MAKO TOOLS SROM 1197 User manual

Instruction Manual

250mm BENCH SAW

Model SROM 1197

Our tool range has you covered for DIY. Whatever the job, make light work of it

with MAKO tools.

Dear Valued Customer,

Thank you for purchasing this Mako Power Tool.

We are dedicated to providing quality Mako Power Tools at competitive prices. Whether you are

serious about DIY or just a casual user, our range of power tools are perfect for any job.

Mako 2 Year DIY Warranty:

All Mako Power Tools are backed by a comprehensive 2 year DIY warranty. If for any reason you

experience a fault with this power tool, please contact the retailer that it was purchased from, and

present the receipt for a full refund or replacement. The warranty is void if damage is not attributable

to normal wear and tear, if the tool is used commercially, the motor is overloaded or is tampered

with, is damaged by accident or if it is bought second hand. Continued use after partial failure, or use

with the incorrect accessories will void the warranty.

This warranty excludes all Mako accessories, which are covered by their own appropriate warranties.

MAKO TOOLS ARE FOR DIY USE ONLY. THEY ARE NOT DESIGNED OR APPROVED FOR

INDUSTRIAL OR COMMERCIAL USE.

CONTENTS:

1. Safety Instructions and Warnings

2. Components

3. Proper Usage

4. General Safety Instructions

5. Specific Safety Instructions

6. Before Starting the Saw

7. Assembly

8. Using the Saw

9. Operation

10. Replacing the Power Cable

11. Maintenance & Cleaning

12. Technical Data

13. Storage

14. Disposal and Recycling

DESCRIPTION OF SYMBOLS:

Please read all of the safety and operating instructions carefully before using

this bench saw. Please pay particular attention to all sections of this User

Guide that carry warning symbols and notices.

Observe caution and safety notes!

Caution - electric shock! Danger to life!

Wear hearing protection, dust protection mask, protective

glasses and protective gloves.

Keep children away from electrical power tools!

Protect electrical power tools from moisture!

Check that the device, mains lead and plug are in good

condition!

Safety class

Ⅱ

Dispose of

packaging and appliance in an

environmentally friendly way!

Caution! Risk of injury! Do not reach into the running

saw blade.

1. SAFETY INSTRUCTIONS AND WARNINGS:

The equipment complies with the safety regulations required for electrical equipment.

Read through the instructions for use before starting up the equipment.

Improper use can lead to personal Injury and properly damage. Persons who are not familiar with the

instructions may not operate the equipment. Keep the instructions for use in safe custody. Children

