GB - 7

OPERATIONAL SAFETY RULES

Walk Around Inspection

Complete a walk around inspection of unit and

work area to understand:

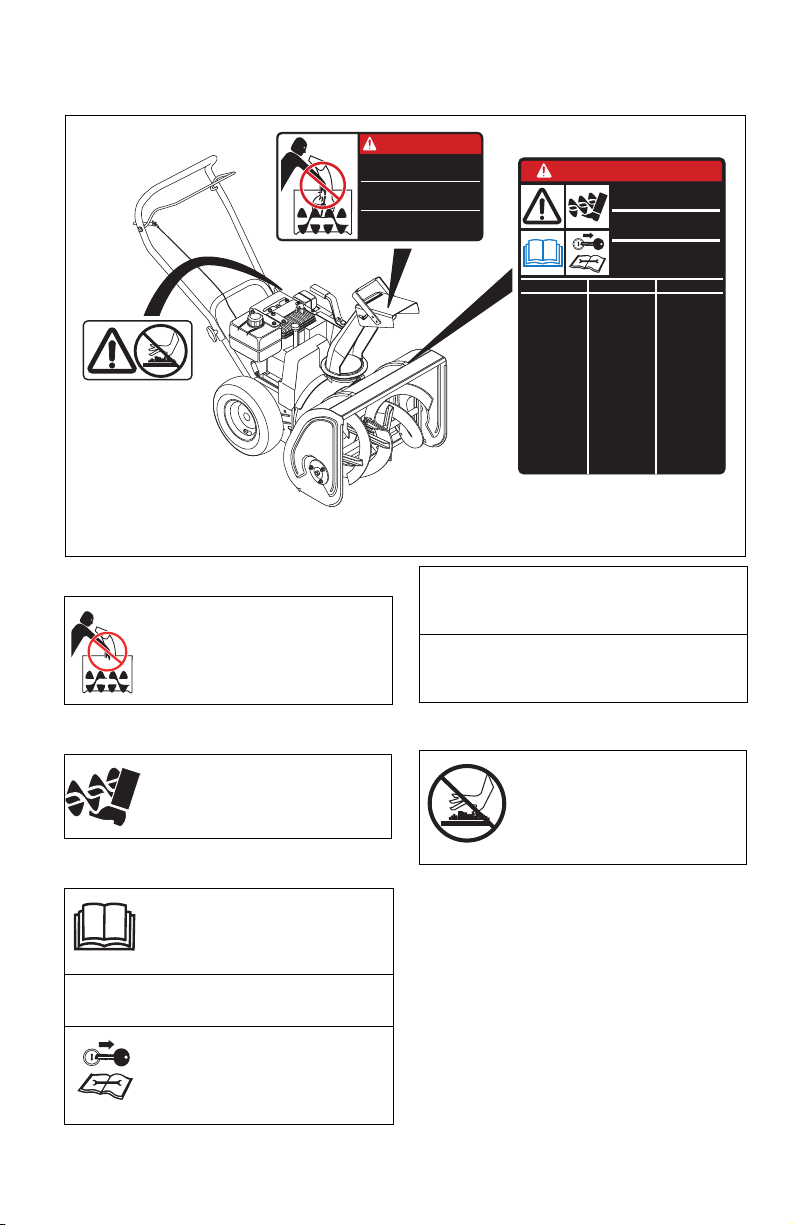

•Work area •Your unit •All safety decals

Work Area

ALWAYS check overhead and side clearances

carefully before operation. ALWAYS be aware

of traffic when operating along streets or

curbs.

Keep children and people away. Keep children

out of work area and under watchful care of a

responsible adult.

NEVER allow children to operate or play on or

near unit. Be alert and shut off unit if children

enter area.

DO NOT allow adults to operate unit without

proper training.

Keep area of operation clear of all toys, pets,

and debris. Thrown objects can cause injury.

Check for weak spots on dock, ramps or

floors. Avoid uneven work areas and rough

terrain. Stay alert for hidden hazards.

Avoid uneven and rough terrain. DO NOT

operate near drop offs, ditches, or

embankments. Unit can suddenly turn over if a

wheel is over the edge of a cliff or ditch, or if

an edge caves in.

Falling snow, fog, etc. can reduce vision and

cause an accident. Operate unit only when

there is good visibility and light.

Personal Safety

Only trained adults may operate unit.

Training includes actual operation.

NEVER operate unit after or during the use of

medication, drugs or alcohol. Safe operation

requires your complete and unimpaired

attention at all times.

NEVER allow anyone to operate this unit when

their alertness or coordination is impaired.

DO NOT operate unit without wearing

adequate winter outer garments. Wear

adequate safety gear and protective gloves.

Wear proper footwear to improve footing on

slippery surfaces.

Protect eyes, face and head from objects that

may be thrown from unit. Wear appropriate

hearing protection.

Avoid sharp edges. Sharp edges can cut.

Moving parts can cut off fingers or a hand.

