Contents

Index

GB

Manufacturer's Declaration…………………………………………………………………………………………………...3

General notes.......................................................................................................................................................... 5

Directives ............................................................................................................................................................ 5

Safety notes........................................................................................................................................................ 5

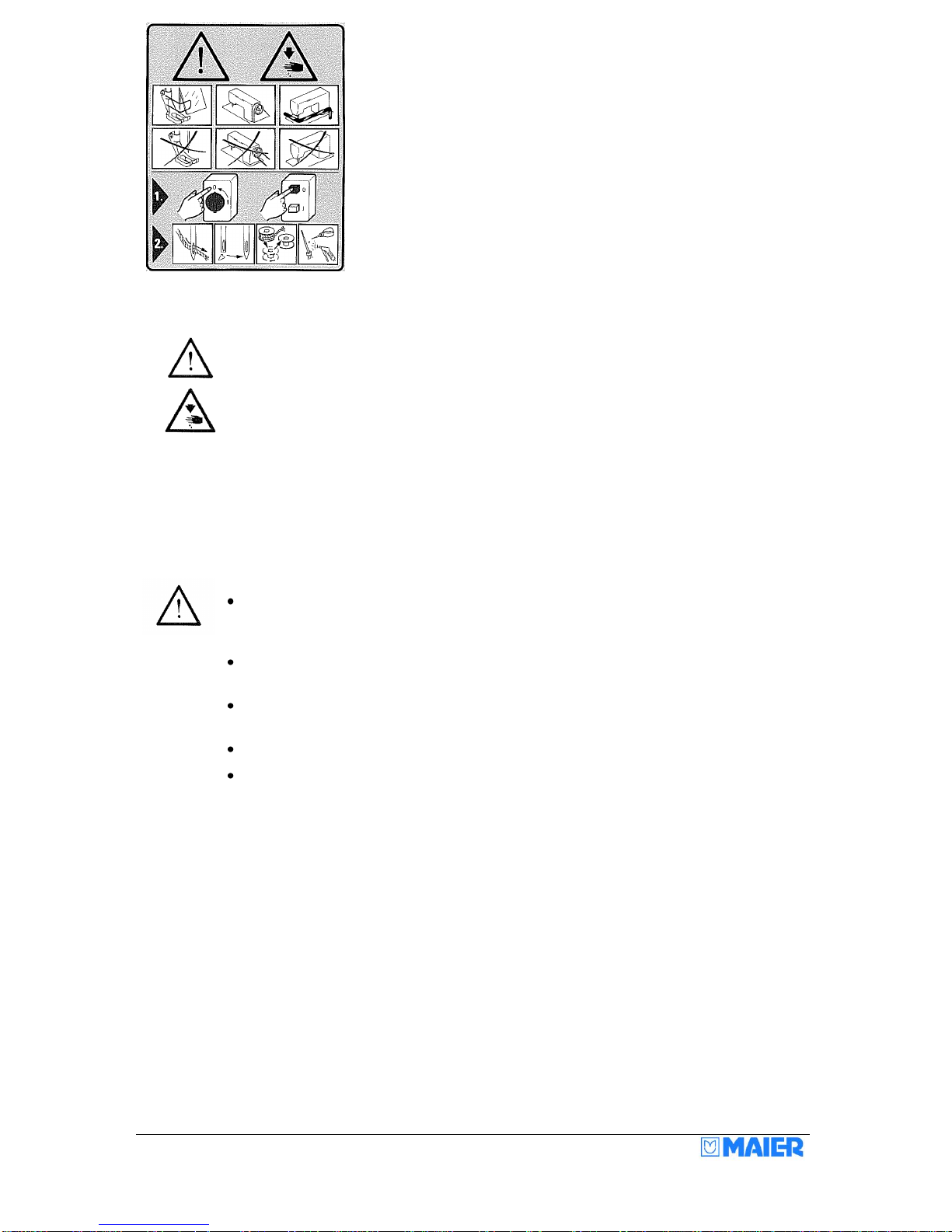

Safety symbols.................................................................................................................................................... 6

Items requiring the Operator's special attention.................................................................................................. 6

Operators and specialist staff.............................................................................................................................. 7

Operators............................................................................................................................................................ 7

Specialist staff..................................................................................................................................................... 7

Hazard warnings................................................................................................................................................. 8

Transport, packaging and storage....................................................................................................................... 8

Installation and initial commissioning.................................................................................................................. 8

Care of the machine............................................................................................................................................ 8

Disposal of the machine...................................................................................................................................... 9

Assembly of the machine ...................................................................................................................................... 10

Installation instructions...................................................................................................................................... 10

Mounting instructions for the mini-motor 46 attachment kit............................................................................... 11

Classes 221 /241/ 251 / 261 /271 ................................................................................................................. 11

Classes 252/352........................................................................................................................................... 11

Automatic frame drop device............................................................................................................................. 12

Accessories:...................................................................................................................................................... 12

Sewing machine table tops ............................................................................................................................... 13

Operation............................................................................................................................................................... 15

Threading.......................................................................................................................................................... 15

Machine without thread cutter (Fig. 1) .......................................................................................................... 15

Machine with thread cutter (Fig. 2) ............................................................................................................... 15

Inserting the cloth and sewing........................................................................................................................... 16

Blind stitch hems on the hem edge............................................................................................................... 16

Blind stitch hems on the cloth tuck................................................................................................................ 16

