8

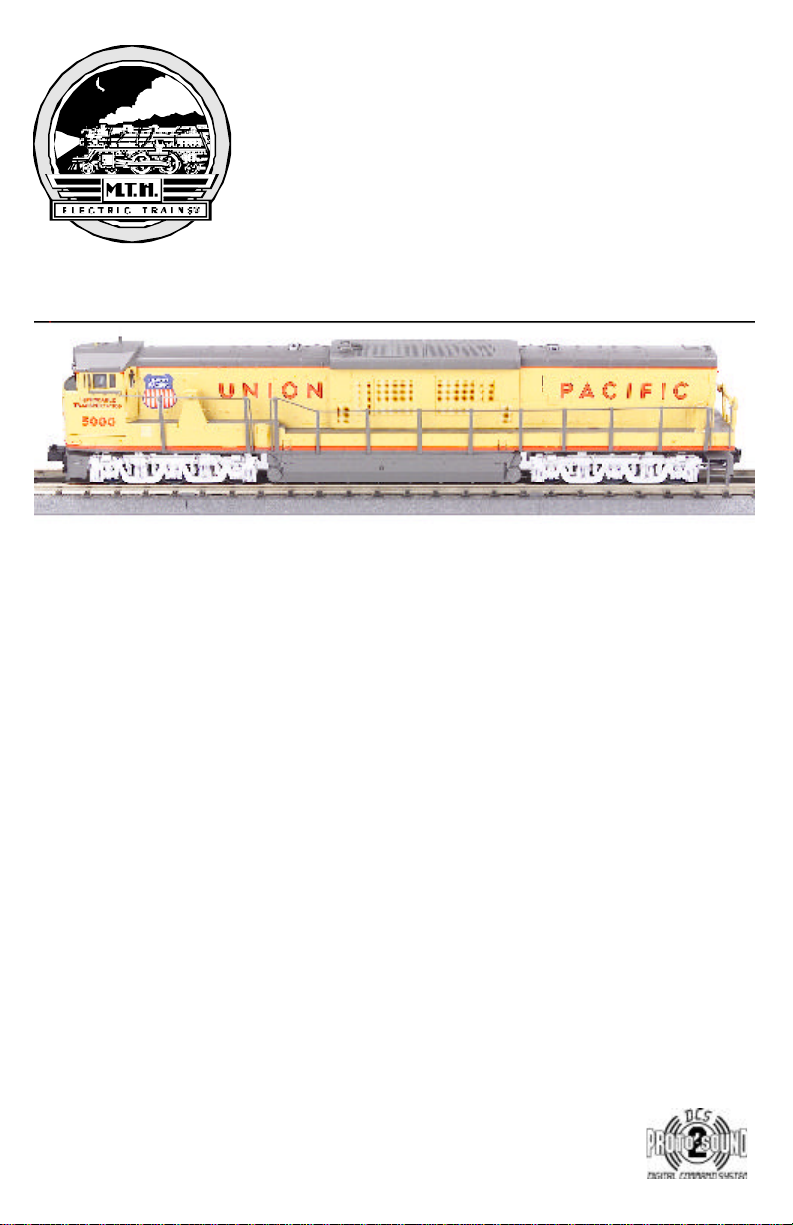

Premier U50C Diesel Engine Operating Instructions

Proto-Coupler® Operation

This locomotive is equipped with two coil-wound Proto-Couplers for remote

uncoupling action. Because the Proto-Coupler is controlled through the

Proto-Sound 2.0 microprocessor, it does not require an uncoupling track

section or modification to your layout to function. Use the codes listed below

to fire the coupler.

Rear Coupler:

To fire the rear coupler, quickly tap the Bell button once followed by three

quick taps of the Whistle button, allowing approximately ½ second to lapse

between each quick button press. The sound of the liftbar and air line

depletion will play, and the knuckle will be released.

Front Coupler:

To fire the front coupler, quickly tap the Bell button once followed by four

quick taps of the Whistle button, allowing approximately ½ second to lapse

between each quick button press. The sound of the liftbar and air line

depletion will play, and the knuckle will be released.

Speed Control:

M.T.H. engines equipped with Proto-Sound 2.0 have speed control capabilities

that allow the engine to maintain a constant speed up and down grades and

around curves, much like an automobile cruise control. You can add or drop

cars on the run, and the engine will maintain the speed you set.

While the engine is programmed to start with the speed control feature

activated, you can opt to turn it off. This means the engine’s speed will fall as

it labors up a hill and increase as it travels downward. It is also affected by the

addition or releasing of cars while on the run.

To turn speed control on and off, put the engine in neutral, thenquickly tap

the transformer’s Whistle button one time then quickly tap the Bell button two

times, allowing approximately ½ second to lapse between each quick button

press. Two horn blasts will indicate that the engine has made the change.

Repeat the 1 whistle, 2 bells code to return it to the other condition. Youwill

want to do this during the initial neutral upon start-up if you ever couple

this engine to another engine that is not equipped with speed control to

avoid damaging the motors in either engine. Each time you shut down the

engine completely, it will automatically turn speed control on. Note: When

speed control is turned off, the Proto-Sound 2.0 system will limit the volume

in order to operate more smoothly at lower voltages. Full volume is restored

upon reactivating speed control.