G

G*

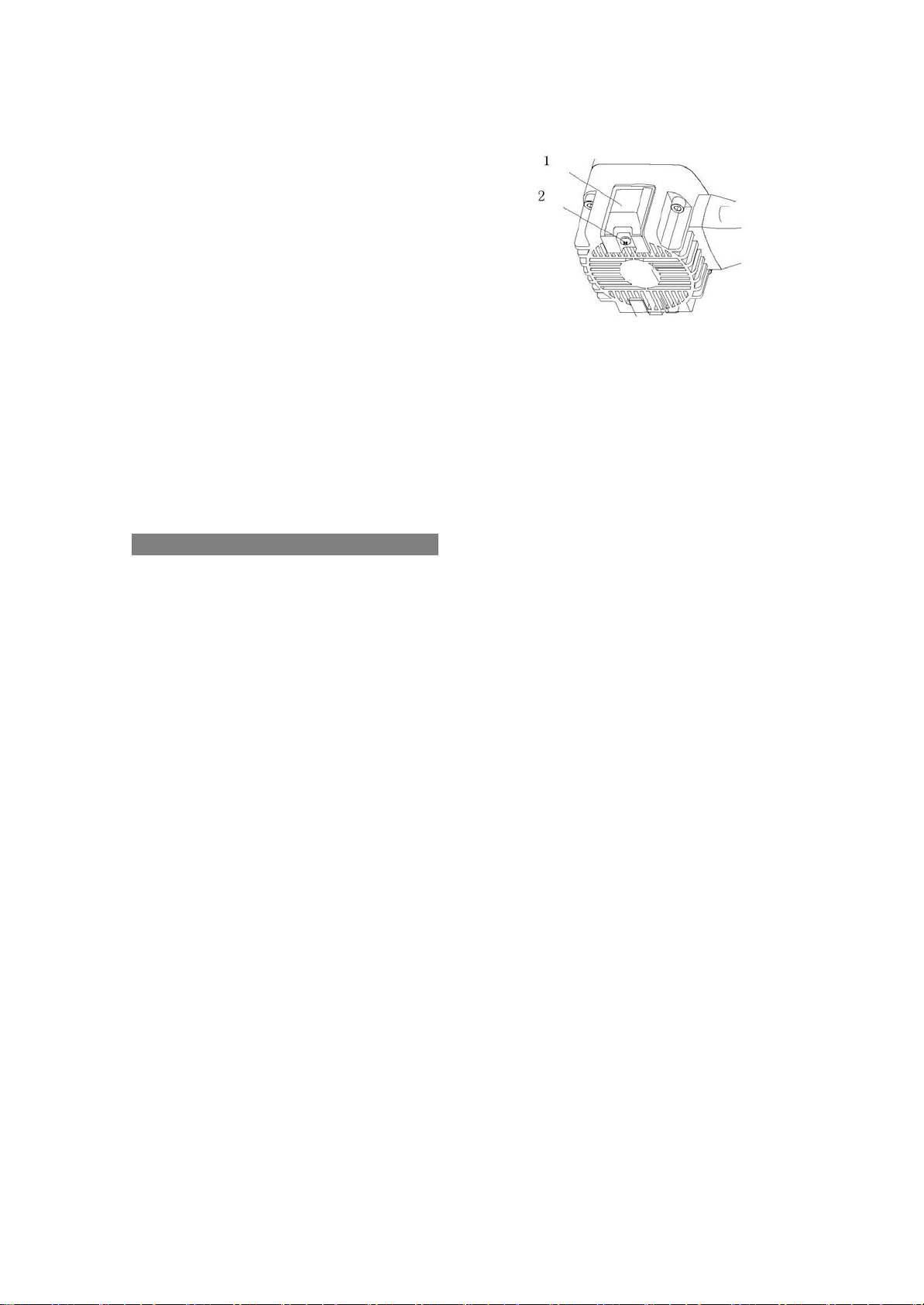

* Maintenance

Warning: In working pause, such as

changing working equipment,

maintenance and adjustment, pull

out the plug. After removing the

screw (2) of brushcap (1) with

screwdriver, take out the brush cover,

and then take out the wearing brush.

Place new brush and re-fix the brush

cover, brushcap.

To ensure the security and reliable of

the tool, all repairing, brush checking

or changing, including other

maintenance or adjustment should

be performed by professional

Distractions can cause you

to lose control

personnel in power tool maintenance

center. 2) Electrical Safety

a) Double insulated tools are

equipped with a polarized

S

Sa

af

fe

et

ty

y R

R

u

ul

l

e

es

s

W

a

rning!

Read and understand all

instructions. Failure to follow all

instructions listed below, may result

in electric shock, fire and/or serious

personal injury.

SAVE THESE INSTRUCTIONS

1) Work Area

a) Keep your work area clean and.

well lit.Cuttered benched and dark

areas invite accidents.

b) Do not operate power tools in

explosive atmosphere,such as

in the presence of flammable

liquids,gases, or dust.

Power tools create sparks which

may ignite the dust or flumes .

c) Keep by-standers, children and

visitors away while operating a

power tool.

plug. Do not change the

plug in any way. Do not use

“AC only“ rated tools with a

DC power supply.

b) Avoid body contact with

grounded surfaces such

as pipes, radiators, ranges

and refrigerators. There is

an increased risk of electric

shock if your body is

grounded.

c) Don’t expose power tools

to rain or wet conditions.

Water entering a power tool

will increase the risk of

electric shock.

d) Do not abuse the cord.

Never use the cord to carry

the tools or pull the plug