Models No.

Description

PRODUCT

TECHNICAL INFORMATION

CONCEPT AND MAIN APPLICATIONS

Specification

Standard equipment

Optional accessories

< Note > The standard equipment for the tool shown may differ from country to country.

P 1 / 12

HP1620, HP1620F, HP1621, HP1621F

Hammer Drills 16mm (5/8")

HP1620 HP1621HP1620F HP1621F

The above products are up-grade version of the existing

models HP1500 and HP1501.

Their features are as follows.

F/R Change by

brush holder unit

LED Job Light

Model No.

Keyless drill chuck

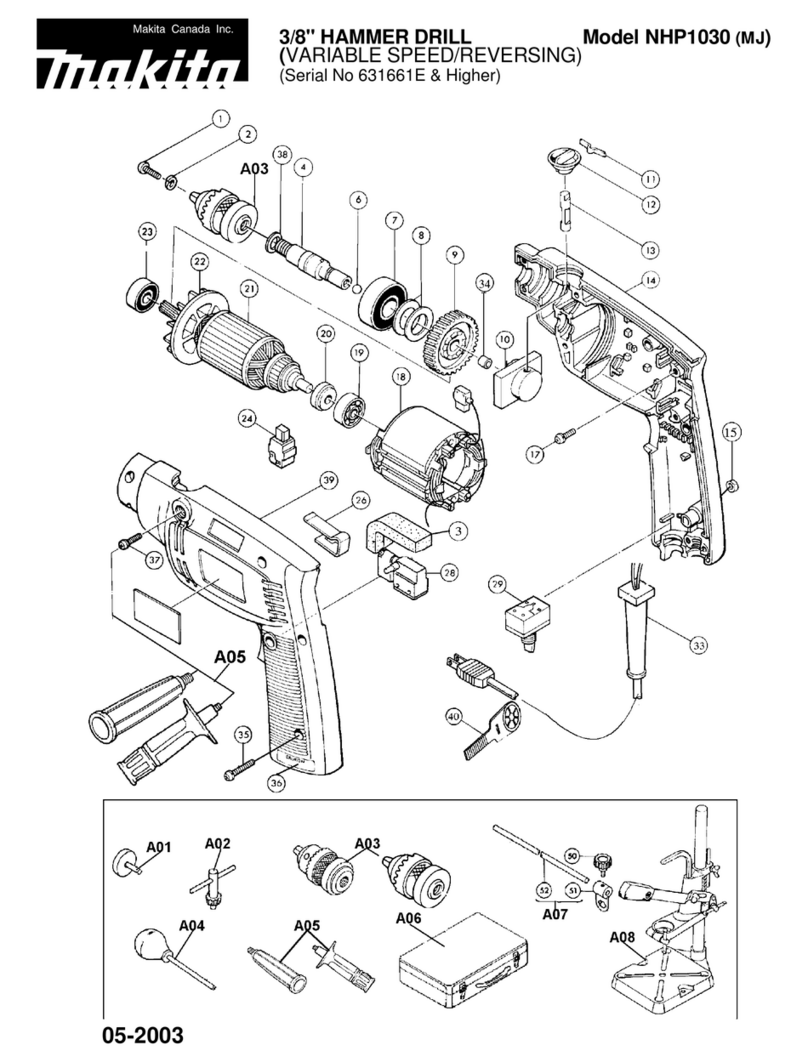

Dimensions : mm ( " )

Width ( W )

Height ( H )

Length ( L )

Model No. HP1620(F) HP1621(F)

303 (11-7/8)

222 (8-3/4)

68 (2-11/16)

HP1620

HP1620F HP1621

HP1621F

LL

HH

WW

Continuous Rating (W)

Voltage (V) Cycle (Hz) Input Output Max. Output(W)

110

120

220

230

240

Current (A)

50 / 60

50 / 60

50 / 60 560

650

650

380

380

320

380

380

380

650

650

650

600

500

500

500

600

600

50 / 60

50 / 60

50 / 60

110 for Taiwan 6.2

5.4

5.7

3.1

3.0

2.9

Model No.

Chuck ability : mm ( " )

Keyless chuck

F/R Change system

LED Job Light

No load speed : (min -1= rpm)

Blows per min. : (min -1= bpm)

Drilling

capacity : mm ( " ) Steel

Concrete

Wood

Protection from electric shock

Net weight :Kg (lbs )

Cord length : m ( ft )

HP1620 HP1620F HP1621 HP1621F

YesNo

No No

No

Yes Yes

Yes

2.0 (6.6)

1.7 (3.8)

Double insulation

Brush holder unit

16 (5/8)

13 (1/2)

30 (1-3/16)

1.5 - 13 (1/16 - 1/2)

0 - 2,800

0 - 44,800

* Side handle ....................................... 1 pc.

* Depth gauge ...................................... 1pc.

* Chuck key S-13................................. 1 pc. (only for HP1620 and HP1620F)

* Plastic carrying case ......................... 1 pc.

* T.C.T. Hammer drill bit ø16mm

* Metal drill bit ø13mm

* Drill bit for wood ø30mm

* Keyless drill chuck set

* Chuck key S-13 (only for HP1620 and HP1620F)

* Plastic carrying case

* Depth gauge

* Drill stand type 43

* Blow out bulb

* Drill chuck set

* Side handle set