Macurco 6 Series User guide

Other Macurco Security Sensor manuals

Macurco

Macurco HD-11 User manual

Macurco

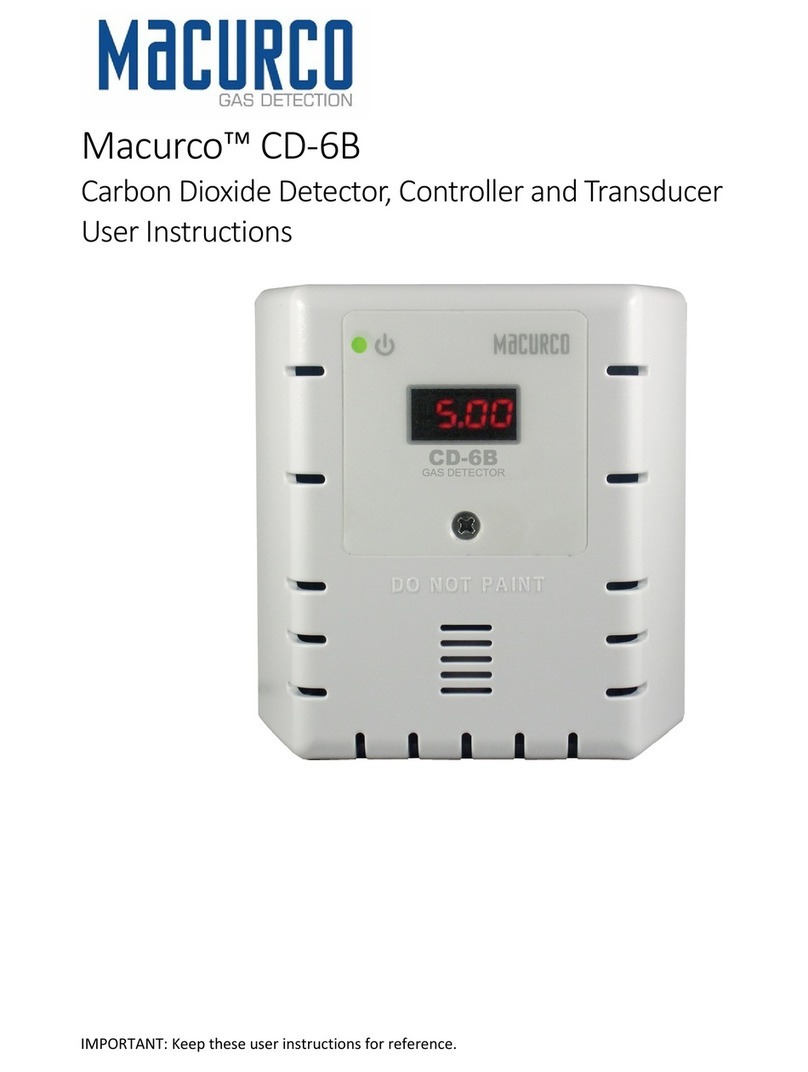

Macurco CD-6B User manual

Macurco

Macurco RD-VRF User manual

Macurco

Macurco OX-6 User manual

Macurco

Macurco GD-2B User manual

Macurco

Macurco OX-12 User manual

Macurco

Macurco RD-6 User manual

Macurco

Macurco RD-6 User manual

Macurco

Macurco CD-6 Installation instructions

Macurco

Macurco CD-12 User manual

Popular Security Sensor manuals by other brands

Shinko

Shinko SE2EA-1-0-0 instruction manual

Det-Tronics

Det-Tronics X Series instructions

ACR Electronics

ACR Electronics COBHAM RCL-300A Product support manual

TOOLCRAFT

TOOLCRAFT 1712612 operating instructions

Elkron

Elkron IM600 Installation, programming and functions manual

Bosch

Bosch WEU PDO 6 Original instructions