and youths are not permitted to operate the equipment

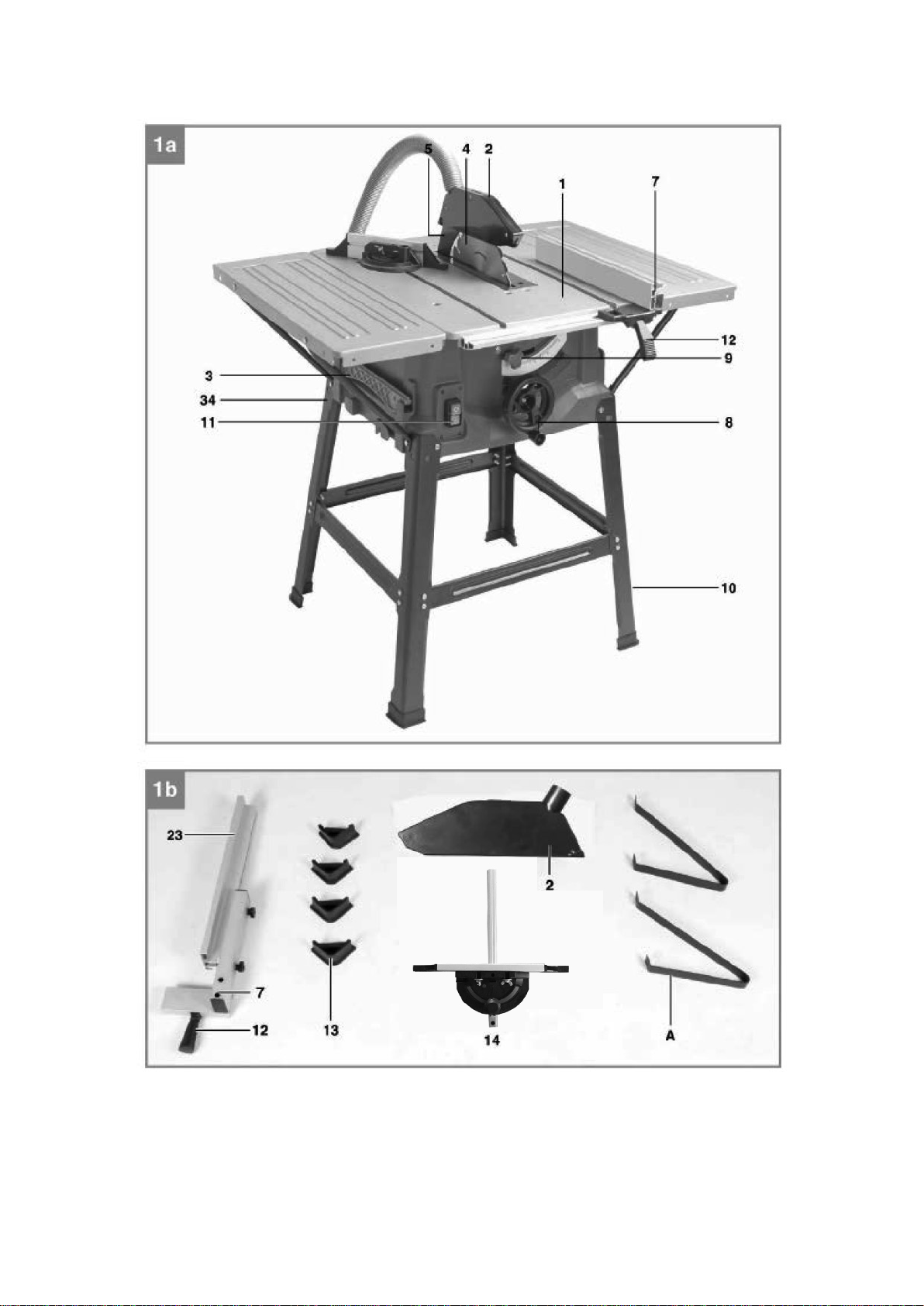

2. COMPONENTS:

1. Saw Table

2. Saw Blade Guard

3. Push Stick

4. Saw Blade

5. Riving Knife

6. Table Insert

7. Rip Fence

8. Hand Wheel

9. Adjusting and Locking Nut

10. Base Frame

11. On/Off Switch

12. Rip Fence Clamp

13. Rubber Foot x4

14. Cross Slide

15. Pivot Screw

16. Extractor Adapter

17. Countersunk Screw

18. Hole (riving knife)

19. Fastening Bolt

20. Pivot Clamp/Handle

21. Table Groove

22. Scale

23. Fence Rail

24. Fence Bracket

25. Slot in Fence

26. Screw and Nut x2

27. Slot in Fence

28. Guide Rail

29. Leg x4

30. Cross Rail x2

31. Side Rail x 2

32. Side Table Braces x4

33. Table Width Extension x2

34. Tool Hook

A. Leg Brace

a. Hex Screw b. Spring Washer

c. Flat Washer d. Nut

Items supplied

Please check that all parts are included as specified above. If parts are missing, please

contact the sales outlet where you made your purchase at the latest within 5 working days

after purchasing the product and upon presentation of a valid receipt .

•Open the packaging and take out the equipment with care.

•Remove the packaging material and any packaging and/or transportation braces (if used).

•Check to see if all items are supplied.

•Inspect the equipment and accessories for transport damage.

•If possible, please keep the packaging until the end of the guarantee period.

Danger!

The equipment and packaging material are not toys. Do not let children play with plastic bags,

foils or small parts. There is a danger of swallowing or suffocating!

3. PROPER USE:

This machine is designed for ripping and crosscutting wood and plastic in sizes corresponding to the

machine size. It is not suitable for cutting firewood or round-wood.

