Page 1

© 2015 Sensata Technologies

Introduction

1.0 Introduction

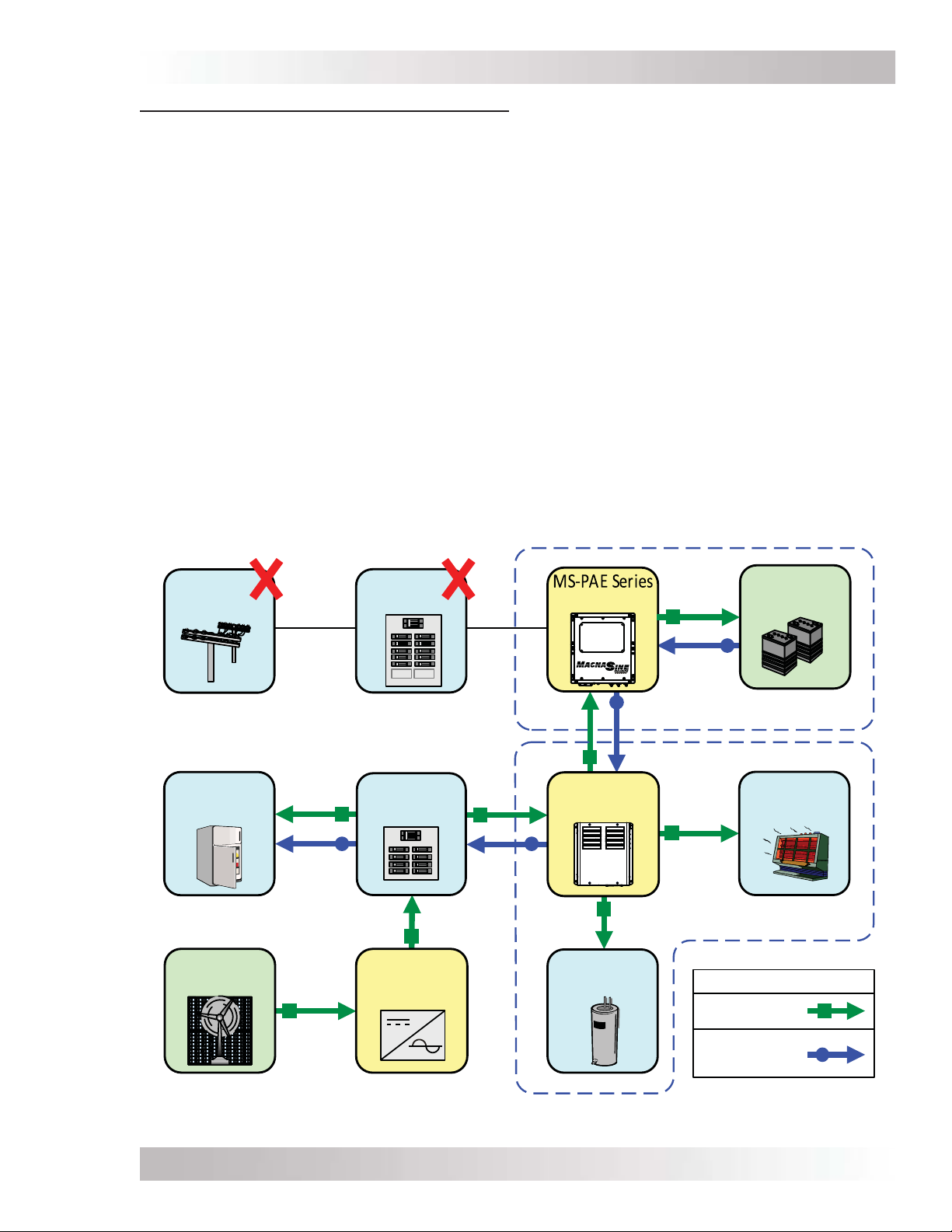

Congratulations on your purchase of the ACLD-40 (AC Load Diversion - 4.0kW) controller. The

ACLD-40 (also know as the ACLD) is designed to be used in an AC coupled system—networked

with a MS-PAE Series1inverter—to provide three-stage battery charging and to divert any excess

power to a resistive load.

The ACLD-40 controller includes the following features:

• Automatic three-stage battery regulation (with adjustable voltage and charging parameters).

• Controls up to 4000 watts of excess power to prevent battery overcharge.

• Automatic battery temperature compensation—provides optimum charging even during

extreme temperature changes (when using the inverter’s Battery Temperature Sensor).

• A networked diversion device—using inverter and network ports.

• ON/OFF mounted switch with status/fault indicator LED; operation and power information

is provided when using the inverter’s remote.

• Designed to work with MS-PAE Series inverters to prevent battery overcharging.

• Diversion load is isolated from in-home AC loads and receives PWM (Pulse Width Modulation)

voltage—prevents AC line disturbance by providing smooth transition when regulating.

• Allows the use of resistive AC household loads (i.e., water heater tanks) instead of expensive

and hard to find DC loads to divert excess current.

• Does not require additional/external sensors to monitor battery inverter output current,

battery voltage, or battery type.

1.1 What is an AC Load Diversion Controller (ACLD)?

The basic operating concept of an AC or DC diversion controller is quite simple. Monitor the battery

bank, and if an energy source (e.g. solar panel, wind generator, etc.) should cause the battery

to rise to a predetermined voltage level, connect a diversion load of sufficient size to prevent the

battery from being overcharged. By diverting the unused energy that your solar panel or wind

generator is producing, you can make use of it—such as heating a hot water or heating a room.

The ACLD-40 is an AC load diversion controller that maximizes the use of onsite-generated power

(i.e., renewable energy) by diverting any excess energy to resistive loads on the AC side. By

diverting the excess current on the AC side and not on the DC side (through the battery-based

inverter), there is less strain on the battery-based inverter. Also, since the wiring is on the AC

side, there is less voltage drop, less expensive system wires and diversion loads, and fewer issues

when trying to determine how to size the diversion loads/hardware.

1.2 What is an AC Coupled system, and why do I need an ACLD?

Many homeowners utilize renewable energy (i.e., PV, wind, etc.) by installing a high efficiency,

battery-less, grid-tie inverter (also known as an utility-interactive inverter) to offset their power

consumption from the utility grid. However, these homeowners soon learn that when a utility

power outage occurs, the grid-tie inverter is required to shut down. This can cause considerable

frustration as the homeowner realizes that the critical loads in the home (refrigerator, lights, water

pump, etc.) are no longer powered and all the energy produced by the renewable energy source

is being wasted while the utility power is out.

To overcome some of the disadvantages of a battery-less, grid-tie inverter; homeowners add a

battery-based inverter and batteries to power critical loads during a utility power outage. However,

the generated power from the renewable energy continues to be wasted until the utility power

returns.

1 This manual will specifically refer to the MS-PAE Series to work with the ACLD-40. How-

ever, the ACLD will work with any battery-based inverter that provides a MagNet communications

port and has an output of 230 or 240 VAC (50 or 60 Hz). This means the MS-PAE Series, MS-E

Series, or MS-PE Series inverters will work with the ACLD-40.