2

Thank you for purchasing a MAKITA product

We want you to be satisÞed with your MAKITA product.

You have decided to buy one of the most up-to-date chain

saws.

The MAKITA chain saw DCS9010 is a high-efÞciency, modern

chain saw for professional application, which can be used for

cutting strong wood. It is ideal for the use in forests and for

cutting long wood in sawmills.

Due to its high-power driving mechanism it is most useful for

cutting down strong trees. At the same time the chain saw is

of a slim, practical design which allows to carry out tension

releasing work without any difÞculties.

The MAKITA DCS9010 is a high-efÞciency universal chain saw

for hard work in forests.

Youhavepurchasedahigh-efÞciencydeviceofanewgeneration,

which has the following outstanding characteristics:

- Excellent power to weight ratio, i. e. high engine power

combined with low weight.

- A high torque at a low rate of revolutions as a result of a

favorable stroke-bore ratio, a computer calculated cylinder

design and an asymmetric combustion chamber.

- Consequently you can use a very wide speed range in which

the engine has a high output. In addition, the chain saw has

a low fuel consumption and as a result only a low emission

of polluting substances.

- The intelligent, programme controlled ignition system

works maintenance-free and allows easy starting, smooth

idling and good running at all speeds.

- The modern light-weight driving mechanism guarantees

fast speeding up, as well as a low rate of vibrations which

is advantageous not only to the device but also to the ope-

rator.

- A particularly easy to service as well as operate, with ergo-

nomicall handle.

The following industrial property rights apply: US 5411382,

EP 0440827, EP 0560201, GBM 8909508, GBM 8913638,

GBM 9203378.

In order to guarantee the optimal function and performance of

your power chain saw and to ensure your personal safety we

would request you to perform the following:

Read this instruction manual carefully before putting the

chain saw into operation for the Þrst time, and strictly

observe the safety regulations! Failure to observe these

precautions can lead to severe injury or death!

Table of contents Page

Packing .................................................................................2

Delivery inventory ...............................................................3

Symbols ................................................................................3

SAFETY PRECAUTIONS .....................................................4

General precautions .........................................................4

Protective equipment ........................................................4

Fuels / Refuelling ..............................................................5

Putting into operation........................................................5

Kickback ...........................................................................6

Working behavior/Method of working............................ 6-7

Transport and storage.......................................................8

Maintenance .....................................................................8

First aid .............................................................................8

Technical data ......................................................................9

Denomination of components ............................................9

PUTTING INTO OPERATION .............................................10

Mounting the guide bar and saw chain......................10-11

Tightening the saw chain................................................11

Chain brake ....................................................................11

Fuels / Refuelling ...................................................... 12-13

Adjusting the chain lubrication........................................13

Starting and stopping the engine....................................14

Checking the chain brake ..............................................14

Checking the chain lubrication........................................14

Adjusting the carburetor ............................................. 15-16

Working in winter ..............................................................16

MAINTENANCE ..................................................................17

Sharpening the saw chain ........................................ 17-18

Cleaning the guide bar....................................................18

Cleaning the chain brake band.......................................18

Checking and replacing the sprocket..............................19

Replacing/cleaning the spark arrester screen (only for Europe)....19

Checking the mufßer screws...........................................19

Replacing the starter cable.............................................20

Replacing the return spring.............................................20

Replacing the suction head ............................................20

Cleaning the air Þlter.......................................................21

Replacing the spark plug ................................................21

Replacing the vibration damper......................................22

Instructions for periodic maintenance.............................23

Service, spare parts and guarantee ........................... 23-24

Troubleshooting ................................................................24

Extract from spare parts list .............................................25

EU Conformity Declaration ...............................................26

Note .....................................................................................27

Packing

TheMAKITADCS9010willbedeliveredinaprotectivecardboard

box to prevent transport damage.

Cardboardisa basic raw materialandisconsequentlyreuseable

or suitable for recycling (waste paper recycling).

Intended use

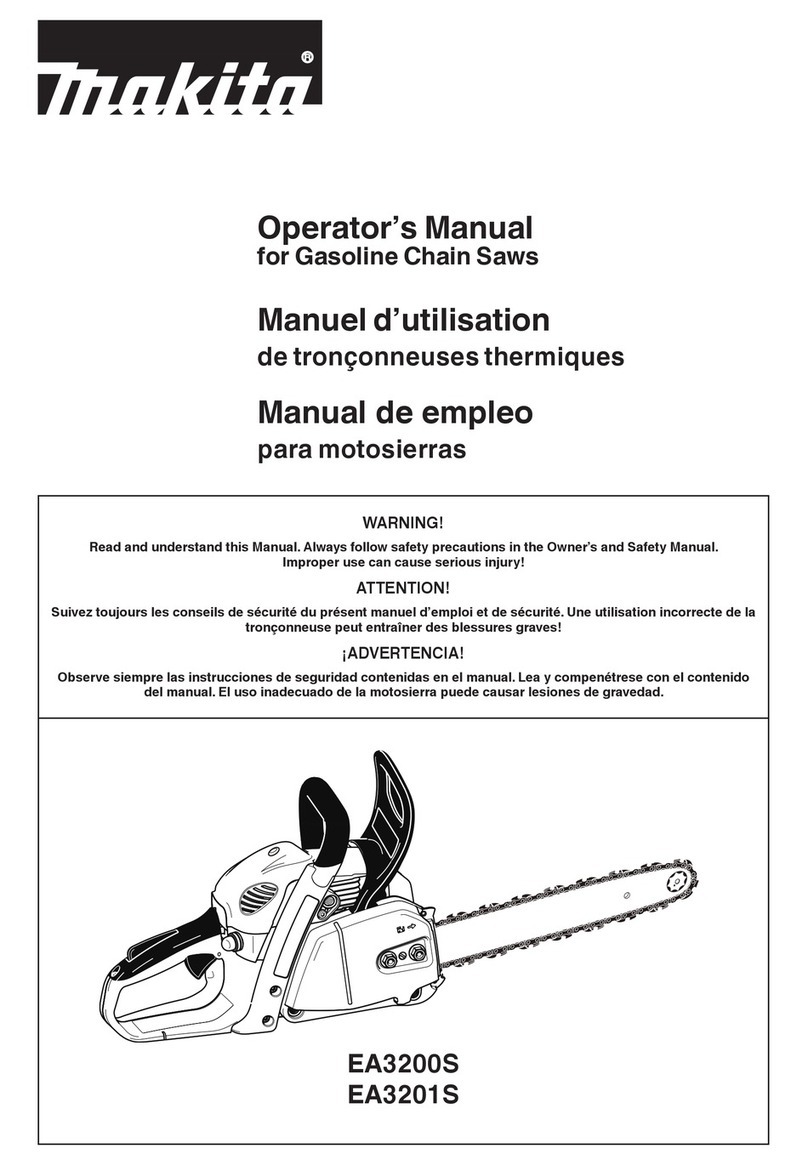

Power chain saws

This power chain saw may be used only for sawing wood out

of doors. It is intended for the followung uses depending on

its class:

- Professionalandmid-class:Use on small, medium and lar-

ge trees: felling, limb removal, cutting to length, thinning.

- Hobbyklasse:Occasionaluseon small trees, fruit-tree care,

felling, limb removal, cutting to length.

Unauthorised users:

Persons who are not familiar with the Instruction Manual, chil-

dren, young people, and persons under the inßuence of drugs,

alcohol or medication must not use this saw.