Use only saw blades which are suitable for the machine. Do not use cutting discs.

The manufacturer assumes no liability whatsoever for improper use, or if the machine has been

tampered with.

Give equal attention to the safety instructions, assembly and operating instructions, as well as all

prevailing accident prevention regulations. Even when the equipment is used as prescribed it is still

impossible to eliminate certain residual risk factors.

The following hazards may arise in connection with the machine‘s construction and design:

•Contact with the saw blade in the uncovered saw zone.

•Reaching into the running saw blade (cut injuries).

•Kick-back of workpieces and parts of workpieces.

•Saw blade fracturing.

•Catapulting of faulty carbide tips from the saw blade.

•Damage to hearing if essential ear-muffs are not used.

•Harmful emissions of wood dust when used in closed rooms.

4. GENERAL SAFETY INSTRUCTIONS:

•This appliance is not intended for use by persons (including children) with reduced physical,

sensory or mental capabilities, or lack of experience and knowledge, unless they have been given

supervision or instruction concerning use of the appliance by a person responsible for their safety.

•Children should be supervised to ensure that they do not play with the appliance.

•Keep your work area clean and well lit to prevent accidents.

•Don’t use electric devices close to flammable liquids or gases, or in wet or damp environments. If

you fail to observe this, there is danger of fire or explosion.

•Never leave the device running unattended.

•Never use the device when you are tired or lack concentration or if your reactions are impaired due

to consumption of alcohol or medication. Lack of attention can lead to serious injury.

•Keep the tools clean and in good working order in order to be able to work better and safer.

•Don’t wear bulky clothing or jewellery.

•Make sure you can stand stably and have shoes that won’t slip.

•Use a head cover if you have long hair. Loose clothing, jewellery, and long hair can become

entangled in moving parts.

•Always wear safety goggles.

•Wear a dust mask when working with materials that produce dust.

•Wear ear protection if a lot of noise is produced.

•Persons using the machines must not be distracted. This could cause one to lose control over the

tool.

•Don’t use any device that has a faultyon/off switch. An electric tool that can no longer be switched

on or off is dangerous and must be repaired.

•Always switch the device on before coming into contact with the material.

•Remove keys and adjusting tools before switching on the device.

•Never overload the machine. If the speed drops, unload the machine or switch it off. You will

work safer and better with the appropriate electric tool in a specific area of application.

•Stop the workpiece from turning, for example with a clamping device or a vice. Don’t work on any

workpiece that is too small to clamp in place. If you hold the workpiece with your hand, then you

can’t operate the tool safely.

•Keep electric tools out of the reach of children.

•Only use accessories recommended by the manufacturer.

•The mains voltage must correspond to the information on the machine’s type plate.

•Avoid body contact to grounded elements, e.g. pipes, radiators, stoves, and refrigerators to prevent

an electric shock

•Never carry the device by the cable. Only pull the cable from the receptacle with the plug. Protect

the cable from oil, heat, and sharp edges. Damaged cables can cause an electric shock.

•Check the device and power cable for damage before starting work.

•When plugging in the tool, make sure that the operating switch is not in the ON position.

•Only use approved extension cables when using the device outside.

•When using a cable drum, unwind it entirely in order to prevent the cable from heating up. The

minimum suitable wire gauge is 1.5 mm2.

•When working outside it is recommended that the tool always be supplied via a residual

current device with a rated current of 30mA or less.

•Pull out the plug when you are not using the device, or are making adjustments.

•Always guide the cable away from the back of the tool.

•Ensure that the socket outlet that the tool is connected to is always accessible during use.

•If the supply cord is damaged, it must be replaced by a special cord or assembly available from the

manufacturer or its service agent.

5. SPECIFIC SAFETY INSTRUCTIONS FOR TABLE SAWS:

1. Safety Precautions:

Warning! Do not use damaged, cracked or deformed saw blades. Replace worn table inserts.

Only use saw blades recommended by the manufacturer, which conform to EN 847-1.

Warning! Ensure, when changing the saw blade, that the cutting width and main body thickness of

the replacement blade is not smaller than the thickness of the riving knife!

•Make sure that a suitable saw blade for the material to be cut is selected.

