TABLE OF CONTENTS

Introduction...................................................................................................................................... i

List of Revisions ...............................................................................................................................ii

1 Safety.................................................................................................................................................... 1

1.1 Signal Words................................................................................................................................... 1

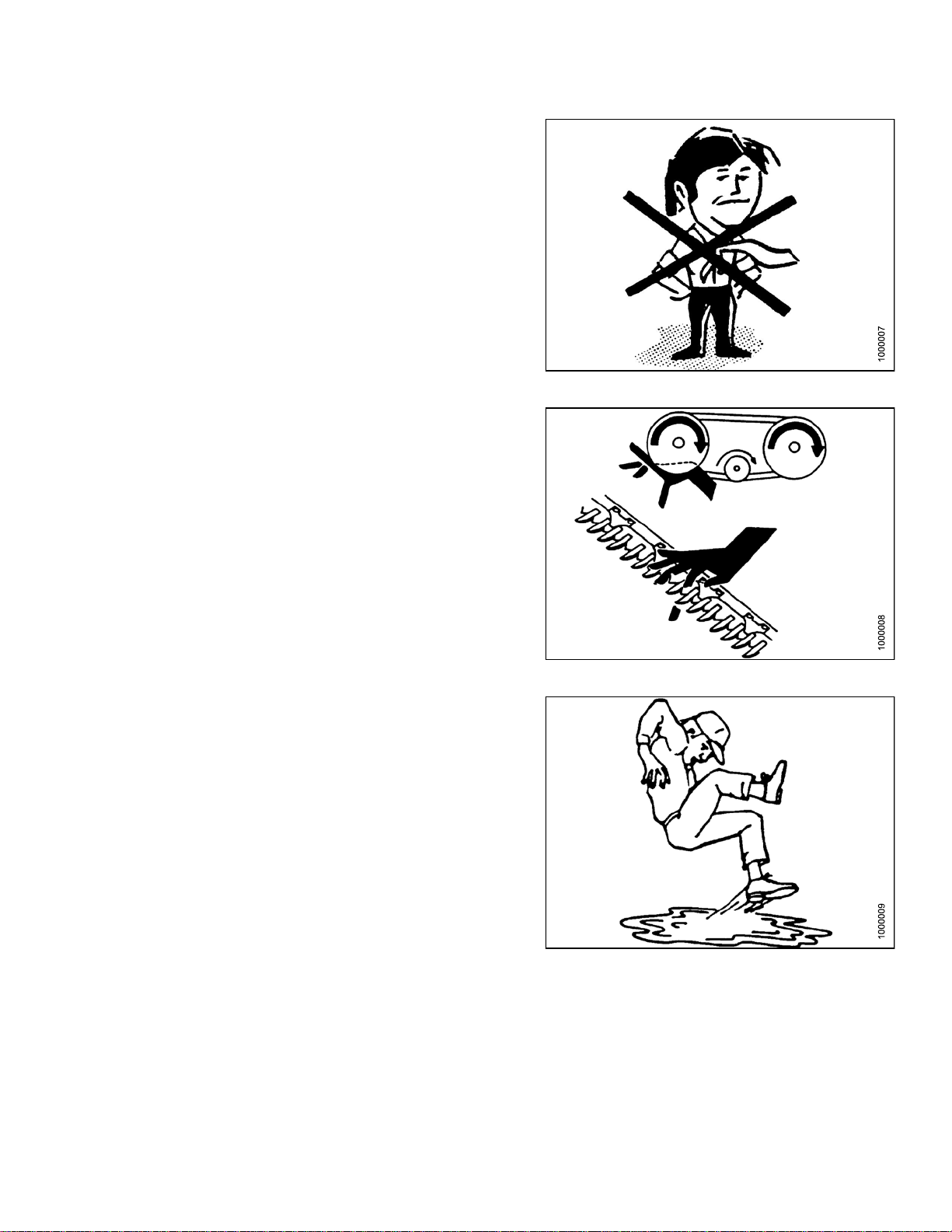

1.2 General Safety ................................................................................................................................ 2

1.3 Safety Signs.................................................................................................................................... 4

2 Recommended Torques ........................................................................................................................ 5

2.1 Torque Specifications....................................................................................................................... 5

2.1.1 SAE Bolt Torque Specifications................................................................................................. 5

2.1.2 Metric Bolt Specifications.......................................................................................................... 7

2.1.3 Metric Bolt Specifications Bolting into Cast Aluminum............................................................... 10

2.1.4 Flare-Type Hydraulic Fittings................................................................................................... 10

2.1.5 O-Ring Boss (ORB) Hydraulic Fittings (Adjustable)................................................................... 12

2.1.6 O-Ring Boss (ORB) Hydraulic Fittings (Non-Adjustable) ........................................................... 14

2.1.7 O-Ring Face Seal (ORFS) Hydraulic Fittings............................................................................ 15

3 Conversion Chart................................................................................................................................ 17

4Definitions........................................................................................................................................... 19

5 Unloading and Assembling the Mower Conditioner............................................................................ 21

5.1 Unloading Shipment....................................................................................................................... 21

5.2 Setting Up Forming Shields............................................................................................................ 23

5.2.1 Setting Up Forming Shield for Finger Conditioner..................................................................... 23

5.2.2 Setting Up Forming Shield for Roll Conditioner......................................................................... 27

5.3 Repositioning Center-Link Top Anchor ............................................................................................28

5.4 Attaching Hitch to Carrier ............................................................................................................... 31

5.5 Installing Steering Cylinder............................................................................................................. 34

5.6 Attaching Aft Driveline.................................................................................................................... 36

5.7 Attaching Steering Arm.................................................................................................................. 38

5.8 Installing Wheels ........................................................................................................................... 41

5.9 Installing Drawbar Hitch ................................................................................................................. 42

5.10 Installing 2-Point Hitch (Cat. II) Adapter .......................................................................................... 44

5.11 Unpacking Curtains ....................................................................................................................... 46

5.12 Installing Options........................................................................................................................... 48

5.12.1 Installing Endwise Transport System ....................................................................................... 48

Installing Components..................................................................................................... 48

Installing Hydraulics........................................................................................................ 54

Installing Electrical.......................................................................................................... 61

5.12.2 Installing Hydraulic Center-Link............................................................................................... 65

5.12.3 Installing Tall Crop Divider....................................................................................................... 66

5.13 Setting Up The Tractor................................................................................................................... 67

5.13.1 Adjusting the Drawbar ............................................................................................................ 67

5.13.2 Installing Drawbar Hitch Adapter ............................................................................................. 68

5.14 Attaching Mower Conditioner to the Tractor..................................................................................... 69

5.14.1 Attaching with Drawbar Hitch.................................................................................................. 69

5.14.2 Attaching with Two-Point Hitch................................................................................................ 71

5.14.3 Connecting Hydraulics............................................................................................................ 73

5.14.4 Connecting Electrical Wiring Harness...................................................................................... 74

5.15 Removing Mower Conditioner from Shipping Pallet.......................................................................... 75

6 Changing the Conditioner................................................................................................................... 77

6.1 Separating Header from Carrier...................................................................................................... 77

6.2 Removing the Conditioner.............................................................................................................. 81

6.3 Installing the Conditioner................................................................................................................ 83

6.3.1 Installing Conditioner Drive ..................................................................................................... 84

169821 iii Revision D