slide the router off the

CRB7 rods.

Place the fence under the base plate so that the 2x brass

threaded inserts of the fence line up under the chosen

countersunk holes in the top surface of the base plate.

Fit the 2 x 25/64” (10mm) CS machine screws.

Do not over tighten.

Slide the router back onto the CRB7 rods and position it in the

approximate area of the desired router pass.

Fine adjustment of the cutter position can then be carried out

using the Micro Adjuster on the CRB7 (please see the CRB7

instruction manual for further details on this process)

WARNING: When edge moulding only a section of the router

cutter may be revealed to the workpiece edge, meaning the back

side of the cutter will cut into the face of the fence. Rather than

permanently damaging the fence; fit an additional sacrificial

fence.

FITTING A SACRIFICIAL FENCE TO THE SIDE FENCE

We recommend making the sacrificial fence from solid hardwood,

however ply or MDF will work.

Cut and machine the sacrificial fence to 12 x 1.3/8 x 7/8” (300 x

35 x 20mm), (Dimensions can vary according to the users needs

or preference).

Ensure the sacrificial fence is machined flat then lightly sand the

edges to remove any splinters.

Accurately mark out the drilling locations for the 2x fixing holes

by:

Measuring and marking a parallel line 9/32” (7mm) in from the top

edge of the sacrificial fence.

Measure and mark the centre point of the sacrificial fence mid

way down the parallel line. Then place it under the baseplate end

drillings. So that the parallel line can be seen through the

drillings. Using a sharp pencil draw through the drillings, marking

the position of the fixing holes (see Fig 5)

Counter bore the outer/top surface of the 2x fixing holes depth

11/16” (17.5mm) use a 3/8” (10mm) drill bit.

IMPORTANT: The counter bore depth must allow the 3/4”

(20mm) CS machine screws to locate fully* into the machine

inserts of the Fence.

*Fully located = 13/64” (5mm) of the CS Machine Screw thread.

(See fig 6)

Note: The counter bores allow the fixing screw heads to sit well

below the sacrificial fence surface when fitted to the fence.

Attach the Sacrificial Fence to the CRB7 Fence using the 2x 3/4”

(20mm) screws. (See fig 7)

The CRB7 Sacrificial Fence is now fitted and ready to be used.

SPARE PARTS

Fence Assembly 40051

Internal Pack 10/20 40075

MAINTENANCE

Continual satisfactory operation depends upon proper tool care

and regular cleaning.

Cleaning: Regularly clean accessory with a soft cloth.

Lubrication: Your accessory requires no additional lubrication.

ENVIRONMENTAL PROTECTION

Re-cycle raw materials instead of disposing as waste.

Packing should be sorted for environmental-friendly recycling.

The product and its accessories at the end of its life should be

sorted for environmental-friendly recycling.

GUARANTEE

All MPOWER products are guaranteed against any defect in

either workmanship or material, except products that have been

damaged due to improper use or maintenance.

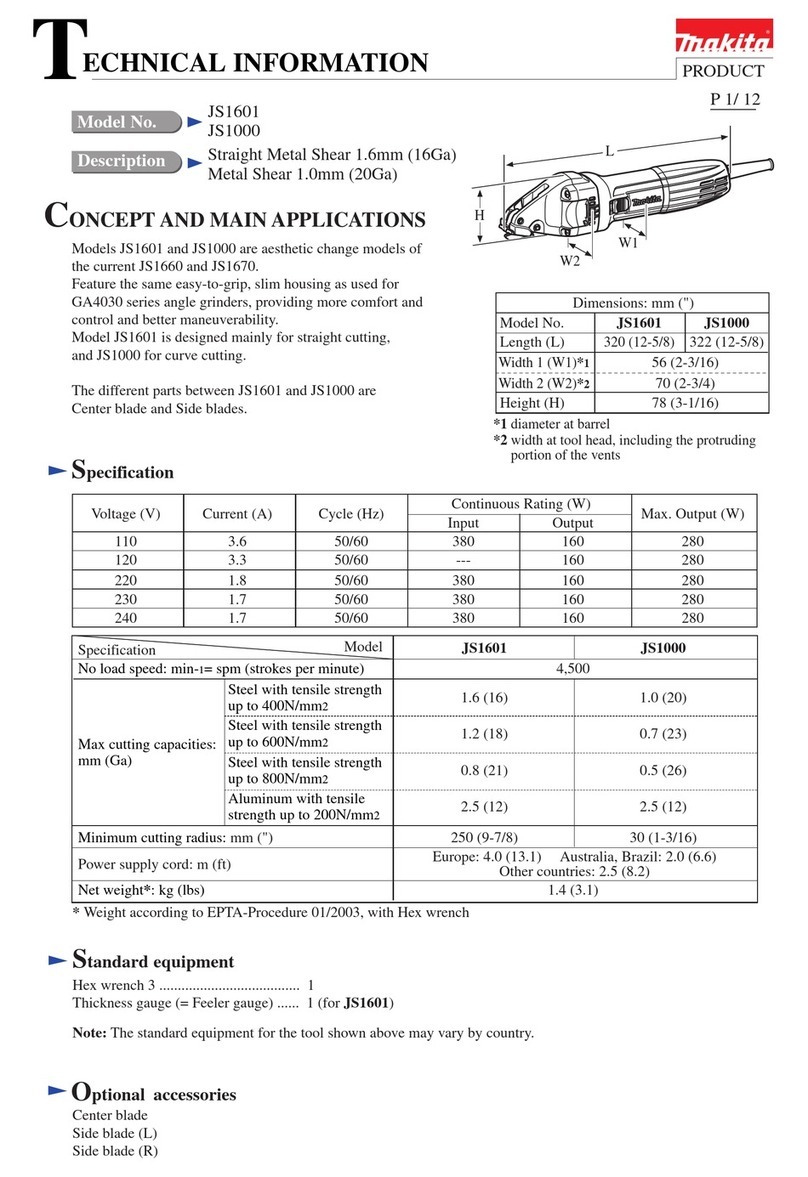

A

Cutter Centre

Workpiece Edge

5/8” (16mm)

3. 7/8” (98mm)

4. 9/32”

(109mm)

7. 1/2”

(190mm)

A CB

SIDE FENCE FIXING POSITIONS

The Side Fence can be mounted in different locations on the

underside of the CRB7 Base Plate (See Fig 2).

1

Sight Line

Sticker

2

9/32”

7(mm)

FIG 5

FIG 4

FIG 3

FIG 1

FIG 2

Through drill the 2x fixing holes using a 3/16” (5mm) drill bit.

FIG 6

FIG 7

Fence

13/64”

Sacrificial

Fence

11/16”

3/16” 3/8”

9/32”

© MPOWER Tools Ltd. 2018

Our policy of continuous improvement means that specifications

may change without notice. MPOWER Tools Limited cannot be

held liable for any material rendered unusable, or for any

form of consequential loss.