•Wear suitable personal protective equipment. This includes: Hearing protection to avoid the risk of

•becoming hearing impaired, Respiratory protection to avoid the risk of inhaling harmful dust,

•Wear gloves when handling saw blades and rough materials.

•Carry saw blades in a container whenever practical.

•Wear goggles. Sparks generated during work or splinters, chippings and dust coming from the

device can lead to loss of eyesight.

•Connect a dust collecting device to the electric tool when sawing wood. The emission of dust is

influenced, among other things, by the type of material to be processed, the significance of local

separation (collection or source) and the correct setting of the hood/guide plates/guides.

•Do not use saw blades made of high-speed alloy steel (HSS steel).

•Wear hearing protection. The generation of noise is influenced by various factors, including the

characteristics of saw blades, condition of saw blade and electric tool. Use saw blades which

were designed for reduced noise development, insofar as possible.

•In times of non-use keep the push stick or the push block with the electrical power tool in its holder

at all times.

2. Maintenance and Repair:

•Pull out the mains plug for any adjustment or repair tasks.

•Maintain the electric tool and tool attachments regularly and if necessary, initiate repairs in order to

reduce noise.

•Report faults on the electric tool, protective devices or the tool attachment to the person

responsible for safety as soon as they are discovered.

3. Safe Work

•Use the push stick or cross-slide, to pass the workpiece securely through the saw blade.

•Make sure that the riving knife is always used, and set up is correct.

•Use the upper blade guard and set it to the correct position.

•Only use saw blades for which the maximum permissible speed is not lower than the maximum

spindle speed of the table saw and which are suitable for the material to be cut.

•Do not cut rebates or grooves without fitting a suitable guard, e.g. a tunnel-type guard, over the

saw table.

•Circular saws must not be used for slotting jobs (cutting grooves which end in the workpiece).

•When transporting the electric tool, only use specified carry points. Never use the protective

devices for handling or transport.

•Make sure that the upper part of the saw blade is covered during transport, e.g. by the guard.

•Be sure to only use spacers and spindle rings specified by the manufacturer as suitable for the

intended purpose.

•The floor around the machine must be level, clean and free of loose particles, such as chips and

cutting residues.

•Always stand to the side of the saw blade when working with the saw.

•Do not remove any cutting residues or other parts of workpieces from the cutting zone while the

machine is running and the saw unit is not at rest.

•Make sure that the machine is always secured on a workbench or a table if at all possible.

•Support long workpieces (e.g. with a roller table) to prevent them sagging at the end of a cut.

•Attention! Never remove loose splinters, chips or jammed pieces of wood while the saw blade is

running. Switch off the machine to troubleshoot or remove jammed pieces of wood.

•Disconnect the main power plug -

Refitting, including adjusting and measuring works, and cleaning must be carried out only when

the motor is switched off.

Before switching on again, ensure that keys and adjustment tools have been removed.

•Warning! This electric tool generates an electromagnetic field during operation. This field can

impair active or passive medical implants under certain conditions. In order to prevent the risk of

serious or deadly injuries, we recommend that persons with medical implants consult with their

physician and the manufacturer of the medical implant prior to operating the electric tool.

4. Safety Instructions for Handling of Saw Blades

•Only use multi-piece blades or cutter heads if you have mastered their use.

•Observe the maximum speed. The maximum speed specified on the multi-piece blade or cutter

head may not be exceeded. If specified, observe the speed range.

•Confirm the motor/saw blade direction of rotation.

•Do not use any multi-piece blades or cutter heads with cracks. Discard them. Repairs are not

permitted.

•Clean grease, oil and water off the clamping surfaces.

•Do not use any loose reducing rings or bushes for the reducing of holes on saw blades.

•Make sure that fixed reducer rings for securing multi-piece blades or cutter heads have the same

diameter and have at least 1/3 of the cutting diameter.

•Make sure that fixed reducer rings are parallel to each other.

•Handle multi-piece blades or cutter heads with caution. They are ideally stored in the original

package or special containers. Wear protective gloves in order to improve grip and to further

reduce the risk of injury.

