3

...OFTEN IMITATED, NEVER DUPLICATED!™

2MAASDAM – THE ORIGINAL...

Step 1: Unreeling Cable or Strap

UNREEL ONLYWHEN PULLER IS NOT

SUPPORTING A LOAD! DO NOT ALLOW

LOADED UNIT TO UNREEL FREELY!

1-1 Attach cable/strap end hook to fixed object strong

enough to support load being moved

or lifted. ENSURE SAFETY LATCH IS SECURELY

CLOSED.

1-2 Place thumb on flat “spring” in “Y”

of handle assembly, aligning it with

two-directional arrow on the label.

1-3 Push until “spring” bows in direction

of “Down (Cable Out)”. PAWL “B” IN HANDLE

ASSEMBLY BECOMES DISENGAGED FROM

RATCHET WHEEL.

1-4 Hold handle and hook assembly such that gold

ratchet guard is on top and then pull upwards on

handle until it no longer moves.

1-5 Place thumb on gold colored lever of Pawl “B” in

handle and press down unti both pawls disengage

(can visually see

disengagement).

1-6 While holding Pawl “B” in down position, walk back-

wards until cable or strap reaches desired length.

MAINTAIN AT LEAST 2 WRAPS OF

CABLE/STRAP ON RATCHET WHEEL DRUM

WHEN UNIT IS UNDER LOAD.

Step 2: Lifting or Pulling a Load

2-1 After completing Step #1 and reaching desired

length, attach swivel end hook to load. ENSURE

SAFETY LATCHES ARE SECURELY CLOSED.

2-2 Place index finger on flat “spring” in “Y” of

handle assembly, aligning it with two-directional

arrow on handle and push until “spring” bows in

direction of “Up (Cable In)”.

2-3 Stand on the hook assembly side of the Puller, tightly

grab hand grip and move handle back and forth to

take up slack. (For Strap Pull’R #WS-25 only) Pull

strap through ratchet guard, walking towards fixed

object as strap is pulled, to take up slack.

2-4 As load begins to move, visually inspect

support object and hooks. KEEP FINGERS,

CLOTHING, HAIR, ETC. AWAY FROM ALL MOV-

ING PARTS! KEEP HAND ON GRIP!

2-4a If support object shows ANY sign of being unable to

support load, STOP immediately and release tension

on load per Step #3. Detach Puller, move to alternate

support object and begin again with Step #1.

2-5 Continue to pull load to desired position/

location. If handle no longer moves, limit of Puller

has now been reached. NEVER use

a “cheater bar” or handle extender! You risk

exceeding the load limit and CAUSING YOURSELF

SERIOUS BODILY INJURY.

Step 3: Lowering or Releasing a Load

3-1 Before releasing tension, BE SURE that positioned

load is supported and secure.

3-2 Place thumb on flat “spring” in “Y” of handle assembly,

aligning it with two-directional arrow on handle. Push

until “spring” bows in direction of “Down (Cable Out)”.

PAWL “B” IN HANDLE ASSEMBLY BECOMES DIS-

ENGAGED FROM RATCHET WHEEL.

3-3 Tightly grab hand grip and pull handle in direction of

swivel hook assembly until handle no longer moves.

RETAINER PAWL “A” IN FRAME ASSEMBLY

RELEASES FROM RATCHET WHEEL. PAWL “B”

WILL ENGAGE PAWL “A” AND PUSH IT OFF THE

RATCHET WHEEL (1 NOTCH AT A TIME).

3-4 Push handle away from swivel hook assembly area

until “click” is heard, then pull handle back towards

swivel hook assembly. Repeat until load is in place. AT

ALL TIMES KEEP ONE HAND ON HAND GRIP

WHILE KEEPING SECOND HAND TOTALLYAWAY

FROM PULLER UNIT!

3-5 Once load is in final position, STOP moving

handle, disconnect both hooks and remove Puller.

3-6

Wind excess cable or strap back onto ratchet wheel per

Step #4.

3-7 Conduct SAFETY INSPECTION of Puller unit,

checking cable or strap, ratchet wheel, hooks and other

moving parts for signs of

damage. LUBRICATE

MOVING PARTS AS NECESSARY.

Step 4: Rewinding Cable or Strap

REWIND ONLYWHEN PULLER IS NOT

SUPPO0RTING A LOAD! AS CABLE OR STRAP IS

REWOUND, INSPECT FOR POSSIBLE DAMAGE.

4-1 Attach cable/strap end hook to fixed object. ENSURE

SAFETY LATCH IS SECURELY CLOSED.

4-2 Place index finger on flat “spring” in “Y” of

handle assembly, aligning it with two-directional

arrow on handle.