Setting the stitch depth (penetration) ................................................................................................................ 18

Classes 220, 221, 240, 241, 251, 261, 271 .................................................................................................. 18

Classes 252 and 352.................................................................................................................................... 19

Setting the cloth retainers for classes 251, 261, 271, 281, 252, 352................................................................. 21

Setting the helical spring................................................................................................................................... 21

Fitting the needle............................................................................................................................................... 22

Checking the needle motion ......................................................................................................................... 22

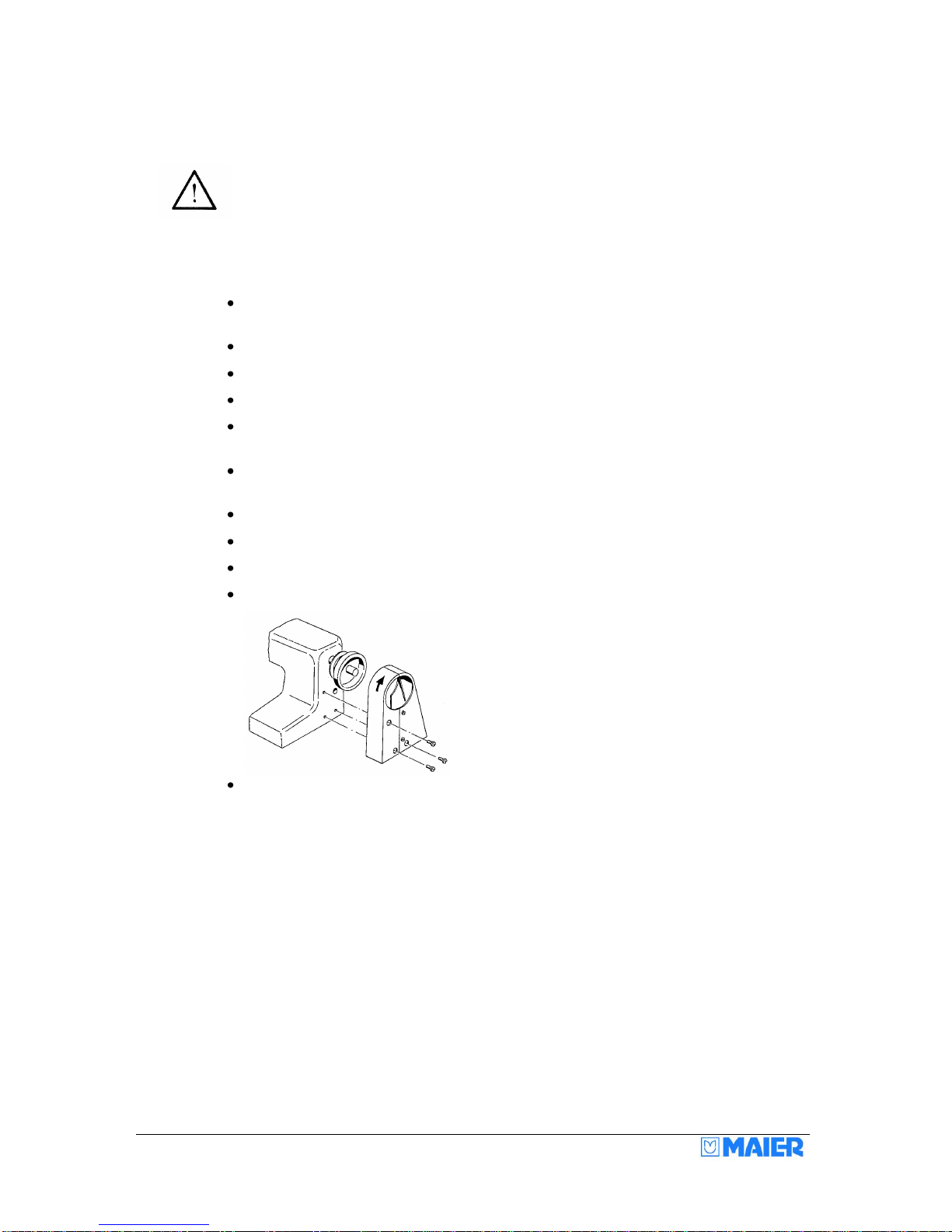

Skip stitch device .............................................................................................................................................. 23

Instructions for the mechanic................................................................................................................................. 24

Setting the stitch plate....................................................................................................................................... 24

Basic setting of the needle movement .............................................................................................................. 25

Fitting and checking the looper ......................................................................................................................... 25

Adjusting the looper .......................................................................................................................................... 26

Adjusting the height of the looper ................................................................................................................. 26

Adjusting the lateral position of the looper.................................................................................................... 26

Adjusting the looper stroke ........................................................................................................................... 27

Setting the thread take-up cam......................................................................................................................... 27

Stitch length adjustment.................................................................................................................................... 28

Plunger (rib shaft) adjustment........................................................................................................................... 29

Radial position.............................................................................................................................................. 29

Axial position................................................................................................................................................. 29

Play............................................................................................................................................................... 30

Setting the plunger (rib shaft) timing............................................................................................................. 30

Plunger (rib shaft) skip stitch timing.............................................................................................................. 30

Feed dog adjustment ........................................................................................................................................ 31

Sewing faults and how to remedy them ............................................................................................................ 32

Sewing tools.......................................................................................................................................................... 33

Technical data....................................................................................................................................................... 34