•Prior to the use of multi-piece blades or cutter heads, make sure that all protective devices are

properly fastened.

•Prior to use, make sure that the multi-piece blade or cutter head meets the technical requirements

of this electric tool and is properly fastened.

•Only use the supplied saw blade for sawing operations in wood, materials similar to wood, plastics

and non-ferrous metals (This tool is NOT suitable for magnesium and alloys containing

magnesium).

6. BEFORE STARTING:

•Assemble the machine in a stable position, in other words on a workbench, a sub-frame or the like.

Secure it if you wish to use the machine on a stationary basis.

•Before starting the machine, check that all covers and safety equipment are correctly fitted.

•The saw blade must be able to run freely.

•Check all the moving parts to ensure that they move easily.

•Before you connect the machine, check the information on the rating plate against the mains data.

Warning! Always pull the power plug before making adjustments to the equipment.

7. ASSEMBLY:

Warning! Always pull the power plug before making adjustments to the equipment.

7.1 Assembling the Base Frame - Fig.15,16,17

Turn the saw body upside down and place it on the floor.

Use the Washers (c) and the Hex Screws (a) to fasten the four Legs (29) loosely to the saw body.

Now use the Hex Screws (a), the Washers (c) and the Nuts (d) to fasten the Side Rails (31) and the

Cross Rails (30) loosely to the legs (29).

Please note: The Side Rails are longer than the Cross Rails.

Finally, tighten all screws and nuts on the base frame.

Screw the Leg Braces (A) to the rear legs (29) so that they point towards the rear of the machine - Fig.

17.

Plug the Rubber Feet (13) onto the Legs (29).

7.2 Fitting & removing the Saw Blade Guard – Fig 3

Mount the Saw Blade Guard (2) on the Riving Knife (5) so that the screw fits through the hole (18) in

the Riving Knife.

Do not tighten the screw (15) too far – the Saw Blade Guard must be able to move freely.

To remove the Saw Blade Guard, proceed in reverse order.

Warning! The Guard (2) must always be lowered over the workpiece before you begin to cut.

7.3. Setting the splitter - Fig. 3,5,6 & 7

Danger! Pull out the power plug before making adjustments to the equipment.

•Set the Saw Blade (4) to maximum cutting depth, move to 0° position and lock in place.

•Remove the Saw Blade Guard - see 6.2.

•Take out the Table Insert (6) - see 6.4.

•Slacken the Fastening Bolt (19).

7.3.1. Setting for maximum cuts - Fig. 5,6 & 7

•Push up the splitter (5) until the gap between the saw table (1) and the upper edge of the splitter

(5) equals approx. 10 cm.

•The distance between the blade (4) and the splitter (5) should be 3-5 mm.

•Retighten the screw (19) and mount the table insert (6) (Fig. 6).

7.4 Changing the table insert - Fig. 6

•To prevent increased likelihood of injury the table insert should be changed whenever it is worn or

damaged.

•Remove the saw blade guard (2).

•Remove the 2 countersunk head screws (17).

•Take out the worn table insert (6).

•To fit the replacement table insert, proceed in reverse order.

7.5 Fitting & replacing the Saw Blade - Fig. 4

Important! Pull out the power plug first.

•Remove the Table Insert by undoing the two Countersunk Screws - see 6.4.

•Undo the nut with a 24mm wrench on the nut itself and a second 10mm wrench on the motor shaft

to apply counter-pressure.

•Important! Turn the nut in the direction of rotation of the Saw Blade.

•Take off the outer flange and pull the old Saw Blade off the inner flange by dropping the blade at

an angle.

•Clean the blade flange thoroughly before fitting the new Saw Blade.

•Mount and fasten the new Saw Blade in reverse order.

•Important! Note the running direction. The cutting angle of the teeth must point in the running

direction, i.e. forwards (see the arrow on the Saw Blade Guard).

•Refit and set the Riving Knife (5) and the Saw Blade Guard (2) - see 6.2, 6.3.

•Check to make sure that all safety devices are properly mounted and in good working condition

before you begin working with the saw again.

7.6 Assembling the Table Width Extensions - Fig. 18

• Use the Screws (a), Nuts (d) and Washers (c) to fasten the Table Width Extensions (33) loosely to the

Saw Table (1).