4-3 Push until “spring” bows in direction of “Up (Cable In)”.

PAWL “B” IN HANDLE ASSEMBLY BECOMES

ENGAGED WITH RATCHET WHEEL.

4-4 While holding other hook in one hand and hand grip in

the other hand, repeatedly ratchet handle back and

forth until cable or strap is fully wound onto ratchet

wheel. WALK TOWARDS FIXED OBJECT AS

CABLE OR STRAP IS WOUND.

4-4a (For Strap Pull’R #WS-25 only) WIND STRAP

ONLY TO THE LIMITS OF THE RATCHET

WHEEL. ONLY 12 FT. OF STRAPPING CAN BE

RATCHED AROUND THE RATCHET WHEEL OR

THE UNIT WILL JAM. TO UNJAM WEBBING,

REMOVE RATCHET WHEEL BOLT WHILE

THERE IS NO LOAD BEING APPLIED. Coil and

bind the remaining strapping for safe keeping.

4-5 Remove hook from fixed object.

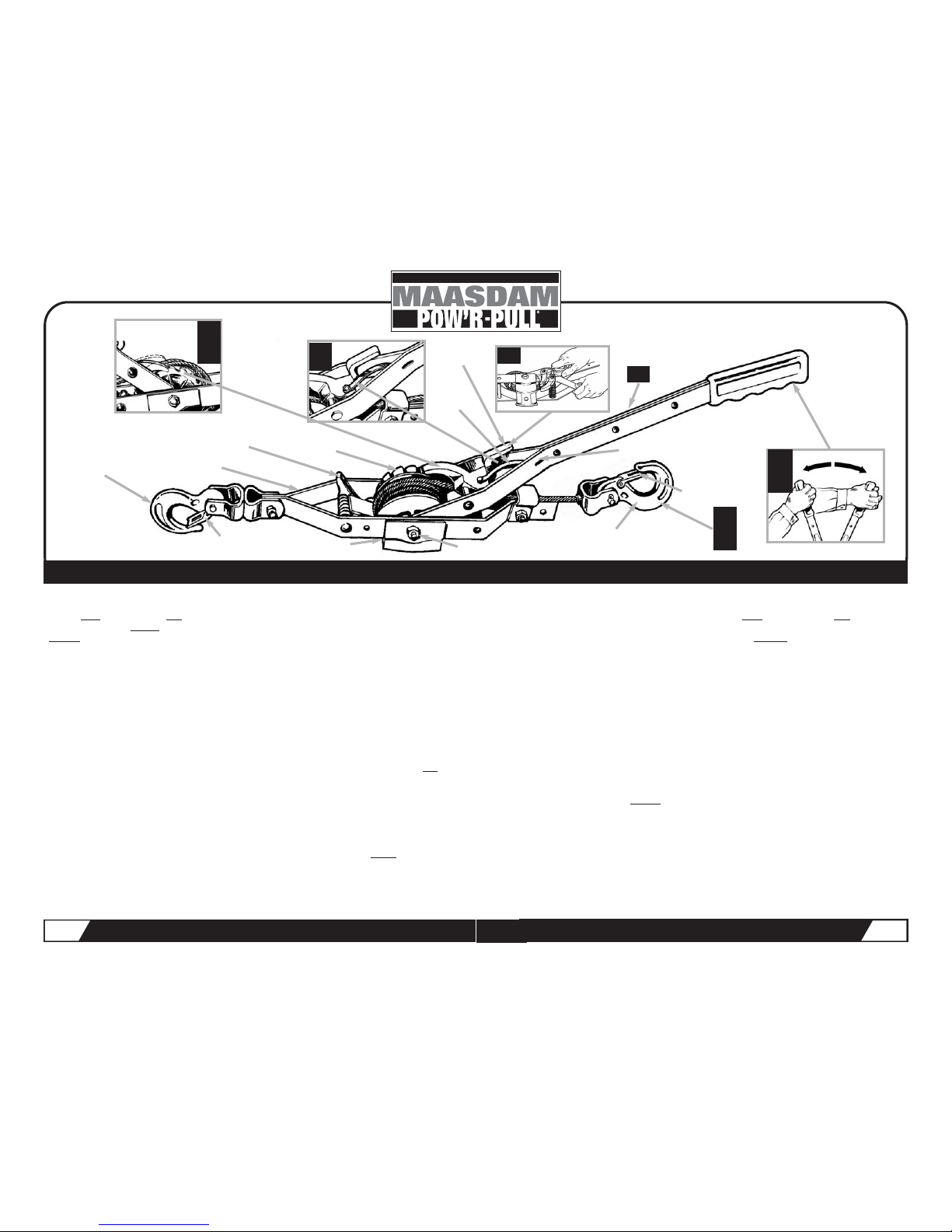

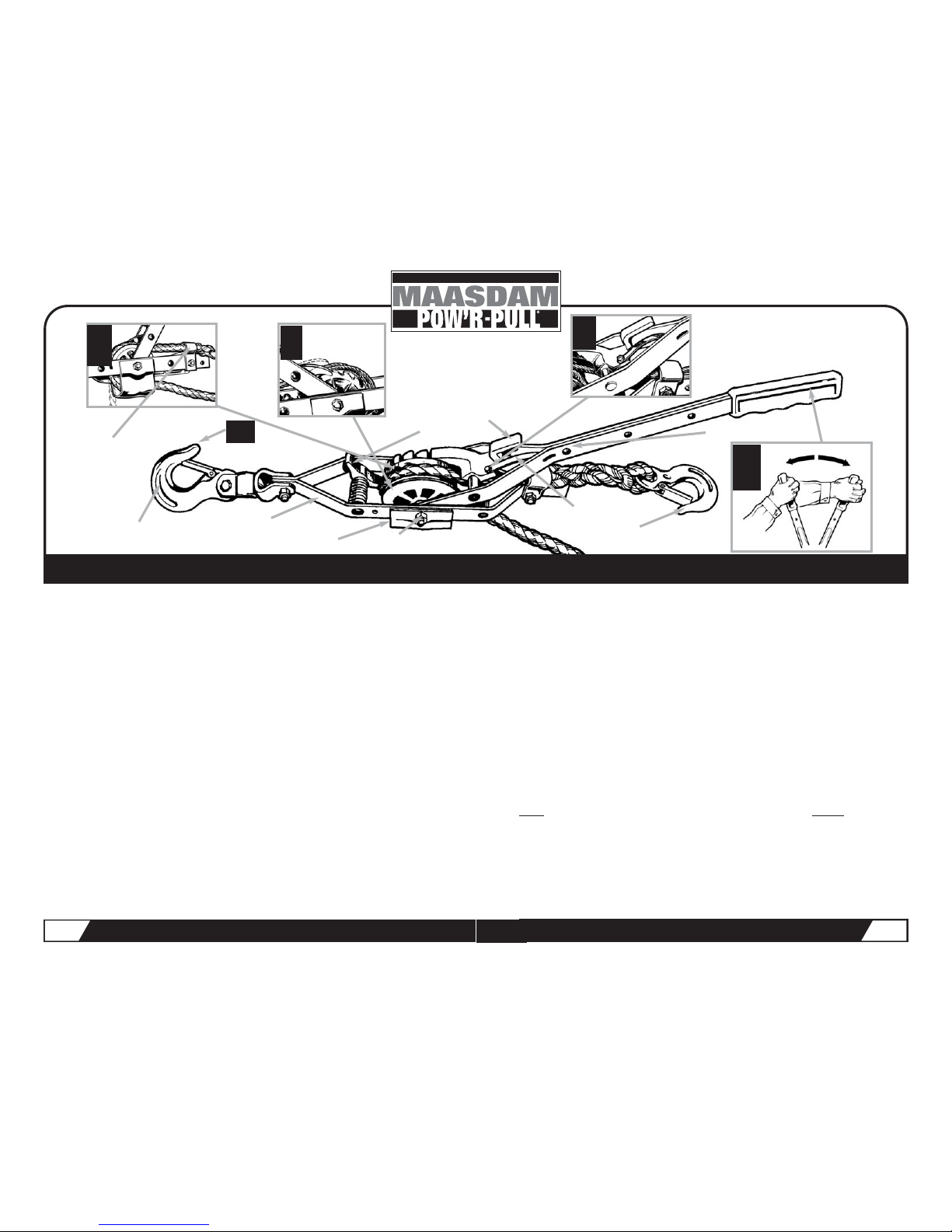

1-1

2-1

4-1

2-3

3-4

4-3

1-2

2-2

1-3

3-3

4-3

Swivel End Hook

Ratchet Guard

Frame

Flat

Spring

Cable/Strap

End Hook

Pawl “A” “Y” of Handle

Pawl “B”

Safety Latch

1-5

WARNING! Units that show wear at/or exceeding

of 1/8-inch, and/or broken ratchet wheel teeth,

should be taken out of service until replacement kit

can be installed.

HOW TO OPERATE A POW’R-PULL/STRAP PULL’R

1-2

Ratchet

Wheel

Ratchet Wheel Bolt