ALWAYS keep hands and feet away from all

rotating parts during operation. Rotating parts

can cut off body parts.

ALWAYS keep hands away from all pinch

points.

DO NOT touch unit parts which might be hot

from operation. Allow parts to cool before

attempting to maintain, adjust or service.

NEVER place your hands or any part of your

body or clothing inside or near any moving

part while unit is running.

DO NOT wear loose clothing or jewelry and tie

back hair that may get caught in rotating parts.

Never direct discharge towards persons or

property that may be injured or damaged by

thrown objects. Use extreme caution on gravel

surfaces. Stay alert for hidden hazards or

traffic.

DO NOT throw snow any higher than

necessary.

Deflected materials can cause injury and

property damage.

Always stand clear of the discharge area when

operating this unit.

Fumes from engine exhaust can cause injury

or death. DO NOT run engine in an enclosed

area. Always provide good ventilation.

Operation

Understand:

•How to operate all controls

•The functions of all controls

•How to STOP in an Emergency

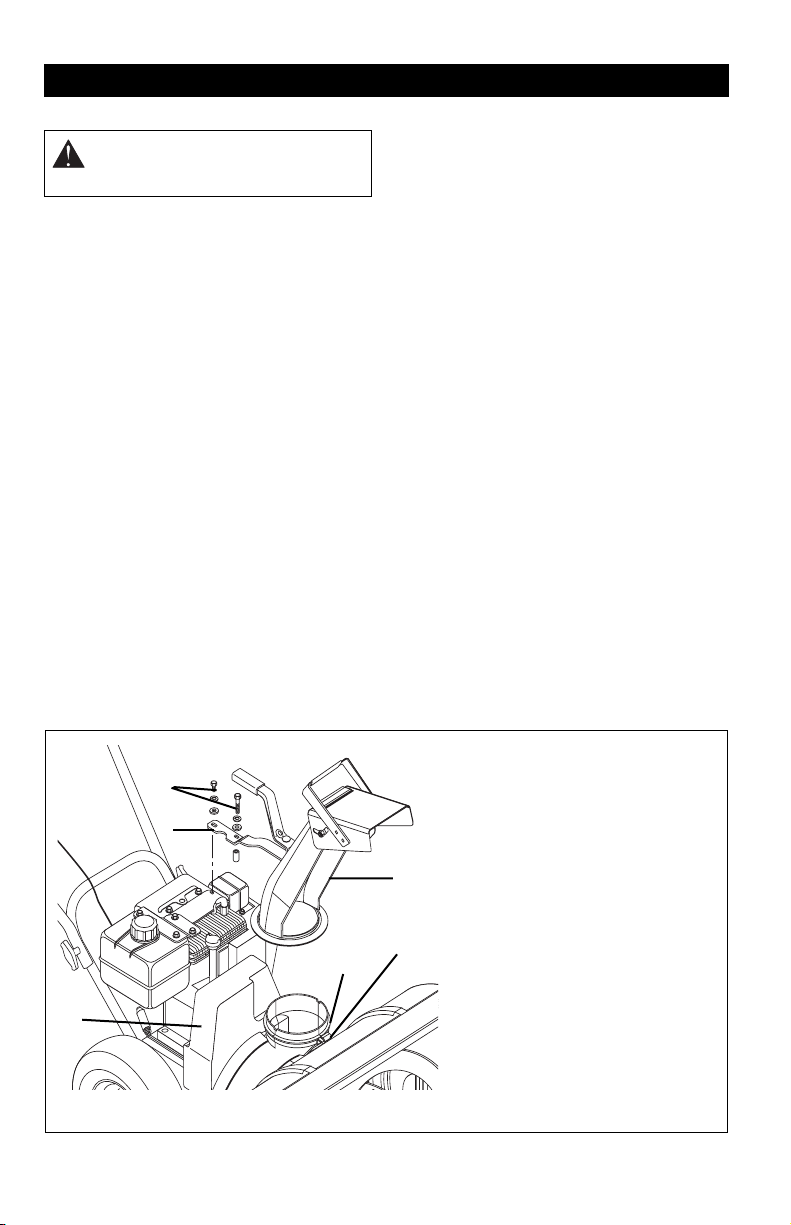

Rotating impeller can cause serious injury. DO

NOT unclog unit while engine is running.

When leaving operator’s position for

any

reason,

ALWAYS disengage auger, stop unit

and engine, remove key and allow moving

parts to stop.

Before starting engine, disengage control(s).

ALWAYS allow unit and engine to adjust to

outdoor temperatures before clearing snow.

Always be sure of your footing, especially

when operating in reverse. Walk, never run

during operation.

DO NOT operate at too fast a rate.

Slow down and turn corners slowly.

Do not operate in reverse unless absolutely

necessary. ALWAYS back up slowly. Always

look down and behind before and while

backing.

Disengage attachment drive when traveling

from one work area to another.

ALWAYS disengage attachment drive, stop

unit and engine, remove key, allow moving

parts to stop before leaving operator’s position

for any reason.