• Screw the Side Table Braces (32) loosely onto the Base Frame (10) and onto the Table Width

Extensions (33).

• Align the Table Width Extensions (33) level with the Saw Table.

• Finally, tighten all Screws (a).

Connect the supplied dust collection hose to the top of the Saw Guard and to the side branch of the Tee

fitting at the lower rear of the saw body.

8. USING THE SAW

8.1 ON/OFF switch - Fig. 1

To turn the saw on, press the green button “I”. Wait for the blade to reach its maximum speed of

rotation before beginning the cut.

To turn the machine off again, press the red button “O”.

8.2 Cutting depth - Fig. 1

Turn the Hand Crank (8) to set the blade (4) to the required cutting depth.

Turn anti-clockwise: larger cutting depth Turn clockwise: smaller cutting depth

8.3 Rip Fence

8.3.1 Fence Height - Fig. 9 & 13

•The Rip Fence (7) supplied with the saw has two different guide faces.

•For thick material you must use the Fence Rail (23) as shown in Fig. 11; for thin material you must

use the Fence Rail as shown in Fig.10.

•To change over the Fence Rail (23) to the Fence Bracket (24), you have to slacken the two Screws

and Nuts (26) in order to disconnect the Fence Rail (23) from the Fence Bracket (24).

•Remove the two knurled Screws (26) from one slot (27) in the Fence Rail (23) and insert in the

other slot (25).

•Remount the Fence Rail (23) on the Fence Bracket (24).

•The procedure for changing over to the high Fence Rail is similar.

8.3.2 Cutting Width:

The Rip Fence (7) has to be used when making longitudinal cuts in wooden workpieces.

•The Rip Fence can be mounted on either side of the saw table (1).

•The Rip Fence (7) has to be mounted in the Guide Rail (28) of the Saw Table (1).

•The Rip Fence (7) can be set to the required dimension with the help of the Scale (22) on the

Guide Rail (1). Note – check settings with a ruler before cutting.

•You can clamp the Rip Fence in the required position by pressing the Rip Fence Clamp (12).

8.3.3 Setting the Fence Rail position - Fig. 9

•The Fence Rail (23) can be moved in backwards and forwards in order to prevent the workpiece

from becoming jammed.

•Rule of Thumb: The rear end of the Fence Rail comes up against an imaginary line that begins

roughly at the center of the blade and runs at an angle of 45° to the rear.

•Set the required cutting width. Slacken the knurled Screws (26) and pull the Fence Rail (23)

forward until the rear touches that imaginary 45° line. Retighten the knurled Screws (26).

Important!

Do not push the Fence Rail (23) too far toward the Saw Blade.The distance between the Fence Rail

(23) and the Saw Blade (4) should be approx. 2 cm.

8.4 Cross Slide – Fig. 8

•Slide the Cross Slide (14) into the Table Groove (21).

•Slacken the Pivot Clamp/Handle (20).

•Turn the Cross Slide (14) until the arrow points to the angle required.

•Retighten the Pivot Clamp/Handle (20).

8.5 Setting the Saw Blade angle - Fig. 14

Undo the Adjusting and Locking Nut (9).

Turn the Hand Wheel to set the desired angle on the scale.

Lock the Adjusting and Locking Nut again in the required angle position.

9. OPERATION

Warning!

After every new adjustment we recommend you to make a trial cut in order to check the new settings.

•After switching on the saw, wait for the blade to reach its maximum speed of rotation before

commencing with the cut.

•Take extra care when starting the cut!

•Never use the equipment without the suction function.

•Regularly check and clean the dust extraction ducts.

•A Vacuum Cleaner hose can be connected to the dust extraction Tee at the rear of the saw for

safe collection of dust produced in cutting.

9.1.1 Making longitudinal cuts – Fig. 19

Longitudinal cutting (also known as ripping) is when you use the saw to cut along the grain of the

wood. Press one edge of the workpiece against the Rip Fence (7) while the flat side lies on the Saw

Table (1). The Blade Guard (2) must always be lowered over the workpiece. When you make a

longitudinal cut, never adopt a working position that is in line with the cutting direction.

