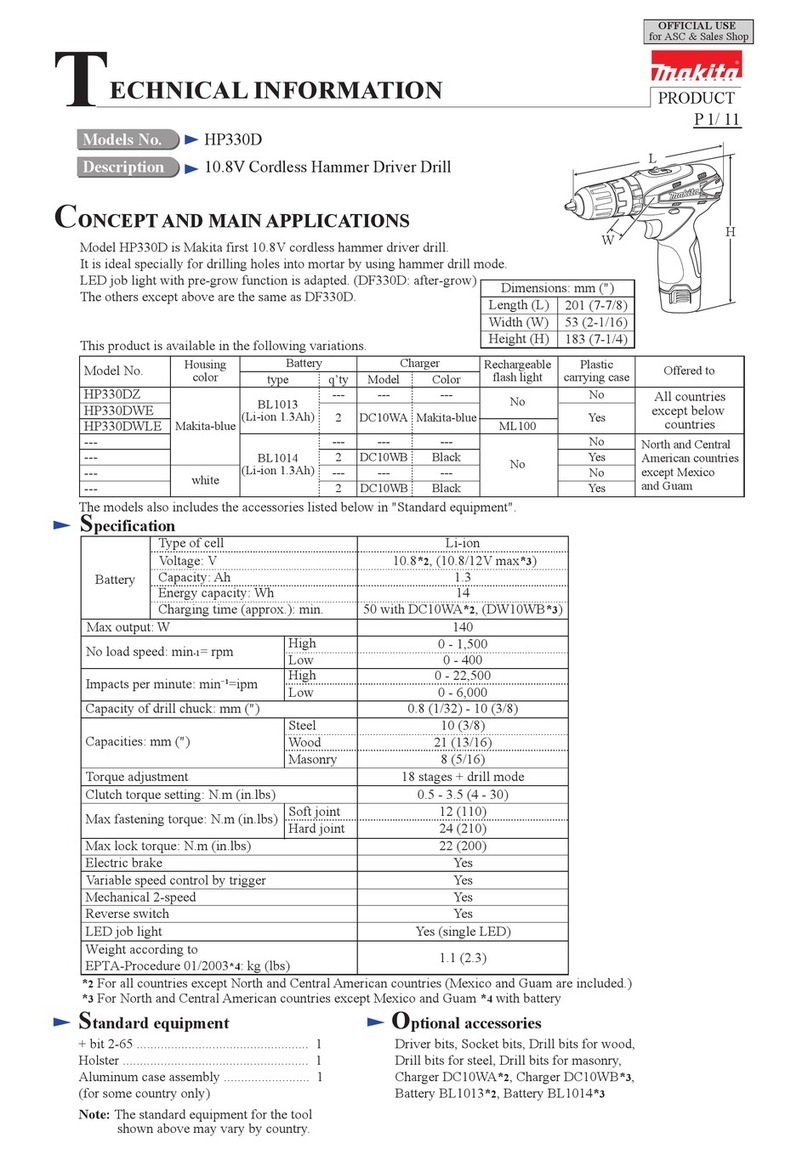

FUNCTIONALDESCRIPTION

Installingor removingbattery

cartridge

*Always switch off the tool before inser-

tionor removalof the batterycartridge.

*To

remove the battery cartridge, with-

draw it from the tool while pressing the

buttonson bothsides

of

the cartridge.

*To

insert the battery cartridge, align the

tongue on the battery cartridge with the

groove in the housing and sliD it into

Battery

cartridge

'e

place. Always insert it

all

the way until it locks in place with

a

little click. If not,

it

may

accidentallyfall out

of

the tool, causing injurytoyouor someonearoundyou.

Do

not use force when insertingthe battery cartridge. If the cartridge does not slide in

easily,

it

isnot beinginsertedcorrectly.

Charging

Plug the battery charger into your power

source.

*Insert the battery cartridge

so

that the

plus and minus terminals on the battery

cartridge are on the same sides as their

respective markings on the battery

charger. Insert the cartridge fully into the

port

so,

that

it

rests on the charger port

floor.

charging will begin.

When the battery cartridge is inserted, the charging light color will flash in red color and

Whencharging iscompleted, the charging light goes out.

If you leavethe battery cartridge inthe charger after the chargingcycle is complete, the

*After charging, remove the battery cartridge from the charger and unplug the charger

CAUTION:

*The battery charger is for charging Makita battery cartridge. Never use it for other pur-

poses or for other manufacture'sbatteries.

Whenyou charge

a

new batterycartridgeor

a

batterycartridgewhich has notbeenused

for

a

long periodof time,

it

may not accept a full charge. This is

a

normalconditionand

does not indicate

a

problem.

You

can rechargethe batterycartridgefully afterdischarging

it

completely and rechargingacoupleof times.

When you charge

a

battery cartridge from

a

just-operated tool or

a

battery cartridge

which has been left in

a

locationexposedto direct sunlight or heat for

a

longtime,

let

it

cooloff. Then reinsert itand try to charge it once more.

Whenyou charge

a

newbatterycartridgeor

a

batterycartridgewhich has notbeen used

for

a

long period, sometimes the charging light will go out soon. If this occurs, remove

the batterycartridgeand reinsert

it.

If the charging light goes out within one minuteeven

after repeatingthis procedure

a

coupleof times, the battery cartridge is dead. Replace

it

with

a

newone.

charger will switch into its "trickle charge (maintenancecharge)" mode.

from the power source.

8