8

1. Цей електроінструмент призначений для

шліфування. Уважно ознайомся зусіма

попередженнями про небезпеку,

інструкціями, ілюстраціями та технічними

характеристиками цього

електроінструменту.Невиконання цих

інструкцій може призвести до ураження

електричним струмом, пожежі та/або

серйозного поранення.

2. За допомогою цього інструменту не

рекомендовано виконувати такі операції як

шліфування, чищення металу за допомогою

металевої щітки, полірування або

відрізання.Використання інструменту не за

призначенням може утворити небезпечне

становище та призвести до поранення.

3. Не слід використовувати допоміжні

приналежності, які спеціально не

призначені та не рекомендовані для цього

інструменту виробником.Навіть якщо вони

добре приєднуються до інструменту, це не

гарантує небезпечної експлуатації.

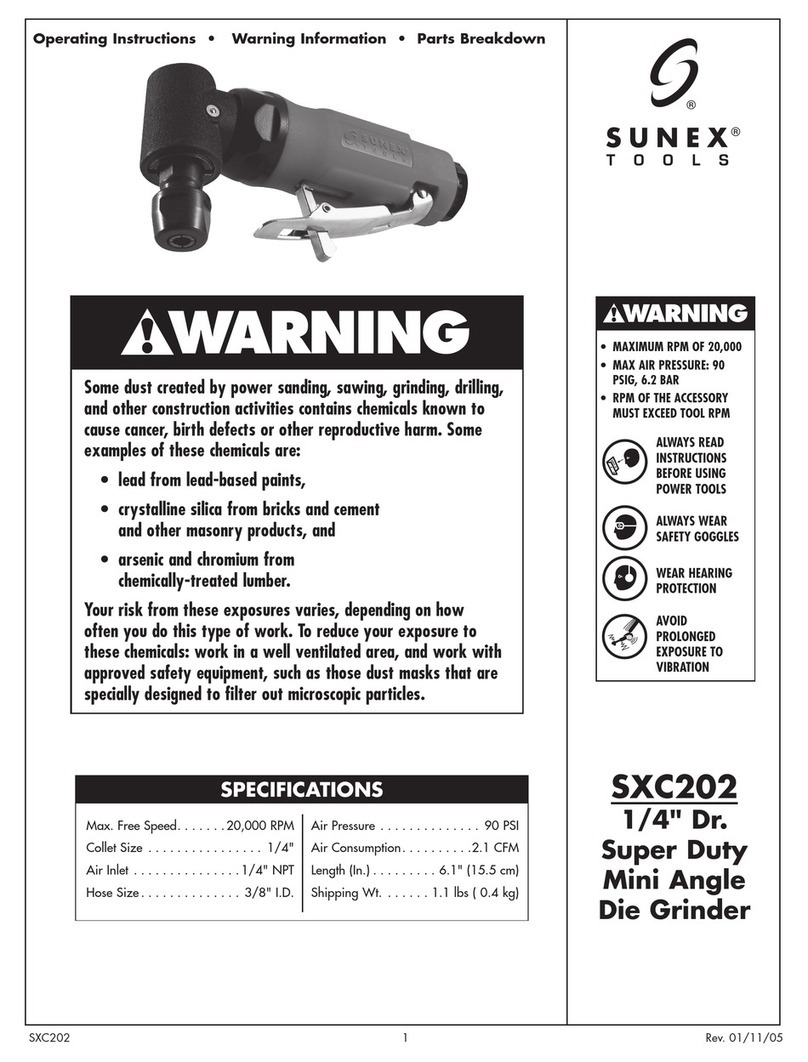

4. Номінальна швидкість допоміжних

пристроїв повинна щонайменш

дорівнюватися максимальній швидкості,

що відзначена на електроінструменті.

Допоміжні пристрої, що працюють швидше

своєї номінальної скорості можуть поламатися

та відскочити.

5. Зовнішній діаметр та товщина вашого

допоміжного приладу повинні бути умежах

паспортної потужності вашого

електроінструменту.Приладдя неналежних

розмірів не можна захистити або контролювати

належним чином.

6. Не слід користуватися пошкодженим

приладдям Щоразу перед користуванням

слід перевіряти допоміжне приладдя,

наприклад абразивні кола на наявність

тирси та тріщин. Уразі падіння інструменту

або приладдя, слід оглянути їх на наявність

пошкоджень або встановити неушкоджене

приладдя. Після огляду та встановлення

приладу, слід зайняти таке положення, коли

ви та ваші сусіди знаходяться на відстані

від площини приладу, що обертається,

запустіть інструмент та дайте йому

попрацювати на максимальній швидкості

без навантаження протягом однієї хвилини.

Під час цього пробного прогону ушкоджені

прилади, як правило, розбиваються.

7. Слід одягати засоби індивідуального

захисту. Слід користуватися

щитком-маскою, захисними окулярами або

захисними лінзами відповідно до області

застосування. Це означає, що слід одягати

пилозахисну маску, засоби захисту органів

слуху, рукавиці та фартух, які здатні

затримувати дрібні частки деталі та наждаку.

Засоби захисту органів зору повинні бути

здатними затримувати сміття, що утворюється

під час виконання різних операцій.

Пилозахисна маска або респіратор повинні

бути здатними фільтрувати часточки, що

утворюються під час роботи. Тривалий вплив

сильного шуму може призвести до втрати

слуху.

8. Спостерігачі повинні знаходитися на

небезпечному відстані від місця роботи.

Кожний, хто приходить вробочу зону

повинен одягати засоби індивідуального

захисту.Частки деталі або уламки приладдя

може відлетіти за межі безпосередньої зони

роботи та поранити.

9. Під час різання, коли ріжучий інструмент

може торкнутися схованої електропроводки

або свого шнуру, інструмент слід тримати за

ізольовані поверхні держака.Торкання

ріжучим приладом струмоведучої проводки

може призвести до передання напруги до

металевих частин інструменту та ураженню

електричним струмом оператора.

10. Шнур слід розміщувати без змотуючого

пристрою.Якщо ви втратите контроль, шнур

може бути перерізаним або пошкодженим та

ваша рука може потрапити до змотуючого

пристрою.

11. Не слід класти інструмент доки прилад

повністю не зупиниться.Змотуючий пристрій

може захопити шнур та вирвати його з-під

контролю.

12. Не слід запускати інструмент, коли ви його

тримаєте збоку себе.Випадкове стикання зі

змотуючим пристроєм може захопити ваш одяг,

що всвою чергу може призвести до штовхання

приладу до вас.

13. Слід регулярно чистити вентиляційні

отвори інструменту. Вентилятор двигуна

втягує пил усередину кожуха та надмірне

скупчення металевого порошку створює ризик

ураження електричним струмом.

14. Не слід працювати біля займистих

матеріалів.Вони можуть спалахнути від іскри.

15. Не слід застосовувати допоміжне приладдя,

що потребує рідких охолоджувачів.

Використання води, або рідких охолоджувачів

може призвести по ураження електричним

струмом або смерті.

16. Віддача та відповідні попереджувальні

заходи

Віддача це несподівана реакція на

защемлення, чіпляння поворотного кола,

підкладки, щітки або якогось іншої

приналежності. Защемлення або чіпляння

призводять до швидкої зупинки поворотної

приналежності, що всвою чергу спричиняє до