•Set the Rip Fence (7) in accordance with the workpiece height and the desired width. (See 8.3.)

•Switch on the saw.

•Place your hands (with fingers closed) flat on the workpiece and push the workpiece along the Rip

Fence (7) and into the Saw Blade (4).

•Guide at the side with your left or right hand (depending on the position of the Rip Fence) only as

far as the front edge of the Blade Guard.

•Always push the workpiece through to the end of the Riving Knife (5).

•Do not remove the offcut until the Saw Blade (4) has completely stopped.

•Secure long workpieces against falling off at the end of the cut with a roller stand or similar.

9.1.2 Cutting narrow workpieces - Fig. 20

•Be sure to use the Push Stick (3) when making longitudinal cuts in workpieces smaller than

120mm in width. A push stick is supplied with the saw! Replace a worn or damaged push stick

immediately.

•Be sure to use a push block when making longitudinal cuts in very narrow workpieces with a width

of 30 mm and less. The low guide face of the parallel stop is best used in this case. There is no

push block supplied with the saw! Replace the push block without delay when it becomes worn.

9.1.3 Making bevel cuts - Fig. 14 & 22

Bevel cuts must always be used using the Rip Fence (7).

•Set the Saw Blade (4) to the desired angle. (See 8.5.)

•Set the Rip Fence (7) according to the workpiece width and height (see 8.3.1)

•Carry out the cut according to the work-piece width (see 8.1.1, 8.1.2 and 8.1.3.)

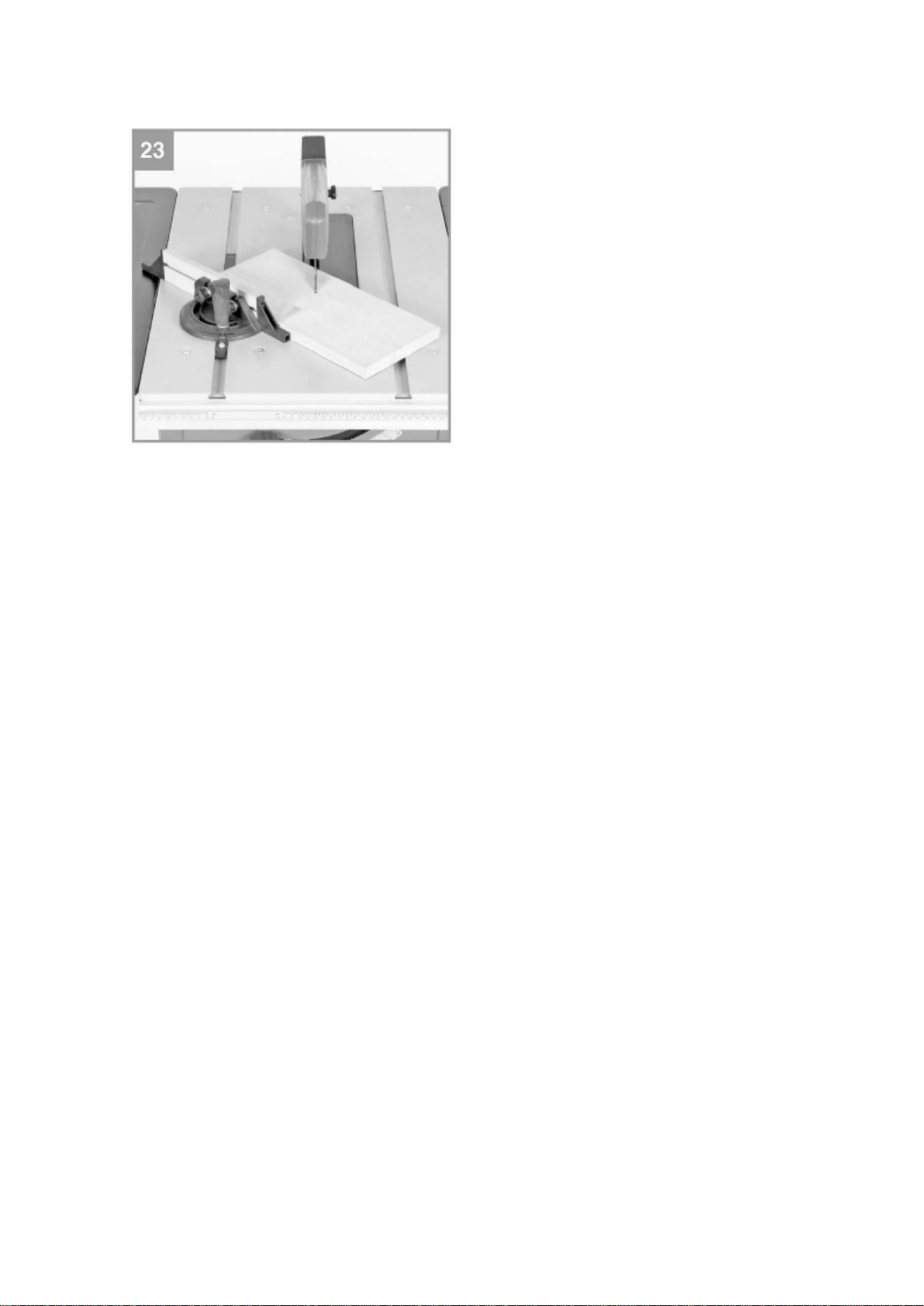

9.1.4 Making cross cuts - Fig. 23

•Slide the Cross Slide (21) into one of the Table Grooves (21) and adjust to the required angle.

(See 8.4.) If you also want to tilt the Saw Blade (4), use the Table Groove (21) which prevents

your hand and the Cross Slide from making contact with the Blade Guard.

•Hold the workpiece firmly against the Cross Slide (14).

•Switch on the saw.

•Push the Cross Slide (14) and the workpiece toward the Saw Blade in order to make the cut.

Warning! Always hold the guided part of the workpiece. Never hold the part which is to be cut off.

•Push the Cross Slide (14) forward until the workpiece is cut all the way through.

•Switch off the saw again. Do not remove the offcut until the blade has stopped rotating.

10. REPLACING THE POWER CABLE

Danger!

If the power cable for this equipment is damaged, it must be replaced by the manufacturer or its

after-sales service or similarly trained personnel to avoid danger.

11.CLEANING, MAINTENANCE AND ORDERING OF SPARE PARTS

Danger! Always pull out the mains power plug before starting any cleaning work.

11.1 Cleaning

Keep all safety devices, air vents and the motor housing free of dirt and dust as far as possible. Wipe

the equipment with a clean cloth or blow it with compressed air at low pressure. We recommend that

you clean the tool immediately each time you have finished using it.

Clean the equipment regularly with a moist cloth and some soft soap. Do not use cleaning agents or

solvents; these could attack the plastic parts of the equipment. Ensure that no water can seep into

the device. The ingress of water into an electric tool increases the risk of an electric shock.

11.2 Carbon brushes

In case of excessive sparking, have the carbon brushes checked only by a qualified electrician.

Danger! The carbon brushes should not be replaced by anyone but a qualified electrician.

11.3 Maintenance

There are no parts inside the equipment which require additional maintenance.

12. TECHNICAL DATA

This machine is double insulated.

Voltage 230-240V, 50Hz

Rating: 1800W

No Load Speed: 3000rpm

Saw blade: 250mm x 30 x 3.2 mm, 48T

Angle or mitre bench: - -45º/0°/+45°

0ºx0º: 310mm x 70mm cutting size

0°x45°: 310mm x 42mm “ “

45x0º: 205mm x 70mm “ “

45x 45º: 205mm x 42mm “ “

13. STORAGE

Store the equipment and accessories in a cool, dry place.Store the electric tool in its original

packaging where possible.

14. DISPOSAL

The equipment is supplied in packaging to prevent it from being damaged in transit.

The raw materials in this packaging can be reused or recycled. The equipment and

its accessories are made of various types of material, such as metal and plastic.

Never place defective equipment in your household refuse. The equipment should

be taken to a suitable collection center for proper disposal. If you do not know the

whereabouts of such a collection point, you should ask in your local council offices.

Table of contents